My latest UOA - 320,000 miles

#46

Well for me I have not experienced any symptoms associated with a worn LOP running my current bypass setup. I would think that excessive wear would show up on a UOA. Secondly, I have a HPOP guage and I have not experienced any drop in ICP while towing our 32' 5th wheel up long grades. She easily holds 3200 psi. So it doesn't look like the last 80,000 miles with the oilguard bypass has hurt my LOP. I guess time will tell.

#47

Gene

I shared your concern about diverting oil from the lube circut through a bypass filter. That's why I did my own flow test into a cup and checked oil pressure before and after the install.

On your C7, a bypass filter is a waste of money. The Fleetguard LF9667 or Donaldson ELF7483 has both full flow and bypass elements already in it. That's why you don't see luberfiners on the side of big rigs any more. Fleetguards website also shows lower engine wear rates when useing bypass filtration. See page 3-18 here. http://www.fleetguard.com/pdfs/produ...LT32599_03.pdf

The company I work for runs extended OCI on it's big rigs of 40k miles with conventional oil. The oldest truck in the fleet (CH Mack) has over 1.5 million miles on it.

I shared your concern about diverting oil from the lube circut through a bypass filter. That's why I did my own flow test into a cup and checked oil pressure before and after the install.

On your C7, a bypass filter is a waste of money. The Fleetguard LF9667 or Donaldson ELF7483 has both full flow and bypass elements already in it. That's why you don't see luberfiners on the side of big rigs any more. Fleetguards website also shows lower engine wear rates when useing bypass filtration. See page 3-18 here. http://www.fleetguard.com/pdfs/produ...LT32599_03.pdf

The company I work for runs extended OCI on it's big rigs of 40k miles with conventional oil. The oldest truck in the fleet (CH Mack) has over 1.5 million miles on it.

#48

#49

From the AMSOIL website...

..."Working in conjunction with the engine’s full-flow oil filter, the AMSOIL Ea By-Pass Filter operates by filtering oil on a “partial-flow” basis. It draws approximately 10 percent of the oil pump’s capacity at any one time."...

From the AMSOIL By-Pass Warranty... THIS WARRANTY DOES NOT APPLY IF THE BY-PASS SYSTEM HAS BEEN USED IN COMPETITIVE RACING OR ON MODIFIED ENGINES!

Of course the AMSOIL "Warranty" is only talking about covering damage to the AMSOIL "By-Pass Filter" ...and even if your engine isn't modified the warranty doesn't cover any damage to your engine that might result from compromised oil flow caused by using their "By-Pass Filter" ...and even if you think your low pressure oil pump’s capacity is sufficient to divert 10% of its flow to a by-pass filter and still provide adequate lubrication to the rest of your engine ...if one of those oil lines shown above springs a serious leak while the engine is under a prolonged maximum load your engine will likely suffer some damage due to compromised oil flow!

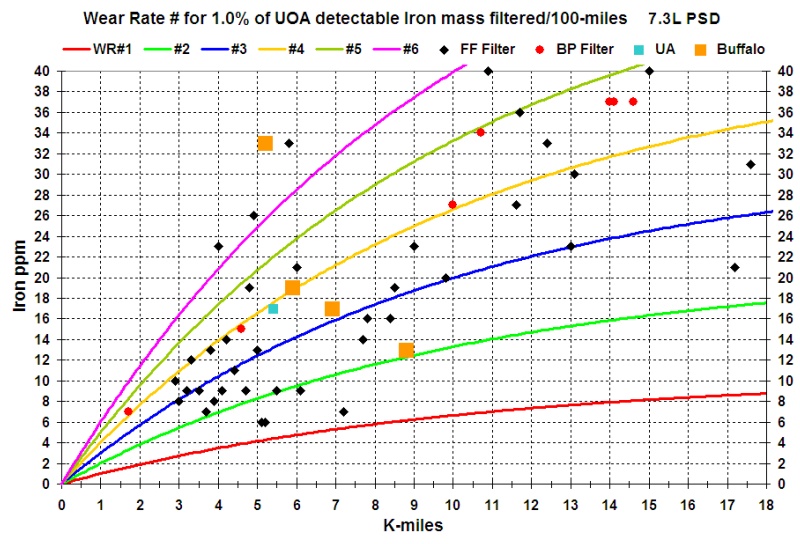

Now seeing as how a by-pass filter draws approximately 10 percent of the low pressure oil pump’s capacity I'm curious to know what percent of the low pressure oil pump’s capacity is being used to supply the HPOP?

The Stealth Pumps website says...

..."The HUEI injection system that the 7.3L Powerstroke utilizes is a brilliant injection system, with one flaw. If you change one of the injection system variables such as an aftermarket computer chip and/or a set of aftermarket injectors the factory HPOP (High Pressure Oil Pump) cannot keep up with the demand."...

...so apparently the HPOP was designed to have little or no margin at all!

From the ITP website...

..."This aftermarket replacement low pressure oil pump from Melling is a direct replacement for the stock pump. This pump is made to meet or exceed factory specifications. Several of our customers have noticed quicker starting, improved drivability and reduced oil aeration (as indicated by foam on the dipstick) after switching to the Melling oil pump."...

...and since the above $80 Melling low pressure oil pump seems to be better than the stock version I doubt the stock LOP has much margin?

Well below is an interesting story regarding the installation of twin HPOPs on a 2001 F350 which is what the Stealth Pump System does to double the HPOP volume flow ...but of course this means the LOP has to divert this extra volume oil flow away from critical engine parts and send it to the second HPOP instead!

2001 F350 7.3l PSD Delo 400 15w40 3,324 miles - Bob Is The Oil Guy

..."During this OCI I installed a new intercooler and new high pressure oil pumps. I believe I'm having a lube oil pressure issue at high RPM and high load. I think when the engine is running 2700 RPM or more the HPOP is starving the engine for oil, however I have not had a chance to prove that theory yet."...

..."Yes, the HPOP feeds the injectors on the truck just like internationals T444E, DT466E, DT530E and CATs, 3126, C7, etc. The truck has a lube oil pump that lubes the engine and supplies oil to the HPOP."...

..."Before the HPOP upgrade I ran the truck harder, 2800-3400RPM all the time and had much lower lead. This is definitely a lack of oil issue."...

