Exhaust Flange Bolts Nightmare

#1

Exhaust Flange Bolts Nightmare

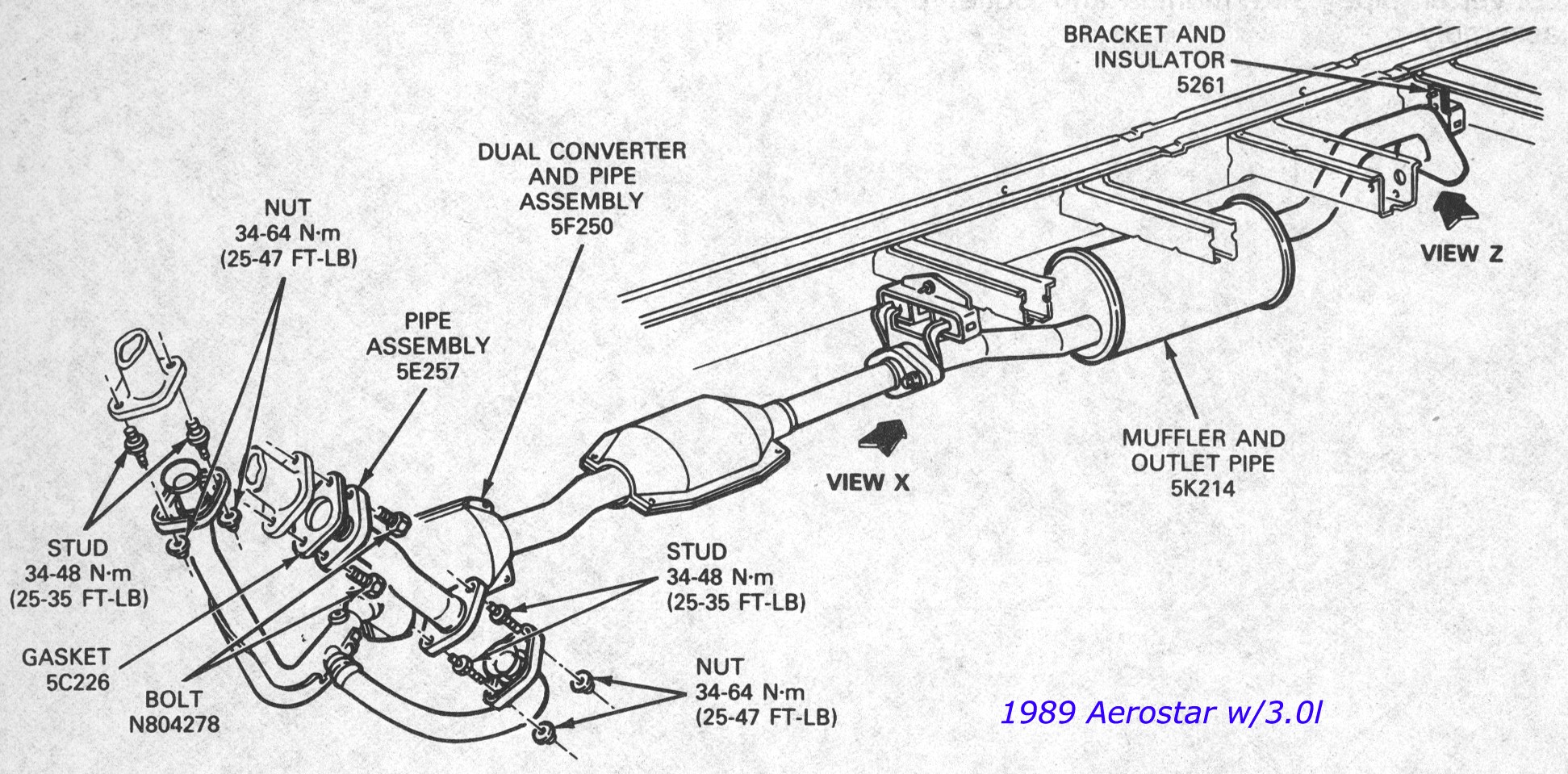

Hiya, I am in the planning process of replacing the entire exhaust system up to the front exhaust flanges on my 93 3.0L shorty Aerostar. The primary reason is because the front catalytic converter was destroyed by an Esso/Exxon car wash which sprays cold water under the vehicle. As a short term solution, the front catalytic converter was replaced with a straight through pipe. Also, the Flex pipe has a growing hole where the hanger "was" welded. It is currently held in place using a wire coat hanger and muffler patch compound. Also, I need to get this done soon because the Environmental Police says it must pass the "clean air" test.

