ICP default on scangaugeII?

#1

ICP default on scangaugeII?

<hr style="color:#D1D1E1; background-color:#D1D1E1" size="1"> Originally had hard start, rough idle, no sync. Replaced crankshaft position sensor, still hard start but got sync, running rough. Decided to go in for the HPOP & replace ICP & IPR while it's easily accessible. Friday night/Saturday morning spent tearing apart top end, fuel/oil filter housing, turbo, intake manifold, wiring harness', etc...

Removed cover from top of HPOP reservoir to find C-clip had let go, end cap was not attached and O-ring hanging out end of pump. I figured this to be a sure sign that it was a faulty HPOP.

Spent the rest of Saturday and part of Sunday morning putting in new HPOP, ICP, & IPR. New intake gaskets & o-rings everywhere possible. Buttoned it all up, read as much info on priming HPOP as I could find and decided it was time to give it a shot.

Cranking and watching ICP climb slowly to 306 after probably ten, 20 second cranking sessions(200amp battery charger connected). Allowing 5-10 minutes for starter cool down between each session. IPR @ 77% FICM power 48volts, 1 Sync.(I have Scan GaugeII, have put in most of the x-gauges & the speed is set to fast)

Believing that, once the hpop is primed, the icp would climb above 500 and allow injectors to function is what I was shooting for.

Decided to attempt a crank session with ICP unplugged(I heard default goes to 750?) I unplugged icp and cranked it and got: ICP 1700, IPR 44%, FICM48V & 1 Sync but still no start.

Question: if ICP pigtail is unplugged, where does ScanGauge come up with the 1700 psi? Is this an actual reading from the ECM?

Am I correct to believe the IPR operating range to be 15-85%? with 15% being wide open and 85% being closed? As I understand it, the HPOP sends oil to ICP(sensor) which reports to ECM which then commands IPR to regulate oil pressure in the system.

Man I wish I had this thirst for knowledge at a younger age But glad I found a site that's not afraid to help and share the knowledge. Thanks for any advice.

But glad I found a site that's not afraid to help and share the knowledge. Thanks for any advice.

Removed cover from top of HPOP reservoir to find C-clip had let go, end cap was not attached and O-ring hanging out end of pump. I figured this to be a sure sign that it was a faulty HPOP.

Spent the rest of Saturday and part of Sunday morning putting in new HPOP, ICP, & IPR. New intake gaskets & o-rings everywhere possible. Buttoned it all up, read as much info on priming HPOP as I could find and decided it was time to give it a shot.

Cranking and watching ICP climb slowly to 306 after probably ten, 20 second cranking sessions(200amp battery charger connected). Allowing 5-10 minutes for starter cool down between each session. IPR @ 77% FICM power 48volts, 1 Sync.(I have Scan GaugeII, have put in most of the x-gauges & the speed is set to fast)

Believing that, once the hpop is primed, the icp would climb above 500 and allow injectors to function is what I was shooting for.

Decided to attempt a crank session with ICP unplugged(I heard default goes to 750?) I unplugged icp and cranked it and got: ICP 1700, IPR 44%, FICM48V & 1 Sync but still no start.

Question: if ICP pigtail is unplugged, where does ScanGauge come up with the 1700 psi? Is this an actual reading from the ECM?

Am I correct to believe the IPR operating range to be 15-85%? with 15% being wide open and 85% being closed? As I understand it, the HPOP sends oil to ICP(sensor) which reports to ECM which then commands IPR to regulate oil pressure in the system.

Man I wish I had this thirst for knowledge at a younger age

But glad I found a site that's not afraid to help and share the knowledge. Thanks for any advice.

But glad I found a site that's not afraid to help and share the knowledge. Thanks for any advice.

#3

Did you dump a quart of oil in the HPO reservoir before reassembly?

