Hi all, there have been a lot of questions going around about the automatic choke - how it works, what it's supposed to do, why yours isn't working, etc. Instead of trying to tackle each one in each thread, I thought I'd start a new thread to cover everything you need to know about that mysterious black cap on the passenger side of your carburetor. Hopefully this will take care of all the doubts, frustrations, mysteries and questions that have been floating around the forum.

What that choke does.

The carburetor's job is to control the air\fuel mixture delivered to the engine. When the engine is cold, the engine needs to run rich, which means the amount of atomized fuel in the mixture needs to be higher than you'd normally have when the engine is warmed up. The carburetor accomplishes this by using a

choke plate at the very top of the throat of the carburetor. When the engine is warmed up and running under normal conditions, the choke plate stands completely vertical and incoming air moves right past. However, when the engine needs to run rich, the choke plate can rotate to close off the throat of the carburetor and

restrict the volume of incoming air. However, because the vacuum signal coming from the intake is still just as strong, this increases the negative pressure in the throttle body of the carburetor, which pulls more fuel from the bowl. That's basically it.

The choke plate is opened and closed through a mechanical linkage which is controlled by the black cap on the passenger side of the carburetor. This is called the

choke cap,

choke spring, or

choke thermostat. Inside the choke cap is a spring. It is

bimetallic meaning it is made of two different metals. Two long pieces of metal are fused on top of one another and wound into a spring. The two metals have different

coefficients of thermal expansion which means as they get hot, one gets bigger than the other. Because they are attached on top of each other, the spring literally unwinds when it gets hot. It doesn't unwind much, but it's enough to make the end of the spring (often called the

tang) to move several degrees. The tang is situated inside a slotted arm which, through the choke linkage, is connected to the choke plate. As the choke spring heats up, the spring unwinds, which in the end opens the choke plate. By the time the choke is as hot as it's going to get, the choke plate is completely vertical and wide open.

That's a lot of words to describe a simple concept, but that's how it works. So you know that the important thing here is

heat - you have to get the choke hot to get the choke plate to open up. Let's move on to

how it gets hot, because that's where most of the questions are coming from.

Hot-air stove.

If you have a factory Motorcraft 2-barrel carburetor with an automatic choke, then you at least have a hot-air stove running things. This setup is often referred to as a

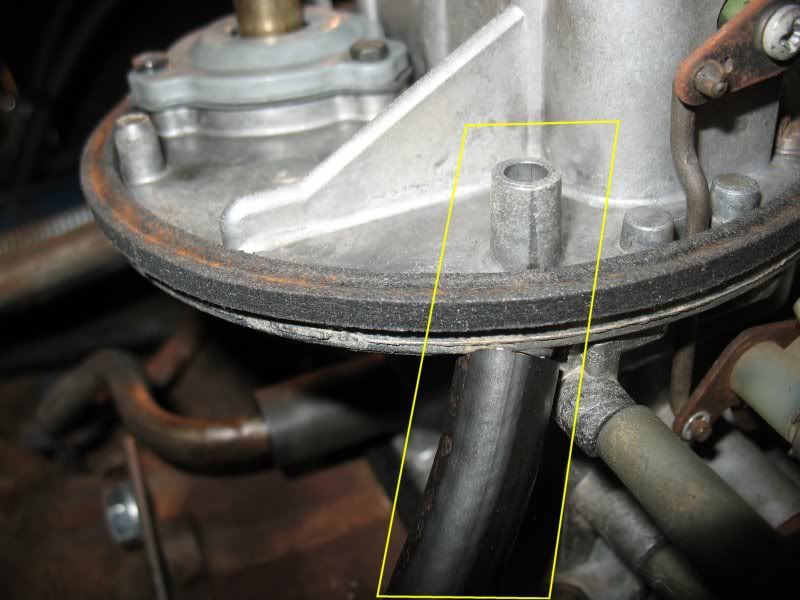

hot-air choke. This literally pulls warm air from an exhaust crossover into the space inside the choke spring to warm it up. I'll start with a general picture, and move on from there.

This picture shows the passenger side of the carburetor. Each component of the system is explained below.

A. Hot air tube

This is a steel line with a flared end that carries warm air to the choke spring. The hot air comes from an exhaust cross-over, often through the intake manifold. It is

not actual exhaust gas, it is air drawn externally that is heated up

by the exhaust. The air that passes through this tube is still very hot, which is why the line is steel and not rubber, like in a vacuum line. The line connects to the choke housing using a flare fitting, as seen in the photo above. The flare nut should only be loosened with a flare wrench, to avoid rounding off the nut. The other end of the line will be explained shortly.