I have purchased all of the parts, stainless steel except for the aluminized steel tail pipe, but not the exhaust flange bolts. I cannot find them anywhere. I would prefer to replace the rusted exhaust flange bolts and nuts with stainless steel bolts and nuts.

Today, after soaking the flange bolts with PB Baster overnight, I managed to remove one of the nuts on the manifold down pipe extension (drives side) using a breaker bar. Wow! What a cracking noise it made! It seems to be a 9/16" nut. Anyway, the other nut looks like it has been under the ocean alongside with the Titanic. So far, there is no chance of removing it without stripping the nut or breaking the bolt. I will try the heat and wax method next week, but looking at it now it does not look promising.

What I really want is a brand new set of exhaust flange bolts and nuts (Stainless Steel please!).

Where are they!!!??? Is there anything available that can be substituted?

I have purchased all of the parts, stainless steel except for the aluminized steel tail pipe, but not the exhaust flange bolts. I cannot find them anywhere. I would prefer to replace the rusted exhaust flange bolts and nuts with stainless steel bolts and nuts.

Today, after soaking the flange bolts with PB Baster overnight, I managed to remove one of the nuts on the manifold down pipe extension (drives side) using a breaker bar. Wow! What a cracking noise it made! It seems to be a 9/16" nut. Anyway, the other nut looks like it has been under the ocean alongside with the Titanic. So far, there is no chance of removing it without stripping the nut or breaking the bolt. I will try the heat and wax method next week, but looking at it now it does not look promising.

What I really want is a brand new set of exhaust flange bolts and nuts (Stainless Steel please!).

Where are they!!!??? Is there anything available that can be substituted?

