[QUOTE=monsterbaby]Murphy a lot of people run plastic cone bottom reactors, here is a link to a coop of biodiesel producers and this is their second reactor setup this way.

http://burlingtonbiodiesel.org/reactor_ii.htm[/QUOTE]

That thing in the photo is a piece of junk.

Me: 20 year industrial process engineer

My advice: Anyone making biodiesel in a plastic tank is probably not making it correctly and is taking a huge fire risk. Think about it.. Common sense.. Hot oil + flammable methanol + caustic chemicals + Plastic = very big molotov cocktail just waiting to happen.

Just because you can do it, doesnt mean its safe...

These people who design these systems don't have a single clue as to what they are doing when it comes to engineering.. Most of these plastic guys say a 140 deg max tank can take a 130 deg reaction.. I'm sure it will.. The speedometer in my car goes to 130MPH but what do you think would happen if I drove 120mph all the time?

The people who use plastic tanks are the same kind of people who ride motorcycles without helmets..

In addition, I have now inspected 3 of these types of processing systems and not a single one of them can pass a simple quality test.. (3/27)

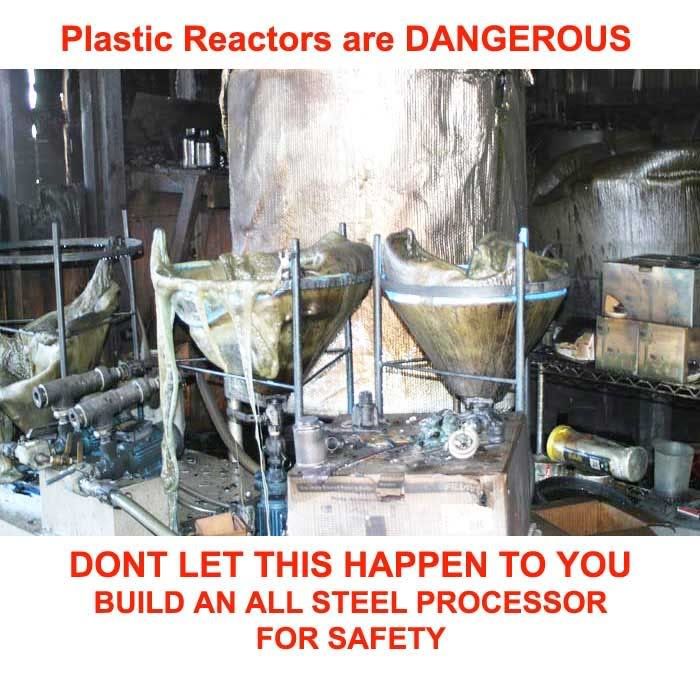

Here is what happens to plastic processors when ANYTHING around them malfunctions: