Edelbrock choke not setting?

#16

#17

If this lever is not "up" or "set" -- rotating the choke cap does nothing. It is like there is no tension on the choke plate.

With the lever in the "up/set" position, as soon as the throttle is touched, the lever flips back down and the choke is unengaged again.

Since it's warm, it's not even the choke that I'm all that concerned about except that I can see that as the choke opens, there is also a mechanism that backs off the fast idle. Since I can't get the choke to stay "set" I also can't get this fast idle mechanism to work correctly as it is all related and works together as a system.

#18

The choke linkage on the throttle side of the carburetor serves two purposes: it operates the fast idle cam to engage the fast idle stop based on choke position, and serves as the "unloader" which opens the choke if the throttle is pushed all the way to the floor (to clear a flooded engine).

Because of the weight of the fast idle cam, the linkage drops as the choke opens provided the throttle is open. In other words, opening the choke lets this linkage fall DOWN. Likewise, pulling this linkage DOWN opens the choke. If the linkage is pulled DOWN and subsequently released, the tension of the choke cap should pull the cam back up so long as the throttle is open. The linkage cannot stay down unless physically held there, or pinned by the fast idle speed screw. At that point, the choke would not be able to be closed. This is why all carburetors need the pedal pushed once before a cold start - it's to unpin the fast idle cam so that the linkage is free to raise up and allow the choke to close. This all assumes that the choke tang engages the linkage under the cap and the tension is set appropriately.

It might help for you to post pictures of the linkage in question, showing the two states you describe.

Because of the weight of the fast idle cam, the linkage drops as the choke opens provided the throttle is open. In other words, opening the choke lets this linkage fall DOWN. Likewise, pulling this linkage DOWN opens the choke. If the linkage is pulled DOWN and subsequently released, the tension of the choke cap should pull the cam back up so long as the throttle is open. The linkage cannot stay down unless physically held there, or pinned by the fast idle speed screw. At that point, the choke would not be able to be closed. This is why all carburetors need the pedal pushed once before a cold start - it's to unpin the fast idle cam so that the linkage is free to raise up and allow the choke to close. This all assumes that the choke tang engages the linkage under the cap and the tension is set appropriately.

It might help for you to post pictures of the linkage in question, showing the two states you describe.

#19

That is exactly the description that I needed! The fast idle cam can be "locked" either up or down if the rod and lever connecting to the choke plate are turned to their extreme in either direction. Somehow I was missing that these extremes should be avoided and that the fast idle cam should actually be hanging.

That problem is solved.