B. Fresh air intake

The air that is heated by the exhaust and passed to the choke has to come from somewhere, and it might as well be clean air. That's what the odd-shaped line going to the back of the top of the carburetor (called the

air horn) is for. The short length of vacuum hose you see here is connected to a small hose fitting on the bottom of the air horn, which is simply routed to the top of the air horn, directly above the fitting. When the air cleaner is installed, this space contains only clean air filtered by the air cleaner. What this all means is that any air drawn through this fresh air line will be clean air. The short length of vacuum hose in this picture runs from this connection, to a metal line. The other end of the line will be explained shortly.

C. Vacuum source (not visible in the overview picture)

Okay, so we've got a way for clean air to come in and hot air to come out, but we need a way to get it all moving. This is done using manifold vacuum and it is done

internally, meaning there is no external line you have to worry about. The vacuum signal is transferred from the throttle bores to the inside of the choke housing through one of the choke housing mounting studs. However, there is still one important piece here and that is the gasket. When you rebuild one of these carburetors and you install the choke housing to the carburetor itself, the rebuild kit comes with a small gasket for this mounting stud. This ensures a good seal for vacuum to pass to the choke housing. I should also mention that the choke cap itself is retained against the choke housing using a gasket as well. Why is this all important? Because inside the choke cap is negative pressure - engine vacuum. This is what actually draws the warm air into the choke housing to heat up the spring. If you remove the choke cap from the engine while it's running (which I do not recommend because it is very hot), the engine will stall because you've created a large vacuum leak.

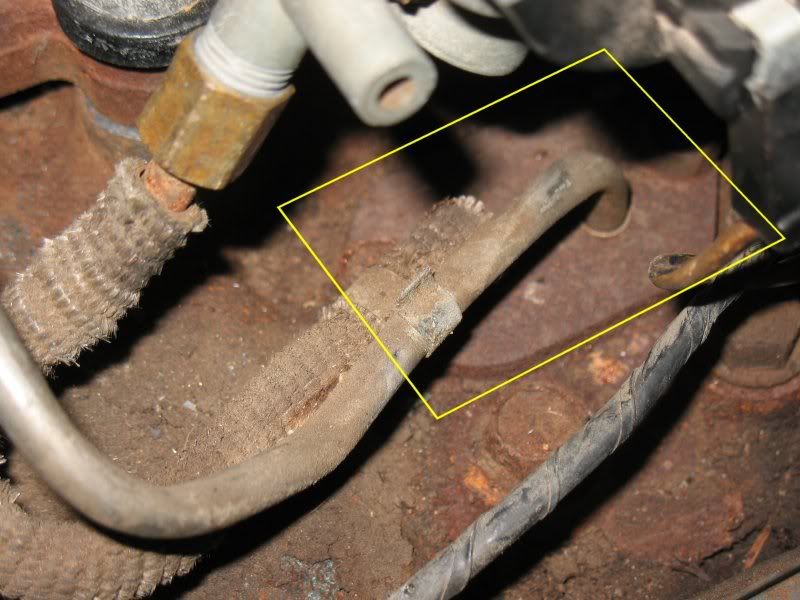

D. Exhaust cross-over

Still with me? So now we're experts on how everything actually connects to the carburetor - but where does everything go from there? I told you how the fresh air tube and the hot air tube connect to the carburetor, but I haven't shown you where they actually come from. Both of these tubes end at a plate which directs them through the exhaust cross-over. Now - where and how this is done can vary widely. The picture I have shown is off a 400 cubic inch engine, but I've seen them in all sorts of places. Unfortunately I can only give you examples. It's up to you to find where yours is, or where it should be. In the picture above, they are connected to the intake manifold on the passenger side, beside the carburetor.

Electric assist.

