Updating brakes

#1

Updating brakes

Now that I finally got the rebuilt 390 sorted out, only took 13 months, I can now move onto the brakes. Now I don't want to hear about pulling parts off a donor truck as there are no donor trucks in the immediate Bay Area anymore except a F250 in the 70's now and then.

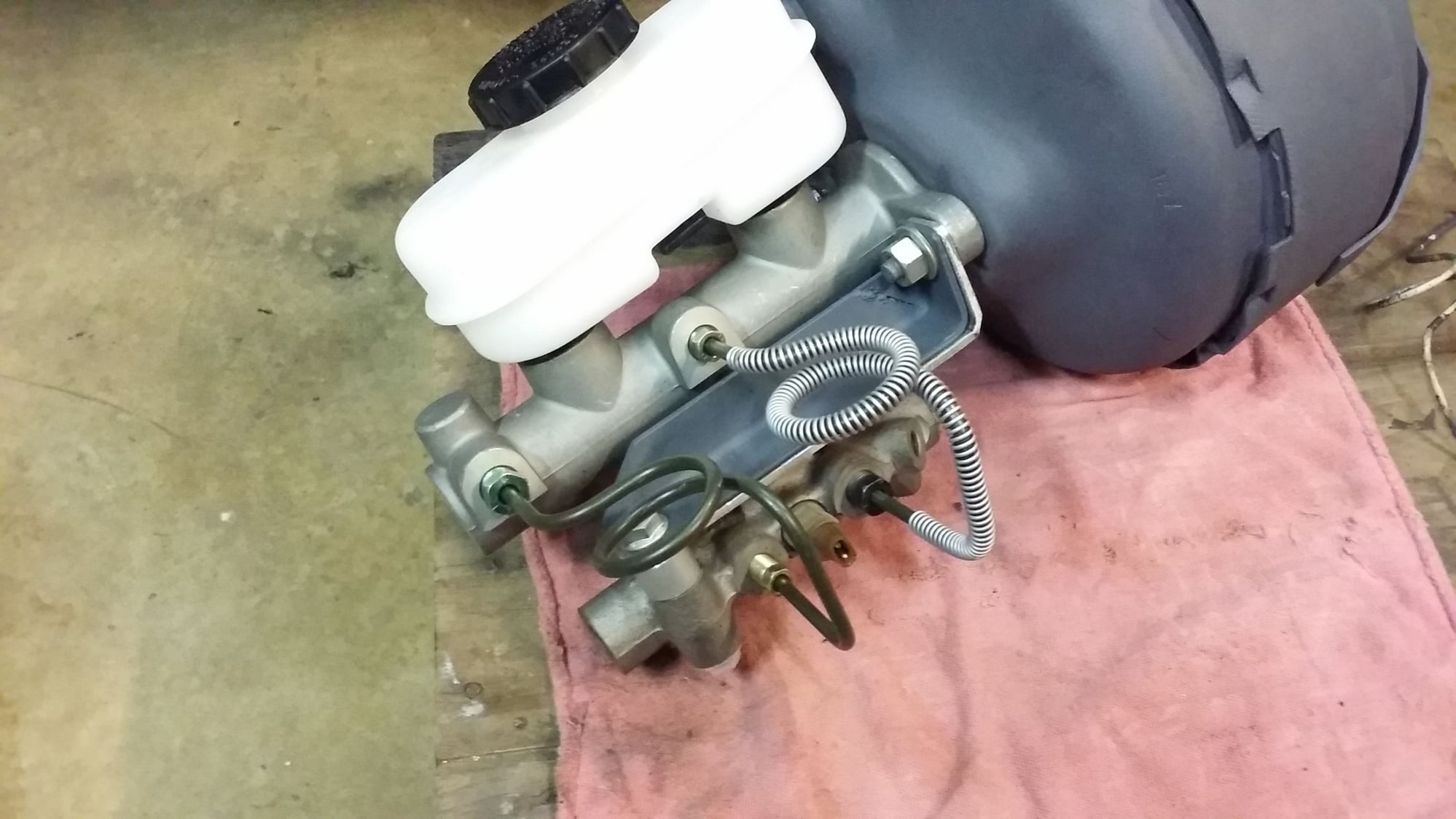

I have the dual master along with a rebuilt 1966 F100 power brake booster by Booster Dewey. That booster came off the last F100 I saw around here in 2009. So the booster assembly will go right in on my 65 as though it came with that from the factory. I am thinking of putting the distribution block up by the master cylinder fabricating a bracket.