I thought about it, it sounds like it would make perfect sense to do this but....no. I never heard of doing this and didn't want to screw things up somehow, nothing in the paperwork included with HPO from Ford dealer mentioned anything about doing that. I suppose it would help speed up the priming of the system.

On the IPR, 15% is closed and 85% is open.

Hmmm wondering if my BRAND NEW IPR(disgustingly expensive) could be faulty and hanging in the open position(77+ while cranking) allowing oil pressure to return to oil pan instead of build pressure behind injectors?

I thought about it, it sounds like it would make perfect sense to do this but....no. I never heard of doing this and didn't want to screw things up somehow, nothing in the paperwork included with HPO from Ford dealer mentioned anything about doing that. I suppose it would help speed up the priming of the system.

On the IPR, 15% is closed and 85% is open.

Hmmm wondering if my BRAND NEW IPR(disgustingly expensive) could be faulty and hanging in the open position(77+ while cranking) allowing oil pressure to return to oil pan instead of build pressure behind injectors?

#4

Did you dump a quart of oil in the HPO reservoir before reassembly?

I thought about it, it sounds like it would make perfect sense to do this but....no. I never heard of doing this and didn't want to screw things up somehow, nothing in the paperwork included with HPO from Ford dealer mentioned anything about doing that. I suppose it would help speed up the priming of the system.

On the IPR, 15% is closed and 85% is open.(I shouldn't say "Open or Close" instead we should recognize "at which position is the IPR" the closer to 77 it is, the more oil being sent towards injectors and the closer to 15 it is the more oil being sent to oil pan)

ScanGaugeII reporting ICP 1997 IPR 55% with ICP unplugged, that should've started it. RPM's were at 145. (Charging batteries right now) Ya I guess it would need to be above 150 rpm to fire. So maybe charge batteries and unplug IPR to see what happens? (going to reattach ICP plug)

Next day it was determined that IPR is correct position, ICP is faulty and RPMs are too low.

I thought about it, it sounds like it would make perfect sense to do this but....no. I never heard of doing this and didn't want to screw things up somehow, nothing in the paperwork included with HPO from Ford dealer mentioned anything about doing that. I suppose it would help speed up the priming of the system.

On the IPR, 15% is closed and 85% is open.(I shouldn't say "Open or Close" instead we should recognize "at which position is the IPR" the closer to 77 it is, the more oil being sent towards injectors and the closer to 15 it is the more oil being sent to oil pan)

ScanGaugeII reporting ICP 1997 IPR 55% with ICP unplugged, that should've started it. RPM's were at 145. (Charging batteries right now) Ya I guess it would need to be above 150 rpm to fire. So maybe charge batteries and unplug IPR to see what happens? (going to reattach ICP plug)

Next day it was determined that IPR is correct position, ICP is faulty and RPMs are too low.

Last edited by JOBPSD1963; 04-16-2014 at 08:53 AM. Reason: update info

#6

So based on those numbers is it right for IPR to be driven to that position even though ICP is so low?

So based on those numbers is it right for IPR to be driven to that position even though ICP is so low?

#7

Trending Topics

#8

Nice Blade, I'm confident she'll fire once all the ducks are in a row Because I changed IPR and IPC along with HPOP, it's possible that the new regulator and or sensor are faulty and not working together to control pressure as designed. 350+ on ICP says "it's got oil but something in the system is leaking" I have old ICP & IPR on bench today for testing. If it's determined they work as designed, I will put em back into service and she should fire. The old saying "If it aint broke, don't fix it" seems to apply here. It's a good thing I'm working with a Diesel guy who keeps pointing me back to the basics. (Heat, fuel, oxygen, compression and lubrication-she should work). It's pretty easy to get sidetracked with all the new technology(sensors and what not). But that's what we're here for, to learn from each other. I wonder if within SGII there is a way to send voltage to IPR to command it "Closed" ? That'd allow me to prove my theory without laying on top of 6.0 for a few hours today.

