Idea to fix Oil Leaks

#1

Idea to fix Oil Leaks

I seem to have some oil leaks at some of the corners of my intake manifold. It's been a little while since I installed the intake, so I'm trying to remember exactly how everything works together to make a good seal.

I have an idea to fix it the next time I have the intake off. I made a little sketch below.

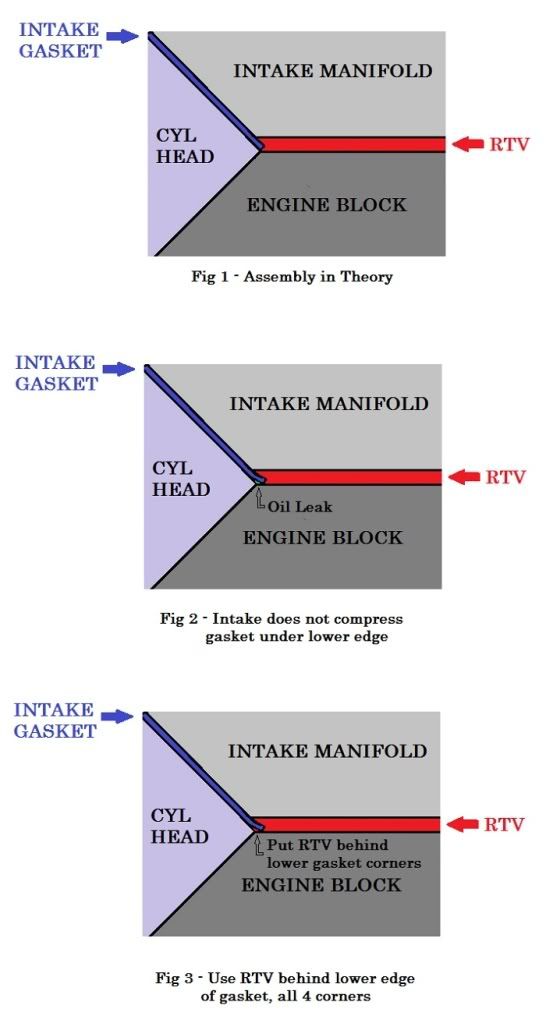

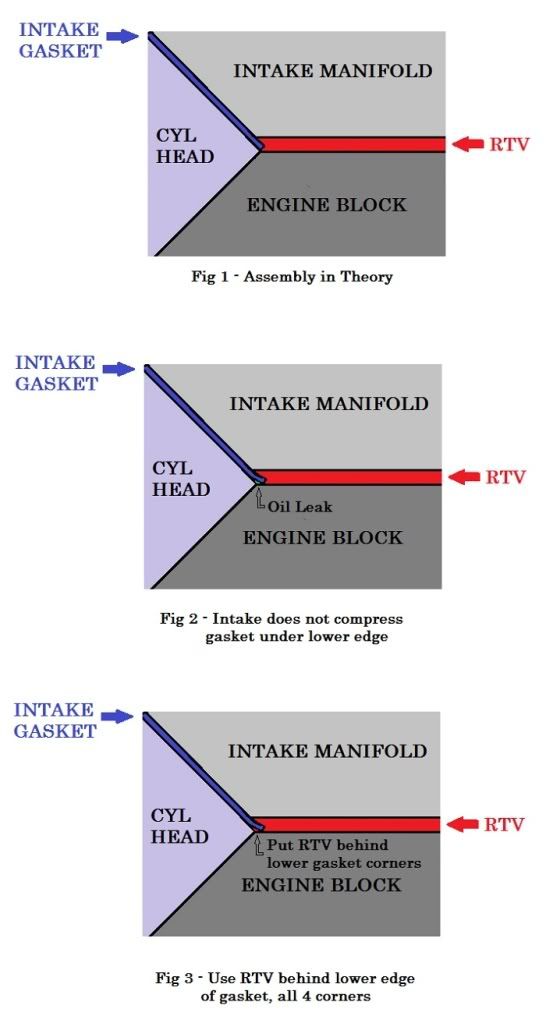

In Figure 1, you can see how I think it all goes together. Note I am showing RTV instead of cork, but that may not matter.

In Figure 2, I am trying to show how there is no intake manifold pressure on the lower portion of the intake gasket. So in the corners, I can see oil leaking behind the gasket and out over the engine block.

In Figure 3, I am showing my thoughts of putting a dab of RTV (or other sealant) behind the gasket to help seal it.

I don't know if it will work, or if I'm way out in left field. I do know that these corner leaks have been a crapshoot for me over the years. Sometimes I get a leak, sometimes I don't. Doesn't seem to matter whether I use cork and a bit of sealant, or just a single bead of sealant.