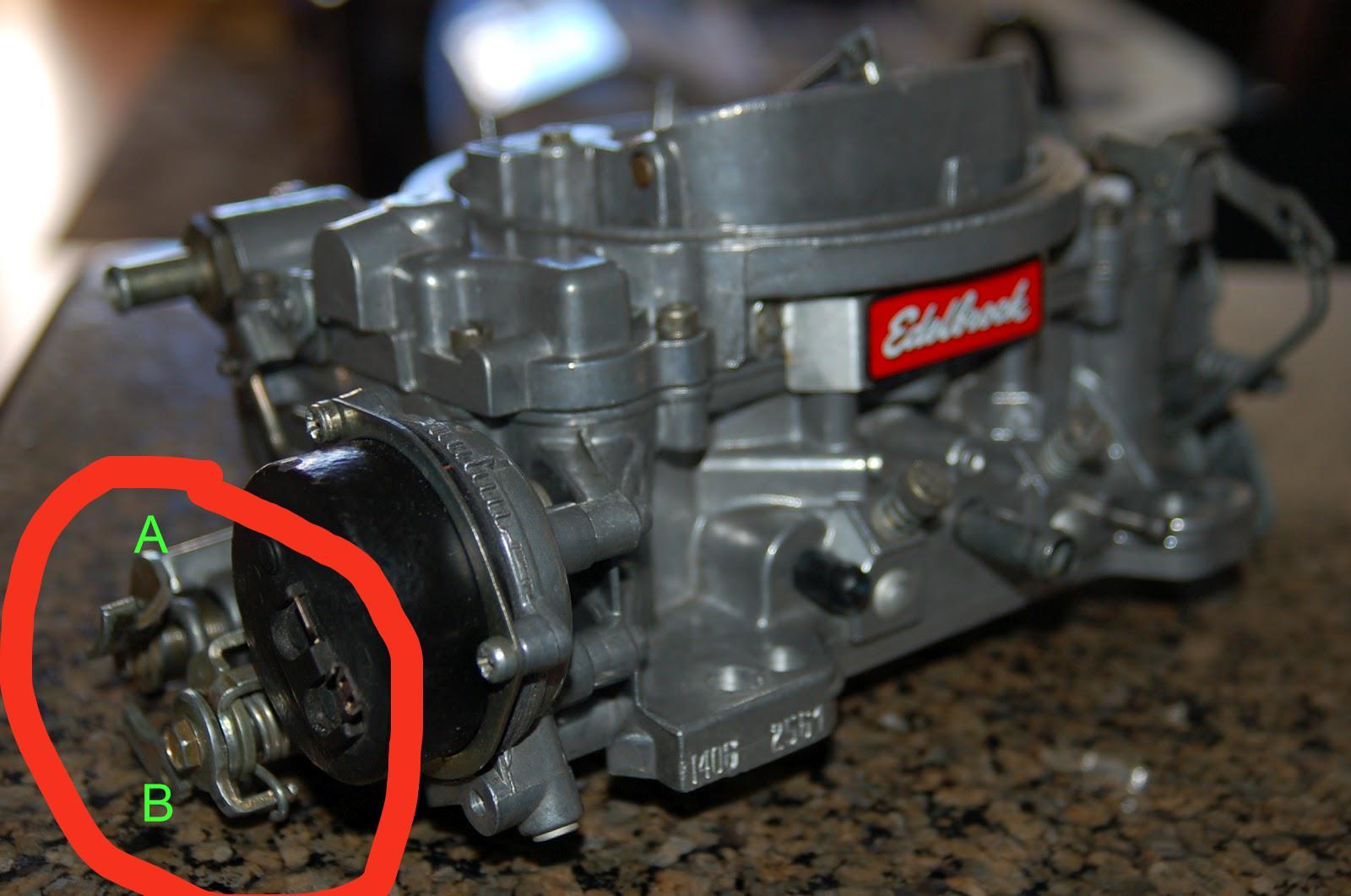

Next question is that on the choke side, there is a spring loaded cam all the way in the bottom rear corner of the carb. I found this image of it and circled it.

On my carb, that choke linkage lever (B) is not touching the cam spring loaded cam (A). I can see on my cam where it is worn as if they should be touching (or have been in the past) -- do I bend the tang on the cam so that it makes contact? If not, what purpose does that these serve and when/why/how do they make contact?

Thanks!

That problem is solved.

Next question is that on the choke side, there is a spring loaded cam all the way in the bottom rear corner of the carb. I found this image of it and circled it.

On my carb, that choke linkage lever (B) is not touching the cam spring loaded cam (A). I can see on my cam where it is worn as if they should be touching (or have been in the past) -- do I bend the tang on the cam so that it makes contact? If not, what purpose does that these serve and when/why/how do they make contact?

Thanks!

#20

The linkage on this side of the carburetor opens and closes the secondary throttle plates as a function of the position of the primary throttle plates. In the case of WOT where both the primary and secondary throttle plates are fully open and the throttle is released so that the vehicle decelerates, lever B pushes against lever A to close the secondary throttle plates along with the primary throttle plates. Back at rest, with the secondary throttle plates closed completely and the primary throttle plates partially closed as dictated by the curb idle speed screw, levers A and B don't necessarily have to stay touching. The marks you see on lever A from lever B are from the deceleration action I've described. Nothing you have described sounds wrong.

