ThinLizzy's '67 F250 CS

#1

ThinLizzy's '67 F250 CS

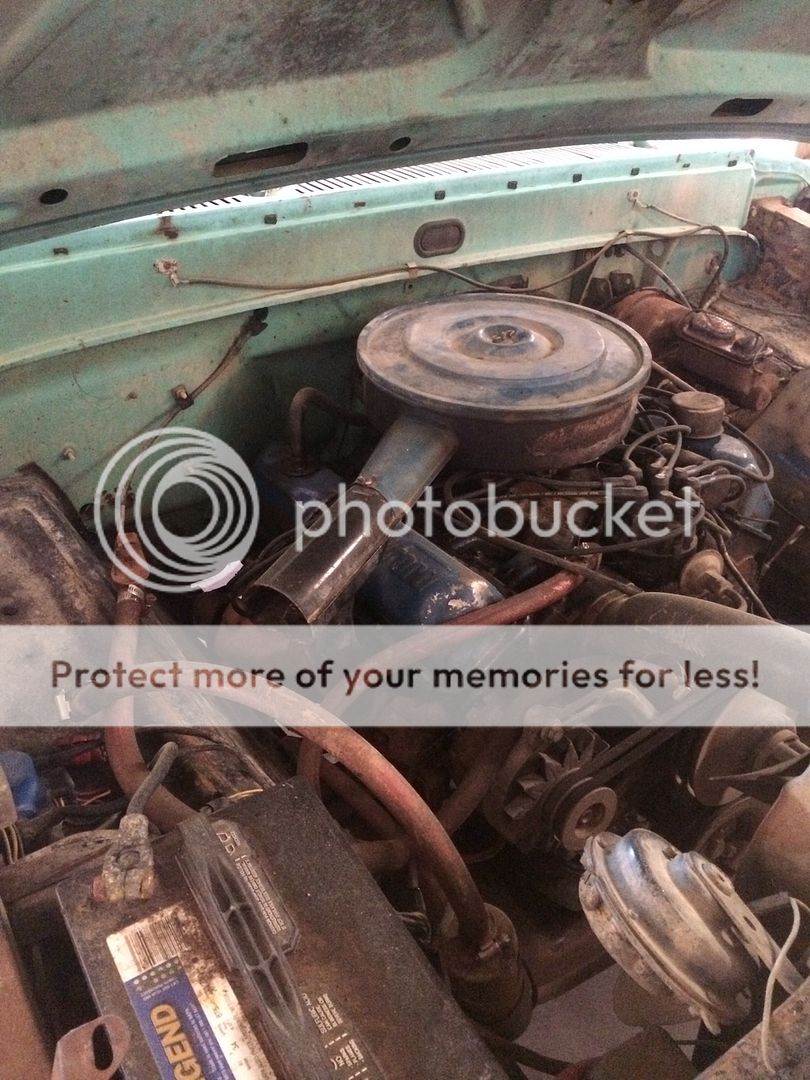

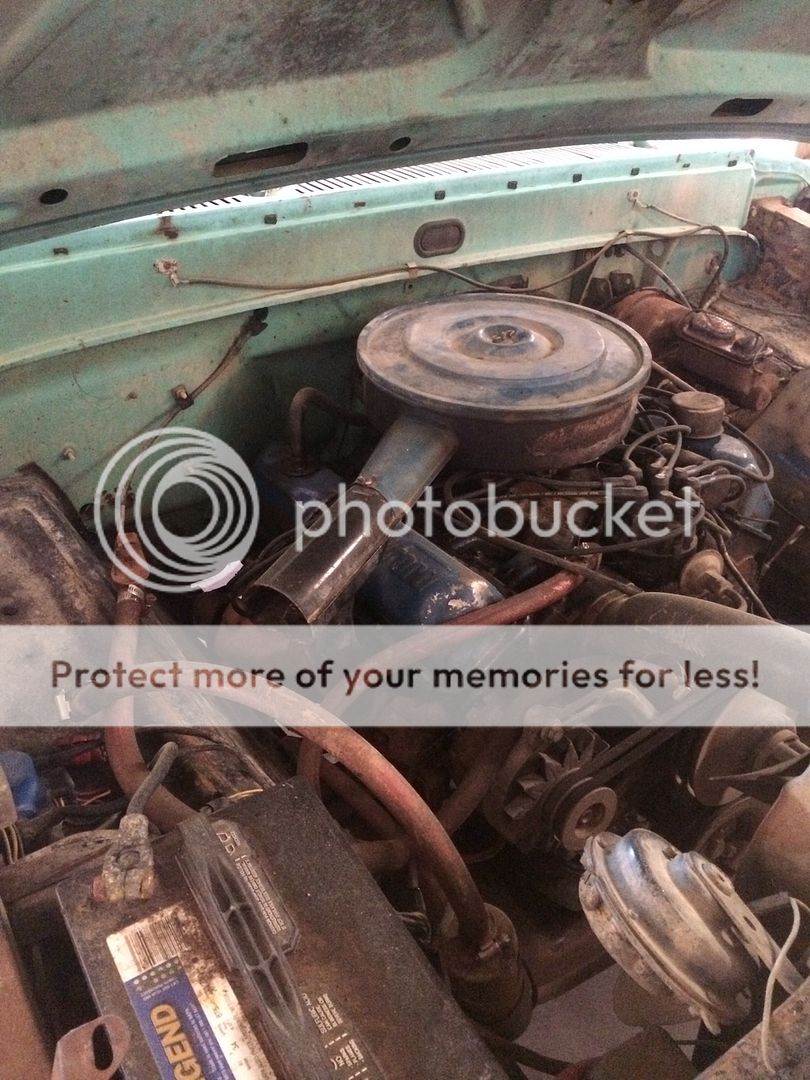

Things have finally slowed down around here and I can start putting some attention into my "new" truck! 1967 F250 custom cab Camper Special. 70k original miles, 352 v8, NP435, and 4.10 gears out back.

The truck seems to be fairly unmolested. As far as I can tell the second battery wiring has been unhooked, the heater core removed, and there's a newish looking clutch fork. Other than that everything looks pretty 67 inside.

Anyway here's some pics of the truck in my friend's barn...excited to actually have concrete underneath a vehicle I'm working on lol.

Topper looks a tad small...

Dealer name plate

Came with a grill guard!

Plans as of now are

#1 fix the clutch

#2 repair passenger side floor pan

#3 new rag joint

#4 trace all the wiring and inspect the brakes

Long term plan is keep it largely stock and *hopefully* one day have it repainted original coloring. Only modern things I may add is a stereo system and A/C.

The truck seems to be fairly unmolested. As far as I can tell the second battery wiring has been unhooked, the heater core removed, and there's a newish looking clutch fork. Other than that everything looks pretty 67 inside.

Anyway here's some pics of the truck in my friend's barn...excited to actually have concrete underneath a vehicle I'm working on lol.

Topper looks a tad small...

Dealer name plate

Came with a grill guard!

Plans as of now are

#1 fix the clutch

#2 repair passenger side floor pan

#3 new rag joint

#4 trace all the wiring and inspect the brakes

Long term plan is keep it largely stock and *hopefully* one day have it repainted original coloring. Only modern things I may add is a stereo system and A/C.

#2

I'll start off by saying I have never worked on a clutch. I've been reading my 67 shop manual and surfing the web so hopefully this goes relatively smoothly.

Issue #1. Clutch doesn't work.

Upon closer inspection I found that...

- clutch fork isn't seated in throw out bearing

- wrong return spring for clutch fork (too long)

- dust cover on bottom of bellhousing missing

- the "clutch fingers" seem to be pretty mashed

Good news is that it's the correct clutch fork for 67.

