4.0L Intake manifold Gasket set question?

#31

Removing the intake with the engine in the van is not a big challenge.

I haven't removed the heads in my van, but I've heard that it can be done with the engine in place. BUT if you used head studs instead of bolts, then I don't think you can pull (or install) the heads with the engine in the van.

I haven't removed the heads in my van, but I've heard that it can be done with the engine in place. BUT if you used head studs instead of bolts, then I don't think you can pull (or install) the heads with the engine in the van.

#32

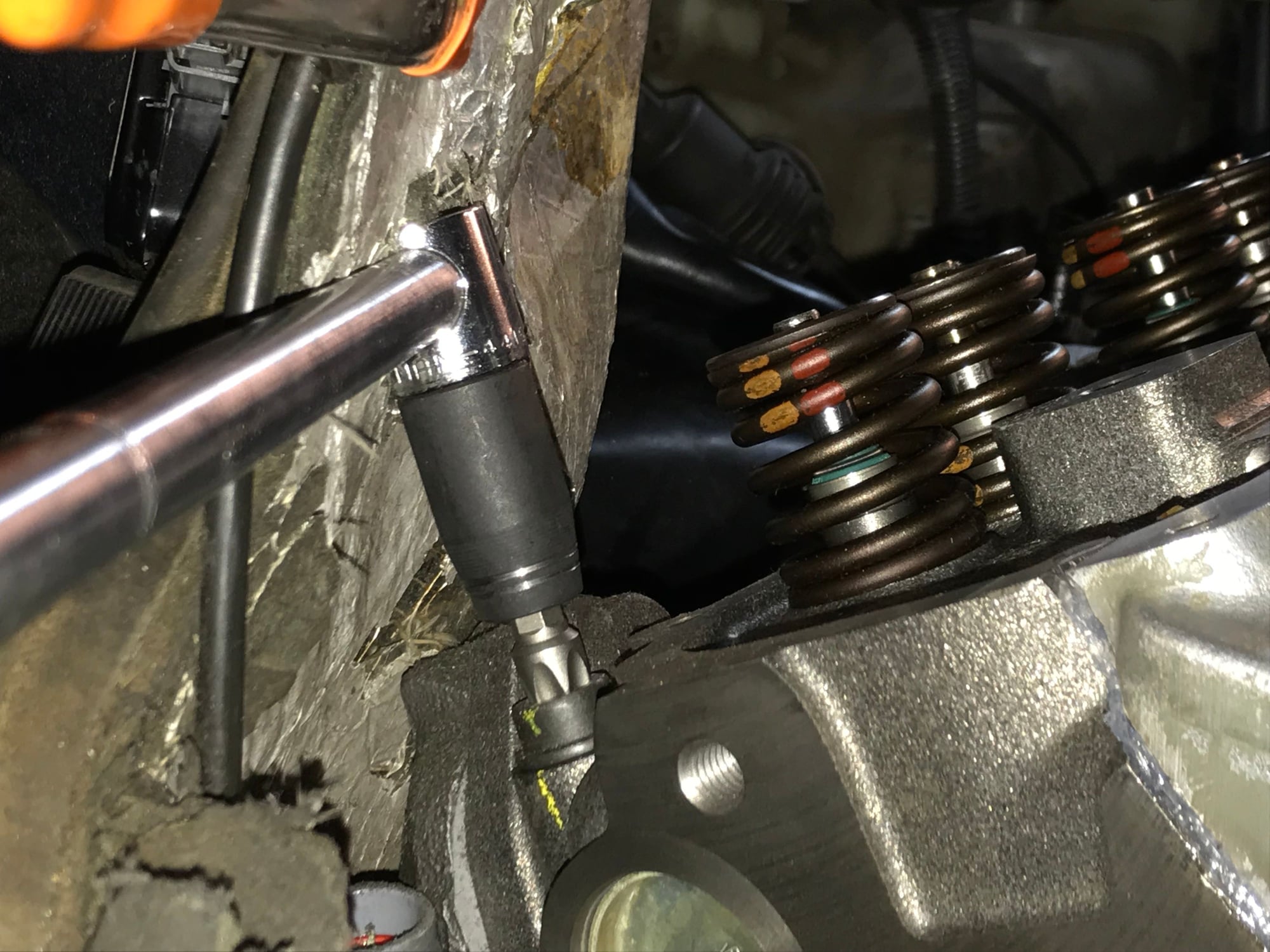

The really challenging head bolts are the aft outboard on each side. The worst was the drivers side..... even with a breaker bar directly on the T55 TORX bit, you are up against sheet metal and the cowl insulation. I fully expect that drivers side headbolt to be quite a bugger on reinstall...... planning to jack the engine at the motor mounts to roll it a bit to aide. That last 80* pull is not going to be fun.... but it shall be done to get the AERO back into service.

#33

Well, I've now been down the road and back. I was able to score a pair of NOS FORD 93TM castings to build my heads from. Purchased new exhaust valves and reused my intakes. ALL gaskets FORD, as well as the clear silicone adhesive used at the junction of block valley, heads, and the lower half of the intake. Of course, brand new TTY head bolts as well.

With the assistance of my son who was in town for a family Xmas gathering, we installed the heads and intake, applied the specified torques. NOW having done one of these German engines, I understand why the alternating procedure of torquing head bolts, intake bolts... until the final specs are achieved. The intake continues to "settle" down into position, and when both heads and intake are torqued to spec the combination surface flushes out for the valve cover gaskets to rest upon.

For certain the outboard aft head bolt on #6 cylinder (drivers side rear) is the bugger. Fortunately we were able to achieve the 85* rotation by use of a slender head 1/2" breaker bar and a skinny T55 torx driver. My larger Craftsman T55 had no chance to fit the confines, but the smaller "no name" T55 did fit along with the breaker bar. We had to alternately tighten from near the radiator core (parallel to the head), and then from inside the cabin (with the access cabin cover removed) to complete the TTY head bolt in that position. The pass. side head bolts were not that challenging. Hopefully within a few weeks of part time wrenching i'll spin the starter..... and she better be watertight.

Last edited by DET17; 01-06-2019 at 06:09 PM. Reason: added pics of torquing worst headbolt

Thread

Thread Starter

Forum

Replies

Last Post

fordguy2100

1973 - 1979 F-100 & Larger F-Series Trucks

8

09-11-2016 06:50 PM

chrisPi

Explorer, Sport Trac, Mountaineer & Aviator

3

05-27-2012 09:05 PM

JoeVR5

1983 - 2012 Ranger & B-Series

3

08-09-2011 09:07 AM

oldblue89

1987 - 1996 F150 & Larger F-Series Trucks

7

06-27-2010 11:38 AM