Note that the secondary throttle plates cannot open unless the choke is open. A lockout mechanism on the throttle side of the carburetor is responsible for this. This appears to be the case of the carburetor in your picture (primary throttle plates open, secondary throttle plates closed, choke closed). I am able to tell the position of the primary and secondary throttle plates based on the positions of levers B and A, respectively.

I'm hesitant to say that I fully understand your original problem and why it's no longer an issue, but as long as the linkage is operating as I described in my previous post, that's all that matters.

Note that the secondary throttle plates cannot open unless the choke is open. A lockout mechanism on the throttle side of the carburetor is responsible for this. This appears to be the case of the carburetor in your picture (primary throttle plates open, secondary throttle plates closed, choke closed). I am able to tell the position of the primary and secondary throttle plates based on the positions of levers B and A, respectively.

I'm hesitant to say that I fully understand your original problem and why it's no longer an issue, but as long as the linkage is operating as I described in my previous post, that's all that matters.

#21

Thank you, that makes perfect sense and I believe that I'm close to being in business. I will take photos of the original "problem" that I had so that you can understand, maybe it will help someone else in the future.

I just tested it out and the fast idle works when the truck is started and then slowly backs off as the choke opens. The only question (and maybe it's operating as designed) is that as soon as the throttle is blipped, the fast idle cancels itself and it drops back to its regular idle. Does that sound right? It wasn't a problem today, but I can see on a cold day if you don't sit and warm the truck up for a minute, it will probably die.

I just tested it out and the fast idle works when the truck is started and then slowly backs off as the choke opens. The only question (and maybe it's operating as designed) is that as soon as the throttle is blipped, the fast idle cancels itself and it drops back to its regular idle. Does that sound right? It wasn't a problem today, but I can see on a cold day if you don't sit and warm the truck up for a minute, it will probably die.

#22

The fast idle cam can only fall as far as the choke will allow. As the choke opens, the fast idle cam can drop further. However, the fast idle cam can only drop if the throttle is opened. This is because the fast idle speed screw (which is connected to the throttle linkage) pins the fast idle cam in place. So if you don't touch the throttle, the choke can open, but the fast idle cam would stay put. The fast idle cam would "catch up" and drop once the throttle opens. This is all in line with your description.

If you imagine the throttle is open such that the fast idle cam can move freely as the choke opens, the fast idle cam is "in the way" of the fast idle speed screw (preventing the throttle plates from closing further, thereby increasing idle speed) with the choke completely closed. Likewise, the cam is pointed away from the fast idle speed screw if the choke is completely open. Somewhere in between, the fast idle cam makes this transition. Ideally the fast idle cam "travel" is adjusted such that the fast idle cam is "in the way" of the fast idle speed screw for most of the time the choke is opening. In other words, you don't want the fast idle to drop until the choke is most of the way open (which indicates the engine is warm and can idle at normal speed). In practice, however, the fast idle linkage is usually adjusted such that the fast idle drops out "earlier" than that. Refer to figure 5 on page 3 of the rebuild sheet below for proper adjustment if necessary.

http://www.edelbrock.com/automotive_.../1000/1477.pdf

If you imagine the throttle is open such that the fast idle cam can move freely as the choke opens, the fast idle cam is "in the way" of the fast idle speed screw (preventing the throttle plates from closing further, thereby increasing idle speed) with the choke completely closed. Likewise, the cam is pointed away from the fast idle speed screw if the choke is completely open. Somewhere in between, the fast idle cam makes this transition. Ideally the fast idle cam "travel" is adjusted such that the fast idle cam is "in the way" of the fast idle speed screw for most of the time the choke is opening. In other words, you don't want the fast idle to drop until the choke is most of the way open (which indicates the engine is warm and can idle at normal speed). In practice, however, the fast idle linkage is usually adjusted such that the fast idle drops out "earlier" than that. Refer to figure 5 on page 3 of the rebuild sheet below for proper adjustment if necessary.

http://www.edelbrock.com/automotive_.../1000/1477.pdf

#23

Same issue

Thank you. It seems like everything is adjusted/engaged on the choke -- it really seems like the linkage on the throttle side is wrong or missing a spring or something. When I adjust the choke housing, I can feel the tang putting pressure on the choke plate and I can adjust it -- but only when that lever on the right is flipped up manually. The throttle linakge doesn't appear to be interfacing correctly with that part, but I can't for the life of me figure out how it's supposed to work.