Snapped some pics the best I could by sticking my phone up through the dust cover area...

I think this is the throw out bearing?

I dunno if the fingers should look like this?

I'm not quite sure how the clutch fork ended up totally behind the throw out bearing. The plan so far is to drop the trans this weekend. Get a look at what's going on in there. Since I'm going through all the trouble to remove everything I'm thinking I will replace the clutch and related parts and make sure everything's correct. Then I'll change the trans fluid and take a gander inside to make sure it's all good before I put everything back together.

If anyone has any tips/insight for me I'm all ears.

Thanks!

Issue #1. Clutch doesn't work.

Upon closer inspection I found that...

- clutch fork isn't seated in throw out bearing

- wrong return spring for clutch fork (too long)

- dust cover on bottom of bellhousing missing

- the "clutch fingers" seem to be pretty mashed

Good news is that it's the correct clutch fork for 67.

Snapped some pics the best I could by sticking my phone up through the dust cover area...

I think this is the throw out bearing?

I dunno if the fingers should look like this?

I'm not quite sure how the clutch fork ended up totally behind the throw out bearing. The plan so far is to drop the trans this weekend. Get a look at what's going on in there. Since I'm going through all the trouble to remove everything I'm thinking I will replace the clutch and related parts and make sure everything's correct. Then I'll change the trans fluid and take a gander inside to make sure it's all good before I put everything back together.

If anyone has any tips/insight for me I'm all ears.

Thanks!

#3

#4

#5

#6

Not sure what the PO was thinking... It has stock exhaust on it now, and it looks like it's been on there for quite a while. Whoever did it welded some thick steel bars to reinforce the x-member. I'm going to get some plate to weld into that hole.

Here's some pics of the clutch in all it's glory...

The flywheel, teeth don't look bad.

Clutch fork is a little worn down from the bearing spinning on it. I have the later style bellhousing and fork (the not anti rattle spring type) that I'm toying with putting in instead. Dunno if it would make a difference.

Everything under there is GRIMEY. I got a lot of cleaning to do. On the plus side the oil/grime protected all the paint.

This is the tranny AFTER I scraped at it for about 30 mins.

Rear main isn't leaking at all so that's good. I didn't really wanna jump into that.

Here's some pics of the clutch in all it's glory...

The flywheel, teeth don't look bad.

Clutch fork is a little worn down from the bearing spinning on it. I have the later style bellhousing and fork (the not anti rattle spring type) that I'm toying with putting in instead. Dunno if it would make a difference.

Everything under there is GRIMEY. I got a lot of cleaning to do. On the plus side the oil/grime protected all the paint.

This is the tranny AFTER I scraped at it for about 30 mins.

Rear main isn't leaking at all so that's good. I didn't really wanna jump into that.

#7

Join Date: Aug 2003

Location: **** hole San Jose ca.

Posts: 7,592

Likes: 0

Received 9 Likes

on

9 Posts

If the flywheel bolt heads have been rubbed from the clutch spring hub it's also time to replace the flywheel to get a 100% of clutch usage. As the clutch lining wears down the clutch hubs gets closer to the bolts until it rubs. Then the clutch will not engage any longer.

Also it looks like the trans input shaft pilot bushing snout is warden down in your picture from the rest of the snout.

A new pilot bushing won't do much good having the input shaft like that. If not this is not corrected the clutch will not center

every time to let out the clutch as you shift will do in the input bearing plus the needle bearing where the input & out put shafts butt together.

Orich

Also it looks like the trans input shaft pilot bushing snout is warden down in your picture from the rest of the snout.

A new pilot bushing won't do much good having the input shaft like that. If not this is not corrected the clutch will not center

every time to let out the clutch as you shift will do in the input bearing plus the needle bearing where the input & out put shafts butt together.

Orich

Trending Topics

#8

Also it looks like the trans input shaft pilot bushing snout is warden down in your picture from the rest of the snout.

