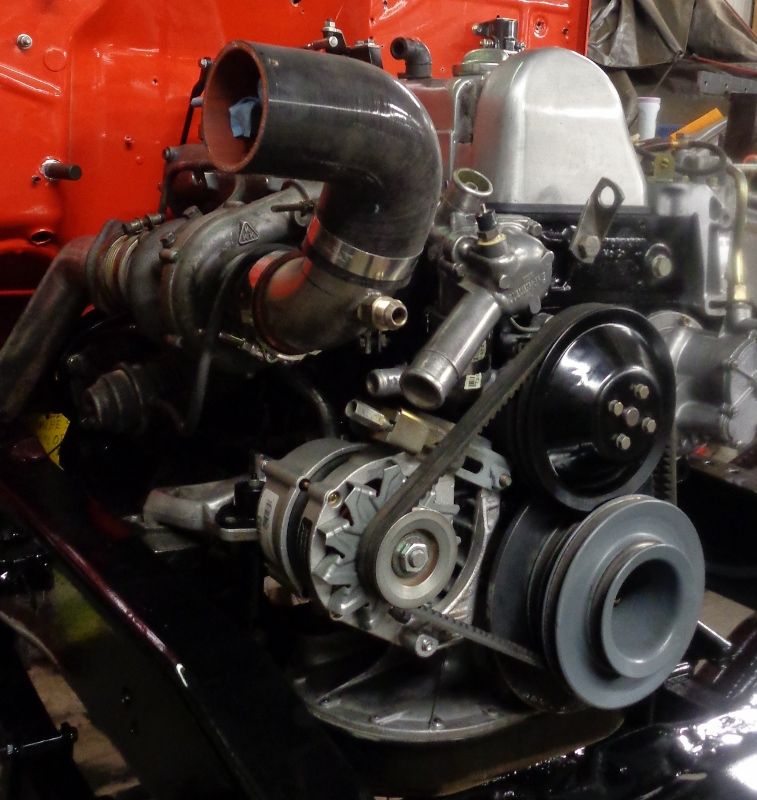

1949 F4 V8 to Mercedes diesel build thread

#155

Thanks fellas for the kind words. It will be a while before I can do a first drive video. I have to modify and plumb the fuel tank for a return line and install the feed line. The brakes will be the biggest hurdle to driving. I have to machine all the brackets for the front disc brake mod and build a master cylinder mount, then run all new brake lines. I do hope to hear the engine run soon though. With all the help and encouragement from this board, I may be able to get this truck finished and drive it

Thanks again, Mark

Thanks again, Mark

#157

I machined a fitting to solder to the top of my fuel tank for the diesel fuel return line from the injection pump. I used a nut and ferrule from a 5/16" compression coupling and machined the fitting to solder to the tank. I will slide the tube thru the fitting to where it is just off of the bottom of the tank and tighten the nut to hold it in place and to seal it.

I also made a tubing straightener from an old mill vise and some rollers that I have. I will use it on the 5/16" steel tube for my fuel lines and the 1/4" steel for my brake lines. It does a pretty decent job of straightening the tube from a coil.

I also made a tubing straightener from an old mill vise and some rollers that I have. I will use it on the 5/16" steel tube for my fuel lines and the 1/4" steel for my brake lines. It does a pretty decent job of straightening the tube from a coil.

#158

#160

You have an amazing attention to detail as most machinest do. When you are finished with your truck it will be very a useful, one of a kind vehicle. I really like what you have done.

Is your fuel tank galvanized inside? If it is the diesel fuel will cause the galv to turn loose and cause problems.

Is your fuel tank galvanized inside? If it is the diesel fuel will cause the galv to turn loose and cause problems.

#161

Daves78crew, Welcome to FTE! Thank you for the kind words. My goal is for the engine to look like it belongs in the truck. I hope I'm succeeding. I believe the fuel tank is tin plated. When I attempted to solder the fitting on that you see in the above post, the fitting wouldn't tin so, I wiped off the excess solder from the tank and the plating wiped off just like the solder. It actually pooled up where the tank was cooler and solidified like solder does. Thanks for the heads up about galvanizing and diesel, I wasn't aware of that.

#162

I have been working on running the fuel supply and return lines this week. I have a filter with a water drain that I want to mount on the rear crossmember for the Brownie. I thought before I mount it I should check to make sure that I have the Brownie setting at the correct angle. As it turned out I had it at too steep an angle. I have the engine setting at 3 degrees, it should be the same as the flathead, if I measured correctly. The rear axle is between 3 3/4 and 4 degrees. I had the Brownie at 7 degrees. I removed the front mount from the Brownie and shortened it about 5/8", now the Brownie is setting at 3 degrees. I will leave the axle alone as I think 3/4-1 degree difference shouldn't be enough to cause any vibration in the driveline. It probably changes some as the truck is loaded anyways. Now I can mount the filter and finish running my fuel lines to the engine. I will post photos next week when I get them finished.

#163

#164

#165