Engine Rebuild Part 2

#211

This is what I was going off of:

USA Performance Parts - Erson 6 Cyl Ford Hydraulic Cams

RV10H specifically:

Ford 6 Cyl 240-300 CID Hydraulic Cam & Lifter Kit - 208/208° @.050 .448/.448 li - USA Performance Parts

That makes sense on the advertised vs the @0.050. I kept up with your cam thread over on fordsix for a while, but haven't looked at it in a bit. I'll have to reread it. That'd be cool if there was one that was close to what you were coming up with, and then just tweak it a bit! 110° seems to be an extremely popular lobe separation for the 300. I'm curious why that is.

Either way, I kinda dig that cam. I also like that the greater separation puts less stress on things.

USA Performance Parts - Erson 6 Cyl Ford Hydraulic Cams

RV10H specifically:

Ford 6 Cyl 240-300 CID Hydraulic Cam & Lifter Kit - 208/208° @.050 .448/.448 li - USA Performance Parts

That makes sense on the advertised vs the @0.050. I kept up with your cam thread over on fordsix for a while, but haven't looked at it in a bit. I'll have to reread it. That'd be cool if there was one that was close to what you were coming up with, and then just tweak it a bit! 110° seems to be an extremely popular lobe separation for the 300. I'm curious why that is.

Either way, I kinda dig that cam. I also like that the greater separation puts less stress on things.

Erson-PBM-World B2C | Hydraulic Flat Tappet

I came across mention of the 110* lobe separation in a thread on the sbf six forum. The guy mentioned it as being a carry over from the v8's, enabling the cam co's to cover a broad range of engines, when actually, the 6's are better served with a 108 lsa for low torque.

Oh, up at about 220* duration @.050 is where you'll get a slight lope at idle.

#212

Alright, some updates!

Not much progress has been done on the engine due to him being a bit back logged with projects, but I went in this morning and we got some work done on a few odds and ends.

He called up his contact at S.I. Valves and they still sell the oversized stainless valves for the 300, so we ordered those up and they're on their way. They should be here in a few days. I'm pretty excited about that.

We also ordered up the rebuild kit so that he can get the bearings, rings, gaskets, oil pump, etc. on the way. We'll get the 1 piece oil pan gasket separately. That way we can get the block together and done.

Next, he's going to send off the head to get ported and polished so that he can get the actual bench flow numbers. With those, we can enter all the data into his system and play around with some different cams and get some actual dyno numbers. That way, we can actually see what going from 110° separation to 108° separation would do for a cam.

Otherwise, as far as getting a clutch and using it during balancing, I asked him about that as well and he said it is preference, but he still recommends it simply due to the lack of quality control in parts anymore. He's had a number of "zero balance" flywheels still be 10 - 20 grams off. He only rebalances the clutch components to better match the crank.

Not much progress has been done on the engine due to him being a bit back logged with projects, but I went in this morning and we got some work done on a few odds and ends.

He called up his contact at S.I. Valves and they still sell the oversized stainless valves for the 300, so we ordered those up and they're on their way. They should be here in a few days. I'm pretty excited about that.

We also ordered up the rebuild kit so that he can get the bearings, rings, gaskets, oil pump, etc. on the way. We'll get the 1 piece oil pan gasket separately. That way we can get the block together and done.

Next, he's going to send off the head to get ported and polished so that he can get the actual bench flow numbers. With those, we can enter all the data into his system and play around with some different cams and get some actual dyno numbers. That way, we can actually see what going from 110° separation to 108° separation would do for a cam.

Otherwise, as far as getting a clutch and using it during balancing, I asked him about that as well and he said it is preference, but he still recommends it simply due to the lack of quality control in parts anymore. He's had a number of "zero balance" flywheels still be 10 - 20 grams off. He only rebalances the clutch components to better match the crank.

#213

That's so odd, I called SI valves about 1--1 1/2 years ago and they said there were not handling the 300 oversize valves any longer. I'm glad you checked.

If I were you I'd use the Felpro $50+ head gasket (can't remember the #), and the Mr. Gasket #260 for the intake/exhaust. Make sure you're getting the best. Why skrimp on gaskets, especially the head gasket?

If I were you I'd use the Felpro $50+ head gasket (can't remember the #), and the Mr. Gasket #260 for the intake/exhaust. Make sure you're getting the best. Why skrimp on gaskets, especially the head gasket?

#214

That's so odd, I called SI valves about 1--1 1/2 years ago and they said there were not handling the 300 oversize valves any longer. I'm glad you checked.

If I were you I'd use the Felpro $50+ head gasket (can't remember the #), and the Mr. Gasket #260 for the intake/exhaust. Make sure you're getting the best. Why skrimp on gaskets, especially the head gasket?

If I were you I'd use the Felpro $50+ head gasket (can't remember the #), and the Mr. Gasket #260 for the intake/exhaust. Make sure you're getting the best. Why skrimp on gaskets, especially the head gasket?

I believe the Fel-Pro gasket is a 1024.

