Air Conditioner charging questions

#16

Here is what I learned in trying to fix my factory air. First, you should have replaced the oil in it to begin with, as the original oil is not compatible with r134. My compressor was leaking from the seal around the pulley shaft. when I tore it apart to repair, I found that my "valve" was broken. The valve assembly is several pieces of thin metal bolted together, and mine had a couple of cracks. I happen to to have another one so I rep[laced the seals in it, and when filling the system with freon, a hose blew. SO I gave up. I found a guy on ebay that sells a sandeen conversion kit for somewhere around $200. Has compressor, brackets, bolts, and new hose kit. If I would have found this before I started working on the system, I would of just went that route.

#17

Seems to me the York oil and refrigerant systems are separate so changing to R134 oil may not be a huge deal. A pound and a half of refrigerant sounds awfully low - I think I used on the order of 2-3 pounds after converting to a Sanden compressor. Based on your responses above, if it were mine I would start shopping a different compressor.

+1 on changing to a Sanden compressor - I did that and even with only a 300 engine I can almost not even feel the compressor kick in. I remember the Yorks would damn near suck the life out of anything.

+1 on changing to a Sanden compressor - I did that and even with only a 300 engine I can almost not even feel the compressor kick in. I remember the Yorks would damn near suck the life out of anything.

#18

Hi, I was told by two AC companies to replace the drier anytime you open the system because it has desiccant in it to pull out the moisture in the system and when you open it you introduce any humidity in the outside air and also have a fliter in them. They don't cost very much money and I don't know about you but I want my air conditioning working the best it can. You might consider flushing the system also because the R12 and R134 oil don't mix. I've never done that before because I installed new systems but I'm sure you can Google it. If you Google how air conditioning driers work there's lots of information on them.

Here is some numbers for filling the system.

R134A TYPE

1. HIGH-SIDE PRESSURE (160 - 250 PSI) * Note - general rule of thumb is two

times the ambient (daytime) temperature, plus 15 - 20%.

2. LOW-SIDE PRESSURE (06- 12 PSI in a steady state)

3. CENTER DUCT TEMPERATURE (36 - 46 DEGREES F.)

Here is some numbers for filling the system.

R134A TYPE

1. HIGH-SIDE PRESSURE (160 - 250 PSI) * Note - general rule of thumb is two

times the ambient (daytime) temperature, plus 15 - 20%.

2. LOW-SIDE PRESSURE (06- 12 PSI in a steady state)

3. CENTER DUCT TEMPERATURE (36 - 46 DEGREES F.)

#19

Thanks all the help. I put another used compressor on and vacuumed out the system for 1.5 hours. The clutch engaged while I put a charge on it and come up with the same result. I have roughly 75 on both the high and the low. Which leads me to believe that it is the compressor. I am going to take one apart, but I think I am heading for a Sanden.

#20

How much refrigerant did you put in? I wouldn't trust the hi/lo readings until there was close to a full charge.

If you have the original hoses, there should be a sight glass in the liquid line just before it goes through the radiator support. With the compressor running, check to see if the glass is clear. If it's cloudy, not enough refrigerant.

If you have the original hoses, there should be a sight glass in the liquid line just before it goes through the radiator support. With the compressor running, check to see if the glass is clear. If it's cloudy, not enough refrigerant.

#21

I am sure I did not put in a full charge. I put some in, then checked my pressures. Once I saw I was at above the pressure for the low side. I stopped. I will try again tomorrow with a clean slate. I will read some more tonight.

I took apart the compressor that was on the truck. I took it down to the pistons. All seemed fine. In fact it was very difficult to separate the valve plate, which leads me to believe that I don't think the compressor was leaking. The pistons move up and down as I turn the pulley. All seems fine. I will read up on this tonight. I will look into a new gasket and maybe some PAG oil. I hate to keep trying this if it will turn out bad, but I really think this compressor and maybe even the one connected are fine.

I just checked my readings and they are both at 40 psi. I left them connected and I will check the gauges in the morning.