..."Well, I installed the aftermarket oil pressure gauge at the same time as the twin HPOPs, so I don't know what the lube oil pressure did before this. I can only assume that the problem was not present before since the lead in the UOAs was low."...

..."I have significantly turned up the fuel rate on the engine. Not only peak fuel rate but it fuels a lot more lower in the RPM range to help get power sooner which helps with the loads I put on the truck. After I try a few things to fix my lube oil problem I'm going to take another sample and see what the lead does."...

..."Well, after running around with a bunch of temporary oil pressure gauges tapped into every port I could get at I can't get it to have a pressure issue. It still has a problem I think, but I never saw less than 20PSI anywhere. That may have to due with the viscosity increase from changed the oil. It may also be due to the fact that during the test I wasn't towing anything, so the oil temp never got very warm."...

..."BlackStone Comments: You mentioned that while this oil was in use your F350 was "heavily loaded." This most likely explains the increase in lead we found. Lead comes from the bearings and you can see the hard work put extra stress on the lower end of your 7.3L. It's a good idea to use short oil runs when you're working your engine extra hard, as the excess wear metals are abrasive."...

Well at least Blackstone got it right this time around ..."It's a good idea to use short oil runs when you're working your engine extra hard, as the excess wear metals are abrasive."... and they didn't advise this customer to extend his OCIs ...and no I can't find any more information ...if there was any it must've been posted on a new thread!

..."Working in conjunction with the engine’s full-flow oil filter, the AMSOIL Ea By-Pass Filter operates by filtering oil on a “partial-flow” basis. It draws approximately 10 percent of the oil pump’s capacity at any one time."...

From the AMSOIL By-Pass Warranty... THIS WARRANTY DOES NOT APPLY IF THE BY-PASS SYSTEM HAS BEEN USED IN COMPETITIVE RACING OR ON MODIFIED ENGINES!

Of course the AMSOIL "Warranty" is only talking about covering damage to the AMSOIL "By-Pass Filter" ...and even if your engine isn't modified the warranty doesn't cover any damage to your engine that might result from compromised oil flow caused by using their "By-Pass Filter" ...and even if you think your low pressure oil pump’s capacity is sufficient to divert 10% of its flow to a by-pass filter and still provide adequate lubrication to the rest of your engine ...if one of those oil lines shown above springs a serious leak while the engine is under a prolonged maximum load your engine will likely suffer some damage due to compromised oil flow!

Now seeing as how a by-pass filter draws approximately 10 percent of the low pressure oil pump’s capacity I'm curious to know what percent of the low pressure oil pump’s capacity is being used to supply the HPOP?

The Stealth Pumps website says...

..."The HUEI injection system that the 7.3L Powerstroke utilizes is a brilliant injection system, with one flaw. If you change one of the injection system variables such as an aftermarket computer chip and/or a set of aftermarket injectors the factory HPOP (High Pressure Oil Pump) cannot keep up with the demand."...

...so apparently the HPOP was designed to have little or no margin at all!

From the ITP website...

..."This aftermarket replacement low pressure oil pump from Melling is a direct replacement for the stock pump. This pump is made to meet or exceed factory specifications. Several of our customers have noticed quicker starting, improved drivability and reduced oil aeration (as indicated by foam on the dipstick) after switching to the Melling oil pump."...

...and since the above $80 Melling low pressure oil pump seems to be better than the stock version I doubt the stock LOP has much margin?

Well below is an interesting story regarding the installation of twin HPOPs on a 2001 F350 which is what the Stealth Pump System does to double the HPOP volume flow ...but of course this means the LOP has to divert this extra volume oil flow away from critical engine parts and send it to the second HPOP instead!

2001 F350 7.3l PSD Delo 400 15w40 3,324 miles - Bob Is The Oil Guy

..."During this OCI I installed a new intercooler and new high pressure oil pumps. I believe I'm having a lube oil pressure issue at high RPM and high load. I think when the engine is running 2700 RPM or more the HPOP is starving the engine for oil, however I have not had a chance to prove that theory yet."...

..."Yes, the HPOP feeds the injectors on the truck just like internationals T444E, DT466E, DT530E and CATs, 3126, C7, etc. The truck has a lube oil pump that lubes the engine and supplies oil to the HPOP."...

..."Before the HPOP upgrade I ran the truck harder, 2800-3400RPM all the time and had much lower lead. This is definitely a lack of oil issue."...

..."Well, I installed the aftermarket oil pressure gauge at the same time as the twin HPOPs, so I don't know what the lube oil pressure did before this. I can only assume that the problem was not present before since the lead in the UOAs was low."...

..."I have significantly turned up the fuel rate on the engine. Not only peak fuel rate but it fuels a lot more lower in the RPM range to help get power sooner which helps with the loads I put on the truck. After I try a few things to fix my lube oil problem I'm going to take another sample and see what the lead does."...

..."Well, after running around with a bunch of temporary oil pressure gauges tapped into every port I could get at I can't get it to have a pressure issue. It still has a problem I think, but I never saw less than 20PSI anywhere. That may have to due with the viscosity increase from changed the oil. It may also be due to the fact that during the test I wasn't towing anything, so the oil temp never got very warm."...

..."BlackStone Comments: You mentioned that while this oil was in use your F350 was "heavily loaded." This most likely explains the increase in lead we found. Lead comes from the bearings and you can see the hard work put extra stress on the lower end of your 7.3L. It's a good idea to use short oil runs when you're working your engine extra hard, as the excess wear metals are abrasive."...

Well at least Blackstone got it right this time around ..."It's a good idea to use short oil runs when you're working your engine extra hard, as the excess wear metals are abrasive."... and they didn't advise this customer to extend his OCIs ...and no I can't find any more information ...if there was any it must've been posted on a new thread!

#50

Well if you think 833K-miles sounds like an "unrealistic goal" then look at the "comments section" of the UOA report in post #1 on this thread which says...

..."Another thing your Ford has going for it is this particular type of Navistar diesel. It's one of the best wearing ones they have ever designed. No wonder it still looks like a pup at 320,000 miles. We have tested some that look this good at ~750K-miles. We think yours will likely be one of them in the future."...

Please note that the "comments section" in this UOA report also says...

..."Your consistent oil change intervals in the 5,000 to 5,200-mile range have also played a role in the excellent test results your diesel is receiving."...