#24

Yes -- For me it was more of a user error. I thought I would be able to give the truck a fast rev once it was started and it would still fast-idle. This does not work. As long as I push the throttle to the floor (to set the fast idle) before I start it, it seems to work. If I rev it fast or accelerate hard right away, the choke will open all the way up again instead of ride on the fast idle cam.

It's a confusing system but I believe mine is working the way that it should.

It's a confusing system but I believe mine is working the way that it should.

#26

Fast Idle Cam Not Setting

Hey guys i have the same problem with me edelbrock carb. From a cold engine, pushing accelerator to the floor and the fast idle cam does NOT fall into position so have a real hard time starting in the morning. After she is warmed up runs fine. Until it cools down again. The more it cools the harder it gets to start.

To the guy who started this thread did you ever find out the problem?

When it finally does start, i have to sit in the truck with foot on gas to keep in fast idle long enough to warm it up. It never starts with one pump to the floor so i have to give a little more gas and then i assume it drops off fast idle cam at that point so i have to hold down gas until it warms up.

I will check all linkage blockage today and anything obvious. I saw this thread looking for answers so thought you might have some input. Morning starts are a pain in the butt I would like to hit that key after one pump and it lock on fast idle but id does now.

Any input is appreciated.

Thanks

Len

To the guy who started this thread did you ever find out the problem?

When it finally does start, i have to sit in the truck with foot on gas to keep in fast idle long enough to warm it up. It never starts with one pump to the floor so i have to give a little more gas and then i assume it drops off fast idle cam at that point so i have to hold down gas until it warms up.

I will check all linkage blockage today and anything obvious. I saw this thread looking for answers so thought you might have some input. Morning starts are a pain in the butt I would like to hit that key after one pump and it lock on fast idle but id does now.

Any input is appreciated.

Thanks

Len

#27

For the fast idle to engage, the throttle has to be opened (which you are doing), AND the choke has to close. Verify that the choke is closing. If the choke is closing, yet the fast idle is NOT engaging, verify that the linkage is intact and the fast idle screw is actually engaging the cam. If the fast idle screw is backed out too far, it will never engage.

Lastly, there is a fast idle index adjustment on these carburetors (to align choke travel with fast idle coverage), but unless the linkage has been physically bent or modified, this should never need to be adjusted. Most often, the linkage has either been put back together incorrectly after a rebuild, the choke is not closing, or the fast idle screw is backed off too far.

Lastly, there is a fast idle index adjustment on these carburetors (to align choke travel with fast idle coverage), but unless the linkage has been physically bent or modified, this should never need to be adjusted. Most often, the linkage has either been put back together incorrectly after a rebuild, the choke is not closing, or the fast idle screw is backed off too far.

#28

FMC thanks for the response. I have been trying everything i can think of and i am making some ground. To answer your questions, the fast idle screw is not backed out to far it hits the cam if i push the choke closed.

Problem is the choke does not close ALL the way on its own to it does not position the high idle cam in the right place hence the hard start i think. Stops about 1/2" from closed. When i adjust the choke wheel, i have to turn it almost 90 degrees for it to move at all. In other words i can move the choke wheel almost an inch before any movement on the choke plate. I dont know if that is normal but is seems it should be more responsive.

If i push choke plate further closed the high idle cam seems to end up on the right spot. So why is the choke not closing all the way was my question. Everything is free and clean from what i can see.

So I looked at the coil spring inside the choke (this was after cleaning all linkage and making sure everything was naturally free). My thought was that maybe that spring is sprung or too weak to pull the choke plate back all the way. So i back wound it just a bit so it had a little more forward spring to it. Then it seemed to pull the choke plate closed more but not sure if that was it. I might have just made a workaround for some other thing.

