Torque Converter Wont Full Seat on C6

#1

Torque Converter Wont Full Seat on C6

Ok, I am in the middle of a engine swap and I have had the new engine in the truck twice and back out. The torque converter studs are hitting the flywheel. I have done this many times and am not new to putting a tranny in a vehicle. But for some reason this torque converter isnt going all the way up and I cant figure it out. Maybe I am missing something so I wanted to see if anyone else has had this problem. It is going on on a definite two clicks for the splines and after measuring it has a good half inch from the mounting surface to the studs and you can run a straight edge across and not hit the snout which at first glance seems fine, but if you measure from the blocks mating surface out its a full 1" to the flywheels mating surface so I need another half inch somewhere. I have spun the converter till my hands were tired, taken it back off and put it on and I am getting nowhere fast. It is the factory converter that came in this truck, All I am doing is switching from a 302 to 351 and I have two flywheels but both appear to have the same dimensions and yes they are both for a 351 and the one on the old 302 measures out the same as well. The only thing I can think is that the flat keyways are not lining up for the front pump to mate up but why? It came off of this vehicle so why wont it go back on? IF someone has experience with this please tell me what to try. I am at a loss here.

#2

Join Date: Mar 2005

Location: Marlboro Mental Hospital.

Posts: 60,970

Received 3,100 Likes

on

2,162 Posts

#3

Because it's a tight fit. If there is ANY damage on the end of the converter it's not going to go in. I've seen where a converter wouldn't seat into the pump, and all we could find was the tiniest nick on the end of the converter. We filed the nick flat and it went right in.

#4

Yes there is a fairly thin steel block plate and it is in place but I need a half inch.

Mark, I will take a look at the converter to see if I can see any bumps or burs on it. I did have to pull the old engine with it still attached so it could have bumped something but I had my hands all over it yesterday and didnt feel anything out of the ordinary and I did eyeball it quite a lot trying to figure it out. But so far thats the best answer I have. lol...

Mark, I will take a look at the converter to see if I can see any bumps or burs on it. I did have to pull the old engine with it still attached so it could have bumped something but I had my hands all over it yesterday and didnt feel anything out of the ordinary and I did eyeball it quite a lot trying to figure it out. But so far thats the best answer I have. lol...

#6

#7

Trending Topics

#8

Ok.. So I am clear which part is the part that i am looking at for damage? The part with the two flat keywas on the snout? or one of the splined pieces? I did take the rod out that is splined on both ends and it seemed to fit in the torque converter cleanly. I am usually messing with manual transmissions. I am not an idiot with automatics but I am also not real familiar with exactly which parts do what on them.

#9

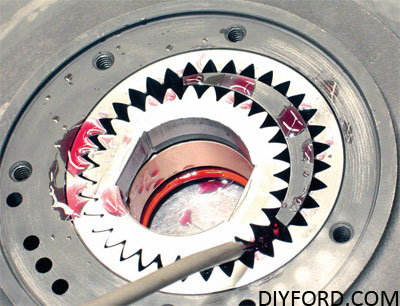

This is what the transmission pump looks like. Those flat spots on the inside "gear" is where the torque converter seats.

By pulling the engine with the torque converter still attached, you very well could have damaged/broken the pump. They're more fragile than you'd think.

This picture is obviously with the pump removed from the case, and opened up. You can't see the pump without disassembly. You might be able to see a little bit of it by pulling the torque converter and shining a light in there, but I don't know that you'd be able to see enough to say go/no go.

#10

You need to make sure the center shaft did get put back all the way. Now the TC studs have to line up with the holes in the flex plate. They will stick through the flex plate by about a 1/2 inch when the trans is up tight against the back of the engine. It's not like a GM tranny where there is space between the TC and the flex plate. Do you have the separator plate in place the flat metal plate that goes between the engine and tranny.

#11

You need to make sure the center shaft did get put back all the way. Now the TC studs have to line up with the holes in the flex plate. They will stick through the flex plate by about a 1/2 inch when the trans is up tight against the back of the engine. It's not like a GM tranny where there is space between the TC and the flex plate. Do you have the separator plate in place the flat metal plate that goes between the engine and tranny.

I can't find my teaching notes at the moment but the input shaft might be in backwards, causing this issue. It's been a while since I've busted my knuckles on a C6 but this sounds like the flexplate may be off dimensionally or the new engine could have a pilot bushing for a manual transmission still in place in the tail of the crank.

Check the hub of the converter for damage and the snout that indexes into the crank. Do a visual of the pump gears if you can. Actually, it wouldn't hurt to try to put the converter up onto the flexplate by itself, just to see if it will go flush to the plate.

Regardless, I would never put an engine and transmission together with no clearance. That's just asking for disaster.

#13

You need to make sure the center shaft did get put back all the way. Now the TC studs have to line up with the holes in the flex plate. They will stick through the flex plate by about a 1/2 inch when the trans is up tight against the back of the engine. It's not like a GM tranny where there is space between the TC and the flex plate. Do you have the separator plate in place the flat metal plate that goes between the engine and tranny.

#14

Oh and no there is not a pilot bushing or bearing in there. That part I am smart enough to do. lol.. Plus if that were the case the studs would never get near the flex plate. This converter has a pretty good snout on it. Its going onto the crank, its the studs that are hitting the flywheel. I can see them and get them close to their holes, but as soon as you even start a bolt to hold the tranny in place they are already touching and your unable to spin the converter. Like I said, I need another 1/2" to have clearance. I agree with the above though, it worries me to try and put it together without clearance. I am going to give everything a visual inspection when I get home and try to see what is going on again. I looked into pulling the front pump and it looks like on the C6/E4OD that is not near as easy as the older transmissions so may not do that. I cant imaging anything happened in there just from taking the engine out. It was working fine before.

#15