Any thoughts?

I have an idea to fix it the next time I have the intake off. I made a little sketch below.

In Figure 1, you can see how I think it all goes together. Note I am showing RTV instead of cork, but that may not matter.

In Figure 2, I am trying to show how there is no intake manifold pressure on the lower portion of the intake gasket. So in the corners, I can see oil leaking behind the gasket and out over the engine block.

In Figure 3, I am showing my thoughts of putting a dab of RTV (or other sealant) behind the gasket to help seal it.

I don't know if it will work, or if I'm way out in left field. I do know that these corner leaks have been a crapshoot for me over the years. Sometimes I get a leak, sometimes I don't. Doesn't seem to matter whether I use cork and a bit of sealant, or just a single bead of sealant.

Any thoughts?

#2

#3

All I ever did was use a bit of that Indian Head Gasket Shellac, or the Permatex Aviation Sealer (the molasses-like stuff) around the water ports.

I'd like to swap out my Offy 2x4 manifold for a Blue Thunder intake and thought I might try something different in helping seal against oil leaks.

I have a Cobra kit car I built years ago, and have had lots of "fun" issues requiring rebuilds. Cracked engine block, broken piston due to detonation, etc. I finally seem to have the engine running well, but this last time I seem to have developed oil leaks.

So, it's not a truck, but these truck guys are more my style. They do things themselves and know their stuff. Asking FE questions in the Cobra forum can get you a good answer, but all too often, the answer is "Why don't you ask your engine builder?"

I'd like to swap out my Offy 2x4 manifold for a Blue Thunder intake and thought I might try something different in helping seal against oil leaks.

I have a Cobra kit car I built years ago, and have had lots of "fun" issues requiring rebuilds. Cracked engine block, broken piston due to detonation, etc. I finally seem to have the engine running well, but this last time I seem to have developed oil leaks.

So, it's not a truck, but these truck guys are more my style. They do things themselves and know their stuff. Asking FE questions in the Cobra forum can get you a good answer, but all too often, the answer is "Why don't you ask your engine builder?"

#4

Your issue is caused by the block being decked and the heads being level cut so that now there is a mismatch where the intake/heads/block meet. Two cures, either cut the intake to match the heads (then the intake will fit this block and heads only) or cut the intake face of the heads so the intake matches properly (then the intake will still work on other engines). Ford has info on how much to cut the intake so that it will match but I'm not able to find it right now. I have always cut the intake in the past but I was building race motors when this issue popped up and didn't plan on separating anything.

#5

There is a formula for the machining operations and like Bear I don't have it at hand so you will have to do a search for it. Instead of silicone I have aways used Gorilla Snot on the end rails and corners when installing the intake on an FE. Gorilla Snot a/k/a 3M trim cement from the tube not a spray or a can.

#6

#7

If block or head milling is done and the angles are maintained, i.e 45 deg (or 90 deg, depending on how you measure), everything still matches up, but the intake will sit too high. I think that formula might be for figuring out how much to take off the intake to get it to drop the correct amount. Just a trignometry thing.

Not that Bear is wrong. I did have the block deck and heads re-surfaced, ...just a skim. Not enough to cause a mismatch where the valve cover has to seal at the point where the intake meets the heads.

So things may be out, but this is the first time I have a non-smoking engine, so as the intake gaskets must be sealing I sort of ruled out maching problems and while thinking about it, came up with sealing under the gasket corners as I showed in the sketch in the first post.

I'd like to get that new intake, but it's not cheap. Might have to use my plastic friend (credit card). Once I get the old one off, I'll see what I can measure for angles, and then check clearances with a test fit of the new intake.

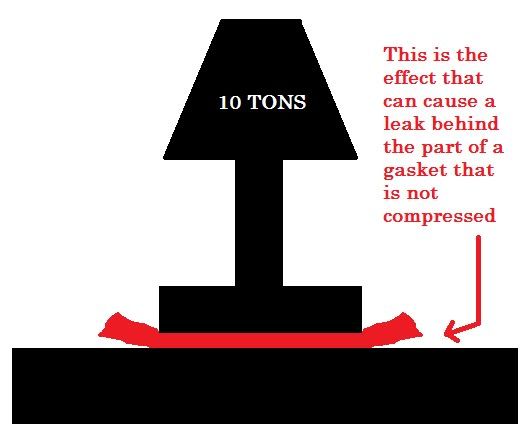

Back to the OP. I still think that oil can leak behind the gasket corners if there isn't sealant there as there is nothing to push the gasket down below the bottom edge of the intake manifold.

Not that Bear is wrong. I did have the block deck and heads re-surfaced, ...just a skim. Not enough to cause a mismatch where the valve cover has to seal at the point where the intake meets the heads.

So things may be out, but this is the first time I have a non-smoking engine, so as the intake gaskets must be sealing I sort of ruled out maching problems and while thinking about it, came up with sealing under the gasket corners as I showed in the sketch in the first post.

I'd like to get that new intake, but it's not cheap. Might have to use my plastic friend (credit card). Once I get the old one off, I'll see what I can measure for angles, and then check clearances with a test fit of the new intake.

Back to the OP. I still think that oil can leak behind the gasket corners if there isn't sealant there as there is nothing to push the gasket down below the bottom edge of the intake manifold.

Trending Topics

#8

I usually use Brake Klean to prep before I install gaskets. And I do think I'll use one of the sealants recommended by many of the FE guys instead of RTV next time.

#9

If block or head milling is done and the angles are maintained, i.e 45 deg (or 90 deg, depending on how you measure), everything still matches up, but the intake will sit too high. I think that formula might be for figuring out how much to take off the intake to get it to drop the correct amount. Just a trignometry thing.

Not that Bear is wrong. I did have the block deck and heads re-surfaced, ...just a skim. Not enough to cause a mismatch where the valve cover has to seal at the point where the intake meets the heads.

So things may be out, but this is the first time I have a non-smoking engine, so as the intake gaskets must be sealing I sort of ruled out maching problems and while thinking about it, came up with sealing under the gasket corners as I showed in the sketch in the first post.

I'd like to get that new intake, but it's not cheap. Might have to use my plastic friend (credit card). Once I get the old one off, I'll see what I can measure for angles, and then check clearances with a test fit of the new intake.

Back to the OP. I still think that oil can leak behind the gasket corners if there isn't sealant there as there is nothing to push the gasket down below the bottom edge of the intake manifold.

Not that Bear is wrong. I did have the block deck and heads re-surfaced, ...just a skim. Not enough to cause a mismatch where the valve cover has to seal at the point where the intake meets the heads.

So things may be out, but this is the first time I have a non-smoking engine, so as the intake gaskets must be sealing I sort of ruled out maching problems and while thinking about it, came up with sealing under the gasket corners as I showed in the sketch in the first post.

I'd like to get that new intake, but it's not cheap. Might have to use my plastic friend (credit card). Once I get the old one off, I'll see what I can measure for angles, and then check clearances with a test fit of the new intake.

Back to the OP. I still think that oil can leak behind the gasket corners if there isn't sealant there as there is nothing to push the gasket down below the bottom edge of the intake manifold.

#10

That would keep the loose edge of the gasket from curling up.

I think you're onto something

#11

I don't know if it really curls up to the extent you could see it, but enough that it isn't tight, and that could cause an oil leak. But now you see what I'm saying.

Mine doesn't seem to be leaking too bad, but I've got a clutch job coming up and one of my thoughts is that oil has leaked out the rear corners of my intake and gotten between the bellhousing and the block contaminating the clutch disc.

Mine doesn't seem to be leaking too bad, but I've got a clutch job coming up and one of my thoughts is that oil has leaked out the rear corners of my intake and gotten between the bellhousing and the block contaminating the clutch disc.

#13

#14

When I scrapped the highboy, the rear of the intake was leaking pretty badly, and there was nothing INSIDE the bellhousing. Of course, that doesn't mean it's impossible...

When I scrapped the highboy, the rear of the intake was leaking pretty badly, and there was nothing INSIDE the bellhousing. Of course, that doesn't mean it's impossible...

#15

The clutch is a whole 'nother story. It chatters when taking off in 1st. I had it apart about 500 miles ago and everything looked fine. The disc looked brown, but McLeod says it's normal for them to turn that colour.

It may be that I never checked my bellhousing alignment and have either ruined the pilot bearing, or worse, the tranny input shaft bearing. Engine and tranny mounts appear fine.

I did check the front of the flywheel through the access under the rear of the block and it was dry. But I guess it doesn't take much oil to screw things up.

Anyway, it was tolerable back then and I cleaned the flywheel from some disc staining, but the same chattering was still there. And now it's worse.

It may be that I never checked my bellhousing alignment and have either ruined the pilot bearing, or worse, the tranny input shaft bearing. Engine and tranny mounts appear fine.

I did check the front of the flywheel through the access under the rear of the block and it was dry. But I guess it doesn't take much oil to screw things up.

Anyway, it was tolerable back then and I cleaned the flywheel from some disc staining, but the same chattering was still there. And now it's worse.