running boards

#16

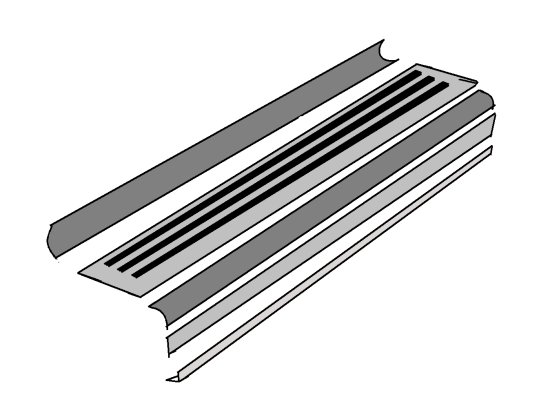

There's always way around having to have the expensive tools. For instance, instead of making the running board out of one solid piece you could stith it together from a series of parts.

Instead of trying to take and roll a piece of sheet metal to make a nice purty roll at the edge of the runnind board you could use some flat sheet metal and some tubing. Use the flat sheetmetal for the vetical and horizontal surfaces, cut the tubing into quarters and use one of the quarters for the rolled edge. (I don't think I'm explaining this very well)

In the long run its probably cheaper to buy the fiberglass boards

Bobby

Instead of trying to take and roll a piece of sheet metal to make a nice purty roll at the edge of the runnind board you could use some flat sheet metal and some tubing. Use the flat sheetmetal for the vetical and horizontal surfaces, cut the tubing into quarters and use one of the quarters for the rolled edge. (I don't think I'm explaining this very well)

In the long run its probably cheaper to buy the fiberglass boards

Bobby

#17

#18

Ah yes, the old time thing. It never fails, when I have time, I have no money, when I finally have a bit of extra money, I have no time.

Its that little scoundrel Murphy of the infamous Murphy's Law fame that controls that sort of thing (someday I'll catch up to him and give him a good kicking)

Bobby

Its that little scoundrel Murphy of the infamous Murphy's Law fame that controls that sort of thing (someday I'll catch up to him and give him a good kicking)

Bobby

#19

I had an idea yesterday, but then I got over it. I had a thought of building some out of hardwood. I know at first thought it sounds cheesy. But I'm not talking about throwing a 2x 12 on the brackets and calling it good. I had that idea when I bought the truck. I am always wanting to do something out of the norm. I especially take pride in doing something that others say will turn out like crap. I am not wanting to rig my running boards. But I do want this truck to look very unique and look good at the same time. Along time ago my ex ol lady had an atique shop. I found myself building cabinets and othe rartsy fartsy things for her shop. When we divorced I couldn't sell that shopsmith fast enough. That's been 10 years ago. But I have the knowledge to craft a set of reall cool looking running boards for this ride. I wanted to build a set that had rounded edges,and a good undercoating on the bottoms. Am I looking to seperate myself from you guys if I do that>?

#20

Way back when I joined this board I remember there was a guy that built some wood running boards. From what I remember they looked really good. I'll see if I can dig up the thread.

You'll find we are a tolerant lot on this board, if you want to build wood running boards, build wood running boards. Oh sure, you'll get a few naysayers, that should be expected no matter what you do to your truck but for the most part you will not offend anyone.

It all comes down to the fact that you are enjoying your truck. Thats what we are all here for. We like our trucks, we like to talk about our trucks, we like other peoples trucks, we like to talk about other peoples trucks. we like to offer advice, and more than anything we love to spout out our opinions as if they actually meant something.

Do what makes you happy

Bobby

You'll find we are a tolerant lot on this board, if you want to build wood running boards, build wood running boards. Oh sure, you'll get a few naysayers, that should be expected no matter what you do to your truck but for the most part you will not offend anyone.

It all comes down to the fact that you are enjoying your truck. Thats what we are all here for. We like our trucks, we like to talk about our trucks, we like other peoples trucks, we like to talk about other peoples trucks. we like to offer advice, and more than anything we love to spout out our opinions as if they actually meant something.

Do what makes you happy

Bobby

#21

I've seen wooden running boards 3 times.....puked 3 times

What about shaped MDF,then waterproofed with fibreglass resin, then sand and paint????

If your riginal boards are in decent SHAPE.....why not strip them and cover NICELY in pleated vinyl like a 50's/60's custom ???

Pics will afford you the MOST help and suggestions!

What about shaped MDF,then waterproofed with fibreglass resin, then sand and paint????

If your riginal boards are in decent SHAPE.....why not strip them and cover NICELY in pleated vinyl like a 50's/60's custom ???

Pics will afford you the MOST help and suggestions!

#22

Oz , That is what I just got through ripping off of these running boards. It was some kind of vinyl that they stretched over it and used floor adhesive to bind it to the metal. But , first they used about 1 1/2 gallons of bondo to smooth out the ridges on the boards. Nowm, can you imagine how much bondo that took.?? What I am wanting to do , is similar , but once I am done with the boards, I am going to use the Rhino liner on them. They will be somewhat textured , but not like a spackled wall.

#23

Here ya go, here is a link to some wooden running boards that is pretty interesting;

https://www.ford-trucks.com/user_gal...&albumid=17348

Bobby

https://www.ford-trucks.com/user_gal...&albumid=17348

Bobby

#24

I'm kinda diggin those running boards. And I even kept my lunch down when I saw them. hehe .But, I have to say ,if you counted the time spent ,and value it at minimum wage, you would probably still have $350 into them. But, you could not say that you did it yourself. My idea is similar, but I do plan to use sheet metal on the skirt up to the cab. I will post some photos this weekend, if I can figure out how to do that. It keeps saying that my photos are too large, but I have reduced them to about half the size needed to be loaded. Oh well, not that important.

#25

Originally Posted by cool 48

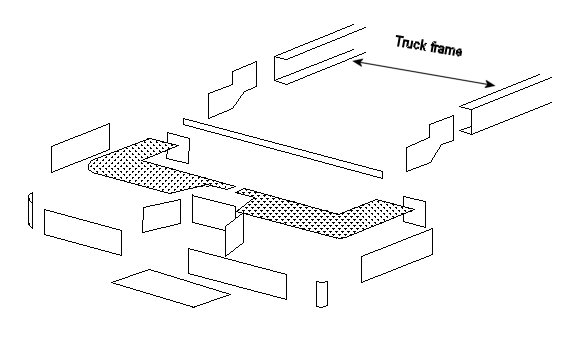

Well, I guess you could say I am handy with a welder. Being a concrete contractor for 26 years ,and ownign a sand and gravel operation along with it, I have had to weld some pretty scary looking stuff in my time . The only problem is that they show using sheet metal stretchers, and shrinkers, and it looks like you need to go buy around $2500 worth of tools to even start.

#26

I am going to post some photos of what I did taday on the running boards. The green on them is a skim coat of filler to even out anyimperfactions in the wood. I will sand them in the morning, then go back at it. I cut the upper portion of the running boards from the actual platform. I will use them after I flatten them out where it curves under the truck. I will have more photos tommorrow.

#27

#28

Most any reliable metal shop can custom cut those piece's for you, you may have to cut the tubing yourself with a bandsaw,...

Putting the large ribs on the board could be tricky..

Build a jig to make them both the same and square...

Seems like a good project...would green astro-turf on the deck for traction be out of line??..just kidding!!

Putting the large ribs on the board could be tricky..

Build a jig to make them both the same and square...

Seems like a good project...would green astro-turf on the deck for traction be out of line??..just kidding!!

#29