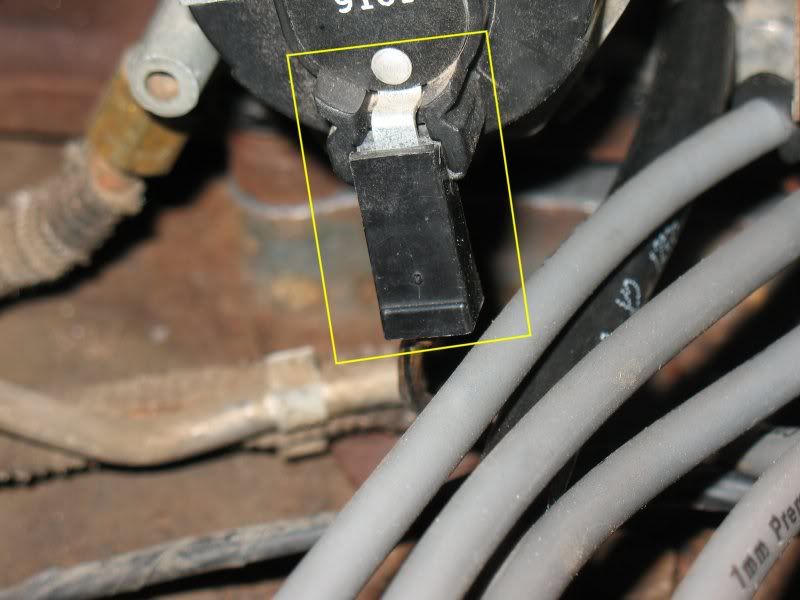

If your choke only has a hot-air stove, then I've told you all you need to know. However, many automatic chokes have an electric assist option which works in conjunction with the hot-air stove. This was introduced originally to help open the choke faster, to reduce emissions caused by the engine running rich. Inside the choke is a resistive element which uses electricity to heat the choke spring. In the photo below is what you're after:

This is the power to the heating element. There are many misconceptions about this power source, so let me clear them up now. In the factory configuration, the wire that powers the choke comes from the neutral point of the

stator of the alternator. The stator is the part of the alternator that sits still (stationary) as opposed to the

rotor which is what actually moves. The voltage seen at the stator is

not a DC signal. It's

not the same thing as pulling power from the battery, or power at the ignition key. The voltage here changes as the rotor moves inside the alternator and is therefore an AC signal. Because of the configuration of the stator, the signal is referred to as a

three-phase signal. That is your fun fact for the day. The reason all this makes a difference is because if you use your voltmeter to look at the choke voltage, you will only see around 7 volts DC. This is because the signal on the stator is actually all over the place, and the

mean seen by the meter is around 7 volts. Why am I telling you this? Because many times, when diagnosing a problem, people will look at the voltage here and see that it's not 12 volts, and think there is a problem. You are

not supposed to see 12 volts. The power from the stator is still more than enough to do the simple job of heating the choke. Why bother with such a hairy signal? Because the stator is only hot when the engine is actually rotating. This is perfect because you only want the choke heating up when the engine is actually running.

That's where the choke's power comes from - how does it ground? You will notice there is

no ground connection for a factory electric assist choke. The choke heating element grounds through the choke spring itself (remember I said it's metal?) The choke spring makes electrical contact where the tang meets the slotted choke lever, which itself is mechanically coupled to the carburetor body. Because the carburetor is bolted to the engine, it too is grounded. Voila, the circuit is complete!

Aftermarket all-electric chokes.

This is probably a good time to mention another class of chokes which are most often seen in aftermarket Holley or Edelbrock carburetors. These are

all-electric and do not use a hot-air stove to heat up. These are not the same as the factory electric assist chokes mentioned earlier. Often these choke caps have two electrical connectors - one for choke power, and one for ground (here, a separate ground wire is necessary). How you power these chokes is up to you, but most often the literature included in the carburetor suggests grabbing power from a 12 volt keyed source. If you do this, make sure the source is fused.

Conclusions.

There you have it folks - everything you wanted to know about how an automatic choke works on a Motorcraft 2 barrel carburetor. Did I put you to sleep yet? Hopefully that clears up what things should look like, and how things are hooked up. I know how frustrating it can be to work on a truck that a previous owner hacked up - it seems like some people just have a natural tendency to rip out vacuum hoses and wires because they feel like it. The number one rule..."if it ain't broke, don't fix it." Ford engineers knew what they were doing, and they wouldn't spend time and money installing equipment on millions and millions of engines if it wasn't necessary. I will leave you with some good advice - if you feel the urge to clean up that engine bay and rip out anything that just "looks like it ain't doing anything" - think about the guy stuck in the cold because he can't get his truck out of the driveway because the choke won't work.

Happy New Year everybody.