slamming a 65. PICS!

#46

#47

update....

full on show truck build now guys

frame off.

heres some new photos.

custom ordered garret t-04s Compressor side is 1.10A/R and the turbine side is .48A/R split scroll. Built-in waste-gate.

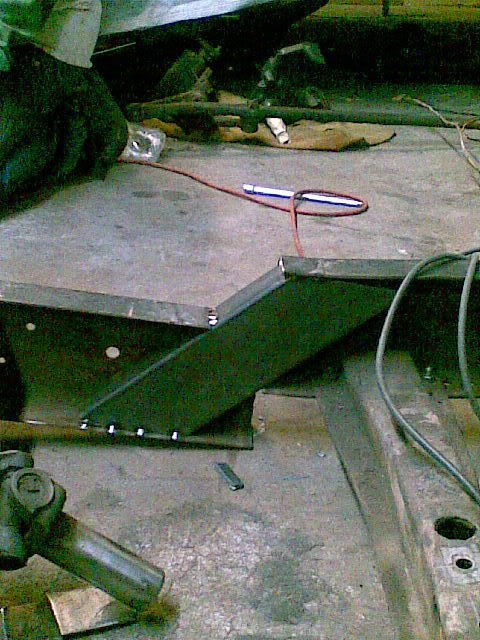

z'd the front of the frame so it will lay out

its now a frame off, since this photo the motor has been pulled and the frame pressure washed

the reason its a frame off now

full on show truck build now guys

frame off.

heres some new photos.

custom ordered garret t-04s Compressor side is 1.10A/R and the turbine side is .48A/R split scroll. Built-in waste-gate.

z'd the front of the frame so it will lay out

its now a frame off, since this photo the motor has been pulled and the frame pressure washed

the reason its a frame off now

#48

Nice progress Brandon...and Im not a fan of modified cars/trucks...BUT I do agree if you are gonna do it, get a bondo bucket or rusty foundation and go from there...it looks pretty good so far though.

I got a couple of questions though...first, do you still have the bedside toolbox and all of its mounting stuff ??

And what kind of welder do you use...those are some pretty welds you got there.

- cs65

I got a couple of questions though...first, do you still have the bedside toolbox and all of its mounting stuff ??

And what kind of welder do you use...those are some pretty welds you got there.

- cs65

#49

thanks for the support. A lot of people arent really into the modification thing on here which is fine, and i can respect that because all old cars are great in their own design. But being a fabricator, i cant leave anything factory, it almost hurts me to do so. I daily drive a 2000 cadillac deville, and its the only car that hasnt been modified yet, and probably wont be. Im going to give it to mom and get a newer caddy.

but anways. what you where saying

the box is gone, plus it was a little beat up. But bill, hes on here somewhere, has it, and he might be willing to sell it to you.

the welder im using is a miller 140. mini mig. running .030 wire.

or a miller syncwave 200 tig welder for welding the tube ends to my link bars, and things i dont really want a bead to be seen on, but be really strong. If i had the right size collet/collet body and tungsten id tig a lot more, but, i dont plus the mig works great.

If any welder ever says they could be better if they had a better machine its bull****. the other 2 guys in my complex have miller 250s, and i can weld circles around them all day with a my 140, just by knowing how to set the machine up and run the beads right. when to stop/start, when to run circles, or weaves.

the only downfall of the 140, is that the electrical in my building sucks, and it pops the breaker sometimes. But ive welded for almost 4 hours with it before and it didnt over heat or have any problems.

but anways. what you where saying

the box is gone, plus it was a little beat up. But bill, hes on here somewhere, has it, and he might be willing to sell it to you.

the welder im using is a miller 140. mini mig. running .030 wire.

or a miller syncwave 200 tig welder for welding the tube ends to my link bars, and things i dont really want a bead to be seen on, but be really strong. If i had the right size collet/collet body and tungsten id tig a lot more, but, i dont plus the mig works great.

If any welder ever says they could be better if they had a better machine its bull****. the other 2 guys in my complex have miller 250s, and i can weld circles around them all day with a my 140, just by knowing how to set the machine up and run the beads right. when to stop/start, when to run circles, or weaves.

the only downfall of the 140, is that the electrical in my building sucks, and it pops the breaker sometimes. But ive welded for almost 4 hours with it before and it didnt over heat or have any problems.

#50

#51

Hey cs65, I ended up with the Tool box from Brandon's truck in trade for the door skin to patch the Huge hole it left I plan to use it on the long bed trailer I will soon be building. Brandon also came by and picked up the 66 cab I had! In trade for some welding on one of my trucks I Really like the Barter system, and with Brandon it's easy, He is a very Cool Young man

I plan to use it on the long bed trailer I will soon be building. Brandon also came by and picked up the 66 cab I had! In trade for some welding on one of my trucks I Really like the Barter system, and with Brandon it's easy, He is a very Cool Young man ! Keep us Updated

! Keep us Updated

I plan to use it on the long bed trailer I will soon be building. Brandon also came by and picked up the 66 cab I had! In trade for some welding on one of my trucks I Really like the Barter system, and with Brandon it's easy, He is a very Cool Young man

I plan to use it on the long bed trailer I will soon be building. Brandon also came by and picked up the 66 cab I had! In trade for some welding on one of my trucks I Really like the Barter system, and with Brandon it's easy, He is a very Cool Young man ! Keep us Updated

! Keep us Updated

#52

its really all about how you set up your machine. Ive noticed with my mini mig(miller 140) That when i first started welding frame stuff, u cranked up the voltage, and the wire speed, typical when you are welding something thicker to turn stuff up.

so for instace, first weld on a frame was at 8 on the voltage, and about 70-80 on the wire speed.

welded great, but didnt penetrate worth a ****.

Then at the job i had started my boss tought me how to set up the welder by sound, not by numbers, or anything.

but the setting i ended up with was 8 on the voltage and 45-50 on the wire speed. and it will penetrate it like no ones business.

a good way to try and set it is crank the voltage up a lot then take a peice of scrap metal, and just hold it on it and weld, not a bead, just hold it there, and turn the wire speed up or down untill it sounds like bacon sizzling rapidly. and you got it.

hope that helps you some.

#53

Thanks, I do the same for my set up. On your Syncrowave try turning your main power source up all the way and tune the machine through the pulser. use your background gor your heat. I use one all day at my job for welding SS and Copper, and it is fun to use, also you can turn the pulses down to 1-2 and use to add filler rod and makes a really pretty bead. The pulser can really make the job of welding really thin stuff like body panels very easy.

#60