For the intake/exhaust gaskets I like the Remflex.FORD Header/Exhaust Manifold Gasket

#215

Yes, I plan on running the Fel-Pro 1024 since it is thinner and is going to get my compression to where I want it.

That Remflex is a pretty interesting looking gasket. I don't believe I've seen that one before. I wonder how it compares to the Mr. Gasket.

And yeah, I'd heard the S.I. valves were discontinued too, but we spoke to them on the phone on speaker phone and ordered them up on the spot. The guy even asked if we wanted the longer or shorter ones since they changed length somewhere along the way. I'm not complaining.

That Remflex is a pretty interesting looking gasket. I don't believe I've seen that one before. I wonder how it compares to the Mr. Gasket.

And yeah, I'd heard the S.I. valves were discontinued too, but we spoke to them on the phone on speaker phone and ordered them up on the spot. The guy even asked if we wanted the longer or shorter ones since they changed length somewhere along the way. I'm not complaining.

#216

Stopped by the machine shop today and got caught up a bit.

Not much has happened lately due to me moving and spending most of my time/money on immediate house projects.

But, the S.I. oversized valves were in, so it was cool to get a look at those.

I didn't get a picture (should have), but we put old against new on both the intake and exhaust. Exhaust wasn't much of a difference, but the intake was a pretty significant difference.

Intake Valves

Stock - 1.78"

Area - 2.488

S.I. - 1.94"

Area - 2.956

Increase: 18.8%

Exhaust Valves

Stock - 1.559"

Area - 1.909

S.I. - 1.60"

Area - 2.011

Increase: 5.3%

Next though is porting and polishing the head. It's going to be about $650 to have it done (and up front), so I have to save up for it. It's on a professional flow bench with a print out of before and after flow numbers, so it should be pretty beneficial.

With that, we'll put the numbers in the computer along with multiple cam profiles and see what works best.

Not much has happened lately due to me moving and spending most of my time/money on immediate house projects.

But, the S.I. oversized valves were in, so it was cool to get a look at those.

I didn't get a picture (should have), but we put old against new on both the intake and exhaust. Exhaust wasn't much of a difference, but the intake was a pretty significant difference.

Intake Valves

Stock - 1.78"

Area - 2.488

S.I. - 1.94"

Area - 2.956

Increase: 18.8%

Exhaust Valves

Stock - 1.559"

Area - 1.909

S.I. - 1.60"

Area - 2.011

Increase: 5.3%

Next though is porting and polishing the head. It's going to be about $650 to have it done (and up front), so I have to save up for it. It's on a professional flow bench with a print out of before and after flow numbers, so it should be pretty beneficial.

With that, we'll put the numbers in the computer along with multiple cam profiles and see what works best.

#217

Alright, a small update.

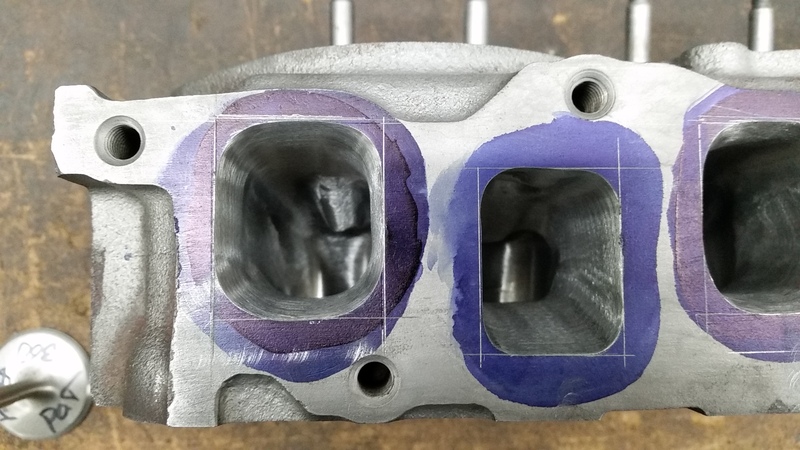

The head has been reground for the oversized valves. It's interesting to see why there really is no point in oversizing the valves if you don't do the work to open up the ports. This first pic you can see the ridge in the port where they started widening it to make room for the valve. He showed me another head that had had the same thing done, but was post-porting, and it looked great. (Didn't take a pic though, but I definitely will when mine comes back).

For curiosity's sake, I put the old valves in on the right and the new ones in on the left.

New Valves:

Old Valves:

He also now has all that he needs to balance it all, so that's next.

The head has been reground for the oversized valves. It's interesting to see why there really is no point in oversizing the valves if you don't do the work to open up the ports. This first pic you can see the ridge in the port where they started widening it to make room for the valve. He showed me another head that had had the same thing done, but was post-porting, and it looked great. (Didn't take a pic though, but I definitely will when mine comes back).

For curiosity's sake, I put the old valves in on the right and the new ones in on the left.

New Valves:

Old Valves:

He also now has all that he needs to balance it all, so that's next.

#219

Great. It's funny: In some of those pix it looks as though you have a ridge from 4 o'clock on the exh. valve to 8 o'clock on the int, and in some pix I can see it is not there.