So Blackstone tells one customer that 5K-mile OCIs are responsible for their low wear-rate and that 5K-mile OCIs "will likely" result in their engine lasting for 750K-miles ...but Blackstone also tells this customer... http://ernesteugene.com/FTE6/UOA_BS3.jpg ...that even though their engine is already wearing at a the "maximum" WR#6 rate with a 5.8K-mile OCI to...

..."Try ~7,500 miles next time and check back for another look at wear."...

...so anyone who thinks it's appropriate to "blindly follow" the advice given by Blackstone please raise your hand!

..."Another thing your Ford has going for it is this particular type of Navistar diesel. It's one of the best wearing ones they have ever designed. No wonder it still looks like a pup at 320,000 miles. We have tested some that look this good at ~750K-miles. We think yours will likely be one of them in the future."...

Please note that the "comments section" in this UOA report also says...

..."Your consistent oil change intervals in the 5,000 to 5,200-mile range have also played a role in the excellent test results your diesel is receiving."...

So Blackstone tells one customer that 5K-mile OCIs are responsible for their low wear-rate and that 5K-mile OCIs "will likely" result in their engine lasting for 750K-miles ...but Blackstone also tells this customer... http://ernesteugene.com/FTE6/UOA_BS3.jpg ...that even though their engine is already wearing at a the "maximum" WR#6 rate with a 5.8K-mile OCI to...

..."Try ~7,500 miles next time and check back for another look at wear."...

...so anyone who thinks it's appropriate to "blindly follow" the advice given by Blackstone please raise your hand!

#51

From the AMSOIL website...

..."Working in conjunction with the engine’s full-flow oil filter, the AMSOIL Ea By-Pass Filter operates by filtering oil on a “partial-flow” basis. It draws approximately 10 percent of the oil pump’s capacity at any one time."...

From the AMSOIL By-Pass Warranty... THIS WARRANTY DOES NOT APPLY IF THE BY-PASS SYSTEM HAS BEEN USED IN COMPETITIVE RACING OR ON MODIFIED ENGINES!

Of course the AMSOIL "Warranty" is only talking about covering damage to the AMSOIL "By-Pass Filter" ...and even if your engine isn't modified the warranty doesn't cover any damage to your engine that might result from compromised oil flow caused by using their "By-Pass Filter" ...and even if you think your low pressure oil pump’s capacity is sufficient to divert 10% of its flow to a by-pass filter and still provide adequate lubrication to the rest of your engine ...if one of those oil lines shown above springs a serious leak while the engine is under a prolonged maximum load your engine will likely suffer some damage due to compromised oil flow!

Now seeing as how a by-pass filter draws approximately 10 percent of the low pressure oil pump’s capacity I'm curious to know what percent of the low pressure oil pump’s capacity is being used to supply the HPOP?

The Stealth Pumps website says...

..."The HUEI injection system that the 7.3L Powerstroke utilizes is a brilliant injection system, with one flaw. If you change one of the injection system variables such as an aftermarket computer chip and/or a set of aftermarket injectors the factory HPOP (High Pressure Oil Pump) cannot keep up with the demand."...

...so apparently the HPOP was designed to have little or no margin at all!

From the ITP website...

..."This aftermarket replacement low pressure oil pump from Melling is a direct replacement for the stock pump. This pump is made to meet or exceed factory specifications. Several of our customers have noticed quicker starting, improved drivability and reduced oil aeration (as indicated by foam on the dipstick) after switching to the Melling oil pump."...

...and since the above $80 Melling low pressure oil pump seems to be better than the stock version I doubt the stock LOP has much margin?

Well below is an interesting story regarding the installation of twin HPOPs on a 2001 F350 which is what the Stealth Pump System does to double the HPOP volume flow ...but of course this means the LOP has to divert this extra volume oil flow away from critical engine parts and send it to the second HPOP instead!

2001 F350 7.3l PSD Delo 400 15w40 3,324 miles - Bob Is The Oil Guy

..."During this OCI I installed a new intercooler and new high pressure oil pumps. I believe I'm having a lube oil pressure issue at high RPM and high load. I think when the engine is running 2700 RPM or more the HPOP is starving the engine for oil, however I have not had a chance to prove that theory yet."...

..."Yes, the HPOP feeds the injectors on the truck just like internationals T444E, DT466E, DT530E and CATs, 3126, C7, etc. The truck has a lube oil pump that lubes the engine and supplies oil to the HPOP."...

..."Before the HPOP upgrade I ran the truck harder, 2800-3400RPM all the time and had much lower lead. This is definitely a lack of oil issue."...

..."Well, I installed the aftermarket oil pressure gauge at the same time as the twin HPOPs, so I don't know what the lube oil pressure did before this. I can only assume that the problem was not present before since the lead in the UOAs was low."...

..."I have significantly turned up the fuel rate on the engine. Not only peak fuel rate but it fuels a lot more lower in the RPM range to help get power sooner which helps with the loads I put on the truck. After I try a few things to fix my lube oil problem I'm going to take another sample and see what the lead does."...

..."Well, after running around with a bunch of temporary oil pressure gauges tapped into every port I could get at I can't get it to have a pressure issue. It still has a problem I think, but I never saw less than 20PSI anywhere. That may have to due with the viscosity increase from changed the oil. It may also be due to the fact that during the test I wasn't towing anything, so the oil temp never got very warm."...

..."BlackStone Comments: You mentioned that while this oil was in use your F350 was "heavily loaded." This most likely explains the increase in lead we found. Lead comes from the bearings and you can see the hard work put extra stress on the lower end of your 7.3L. It's a good idea to use short oil runs when you're working your engine extra hard, as the excess wear metals are abrasive."...

Well at least Blackstone got it right this time around ..."It's a good idea to use short oil runs when you're working your engine extra hard, as the excess wear metals are abrasive."... and they didn't advise this customer to extend his OCIs ...and no I can't find any more information ...if there was any it must've been posted on a new thread!

..."Working in conjunction with the engine’s full-flow oil filter, the AMSOIL Ea By-Pass Filter operates by filtering oil on a “partial-flow” basis. It draws approximately 10 percent of the oil pump’s capacity at any one time."...

From the AMSOIL By-Pass Warranty... THIS WARRANTY DOES NOT APPLY IF THE BY-PASS SYSTEM HAS BEEN USED IN COMPETITIVE RACING OR ON MODIFIED ENGINES!