Also, since I am not a fan of cutting and flaring old original brake lines, I am considering new lines. Now who would be a good vendor for a LWB truck?

For the sender I am also leaning towards using it in the lines with a T rather than a sender on the brake pedal. Oh, the brakes are remaining drum on all fours for the foreseeable future.

I have the dual master along with a rebuilt 1966 F100 power brake booster by Booster Dewey. That booster came off the last F100 I saw around here in 2009. So the booster assembly will go right in on my 65 as though it came with that from the factory. I am thinking of putting the distribution block up by the master cylinder fabricating a bracket.

Also, since I am not a fan of cutting and flaring old original brake lines, I am considering new lines. Now who would be a good vendor for a LWB truck?

For the sender I am also leaning towards using it in the lines with a T rather than a sender on the brake pedal. Oh, the brakes are remaining drum on all fours for the foreseeable future.

#2

Since a '65 F100 never came with a tandem MC, you're not going to find any prefabbed brake lines to directly fit your truck because of this deviation. I'm not sure if you're referencing the brake line manifold that would have been on a '65 F100 or, if you've installed the pressure differential brake valve that would have been used on a '67-'72 truck with the split brake system and a tandem MC.

If you have the '67-up pressure differential brake valve, this deviation is also going to make it a problem in getting prefabbed brake lines to fit your application. Moving the '65 F100 brake line Tee (manifold) to another location is also going to complicate the issue of obtaining prefabbed lines that would fit.

With things changed up from what was original, you're pretty much going to have to fab your own brake lines --not an overly difficult task to accomplish.

https://www.ford-trucks.com/forums/1...o-booster.html

If you have the '67-up pressure differential brake valve, this deviation is also going to make it a problem in getting prefabbed brake lines to fit your application. Moving the '65 F100 brake line Tee (manifold) to another location is also going to complicate the issue of obtaining prefabbed lines that would fit.

With things changed up from what was original, you're pretty much going to have to fab your own brake lines --not an overly difficult task to accomplish.

https://www.ford-trucks.com/forums/1...o-booster.html

#4

I should have been more clear. I fully expect to fab the lines from the MC to the block. If I got new lines to replace the old ones I could mount the distribution block down lower where the three lines come to a junction as thet do now with the single pot. I would then have to fab the two lines from the dual MC down to the distribution block.

That way the truck would have a axle line, a long bed line, the front cross member line and a line to the left front wheel as all new. The fitting to the block would be where those three lines meet down below with appropriate bending and or cutting. I would be left to create two lines for the MC.

Or, buy bulk, remove my lines, create new lines from the old ones, and then create the two from the MC. Just have to get a good flaring tool that makes this trouble free like the Eastwood one. My hand held, where you twist, is a PIA to get a consistently perfect double flare.

Now steel OEM or copper nickle lines?

That way the truck would have a axle line, a long bed line, the front cross member line and a line to the left front wheel as all new. The fitting to the block would be where those three lines meet down below with appropriate bending and or cutting. I would be left to create two lines for the MC.

Or, buy bulk, remove my lines, create new lines from the old ones, and then create the two from the MC. Just have to get a good flaring tool that makes this trouble free like the Eastwood one. My hand held, where you twist, is a PIA to get a consistently perfect double flare.

Now steel OEM or copper nickle lines?

#5

I'm not understanding what you're asking. I would not reuse old lines, and I don't see any benefit to buying OEM lines unless you could get pre-bent and pre-flared which I doubt (like Ultraranger said). I would not try to flare stainless (in case that's what you mean by OEM steel). I've read stainless is tricky to flare without it cracking. NAPA's EZ bend will perform well and flares as easy as can be.

#6

Nowhere did I say use old lines, for the MC, other than the three main lines to the wheels. Even then in hindsight those may not be able to get to the distribution block.

Asked about buying lines and then modify them for what I need. Then thought of making new lines myself using steel (OEM) or copper nickle. It is going to be copper nickle as I have already ordered 25ft. along with fittings.

Asked about buying lines and then modify them for what I need. Then thought of making new lines myself using steel (OEM) or copper nickle. It is going to be copper nickle as I have already ordered 25ft. along with fittings.