Because I changed IPR and IPC along with HPOP, it's possible that the new regulator and or sensor are faulty and not working together to control pressure as designed. 350+ on ICP says "it's got oil but something in the system is leaking" I have old ICP & IPR on bench today for testing. If it's determined they work as designed, I will put em back into service and she should fire. The old saying "If it aint broke, don't fix it" seems to apply here. It's a good thing I'm working with a Diesel guy who keeps pointing me back to the basics. (Heat, fuel, oxygen, compression and lubrication-she should work). It's pretty easy to get sidetracked with all the new technology(sensors and what not). But that's what we're here for, to learn from each other. I wonder if within SGII there is a way to send voltage to IPR to command it "Closed" ? That'd allow me to prove my theory without laying on top of 6.0 for a few hours today.

Because I changed IPR and IPC along with HPOP, it's possible that the new regulator and or sensor are faulty and not working together to control pressure as designed. 350+ on ICP says "it's got oil but something in the system is leaking" I have old ICP & IPR on bench today for testing. If it's determined they work as designed, I will put em back into service and she should fire. The old saying "If it aint broke, don't fix it" seems to apply here. It's a good thing I'm working with a Diesel guy who keeps pointing me back to the basics. (Heat, fuel, oxygen, compression and lubrication-she should work). It's pretty easy to get sidetracked with all the new technology(sensors and what not). But that's what we're here for, to learn from each other. I wonder if within SGII there is a way to send voltage to IPR to command it "Closed" ? That'd allow me to prove my theory without laying on top of 6.0 for a few hours today.

Because I changed IPR and IPC along with HPOP, it's possible that the new regulator and or sensor are faulty and not working together to control pressure as designed. 350+ on ICP says "it's got oil but something in the system is leaking" I have old ICP & IPR on bench today for testing. If it's determined they work as designed, I will put em back into service and she should fire. The old saying "If it aint broke, don't fix it" seems to apply here. It's a good thing I'm working with a Diesel guy who keeps pointing me back to the basics. (Heat, fuel, oxygen, compression and lubrication-she should work). It's pretty easy to get sidetracked with all the new technology(sensors and what not). But that's what we're here for, to learn from each other. I wonder if within SGII there is a way to send voltage to IPR to command it "Closed" ? That'd allow me to prove my theory without laying on top of 6.0 for a few hours today.

Last edited by JOBPSD1963; 04-16-2014 at 08:46 AM. Reason: update info

#9

OK here"s a question, Diesel tech Ron says (

) if IPR is at 77% it's making up for a leak somewhere and close to 15% it's dumping too much. Based on his video and years of experience, this leads me to believe that at 77% the valve closes off the oil passage to the oil pan and opens wide the passage to injectors? I mean that's all it is right? A valve with a solenoid? And based on voltage from ECM it either opens or closes the pasages diverting the oil to either the oil pan or injectors etc...? All help is appreciated.

