Diesel Fuel Gel test - Pwr Srvc, Howe's, Schaeffer

#1

Diesel Fuel Gel test - Pwr Srvc, Howe's, Schaeffer

Being that the OAT was getting down to -10 F this week I though this would be a good opportunity to do a comparison of some anti-gelling fuel additives. This wasn’t a very scientific test, but a good visual representation of how the fuel I used reacted with 3 different anti-gel additives.

The additives I used were:

Power Service Diesel Kleen (white bottle)

Howe’s Dieseltreat anti-gel

Schaeffer’s Dieseltreat 2000 Winterized

I would have also liked to use Stanadyne Winter 1000 but I could not find any on short notice.

The diesel fuel I used came from a local gas station and kept in my garage where the inside air temp was 52 F. I wanted to make sure the fuel was above the cloud point since it is key to add an anti-gel additive to fuel before it reaches it’s cloud point. If you add an anti-gel additive after the fuel has reached the cloud point then it will not be able to disperse the wax crystals since they have already stared to form and grow.

I mixed each additive with 20 oz of #2 diesel. Since Howe’s recommended a double treatment for Pickups and/or when OAT is below 0 degrees F. I decided to be fair and double dose the treatment ratio of all the additives.

1) For pickups Howe’s recommends a treatment ratio of 1 oz per 2.5 gallons of fuel. Which equals .4oz per gallon.

2) Diesel Kleen’s Double treatment ratio is 8 oz per 10 gallons. Which equals .8 oz per gallon.

3) Schaeffer’s double treatment ratio is 16 oz per 62.5 gallons. Which equals .256 oz per gallon.

Howe’s .4 oz per gallon -------- -----0.0625 oz for 20 oz of fue

Diesel Kleen .8 oz per gallon --------- 0.125 oz for 20 oz of fuel

Schaeffer’s .256 oz per gallon ------- 0.04 oz for 20 oz of fuel

I mixed the samples at 2 pm. Garage air temp 52 degrees.

I placed the samples outside at 7 pm, outside air temp 4 F. I wanted to simulate an approximate time period the truck would be sitting outside overnight.

The additives I used were:

Power Service Diesel Kleen (white bottle)

Howe’s Dieseltreat anti-gel

Schaeffer’s Dieseltreat 2000 Winterized

I would have also liked to use Stanadyne Winter 1000 but I could not find any on short notice.

The diesel fuel I used came from a local gas station and kept in my garage where the inside air temp was 52 F. I wanted to make sure the fuel was above the cloud point since it is key to add an anti-gel additive to fuel before it reaches it’s cloud point. If you add an anti-gel additive after the fuel has reached the cloud point then it will not be able to disperse the wax crystals since they have already stared to form and grow.

I mixed each additive with 20 oz of #2 diesel. Since Howe’s recommended a double treatment for Pickups and/or when OAT is below 0 degrees F. I decided to be fair and double dose the treatment ratio of all the additives.

1) For pickups Howe’s recommends a treatment ratio of 1 oz per 2.5 gallons of fuel. Which equals .4oz per gallon.

2) Diesel Kleen’s Double treatment ratio is 8 oz per 10 gallons. Which equals .8 oz per gallon.

3) Schaeffer’s double treatment ratio is 16 oz per 62.5 gallons. Which equals .256 oz per gallon.

Howe’s .4 oz per gallon -------- -----0.0625 oz for 20 oz of fue

Diesel Kleen .8 oz per gallon --------- 0.125 oz for 20 oz of fuel

Schaeffer’s .256 oz per gallon ------- 0.04 oz for 20 oz of fuel

I mixed the samples at 2 pm. Garage air temp 52 degrees.

I placed the samples outside at 7 pm, outside air temp 4 F. I wanted to simulate an approximate time period the truck would be sitting outside overnight.

#2

After 1 hour – 8 p.m. ----- no visual difference, OAT +2F.

After 2 hours 20 min - 9:20 p.m. ----- all samples show clouding, OAT +1 F.

After 3 hours – 10 p.m. ----- equal cloudiness, OAT 0 F.

After 4 hours 20 min – 11:20 p.m. ----- layering/wax drop out starting OAT -2F.

A little tough to see in the photo but if you look closely you can start to see some layering at the top of the jar as the wax crystals grow in size. They

reach a particle size which is too great to remain suspended in the fuel and start to drop out.

After 2 hours 20 min - 9:20 p.m. ----- all samples show clouding, OAT +1 F.

After 3 hours – 10 p.m. ----- equal cloudiness, OAT 0 F.

After 4 hours 20 min – 11:20 p.m. ----- layering/wax drop out starting OAT -2F.

A little tough to see in the photo but if you look closely you can start to see some layering at the top of the jar as the wax crystals grow in size. They

reach a particle size which is too great to remain suspended in the fuel and start to drop out.

#3

After 5 hours 15 min – 12:15 a.m. ----- cloudiness continues to increase. Not much change from an hour ago, but some increased cloudiness.