I would only say that if you do have that ridge, I'd remove it as in the photo I am posting of pmuller9's chamber. He removed the ridge. The other chamber is mine, with the ridge and over-size valves. Simple logic says the ridge hinders flow. Thx for the update.

I would only say that if you do have that ridge, I'd remove it as in the photo I am posting of pmuller9's chamber. He removed the ridge. The other chamber is mine, with the ridge and over-size valves. Simple logic says the ridge hinders flow. Thx for the update.

#220

#221

Alrighty, a slew of updates!

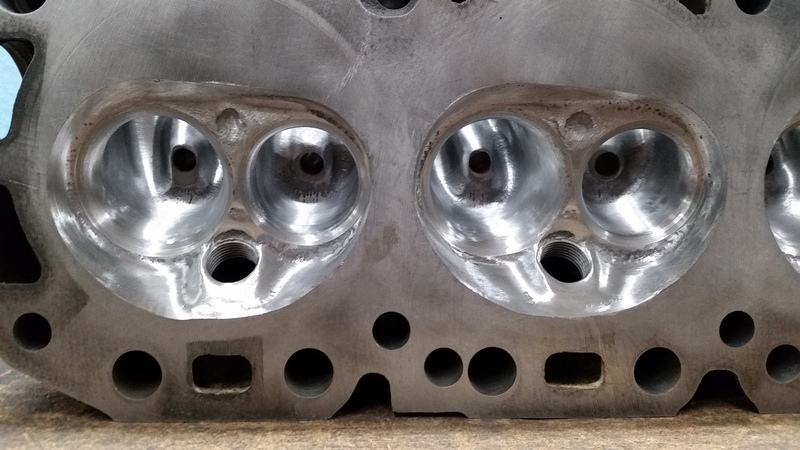

First off, the head is ported and polished, and it looks amazing.

Before:

After:

And some more pics:

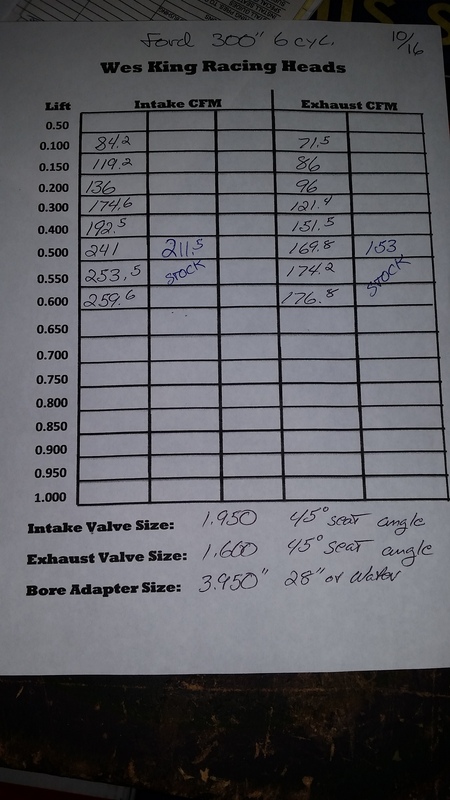

The head was also supplied with some flow numbers.

Unfortunately, they only did 0.500 lift on the stock head (it've been interesting to see all of it), but it's still a great comparison:

Intake had an increase of 14% and exhaust had an increase of 11%. My builder said that's more than most people could even hope for, so I should be very pleased.

Lastly, we settled on a cam. My builder ran some numbers and then passed the flow ratings by Erson, as well as the mods I have and they highly suggested an Erson E270321.

"Works great in slightly modified engines with up to 9.5:1 compression. High-lift and short duration builds good torque and mid-range performance."

Duration:

Advertised:

Intake: 284°

Exhaust: 284°

@0.050:

Intake: 214°

Exhaust: 214°

Gross Lift:

Intake: 0.478"

Exhaust: 0.478"

Lobe Center

110°

Advance:

4°

Still some more things to do, such as balancing it all, putting screw in adjustable rocker studs in, etc. but it's getting closer!

First off, the head is ported and polished, and it looks amazing.

Before:

After:

And some more pics:

The head was also supplied with some flow numbers.

Unfortunately, they only did 0.500 lift on the stock head (it've been interesting to see all of it), but it's still a great comparison:

Intake had an increase of 14% and exhaust had an increase of 11%. My builder said that's more than most people could even hope for, so I should be very pleased.

Lastly, we settled on a cam. My builder ran some numbers and then passed the flow ratings by Erson, as well as the mods I have and they highly suggested an Erson E270321.

"Works great in slightly modified engines with up to 9.5:1 compression. High-lift and short duration builds good torque and mid-range performance."

Duration:

Advertised:

Intake: 284°

Exhaust: 284°

@0.050:

Intake: 214°

Exhaust: 214°

Gross Lift:

Intake: 0.478"

Exhaust: 0.478"

Lobe Center

110°

Advance:

4°

Still some more things to do, such as balancing it all, putting screw in adjustable rocker studs in, etc. but it's getting closer!

#223