Of course the AMSOIL "Warranty" is only talking about covering damage to the AMSOIL "By-Pass Filter" ...and even if your engine isn't modified the warranty doesn't cover any damage to your engine that might result from compromised oil flow caused by using their "By-Pass Filter" ...and even if you think your low pressure oil pump’s capacity is sufficient to divert 10% of its flow to a by-pass filter and still provide adequate lubrication to the rest of your engine ...if one of those oil lines shown above springs a serious leak while the engine is under a prolonged maximum load your engine will likely suffer some damage due to compromised oil flow!

Now seeing as how a by-pass filter draws approximately 10 percent of the low pressure oil pump’s capacity I'm curious to know what percent of the low pressure oil pump’s capacity is being used to supply the HPOP?

The Stealth Pumps website says...

..."The HUEI injection system that the 7.3L Powerstroke utilizes is a brilliant injection system, with one flaw. If you change one of the injection system variables such as an aftermarket computer chip and/or a set of aftermarket injectors the factory HPOP (High Pressure Oil Pump) cannot keep up with the demand."...

...so apparently the HPOP was designed to have little or no margin at all!

From the ITP website...

..."This aftermarket replacement low pressure oil pump from Melling is a direct replacement for the stock pump. This pump is made to meet or exceed factory specifications. Several of our customers have noticed quicker starting, improved drivability and reduced oil aeration (as indicated by foam on the dipstick) after switching to the Melling oil pump."...

...and since the above $80 Melling low pressure oil pump seems to be better than the stock version I doubt the stock LOP has much margin?

Well below is an interesting story regarding the installation of twin HPOPs on a 2001 F350 which is what the Stealth Pump System does to double the HPOP volume flow ...but of course this means the LOP has to divert this extra volume oil flow away from critical engine parts and send it to the second HPOP instead!

2001 F350 7.3l PSD Delo 400 15w40 3,324 miles - Bob Is The Oil Guy

..."During this OCI I installed a new intercooler and new high pressure oil pumps. I believe I'm having a lube oil pressure issue at high RPM and high load. I think when the engine is running 2700 RPM or more the HPOP is starving the engine for oil, however I have not had a chance to prove that theory yet."...

..."Yes, the HPOP feeds the injectors on the truck just like internationals T444E, DT466E, DT530E and CATs, 3126, C7, etc. The truck has a lube oil pump that lubes the engine and supplies oil to the HPOP."...

..."Before the HPOP upgrade I ran the truck harder, 2800-3400RPM all the time and had much lower lead. This is definitely a lack of oil issue."...

..."Well, I installed the aftermarket oil pressure gauge at the same time as the twin HPOPs, so I don't know what the lube oil pressure did before this. I can only assume that the problem was not present before since the lead in the UOAs was low."...

..."I have significantly turned up the fuel rate on the engine. Not only peak fuel rate but it fuels a lot more lower in the RPM range to help get power sooner which helps with the loads I put on the truck. After I try a few things to fix my lube oil problem I'm going to take another sample and see what the lead does."...

..."Well, after running around with a bunch of temporary oil pressure gauges tapped into every port I could get at I can't get it to have a pressure issue. It still has a problem I think, but I never saw less than 20PSI anywhere. That may have to due with the viscosity increase from changed the oil. It may also be due to the fact that during the test I wasn't towing anything, so the oil temp never got very warm."...

..."BlackStone Comments: You mentioned that while this oil was in use your F350 was "heavily loaded." This most likely explains the increase in lead we found. Lead comes from the bearings and you can see the hard work put extra stress on the lower end of your 7.3L. It's a good idea to use short oil runs when you're working your engine extra hard, as the excess wear metals are abrasive."...

Well at least Blackstone got it right this time around ..."It's a good idea to use short oil runs when you're working your engine extra hard, as the excess wear metals are abrasive."... and they didn't advise this customer to extend his OCIs ...and no I can't find any more information ...if there was any it must've been posted on a new thread!

As for the warranty, just how many parts can you find that are covered in competition.

Your example's problems with lead are almost another subject entirely. A Cummins engine has 7 main bearings. Our engines have five, so it's not hard to see how the oil film can be penitrated on a modified engine during a hard pull. That would explain the lead in your example. I believe it is also the source of oil sheer in the powerstroke engines.

#52

Also need to keep in mind that folks running hybrids and single shot injectors actually have a lower demand of oil from the HPOP since they require much less oil than the stock split shot injectors.

In addition, those that experience foaming are ussually running much higher HP levels.

I think most agree that the higher the HP modified 7.3L the more frequent the oil change.

But to say all bypass systems will destroy your engine because the take oil flow away, bypass 10 percent of the oil, cause the low press oil pump to wear excessively, cause foaming and increased lead wear is wrong.

In addition, those that experience foaming are ussually running much higher HP levels.

I think most agree that the higher the HP modified 7.3L the more frequent the oil change.

But to say all bypass systems will destroy your engine because the take oil flow away, bypass 10 percent of the oil, cause the low press oil pump to wear excessively, cause foaming and increased lead wear is wrong.

#53

...Well if you carefully read the thread I gave the link to... My "Numbered" Wear-Rate Scale for 7.3L PSDs... and you're still confused about what constitutes "increased engine wear" then just quote back the parts of that thread you find confusing and I'll address them in more detail.

