...Doing a leveling KIT install right now... need help...

#1

...Doing a leveling KIT install right now... need help...

Hello all!

I just had the motivation to install my HELLBENT STEEL Front LEVELING KIT, that I bought from ebay.

It is the Hellbent Steel 2.5 inch version, for my 2005 FX4 F-150.

I was just reading the directions and I have a little question, for those who have experience in this area...

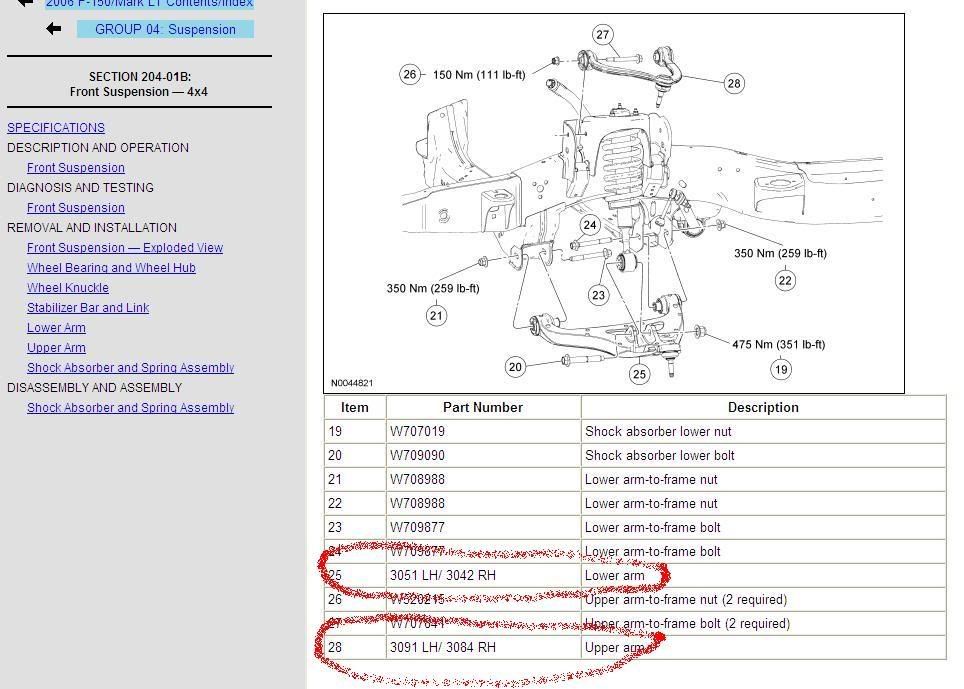

Q: (Is this torque spec. correct?) It is saying on the directions that I should torque the Shock Absorber-to-Lower Arm Nut and Bolt to 351 foot pounds.

I was just wondering if that meant 351 inch pounds?

I don't think I have a torque wrench that goes up over 125-150 foot lbs. or so...???

What should I do?

Any help pretty please?

TONY Z.

#40

I just had the motivation to install my HELLBENT STEEL Front LEVELING KIT, that I bought from ebay.

It is the Hellbent Steel 2.5 inch version, for my 2005 FX4 F-150.

I was just reading the directions and I have a little question, for those who have experience in this area...

Q: (Is this torque spec. correct?) It is saying on the directions that I should torque the Shock Absorber-to-Lower Arm Nut and Bolt to 351 foot pounds.

I was just wondering if that meant 351 inch pounds?

I don't think I have a torque wrench that goes up over 125-150 foot lbs. or so...???

What should I do?

Any help pretty please?

TONY Z.

#40

#4

#7

Why so flippin tight???

Is it absolutely necessary to get it to that torque?

I mean I bench press 365 lbs. cleanly, but I don't think I have it in me to pull 350 lbs sitting down under my truck???

PS. thank you so much guys for your quick responses!!!

I have the wheels off and I am looking at it now.

I mean here is the story to... I am actually taking it to the dealership tommorrow to get it serviced, aligned and recall issue (power brake booster vac. line replaced).

I asked the dealers if they could do the leveling kit install for me, and they appropriately said nope!

If I get this kit installed tonight, I could kill all birds with one dealership visit.

Get it serviced, and most importanly wheel alignmented! :>)

PS. Dealership is about 10 miles away from the house, so if I get it torqued down to about specs.... will that count?? I could just tell them at the dealership to torque it down to spec?

TONY Z.

#40

Is it absolutely necessary to get it to that torque?

I mean I bench press 365 lbs. cleanly, but I don't think I have it in me to pull 350 lbs sitting down under my truck???

PS. thank you so much guys for your quick responses!!!

I have the wheels off and I am looking at it now.

I mean here is the story to... I am actually taking it to the dealership tommorrow to get it serviced, aligned and recall issue (power brake booster vac. line replaced).

I asked the dealers if they could do the leveling kit install for me, and they appropriately said nope!

If I get this kit installed tonight, I could kill all birds with one dealership visit.

Get it serviced, and most importanly wheel alignmented! :>)

PS. Dealership is about 10 miles away from the house, so if I get it torqued down to about specs.... will that count?? I could just tell them at the dealership to torque it down to spec?

TONY Z.

#40

Trending Topics

#8

Well that joint takes an overwhelming amount of the force of suspension articulation. I would get it as tight as absolutely possible.... and carefully drive the 10 miles. You should be fine, but I would definitely cough up a few bucks to have the Ford tech hit any fitting you touched, with the appropriate force.

#13

Wow, 351 ft-lbs is a lot! I installed a AS 2" front spacer. The instructions there called for 255 ft-lbs and I thought that was a lot. I also confirmed with some others that had installed, but I see the spec sheet Tylus posted. It was about all I could do to tighten it using a 250 ft-lb torque wrench (long handle!).

#14

#15

you have to put the upper part of the coil over in there first. then push your lower control arm down (if needed) and slide the coil-over to where is sits. then lift the lower control arm and slide that big freaking bolt through there. tighten it up to the 351 ft-lbs (or as close as possible).

now install the 3 nuts ontop of the coil-over.

carefully place a jack under the lower control arm at the outermost edge. jack the lower control arm upwards until the upper part of the spindle will connect with the ball joint on the upper control arm.

it's a PITA to do this part. but as soon as you get enough threads, you can run the nut onto the ball joint and use that to cinch it the rest of the way down

now install the 3 nuts ontop of the coil-over.

carefully place a jack under the lower control arm at the outermost edge. jack the lower control arm upwards until the upper part of the spindle will connect with the ball joint on the upper control arm.

it's a PITA to do this part. but as soon as you get enough threads, you can run the nut onto the ball joint and use that to cinch it the rest of the way down