A new pilot bushing won't do much good having the input shaft like that. If not this is not corrected the clutch will not center

every time to let out the clutch as you shift will do in the input bearing plus the needle bearing where the input & out put shafts butt together.

Orich

1967 Bumps 6 and 8 cyl 4X2 NP435's could have been tranny tag numbers C7TA-M or C7TA-N. Both took input shaft part number C5TZ7017B. Replaced by D7TZ7017C.

C5TZ7017B is listed as in stock by:

Premium Listings

Recently Updated<table class="static info_table"><tbody><tr><td class="label">Part Number:</td><td>C5TZ7017B</td><td>

</td><td class="label">Seller:</td><td>Green Sales Company - View Profile</td></tr><tr class="even"><td class="label">Description:</td><td>

</td><td>

</td><td class="label">Phone:</td><td id="phone_primary344921">(513) 294-8385

Tell them you found it on RearCounter.com</td></tr><tr><td class="label">Price:</td><td>Request Pricing</td><td>

</td><td class="label">Email:</td><td>Send Seller Email Inquiry</td></tr><tr class="even"><td class="label">Quantity:</td><td>4</td><td>

</td><td class="label">Location:</td><td>Cincinnati, Ohio Map & Directions</td></tr><tr><td colspan="5" style="text-align:right; padding-top:5px; padding-bottom:5px">

</td></tr></tbody></table>

<table class="static info_table"><tbody><tr class="even"><td class="label">Part Number:</td><td>C5TZ-7017-B</td><td>

</td><td class="label">Seller:</td><td>Miller Obsolete Parts - View Profile</td></tr><tr><td class="label">Description:</td><td>TRANS. INPUT SHAFT ASSY.</td><td>

</td><td class="label">Phone:</td><td id="phone_primary174049">(607) 722-5371

Tell them you found it on RearCounter.com</td></tr><tr class="even"><td class="label">Price:</td><td>Request Pricing</td><td>

</td><td class="label">Email:</td><td>Send Seller Email Inquiry</td></tr><tr><td class="label">Quantity:</td><td>1</td><td>

</td><td class="label">Location:</td><td>Binghamton, New York Map & Direction</td></tr></tbody></table>*******************************************

D7TZ7017C listed by:

Premium Listings

Recently Updated<table class="static info_table"><tbody><tr><td class="label">Part Number:</td><td>D7TZ-7017-C</td><td>

</td><td class="label">Seller:</td><td>Dennis Carpenter Ford Restoration Parts - View Profile</td></tr><tr class="even"><td class="label">Description:</td><td>NOS** GEAR</td><td>

</td><td class="label">Phone:</td><td id="phone_primary780265">(800) 476-9653

Tell them you found it on RearCounter.com</td></tr><tr><td class="label">Price:</td><td>Request Pricing</td><td>

</td><td class="label">Email:</td><td>Send Seller Email Inquiry</td></tr><tr class="even"><td class="label">Quantity:</td><td>1</td><td>

</td><td class="label">Location:</td><td>Concord, North Carolina Map & Directions</td></tr><tr><td colspan="5" style="text-align:right; padding-top:5px; padding-bottom:5px">

</td></tr></tbody></table>

Recently Updated<table class="static info_table"><tbody><tr class="even"><td class="label">Part Number:</td><td>D7TZ7017C</td><td>

</td><td class="label">Seller:</td><td>Green Sales Company - View Profile</td></tr><tr><td class="label">Description:</td><td>

</td><td>

</td><td class="label">Phone:</td><td id="phone_primary344921">(513) 294-8385

Tell them you found it on RearCounter.com</td></tr><tr class="even"><td class="label">Price:</td><td>Request Pricing</td><td>

</td><td class="label">Email:</td><td>Send Seller Email Inquiry</td></tr><tr><td class="label">Quantity:</td><td>3</td><td>

</td><td class="label">Location:</td><td>Cincinnati, Ohio Map & Directions</td></tr></tbody></table>

#9

Wow thanks for the leads JEFFAFA!