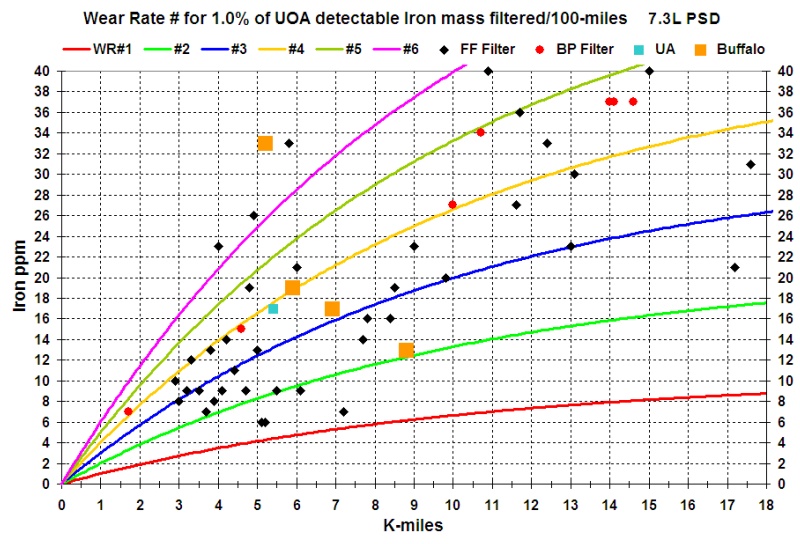

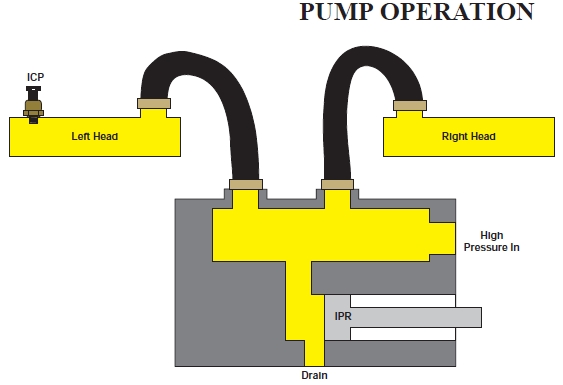

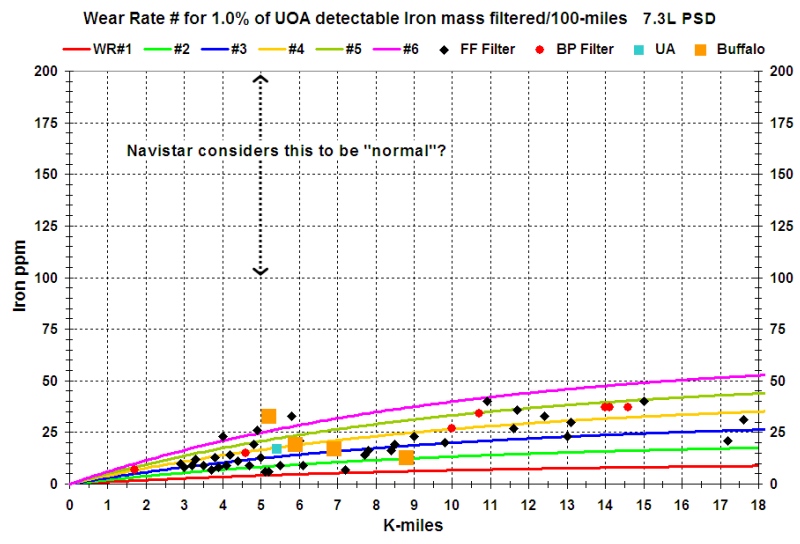

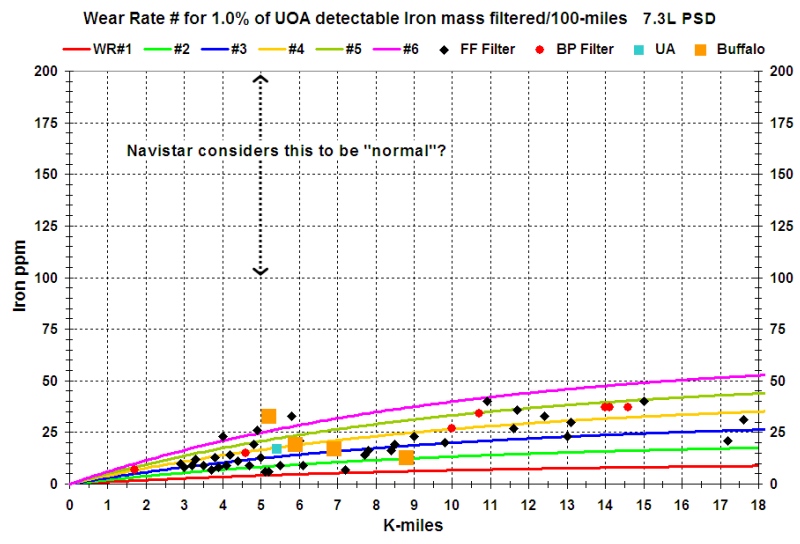

These are the 4 data points from your post #6 above... 5.2K-miles 33 ppm Iron, 5.9K-miles 19 ppm Iron, 6.9K-miles 17 ppm Iron, 8.8K-miles 13 ppm Iron ...and below I plotted them on one of my "wear-rate#" graphs.

Your data point... 19 ppm Iron at 5.9K-miles ...falls on the WR#4 curve as does the Blackstone "Universal Average" ...but I don't consider being "average" the same as being "good" or "desirable"! For example blood testing labs compare my cholesterol reading with a "universal average" for men in my age group ...and being "average" means I've got a 50% probability of having a heart attack which most definitely isn't a "good" or "desirable" situation to contemplate!...

These are the 4 data points from your post #6 above... 5.2K-miles 33 ppm Iron, 5.9K-miles 19 ppm Iron, 6.9K-miles 17 ppm Iron, 8.8K-miles 13 ppm Iron ...and below I plotted them on one of my "wear-rate#" graphs.

Your data point... 19 ppm Iron at 5.9K-miles ...falls on the WR#4 curve as does the Blackstone "Universal Average" ...but I don't consider being "average" the same as being "good" or "desirable"! For example blood testing labs compare my cholesterol reading with a "universal average" for men in my age group ...and being "average" means I've got a 50% probability of having a heart attack which most definitely isn't a "good" or "desirable" situation to contemplate!...

...The HPOP is a fixed displacement pump. In every flow chart I have seen, it's out put either goes to the injectors where is is used and dumped back to sump or to the IPR where it is dumped back to sump. All of it's flow goes back to sump all the time. Chips, engine load ect. have no effect on the HPOP's demand for oil. For every revolution it pumps a given number of ccs of oil...

...Well for that matter the LOP is also a fixed displacement pump ...but what does that have to do with the issue at hand? My actual statement was...

...Now here's some more of the story which I think supports my concern about towing up a long grade on a hot day while diverting 10% or more of the LOP flow to feed a by-pass filter because when the engine is under a maximum load all of the LOP flow is needed to supply the HPOP and to lubricate critical engine parts and to cool the pistons! As you can read below just after the by-pass filter was installed the engine was worked hard and the Iron ppm increased dramatically!!!