#11

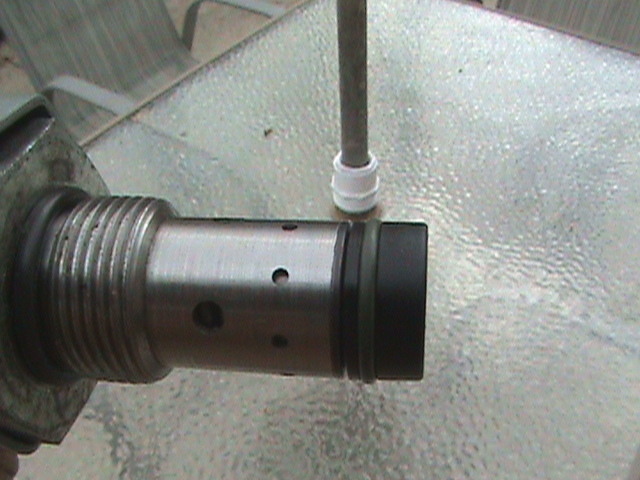

Thanks Blade for confirming my thoughts.  This is the IPR that is driven to a position that directs oil pressure from the HPOP. On the valve end of the IPR exist, 8 small holes and 4 larger holes(I imagine these line up with passages to injectors and oil pan) and when the ECM signals IPR solenoid, the solenoid either extends or retracts the shaft within the IPR valve end that determines which passage gets how much oil. The socket size is 1 3/8" and the depth of the socket should be at least 2 3/8" with a slot that will fit without disrupting plug on end. Here's a picture of a homemade device for IPR removal and installation. $50 for a socket at OReillys [ATTACH]96368[/

This is the IPR that is driven to a position that directs oil pressure from the HPOP. On the valve end of the IPR exist, 8 small holes and 4 larger holes(I imagine these line up with passages to injectors and oil pan) and when the ECM signals IPR solenoid, the solenoid either extends or retracts the shaft within the IPR valve end that determines which passage gets how much oil. The socket size is 1 3/8" and the depth of the socket should be at least 2 3/8" with a slot that will fit without disrupting plug on end. Here's a picture of a homemade device for IPR removal and installation. $50 for a socket at OReillys [ATTACH]96368[/ ATTACH]

ATTACH]  I imagine the plug end on solenoid was designed to "TURN" 360 degrees thus allowing us to position the plug as far from turbo exhaust as possible(on the 03/early 04 models). So far I've spun 2 plug ends with no damage and it would be next to impossible to remove or install IPR AND position the plug properly if this end wasn't designed to rotate 360 degrees.

I imagine the plug end on solenoid was designed to "TURN" 360 degrees thus allowing us to position the plug as far from turbo exhaust as possible(on the 03/early 04 models). So far I've spun 2 plug ends with no damage and it would be next to impossible to remove or install IPR AND position the plug properly if this end wasn't designed to rotate 360 degrees.

Last edited by JOBPSD1963; 04-16-2014 at 08:31 AM. Reason: Adding more info

#12

Did you dump a quart of oil in the HPO reservoir before reassembly?

I thought about it, it sounds like it would make perfect sense to do this but....no. I never heard of doing this and didn't want to screw things up somehow, nothing in the paperwork included with HPO from Ford dealer mentioned anything about doing that. I suppose it would help speed up the priming of the system.

On the IPR, 15% is closed and 85% is open.

Hmmm wondering if my BRAND NEW IPR(disgustingly expensive) could be faulty and hanging in the open position(77+ while cranking) allowing oil pressure to return to oil pan instead of build pressure behind injectors?

I thought about it, it sounds like it would make perfect sense to do this but....no. I never heard of doing this and didn't want to screw things up somehow, nothing in the paperwork included with HPO from Ford dealer mentioned anything about doing that. I suppose it would help speed up the priming of the system.

On the IPR, 15% is closed and 85% is open.

Hmmm wondering if my BRAND NEW IPR(disgustingly expensive) could be faulty and hanging in the open position(77+ while cranking) allowing oil pressure to return to oil pan instead of build pressure behind injectors?

#13

#14

Low RPM

Today it's on to determine why RPMs are below 150. Batteries tested again were shot(cuz of all this cranking + they were 3 years old) New batteries, fully charged(by me, not charged 100% out of the box) 40 amps for about 1 hour. KOEO voltage 12.8, RPM while cranking still never above 150? Removed serpentine belt and made another attempt at cranking got same thing, low RPM(139). Voltage drop test of cable to started shows "no loss of voltage" (Voltage is exactly identical at starter as it is at battery) So Cable is good. I guess it could be the starter motor wearing out? Poor ground of starter to frame? Either way, starter's gotta be removed and tested@ OReillys (free) and all ground/power connections cleaned and greased(to prevent corrosion and rust). Temps expected in middle 50's today my kinda wrenchin weather, keeps beer from warming and me from sweating. Will report back later.