Thanks for the help

I took apart the compressor that was on the truck. I took it down to the pistons. All seemed fine. In fact it was very difficult to separate the valve plate, which leads me to believe that I don't think the compressor was leaking. The pistons move up and down as I turn the pulley. All seems fine. I will read up on this tonight. I will look into a new gasket and maybe some PAG oil. I hate to keep trying this if it will turn out bad, but I really think this compressor and maybe even the one connected are fine.

I just checked my readings and they are both at 40 psi. I left them connected and I will check the gauges in the morning.

Thanks for the help

#25

I was thinking maybe the expansion valve is stuck open but that idea was shot down by the question being asked in another forum.

Here was their answer:

equal pressure while running, can be only one thing. compressor.

like said above, expansion valve stuck closed will cause a vacuum, stuck open would still provide quite a pressure drop.

Whats confusing to me is why would two different compressors show the same symptoms if it actually is a bad compressor? I would still look at the expansion valve. On the '77s they're a bit of a pain, buried up against the firewall next to the evaporator housing.

Here was their answer:

equal pressure while running, can be only one thing. compressor.

like said above, expansion valve stuck closed will cause a vacuum, stuck open would still provide quite a pressure drop.

Whats confusing to me is why would two different compressors show the same symptoms if it actually is a bad compressor? I would still look at the expansion valve. On the '77s they're a bit of a pain, buried up against the firewall next to the evaporator housing.

#26

First off. Thanks for sticking with me.

I just checked the gauges after sitting overnight. Same pressures. I checked to see if I messed up on the high/low side. I did not. The clutch does engage when adding the Freon. I was planning on taking every hose off today to see if something was blocked. Mikes suggestion seems good to me. Once I get some sunlight I will get started. Thanks

I just checked the gauges after sitting overnight. Same pressures. I checked to see if I messed up on the high/low side. I did not. The clutch does engage when adding the Freon. I was planning on taking every hose off today to see if something was blocked. Mikes suggestion seems good to me. Once I get some sunlight I will get started. Thanks

#27

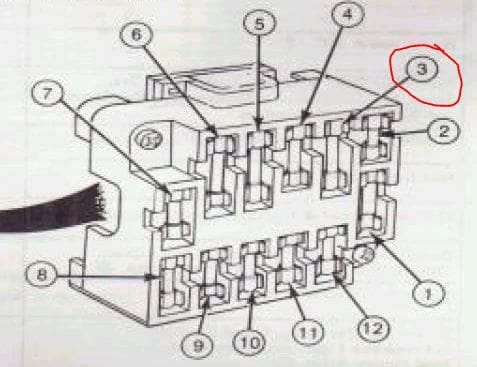

I took apart all the hoses and fittings and then reconnected everything. I vacuumed out the system for 1.5 hours. I charged the system and got COLD air. VERY HAPPY. While playing around with the truck and turning on and off, I noticed no more cold air. I checked the clutch and there is no power. I have checked all the fuses and they are fine. I will now start to research why I have no power at the clutch.

FROM KEGGER66

2. When I hooked, what I think is the AC wire up and switched from Vent to AC the fuse blew. I switched back to Vent and replaced the fuse (35amp), worked fine - switched to AC - fuse blew again.

3. I UNHOOKED the wire at the compressor, put a new fuse in and have it on Vent. I could move to AC and back to Vent multiple times with no issue.

4. I then put a multimeter on the "AC Wire" while it was switched to AC to see if I could read anything. Fuse blew...

I do not see a fuse on mine. I will go take the harness apart that runs through the firewall.

FROM KEGGER66

2. When I hooked, what I think is the AC wire up and switched from Vent to AC the fuse blew. I switched back to Vent and replaced the fuse (35amp), worked fine - switched to AC - fuse blew again.

3. I UNHOOKED the wire at the compressor, put a new fuse in and have it on Vent. I could move to AC and back to Vent multiple times with no issue.

4. I then put a multimeter on the "AC Wire" while it was switched to AC to see if I could read anything. Fuse blew...

I do not see a fuse on mine. I will go take the harness apart that runs through the firewall.

Last edited by benbuilder; 07-02-2016 at 08:39 AM. Reason: did some research

#28

#29

#30