351m / 400 transmission & TC options in early bronco

#46

#47

Slowly but surely....

got the flywheel chamfered today to match the spacer so they sit flush and after work I installed the flywheel and spacer with the special flywheel bolts I picked up...

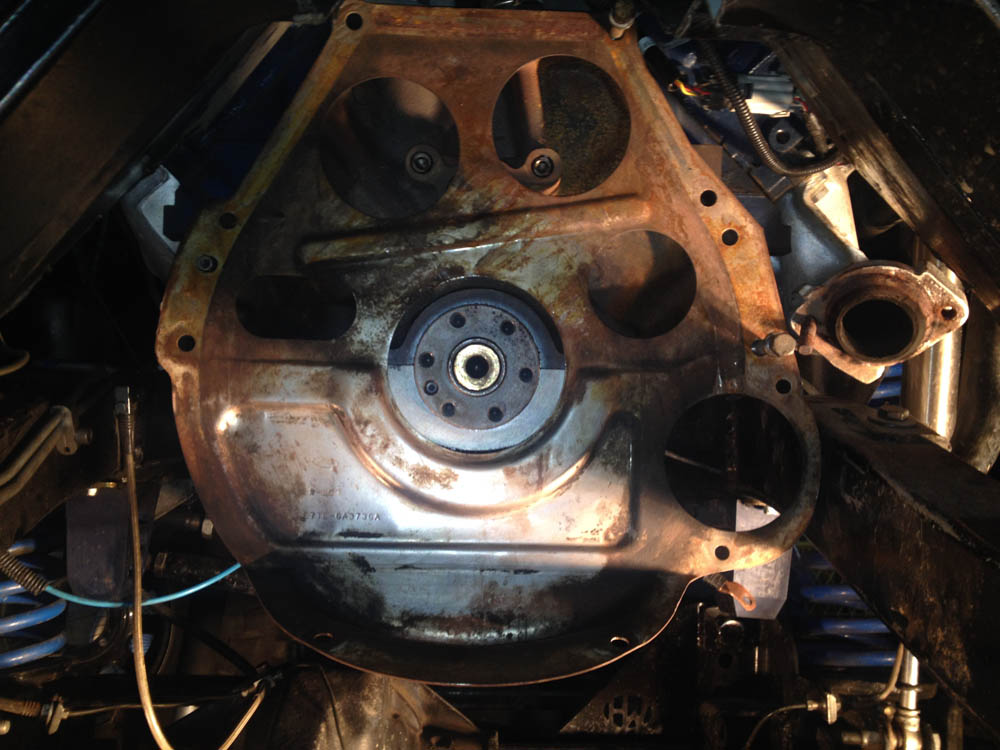

still pretty clean back here...

metal plate thingy installed had to grind a little off by the frame, probably have to do the same to the bellhousing on the zf.. we will see....

had to grind a little off by the frame, probably have to do the same to the bellhousing on the zf.. we will see....

spacer on the crank...

and the flywheel torqued and installed

thats about as far as I got tonight, tomorrow I need to unscrew the stud from the exhaust manifold and then probably try to stab the zf in there to see what happens and take the grinder to the bits I need to relieve on the bellhousing.

got the flywheel chamfered today to match the spacer so they sit flush and after work I installed the flywheel and spacer with the special flywheel bolts I picked up...

still pretty clean back here...

metal plate thingy installed

had to grind a little off by the frame, probably have to do the same to the bellhousing on the zf.. we will see....

had to grind a little off by the frame, probably have to do the same to the bellhousing on the zf.. we will see....spacer on the crank...

and the flywheel torqued and installed

thats about as far as I got tonight, tomorrow I need to unscrew the stud from the exhaust manifold and then probably try to stab the zf in there to see what happens and take the grinder to the bits I need to relieve on the bellhousing.

#48

#49

I'm going out there in an hour or so to put the clutch in and get the trans mounted up so I guess if I was going to do it I have to now.

#50

#51

Does the 351w Auto starter require any modifications? I was re-reading your thread and you had a spacer in there? or did you remove the metal spacer that goes around the starter hole?

#52

#53

Ah so you cut the bottom half off the metal spacer to fill that void... got it.. crap thats what i should have done... we wrestled with that thing trying to get things aligned. Maybe i will just cut that sucker off as I have to pull the tranny back out to try and realign the clutch plate. The clutch didn't come with an alignment tool and I will guess a 1 1/4 alignment tool isn't too common. We just couldn't get the zf all the way in right now.

The good news is, its fits.. barely.. man its tight but its going to work out. I will pull the ZF back out tomorrow and clean up the underside of the floor, clear the starter area for the manifold and anything else i can do before I try again.

After that I will need to fab up a cross member so, time for a ride to the metal yard to go through their scrap

The good news is, its fits.. barely.. man its tight but its going to work out. I will pull the ZF back out tomorrow and clean up the underside of the floor, clear the starter area for the manifold and anything else i can do before I try again.

After that I will need to fab up a cross member so, time for a ride to the metal yard to go through their scrap

#55

#56

Glad it fits. You are closing in. And, Ken is suggesting a step I should have mentioned. (And, btw, he's the one that came up with the process to make the spacer.). You should check the runout on your flywheel. I think factory is something like .010" IIRC, and mine was .004".

Actually I should have looked up the flywheel install procedure before.. so no worries

#58

so not too much done today, more running around picking up a few things i needed.

Found a clutch centering tool thought it would be good to have as I was having quite a bit trouble centering the zf, but turns out it was probably not the case.

Pulled everything apart again, measured the run out and was no more than .055 so it looks good.

I wrestled with the zf for a while and realized the throwout bearing center housing was hitting the fingers on the centerforce clutch.

Tomorrow I will take the clutch off once again and grind the fingers down 1/8th of an inch and try again. You can see where the fingers are hitting in the pics.

Found a clutch centering tool thought it would be good to have as I was having quite a bit trouble centering the zf, but turns out it was probably not the case.

Pulled everything apart again, measured the run out and was no more than .055 so it looks good.

I wrestled with the zf for a while and realized the throwout bearing center housing was hitting the fingers on the centerforce clutch.

Tomorrow I will take the clutch off once again and grind the fingers down 1/8th of an inch and try again. You can see where the fingers are hitting in the pics.

#60

yes its is.. iam wondering if i should just put in a stock zf bearing. However right now thats not the problem.

Are you thinking that dodge bearing may not work? is there a way to check? Would rather make sure the throwout bearing works before i get this thing together..

Are you thinking that dodge bearing may not work? is there a way to check? Would rather make sure the throwout bearing works before i get this thing together..