...and for some reason you intentionally cut-off the part of my statement about ..."and to lubricate critical engine parts and to cool the pistons!" ...which is a separate and much more "lubrication critical" function of the LOP than just supplying oil to the HPOP ...because if the LOP flow isn't sufficient to supply the HPOP the only downside is a loss of power due to lower injection pressure ...but if the if the LOP flow isn't sufficient for lubricating the critical engine parts and for cooling the pistons the engine will be destroyed!!!...

...Now here's some more of the story which I think supports my concern about towing up a long grade on a hot day while diverting 10% or more of the LOP flow to feed a by-pass filter because when the engine is under a maximum load all of the LOP flow is needed to supply the HPOP and to lubricate critical engine parts and to cool the pistons! As you can read below just after the by-pass filter was installed the engine was worked hard and the Iron ppm increased dramatically!!!

...and for some reason you intentionally cut-off the part of my statement about ..."and to lubricate critical engine parts and to cool the pistons!" ...which is a separate and much more "lubrication critical" function of the LOP than just supplying oil to the HPOP ...because if the LOP flow isn't sufficient to supply the HPOP the only downside is a loss of power due to lower injection pressure ...but if the if the LOP flow isn't sufficient for lubricating the critical engine parts and for cooling the pistons the engine will be destroyed!!!...

What I actually said was...

Well since you're obviously the one who could better benefit by finding and quoting back what I "actually said" on these topics I'll leave that task for you to do ...and good luck finding my quote about... "cause foaming"!!!

#54

we went through this before on a previous thread. The 33 ppm iron at 5.6K was after running the truck at the track and also on the dyno. If you remember the 13 ppm at 8.8K miles was after towing our 5th wheel about 5,000 miles to the Smokies and the Black hills. Which after plotted was on a much lower wear curve and less than half of the value of Blackstones universal average for iron,

I don't agree with how you are comparing UOA's from 7.3L's with totally different setups. You should not compare UOA between a 7.3L with dual HPOP's and a stock setup or a C7. You are comparing apples to oranges. Any UOA lab will tell you not to compare vehicles with different modifications or those used under different service conditions.

Plus 100 ppm iron at 5K miles is considered normal and navistar considers 200 ppm normal in the 7.3L used in a pick-up application. So there is nothing excessive in the wear numbers posted.

I don't agree with how you are comparing UOA's from 7.3L's with totally different setups. You should not compare UOA between a 7.3L with dual HPOP's and a stock setup or a C7. You are comparing apples to oranges. Any UOA lab will tell you not to compare vehicles with different modifications or those used under different service conditions.

Plus 100 ppm iron at 5K miles is considered normal and navistar considers 200 ppm normal in the 7.3L used in a pick-up application. So there is nothing excessive in the wear numbers posted.

#55

I'm going to go get an oil pressure gauge and test oil pressure with the engine full warmed after a highway run. Then install my bypass system and test the pressure again after the same highway run. Stay tuned, it may take me a while to get done it' not yet due for and oil change and I want to be sure both tests are with the same oil. I want to be as scientificaly accurate as a shade tree wrench can get.

#56

..."Working in conjunction with the engine’s full-flow oil filter, the AMSOIL Ea By-Pass Filter operates by filtering oil on a “partial-flow” basis. It draws approximately 10 percent of the oil pump’s capacity at any one time."...

..."At normal operating RPMs the EaBP Filter will filter all of the oil in a typical five quart sump in less than 10 minutes."...

...and this works out to be a "minimum" flow rate of (5/4)/(10)=0.125 gpm ...and presumably the above 2 statements combined mean that 10% of the flow rate from some "unspecified" type of LOP at some "unspecified" RPM equals 0.125 gpm!

Well based on a "five quart sump" Amsoil clearly isn't talking about a diesel engine when they quote a 0.125 gpm flow rate through their Ea By-Pass Filter ...and I take their 0.125 gpm example to mean that a bypassed flow rate of 0.125 gpm represents 10% of the flow rate from a lube pump on some gasser engine at some unspecified RPM ...and a 7.3L PSD LOP needs to have a higher flow rate than for a gasser to feed the piston cooling jets, the larger rod and main bearings, the turbo, HPOP, etc...

Well the Gulf Coast Filter's website which is probably a better reference for diesel engines says...

..."Gulf Coast Filter’s Model O-1 Bypass Oil Filter cleans the bypassed oil at a rate of only one-half gallon of oil per minute."...

...and this 0.5 gpm flow rate which is 4 times higher than the 0.125 gpm bypassed flow rate that Amsoil gave in their gasser example is probably a better gpm estimate for a diesel ...and is still consistent with the Amsoil 10% number !

But my real bottom-line concern with by-pass filters isn't the "exact gpm" of oil flow that's being by-passed but rather the fact that by-pass filters are installed with the expressed intent of running extended OCIs ...and as I posted in response to this OP's question below on another thread ...all of the 7.3L PSD UOA data I've found to date indicates that running extended OCIs isn't conducive with maximizing engine life ...and if there's even the slightest risk for causing even more engine wear than just from the extended OCI itself due to compromised LOP flow that's just an additional reason not to install a by-pass filter!

...Almost everyone seems to think that they can "safely" run extended OCIs by using "synthetic oils" and/or "by-pass filters" however many 7.3L PSD owners who've tried this experienced poor UOAs and increased engine wear!... Below are just a few ..."quotes"... from the BITOG site...

..."Blackstone advised dumping the oil. I just changed the oil, went back to 15/40 Rotella T and OEM full flow filters. I did this as I will make 2 quick changes of oil and filter and with a 3rd fresh oil and filter change sample after 3,000 miles. I went back to factory system as changing Amsoil full flow and bypass 3 times is too expensive"...

High Iron, copper, lead 7.3 Amsoil Syn - Bob Is The Oil Guy

..."Pretty pleased with this sample. I removed my oilguard bypass and just ran a Fleetguard Stratapore ...the 15W40 dino performed just as well as the 5W40 Delo Syn I used to run for 1/2 the cost"...

1999 7.3L Ford Powerstroke - Delo 400 15W40 6281km - Bob Is The Oil Guy

..."Well Terry and I are concerned about the high FE trend that has developed. So the amsoil is going to come out and I am going to run a 5,000 interval of DELO 400 and resample"...

Amsoil 15W40 F350 02- 10,767 miles - Bob Is The Oil Guy

..."After almost 60 UOA's comparing/contrasting data logged for UOAs and bypass systems, I can tell you that there is precious little difference in actual performance when looking at UOA results."...