#2

#3

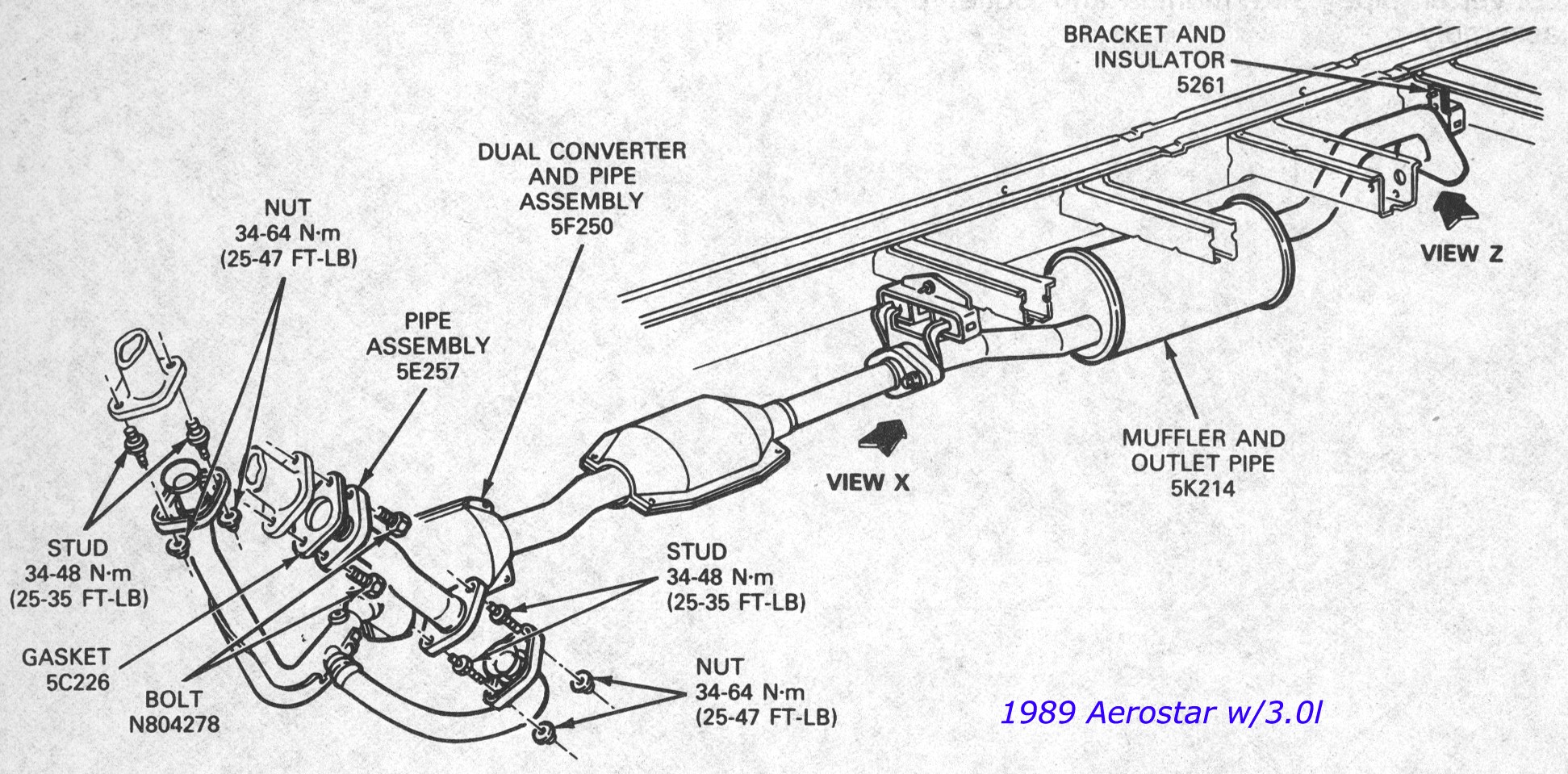

A blast from the past . . . I captured this pic in 2002, eleven years ago.

Click here for larger

That shows double-ended studs on the pass. side, and bolts on the driver's side. From what I recall, they were not all that special (other than removing them the first time; I always use anti-seize on exhaust stuff, so after the first time, they come off without problems). Metric, or course, and I believe I found some 10.8 or 12.8 replacements.

Click here for larger

That shows double-ended studs on the pass. side, and bolts on the driver's side. From what I recall, they were not all that special (other than removing them the first time; I always use anti-seize on exhaust stuff, so after the first time, they come off without problems). Metric, or course, and I believe I found some 10.8 or 12.8 replacements.

#4

Hey! That looks exactly like my 93 exhaust but without the Flex Pipe detail.

Thanks for upping the photo Savage. That's them Exhaust Flange nut/bolts.

I am going to try using an impact driver to release the corroded nut.

The other three nuts are in good shape, it's the bottom one that is toast.

Thanks for upping the photo Savage. That's them Exhaust Flange nut/bolts.

I am going to try using an impact driver to release the corroded nut.

The other three nuts are in good shape, it's the bottom one that is toast.

#5

I've had pretty good luck using a Dremel and a 1/8" carbide burr to cut away a lot of the rusted nut, then spray again, then grab the remains with needle-nose vise grips, but sometimes you have to cut it off flush as you can, then drill it out from the bottom. I don't bother with trying to drill exactly on-center on in-frame jobs like these, I just go oversize and plant a coil insert in the manifold, and use a new bolt. There's lots of ways of dealing with it, but if you can remove it without cutting, that's best of course.

Depending on access, I've often used a torch (not propane) to make the manifold's ear red-hot, then the stud or both almost always comes right out, but sometimes you can't get that much heat on the flange's ear when it's installed.

Depending on access, I've often used a torch (not propane) to make the manifold's ear red-hot, then the stud or both almost always comes right out, but sometimes you can't get that much heat on the flange's ear when it's installed.

#6

Well... my biggest fear came true. The bottom driver side rusty exhaust flange nut broke off, and I'm pretty sure the passenger side bottom nut will also break off. The top nuts on both sides of the exhaust are in good shape.

While I was looking at the exhaust flange bolts, It got me thinking... why not remove all of them, and replace them with readily available stainless steel bolts, nuts, and washers? See example pic below:

While I was looking at the exhaust flange bolts, It got me thinking... why not remove all of them, and replace them with readily available stainless steel bolts, nuts, and washers? See example pic below:

#7

That will work just fine, especially on an Aerostar where the fix will probably outlast the vehicle. I should have done that on my daughter's Mustang instead of chasing down some exhaust parts that were discontinued by Ford and buying them from all parts of the country.

Trending Topics

#8

You should use studs, not bolts. The main reason is that if a nut strips out, you can still extract a stud. If the nut won't turn, chances are the entire stud will unthread, giving you 2 ways to remove it. With a bolt, you have only one option, if it strips or breaks, you have to cut it off and resort to extraction.

#9

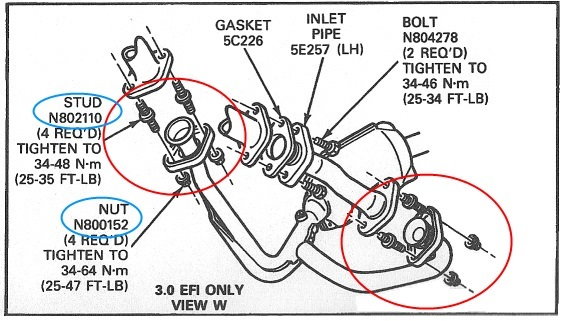

Here is a pic of my drivers side broken Exhaust Flange Bolt:

As you can see in the above pic, the shank of the primary section of the stud rusted away. But the secondary shank that attaches to the manifold down pipe coupling, or the drivers side manifold extension pipe coupling, is still intact and removable. I am having the same exact problem with the passenger side flange bolts, the top bolt is removable, while the bottom bolt won't even nudge while using an impact driver, PB Blaster, and a propane torch. The bottom bolts on both sides are to be considered sacrificial lambs. They won't budge without the use of a breaker bar. The breaker bar brakes the outer flange nut off, which leaves the inner bolt stud intact. The inner bolt and stud is more heftier, which makes it easier to remove, and it is also more protected from the environment because it is isolated.