Orich - the flywheel bolts haven't been rubbed on by the clutch. I don't think the flywheel has ever been taken out. Is the worn part you're talking about the shiny spot to the left of the splines? I cleaned it up a bit and ran my finger over it and there doesn't seem to be a ridge. I'll post a pic of it when I get a chance.

Also I was incorrect in thinking it had a new clutch fork. The clutch fork is just still painted (and the bellhousing and trans for that matter). Most trucks I've worked on have been fairly meddled with or from the north so I'm not used to seeing things still painted/intact lol. Now that I've gotten it apart it seems that everything that was supposed to be in there was- minus the clips that hold the throw out bearing to the fork

Orich - the flywheel bolts haven't been rubbed on by the clutch. I don't think the flywheel has ever been taken out. Is the worn part you're talking about the shiny spot to the left of the splines? I cleaned it up a bit and ran my finger over it and there doesn't seem to be a ridge. I'll post a pic of it when I get a chance.

Also I was incorrect in thinking it had a new clutch fork. The clutch fork is just still painted (and the bellhousing and trans for that matter). Most trucks I've worked on have been fairly meddled with or from the north so I'm not used to seeing things still painted/intact lol. Now that I've gotten it apart it seems that everything that was supposed to be in there was- minus the clips that hold the throw out bearing to the fork

#10

Join Date: Aug 2003

Location: **** hole San Jose ca.

Posts: 7,592

Likes: 0

Received 9 Likes

on

9 Posts

Yeah, The splined end tip that we call the spline snout is not suppose to be under cut like what it looks to be about a 1/2" of the tip this is how far it goes into the into pilot bushing.

That really needs to be replaced okay, if the input shaft is not, you'll end up fixing or having to replace the tranny later.

When you get a new clutch kit most come with a pilot bushing place it on the snout tip and you'll see the play in it's fit.

If you can wobble it on the snout tip, that's not good..

Orich

That really needs to be replaced okay, if the input shaft is not, you'll end up fixing or having to replace the tranny later.

When you get a new clutch kit most come with a pilot bushing place it on the snout tip and you'll see the play in it's fit.

If you can wobble it on the snout tip, that's not good..

Orich

#15

Join Date: Aug 2003

Location: **** hole San Jose ca.

Posts: 7,592

Likes: 0

Received 9 Likes

on

9 Posts

Now that you've taken a close up the shaft snout looks much better. The part where the T.O bearing ride just looks kind of scored some.

Try sanding it with some 400-600 grit or finer see how it cleans up. The is called the

front bearing retainer.

The cheap throw out bearing don't have a grease fitting this looks like it never was grease very good in the first place. Napa was where, I ordered a T.O bearing with a grease fitting I thing they called it for a HD one it was not cheap used it for a few yrs.

Then, I converted to a dodge 5spd o/drive.

I believe your bearing retainer can't be turn 180* as it has an oil return pocket in it.

Some can be turned as they normally wear just on the upper part.

Orich

Try sanding it with some 400-600 grit or finer see how it cleans up. The is called the

front bearing retainer.

The cheap throw out bearing don't have a grease fitting this looks like it never was grease very good in the first place. Napa was where, I ordered a T.O bearing with a grease fitting I thing they called it for a HD one it was not cheap used it for a few yrs.

Then, I converted to a dodge 5spd o/drive.

I believe your bearing retainer can't be turn 180* as it has an oil return pocket in it.

Some can be turned as they normally wear just on the upper part.

Orich

While out I would reseal and gasket the trans. While you are close, is the engine's rear main seal leaking also? Just sayin'.

While out I would reseal and gasket the trans. While you are close, is the engine's rear main seal leaking also? Just sayin'.