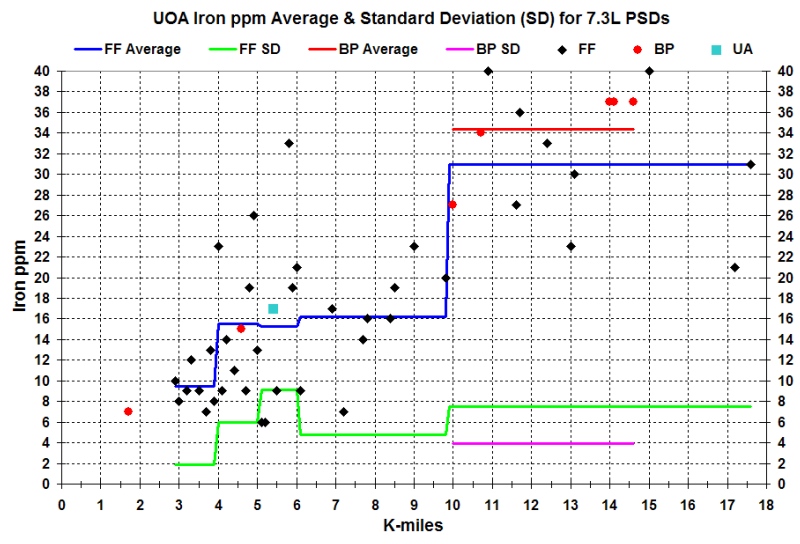

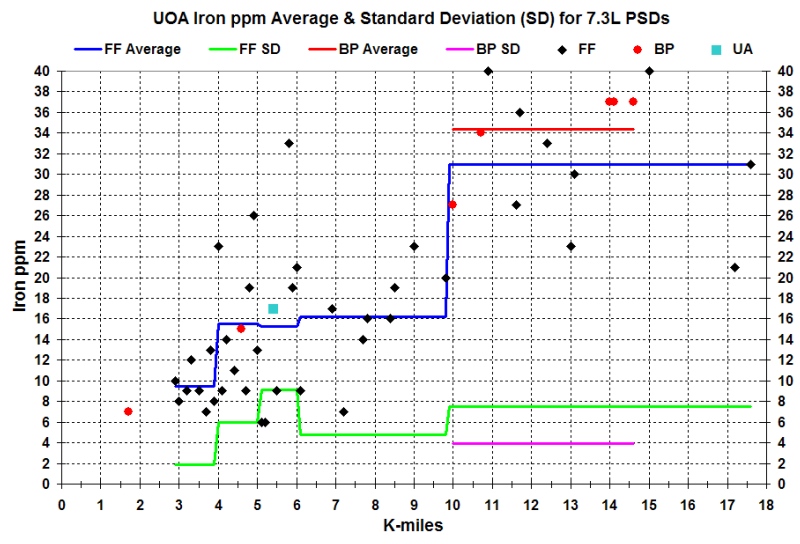

My own analysis of many 7.3L PSD UOA reports which is summarized below also indicates there's no "statistically significant" difference in UOA "Iron ppm" readings (which are the best indicator of "normal" engine wear) between a full-flow filter only and a full-flow filter combined with a by-pass filter ...and if anything the engine's with by-pass filters indicate a little more wear than the ones with full-flow filters!

..."Blackstone advised dumping the oil. I just changed the oil, went back to 15/40 Rotella T and OEM full flow filters. I did this as I will make 2 quick changes of oil and filter and with a 3rd fresh oil and filter change sample after 3,000 miles. I went back to factory system as changing Amsoil full flow and bypass 3 times is too expensive"...

High Iron, copper, lead 7.3 Amsoil Syn - Bob Is The Oil Guy

..."Pretty pleased with this sample. I removed my oilguard bypass and just ran a Fleetguard Stratapore ...the 15W40 dino performed just as well as the 5W40 Delo Syn I used to run for 1/2 the cost"...

1999 7.3L Ford Powerstroke - Delo 400 15W40 6281km - Bob Is The Oil Guy

..."Well Terry and I are concerned about the high FE trend that has developed. So the amsoil is going to come out and I am going to run a 5,000 interval of DELO 400 and resample"...

Amsoil 15W40 F350 02- 10,767 miles - Bob Is The Oil Guy

..."After almost 60 UOA's comparing/contrasting data logged for UOAs and bypass systems, I can tell you that there is precious little difference in actual performance when looking at UOA results."...

My own analysis of many 7.3L PSD UOA reports which is summarized below also indicates there's no "statistically significant" difference in UOA "Iron ppm" readings (which are the best indicator of "normal" engine wear) between a full-flow filter only and a full-flow filter combined with a by-pass filter ...and if anything the engine's with by-pass filters indicate a little more wear than the ones with full-flow filters!

#57

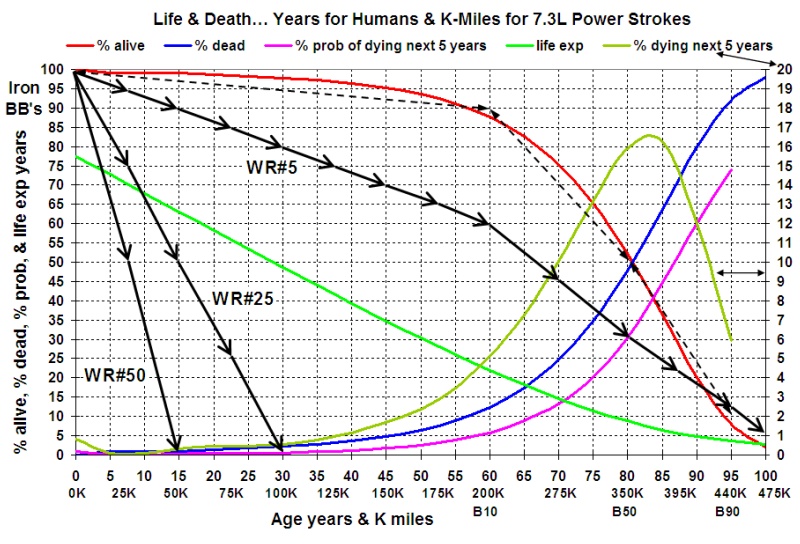

Well here's what your above claim looks like on a graph of engine life expectancy...