I am now in the process of rethinking. I have considered the use of studs but I cannot figure out the tread count per inch (I think it is metric 14), nor the exact width. They are that corroded. I now think, why not just get a couple of 2" x 3/8" SS bolts and complimentary SS flange nuts. I do realize SS bolts are not as strong Grade 8 bolts, but at the same time I don't think these Ford Exhaust Flange Bolts are NOT anywhere near Grade 8!

This is just an exhaust pipe connector, not like a cylinder head!!!

As you can see in the above pic, the shank of the primary section of the stud rusted away. But the secondary shank that attaches to the manifold down pipe coupling, or the drivers side manifold extension pipe coupling, is still intact and removable. I am having the same exact problem with the passenger side flange bolts, the top bolt is removable, while the bottom bolt won't even nudge while using an impact driver, PB Blaster, and a propane torch. The bottom bolts on both sides are to be considered sacrificial lambs. They won't budge without the use of a breaker bar. The breaker bar brakes the outer flange nut off, which leaves the inner bolt stud intact. The inner bolt and stud is more heftier, which makes it easier to remove, and it is also more protected from the environment because it is isolated.

I am now in the process of rethinking. I have considered the use of studs but I cannot figure out the tread count per inch (I think it is metric 14), nor the exact width. They are that corroded. I now think, why not just get a couple of 2" x 3/8" SS bolts and complimentary SS flange nuts. I do realize SS bolts are not as strong Grade 8 bolts, but at the same time I don't think these Ford Exhaust Flange Bolts are NOT anywhere near Grade 8!

This is just an exhaust pipe connector, not like a cylinder head!!!

#11

I finally scanned a pic of the exhaust flange bolts from the service manual:

The stud is N802110, and the nut is N800152. Part number sometimes needs the suffix "-S".

I do NOT plan on purchasing these stock Ford parts. I do not want them for the reason that they cannot be removed after usage.

I went to Home Depot, in order to figure out the bolt size and thread count. The closest match was M12 and 1/2", but neither of them fit perfectly on the rusty bolt end.

So I am now settled with my original plan of using 3/8" x 2" SS bolts:

Except... they will be installed upside down from my original plan.

The stud is N802110, and the nut is N800152. Part number sometimes needs the suffix "-S".

I do NOT plan on purchasing these stock Ford parts. I do not want them for the reason that they cannot be removed after usage.

I went to Home Depot, in order to figure out the bolt size and thread count. The closest match was M12 and 1/2", but neither of them fit perfectly on the rusty bolt end.

So I am now settled with my original plan of using 3/8" x 2" SS bolts:

Except... they will be installed upside down from my original plan.

#12

#14

#15

Although, they did send me an email requesting to review their product. It has not yet been published on their website. And it probably won't be because they have zero reviews for any of their products.

Here it is:

The stainless steel quality and reasonable price far surpass anything out there.

But the following minor concerns are why I did NOT give it the deserved 5 stars:

1) Accommodating Stainless Steel Band Clamps. The front Y-Pipe tail end needs to be a bit longer where it connects to the CAT pipe section, and the CAT pipe section where it connects to the front Y-Pipe needs to be as short as possible in order to have enough pipe length on the front Y-Pipe, with out interfering with the Oxygen Sensor and cross pipe, in order to install Stainless Steel band/mega clamps. I managed to install an SS band, but it was because I pulled the CAT pipe section backwards a little bit. Also related to the above, is reusing the Ford factory pipe heat shield. The heat shield cannot be transferred when using an SS band because there is not enough pipe length on the Y-Pipe to clamp it on using a couple of SS screw bands.

2) Flex Pipe Alignment. The tail end of the CAT pipe section is a little bent off by a few degrees in order to connect it to the factory Flex pipe properly. The tail end of the CAT pipe section is pointing a bit downwards, instead of pointing directly at the Flex pipe in the eye. No matter how much I twisted the CAT pipe section, in would not align it self with the Flex pipe. This puts abnormal strain on the Flex pipe.

Other than the above, a fantastic product that not only looks great, but is also solid.