Anyway I took a bunch of videos. Start with this one showing the exact position of everything first thing in the morning without touching anything. Then i made subsequent videos each step i moved forward in my troubleshooting. Not a pro to be sure just trying to figure this out . Maybe you can get something from my videos i am not expressing here.

Here is the first one: < https://www.youtube.com/channel/UCTjC2Co3oEB0-QDhcsKX24w>

I made a <1954 Truck Channel> you will see that link when you play this video above, it will take you to all the other videos.

Let me know what you think. I appreciate your input. Thanks --Len

Problem is the choke does not close ALL the way on its own to it does not position the high idle cam in the right place hence the hard start i think. Stops about 1/2" from closed. When i adjust the choke wheel, i have to turn it almost 90 degrees for it to move at all. In other words i can move the choke wheel almost an inch before any movement on the choke plate. I dont know if that is normal but is seems it should be more responsive.

If i push choke plate further closed the high idle cam seems to end up on the right spot. So why is the choke not closing all the way was my question. Everything is free and clean from what i can see.

So I looked at the coil spring inside the choke (this was after cleaning all linkage and making sure everything was naturally free). My thought was that maybe that spring is sprung or too weak to pull the choke plate back all the way. So i back wound it just a bit so it had a little more forward spring to it. Then it seemed to pull the choke plate closed more but not sure if that was it. I might have just made a workaround for some other thing.

Anyway I took a bunch of videos. Start with this one showing the exact position of everything first thing in the morning without touching anything. Then i made subsequent videos each step i moved forward in my troubleshooting. Not a pro to be sure just trying to figure this out . Maybe you can get something from my videos i am not expressing here.

Here is the first one: < https://www.youtube.com/channel/UCTjC2Co3oEB0-QDhcsKX24w>

I made a <1954 Truck Channel> you will see that link when you play this video above, it will take you to all the other videos.

Let me know what you think. I appreciate your input. Thanks --Len

#29

Your video looked fine to me, with one exception. The choke plate should not freely move unless the throttle is pulled back first. The throttle will prevent the choke plate from closing after the fast idle linkage has dropped. This is why you must pump the pedal once to start a carbureted engine cold. Otherwise, the fast idle linkage is not engaging properly, due to the fast idle speed screw having been backed too far out. That is, unless you "reset" the linkage (pressed the throttle once) prior to starting your video, in which case the choke will move freely and all is well.

The movement of the choke plate itself looked fine. It's normal for there to be some "slop" in the spring. The important thing is that the choke plate can close once the painted mark on the cap moves toward the rich marks. The choke plate should be closed when the engine starts cold. An internal vacuum-actuated pulloff will open the choke slightly once the engine starts cranking so that just enough air can come in for the engine to run.

Sounds like you're good to go.

The movement of the choke plate itself looked fine. It's normal for there to be some "slop" in the spring. The important thing is that the choke plate can close once the painted mark on the cap moves toward the rich marks. The choke plate should be closed when the engine starts cold. An internal vacuum-actuated pulloff will open the choke slightly once the engine starts cranking so that just enough air can come in for the engine to run.

Sounds like you're good to go.

#30

Auto Choke Plate

FMC

Check this video...

First thing in the morning. When i push the accelerator forward, the high idle cam does not move at all. Nothing happens. Does that look normal?

I know the accelerator must be pushed before choke plate will open. What you cant see in the video is that i am using my left wrist to hold the accelerator while i am demonstrating moving the choke wheel around.

Thanks for your input.

Len

Check this video...

First thing in the morning. When i push the accelerator forward, the high idle cam does not move at all. Nothing happens. Does that look normal?

I know the accelerator must be pushed before choke plate will open. What you cant see in the video is that i am using my left wrist to hold the accelerator while i am demonstrating moving the choke wheel around.

Thanks for your input.

Len