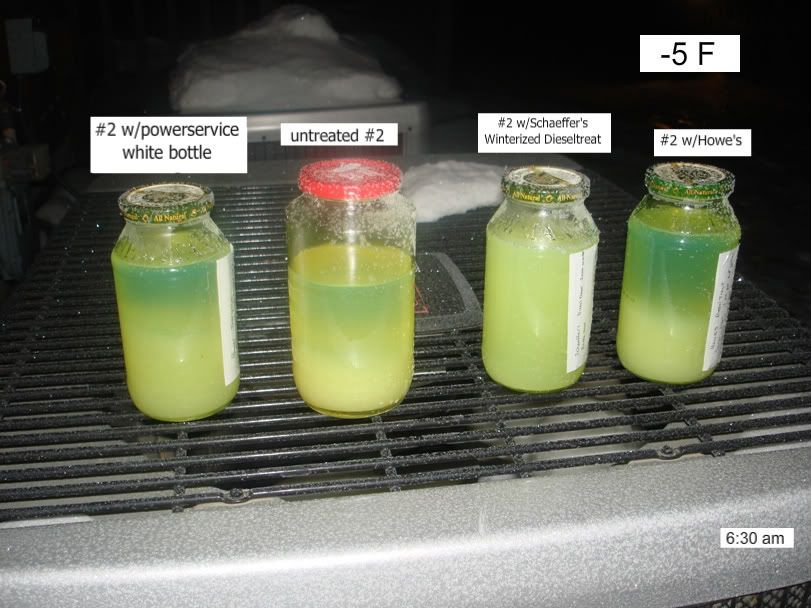

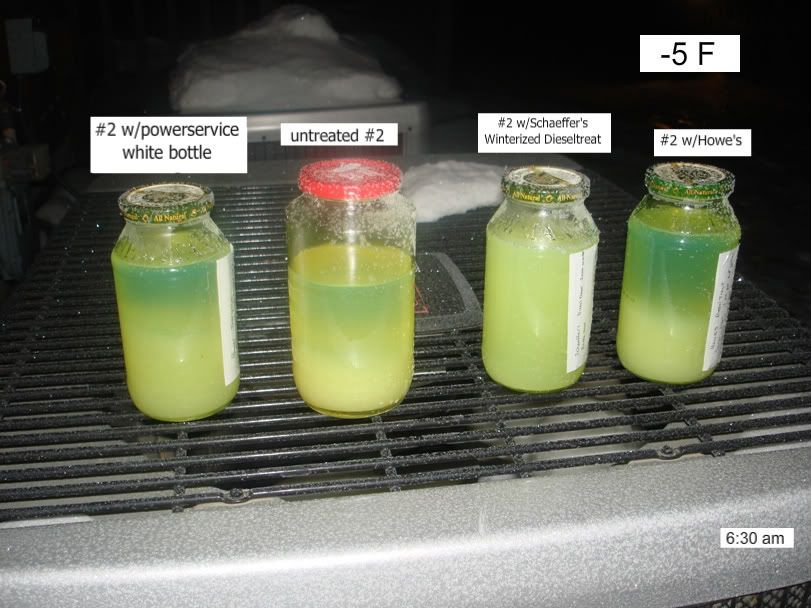

After 11 hours 15 min – 6:30 a.m. ----- wax drop out

You can see the wax drop out in 3 out of 4 of the samples. So this is what I could have had happening in my fuel tank if my truck was parked outside overnight.

13 hours later – 8:00 a.m. -----

Here are some close ups of the individual samples.

Ok, so with this type of fuel each additive affected the gel point differently. But, I put the samples back in the garage and after 2 hours each of the treated fuel samples were clear and the wax crystals were able to be dispersed & suspended back in the fuel. The untreated sample still has some wax drop out.

Next I plan to add about 5mm of water to the samples and see what affect that has on them.

Two important notes to consider:

1. There are different ways that diesel fuel is refined and each refining process reacts differently with additives. That is why you see some additives work well for one person in one area of the country and then not work as well for someone else in another area. So it is very difficult to say that one additive is best. This is probably why you here about one additive working well for someone – then not work so well for someone else in a different region of the country.

2. If you can keep the fuel moving then it slows the wax drop out process considerably. That might be why systems with a fuel tank return line/Reg return will help prevent the wax drop out from happening so quickly.

After 11 hours 15 min – 6:30 a.m. ----- wax drop out

You can see the wax drop out in 3 out of 4 of the samples. So this is what I could have had happening in my fuel tank if my truck was parked outside overnight.

13 hours later – 8:00 a.m. -----

Here are some close ups of the individual samples.

Ok, so with this type of fuel each additive affected the gel point differently. But, I put the samples back in the garage and after 2 hours each of the treated fuel samples were clear and the wax crystals were able to be dispersed & suspended back in the fuel. The untreated sample still has some wax drop out.

Next I plan to add about 5mm of water to the samples and see what affect that has on them.