...and if you think having a 7.3L PSD engine wear-out in 50K-miles to 100K-miles is "normal" then I don't want to hear your definition of "abnormal" engine wear!!!

The last time you posted this same claim...

...I'd sure like to see a reference to support this claim because I think the typical Penn & Teller comments apply here ...and I'll give some calculations, pictures, and graphs to support this contention!...

...To perhaps put this in better perspective consider the graph below which compares the "Navistar claim" to "my claim"!...

...To perhaps put this in better perspective consider the graph below which compares the "Navistar claim" to "my claim"!...

...The definition of "normal" is "usual" or "typical" and "engine wear" due to the "usual" or "typical" rubbing and sliding of its parts is called "normal wear" ...as opposed to "abnormal wear" which occurs in "unusual" or "atypical" situations like dusting, overheating, contaminated oil, or a sticking piston ring like is depicted here ...http://ernesteugene.com/FTE6/OCI_Ring.jpg... Most of the "normal wear" in a 7.3L PSD engine occurs in its "iron cylinders" and "steel parts" ...and since "steel" is just "iron" with some impurities removed and trace amounts of alloying elements added to improve hardness and strength ...the "rate" of normal wear in a 7.3L PSD engine can be defined by the "rate" at which "Iron mass" is worn away from its iron and steel parts...

...I don't agree with how you are comparing UOA's from 7.3L's with totally different setups. You should not compare UOA between a 7.3L with dual HPOP's and a stock setup or a C7. You are comparing apples to oranges. Any UOA lab will tell you not to compare vehicles with different modifications or those used under different service conditions...

...After reviewing about 60 UOA reports on 7.3L PSDs and eliminating the one's with "abnormal" issues like coolant leaks etc... I was left with a database containing 48 entries of "Iron ppm" versus "K-miles" traveled when the oil was sampled ...and my statistical analysis indicates this database contains a fairly representative sampling of "normal" engine wear. Some of the database entries are from trucks towing with a chip whereas others are from stock trucks running empty ...and that's one reason why there's a spread in the "Iron ppm" data points for a given "K-miles" traveled...

...I did some routine statistical analyses to see if the 48 entries constitute a "representative" sampling of wear rates for 7.3L PSDs ...and here are the tabulated results ...http://ernesteugene.com/FTE6/Statistics1.jpg... ...http://ernesteugene.com/FTE6/Statistics2.jpg... and here's the same data in graphical form ...http://ernesteugene.com/FTE6/PSD_DBS.jpg... and as you can see the "Calculated Average" of 15.6 ppm Iron over the 4.0 to 6.0 K-mile interval agrees fairly well with the Blackstone "Universal Average" of 17 ppm Iron at 5.4K-miles...

...Over a given K-mile interval the "SD=Standard Deviation" gives the "likely" spread of Iron ppm values about the "Average" Iron ppm value ...and for a "normal distribution" about 68% of the values are between +/- 1 SD, about 95% of the values are between +/- 2 SD, and about 99.7% of the values are between +/- 3 SD...

...I did some routine statistical analyses to see if the 48 entries constitute a "representative" sampling of wear rates for 7.3L PSDs ...and here are the tabulated results ...http://ernesteugene.com/FTE6/Statistics1.jpg... ...http://ernesteugene.com/FTE6/Statistics2.jpg... and here's the same data in graphical form ...http://ernesteugene.com/FTE6/PSD_DBS.jpg... and as you can see the "Calculated Average" of 15.6 ppm Iron over the 4.0 to 6.0 K-mile interval agrees fairly well with the Blackstone "Universal Average" of 17 ppm Iron at 5.4K-miles...

...Over a given K-mile interval the "SD=Standard Deviation" gives the "likely" spread of Iron ppm values about the "Average" Iron ppm value ...and for a "normal distribution" about 68% of the values are between +/- 1 SD, about 95% of the values are between +/- 2 SD, and about 99.7% of the values are between +/- 3 SD...

...your WR#8+ wear-rate is the highest I've found after looking through 50+ pages on BITOG and on FTE ...and if you check your UOA report I think you'll find that your Iron ppm reading of 33 ppm Iron occurred at 5.2K-miles sampled not at the 5.6K-miles you state above!

#58

But my real bottom-line concern with by-pass filters isn't the "exact gpm" of oil flow that's being by-passed but rather the fact that by-pass filters are installed with the expressed intent of running extended OCIs ...and as I posted in response to this OP's question below on another thread ...all of the 7.3L PSD UOA data I've found to date indicates that running extended OCIs isn't conducive with maximizing engine life ...and if there's even the slightest risk for causing even more engine wear than just from the extended OCI itself due to compromised LOP flow that's just an additional reason not to install a by-pass filter!

As for your other concerns in regards to extended drain intervals, I've always felt the closer you can get to a wear number of 0, the better off you are. When you combine the HEUI system into the equation, that's even a better reason in my mind to stick with the recommended OCI.

Of course nothing anyone says here is going to make me change my mind on how I maintain my truck, but I do enjoy the discussion and am encouraged that my engine seems to wear better than many others around here.

#59

Yes, 1 out of 4 UOA reports was higher in iron than the others. You continue to focus on that one UOA report with 33 ppm iron. I explained before in a previous thread that this oil analysis was after changing injectors, running at the track and on the dyno. Any lab will tell you it is perfectly normal to see a temporary increase in wear metals after any engine work as long as they continue to trend down afterwards. If you call any lab you will find out that 33 ppm is not considered excessive. You didn't mention in your last post that my current UOA had iron at 13 ppm at almost 9k miles. Doesn't that put my wear curve back between curve 1 and 2? Sorry fdor any typos, been doing this from my cell phone.

The UOA reports I see from the trucks at the track hang around 50 to 80 ppm iron.

The UOA reports I see from the trucks at the track hang around 50 to 80 ppm iron.

#60

I was just curious to see if my truck liked one better than the other. I thought I was getting up there in mileage and wanted to know if my engine liked one additive package better than another. The only thing I really noticed were the difference in the sound, the amount of smoke out the CCV, and the odor out the CCV. Other than that, everything seems good.

We've all seen the which oil threads. I guess my curiosity got the better of me.

We've all seen the which oil threads. I guess my curiosity got the better of me.

That Delo add pack looks like a definite cut above the rest though.