#7

The copper-nickel should be soft enough to work with. I have purchased brake lines that were so hard my Ridgid flaring tool could not work them. I blamed the tool, but it was explained to me that those really hard ones are not meant to be re-worked.

Eric

Eric

Last edited by 6t6merc; 01-05-2017 at 03:32 PM. Reason: More information

Trending Topics

#8

I just got done reading every review on this Mastercool product that ultraranger uses and this is on my list now.

https://www.amazon.com/Mastercool-71.../dp/B007TN15EG

.

https://www.amazon.com/Mastercool-71.../dp/B007TN15EG

.

#9

I just got done reading every review on this Mastercool product that ultraranger uses and this is on my list now.

https://www.amazon.com/Mastercool-71.../dp/B007TN15EG

.

https://www.amazon.com/Mastercool-71.../dp/B007TN15EG

.

#10

#12

#13

I just got done reading every review on this Mastercool product that ultraranger uses and this is on my list now.

https://www.amazon.com/Mastercool-71.../dp/B007TN15EG

.

https://www.amazon.com/Mastercool-71.../dp/B007TN15EG

.

http://www.tooldiscounter.com/default.cfm?nav=inc/specials.cfm

#14

I have a 65 that I added a power brake booster with a double MC from MP brakes. The original MC was the single line MC with one tube down to a tee under the steering box. I did like you kept the drums all around. MP brakes sent me a MC designed for drums all around and thus did not require a proportioning valve. I disconnected the brake line to the front wheels from the tee and installed a plug. I then ran two lines down from the MC one when to the tee to the back wheels and the other line went to the line to the front wheels with a coupling. Works great. The only problem (there always is a problem with after market parts) was the bracket did not fit and I had to cut it and weld it back together in a different configuration.

MP brakes was very good about it and offered to refund my money but I wanted the power brakes so I fixed it.

When you run new brake lines use the new tubing that is flexible and easy to flare. I also put a tee in the line and used the original brake switch for the brake lights.

MP brakes was very good about it and offered to refund my money but I wanted the power brakes so I fixed it.

When you run new brake lines use the new tubing that is flexible and easy to flare. I also put a tee in the line and used the original brake switch for the brake lights.

#15

Join Date: Feb 2004

Location: West Vancouver BC Canada

Posts: 196

Likes: 0

Received 2 Likes

on

2 Posts

I have a '66F250 that I've upgraded to a dual master cylinder, but kept the drum brakes all around.

I am using a Wagner dual chamber MC for a '67F250, and purchased a distribution block off eBay for a 67 Galaxie(entrance fittings for each line from MC, 2 exit fittings for front, 1 for rears). Had to custom make a bracket to mount it.

Bought pre-bent 3/16 inch SS brake lines from InLine Tube for a '67F250 and they all mounted perfectly on the '66 frame and connected perfectly to the distribution block and the fittings at each drum and rear axle housing.

The only mod I needed was to reverse the fittings on the two lines from the MC to the distribution block to fit the entrance fittings. I had InLine do that for me.(mods not expensive, but USPS wasn't cheap) They did a great job and added protection coiling to exposed legs from bracket at PS box to distribution block.

I'll mount a Tee with an 1/8NPT at the exit to the rear chamber to mount the line-pressure activated brake light switch.

Overall, keeps the set-up fairly close to original but increases safety with dual MC.

I am using a Wagner dual chamber MC for a '67F250, and purchased a distribution block off eBay for a 67 Galaxie(entrance fittings for each line from MC, 2 exit fittings for front, 1 for rears). Had to custom make a bracket to mount it.

Bought pre-bent 3/16 inch SS brake lines from InLine Tube for a '67F250 and they all mounted perfectly on the '66 frame and connected perfectly to the distribution block and the fittings at each drum and rear axle housing.

The only mod I needed was to reverse the fittings on the two lines from the MC to the distribution block to fit the entrance fittings. I had InLine do that for me.(mods not expensive, but USPS wasn't cheap) They did a great job and added protection coiling to exposed legs from bracket at PS box to distribution block.

I'll mount a Tee with an 1/8NPT at the exit to the rear chamber to mount the line-pressure activated brake light switch.

Overall, keeps the set-up fairly close to original but increases safety with dual MC.