Two important notes to consider:

1. There are different ways that diesel fuel is refined and each refining process reacts differently with additives. That is why you see some additives work well for one person in one area of the country and then not work as well for someone else in another area. So it is very difficult to say that one additive is best. This is probably why you here about one additive working well for someone – then not work so well for someone else in a different region of the country.

2. If you can keep the fuel moving then it slows the wax drop out process considerably. That might be why systems with a fuel tank return line/Reg return will help prevent the wax drop out from happening so quickly.

#4

#5

#7

Trending Topics

#9

Seeing is believing, Rich, and your test helped that a lot. Thanks for doing it. Would have been interesting to see what the "pourability" of each would have been through a 3/8" hose when appearing gelled. I can definitely guess what the flowability would have been through a filter, especially the untreated.

Interesting comment about the different refining processes. Helps us understand the effects of different additives.

Like the Indian sign!

Interesting comment about the different refining processes. Helps us understand the effects of different additives.

Like the Indian sign!

#10

I'm curious what would happen with a little of the PS D-911 as well. Can you leave them out tonight and put in the prescribed dose in each in the morning?

#11

Thanks for sacrificing some sleep for the cause. As I see your photos, it looks like the Schaeffers clouded like the other samples, but didn't separate.

I use Schaeffers year round and have experienced zero problems, even in single digit temps near St Louis MO, while many around me were gellin' (and I don't mean wearing Dr Scholls shoe inserts).

I use Schaeffers year round and have experienced zero problems, even in single digit temps near St Louis MO, while many around me were gellin' (and I don't mean wearing Dr Scholls shoe inserts).

#15

I had to edit some of the pics. I noticed that when I copied this post from MS Office some of the temps did not copy in the text above the photos. So I added the OAT to the pics.

Yes they can. ULSD contains more wax than the previous LSD. As the temperature of the Ultra Low Sulfur Diesel Fuel drops, these increased amounts of wax molecules can begin to rapidly drop out of the fuel and form wax crystals (as you can see in some of the photos) that can quickly plug fuel lines and filters. Since the fuel pick up is located at the bottom of the tank in our PSDs, the wax is the first to get sucked up. The longer the fuel sits in this situation the higher the level of wax drop out.

Will do. Unfortunately we have a heat wave this week (+10 to +25F ) so it might be a while until we get some sub zero temps so I can get some good wax drop out like this:

) so it might be a while until we get some sub zero temps so I can get some good wax drop out like this:

Yes, it did not seperate as much as the others so it kept the wax crystals dispersed and prevented them for growing large enough to precipitate out of the fuel. It was also interesting to note the difference in treatment levels between the additives I used.

Howe's .8 oz /gal

DK .4 oz/gal

Schaeffer .25 oz/gal

But, like I said - there are different ways that ULSD is refined - so these results may be different for different refining processes.

here is a link to some diesel fuel test done by Schaeffer's Lab. Not a huge amount of info but you can click on the region and get an understanding of the baseline Cold Filter Plug Point (CFPP) and the CFPP with different treatment ratios and additives. The red bar is the #2 Diesel fuel baseline CFPP and the other bars show Cold Filter Plug Point (where the fuel will clog a 45 micron fuel filter according to the ASTM D-6371 test) with Schaeffer's fuel additives at various treatment ratios. Unfortunatley It does not show the other additives like Stanadyne, PS & Howe's. Never the less, interesting to see the variation of the baseline fuels CFPP. It is a relatively new web page so they are still adding sample data.

http://schaefferoil.com/winter-fuelresults.html

) so it might be a while until we get some sub zero temps so I can get some good wax drop out like this:

) so it might be a while until we get some sub zero temps so I can get some good wax drop out like this:

Thanks for sacrificing some sleep for the cause. As I see your photos, it looks like the Schaeffers clouded like the other samples, but didn't separate.

I use Schaeffers year round and have experienced zero problems, even in single digit temps near St Louis MO, while many around me were gellin' (and I don't mean wearing Dr Scholls shoe inserts).

I use Schaeffers year round and have experienced zero problems, even in single digit temps near St Louis MO, while many around me were gellin' (and I don't mean wearing Dr Scholls shoe inserts).

Howe's .8 oz /gal

DK .4 oz/gal

Schaeffer .25 oz/gal

But, like I said - there are different ways that ULSD is refined - so these results may be different for different refining processes.

here is a link to some diesel fuel test done by Schaeffer's Lab. Not a huge amount of info but you can click on the region and get an understanding of the baseline Cold Filter Plug Point (CFPP) and the CFPP with different treatment ratios and additives. The red bar is the #2 Diesel fuel baseline CFPP and the other bars show Cold Filter Plug Point (where the fuel will clog a 45 micron fuel filter according to the ASTM D-6371 test) with Schaeffer's fuel additives at various treatment ratios. Unfortunatley It does not show the other additives like Stanadyne, PS & Howe's. Never the less, interesting to see the variation of the baseline fuels CFPP. It is a relatively new web page so they are still adding sample data.

http://schaefferoil.com/winter-fuelresults.html