1950 ford f1 226 hard start issues

#16

JD, I just google searched generic parts terms and found part numbers. Then googled the part numbers. Ebay and Amazon have most of what you may need. Usually with free shipping.

I got all my starter parts from several sources and it totaled about $32. I didn't need an armature or coils though. Bushings, brushes, terminal and insulator and a fiber thrust washer.

I got all my starter parts from several sources and it totaled about $32. I didn't need an armature or coils though. Bushings, brushes, terminal and insulator and a fiber thrust washer.

#17

I have been buying the nos starter parts as they have shown up on eBay over the last several months. I even bought a 1/2 drive square bit to remove the coil bolts and a 300 watt solder gun for the pole screw. When I have another free morning I am going to tackle the swap out. I can tell by looking at the one in the truck its a mess on the inside. If it's like everything else I have repaired it's full of grease, rust, sand. It has to be gummed up inside with the road draft tube right there beside it.

JB

JB

#19

I had put new #00 battery cables, battery tested good, good grounds and still cranked slow.

Opened starter and it looked like it got pulled off the Titanic. I'm surprised it worked at all. I got lucky as all it needed was a clean up, brushes, bushings and a new post. Works great.

I agree with the Volt drop test. I should have specified. Good catch.

Opened starter and it looked like it got pulled off the Titanic. I'm surprised it worked at all. I got lucky as all it needed was a clean up, brushes, bushings and a new post. Works great.

I agree with the Volt drop test. I should have specified. Good catch.

#21

No didn't have to pull pan. Mine is on a 239 V8 Flathead if that matters.

Just two mounting bolts that ran through the starter. One ran through an angle bracket that bolts to the pan with one of the pan bolts. Supports the end of the starter.

The mounting bolts also hold the starter together. You can thread a couple nuts on to hold things together once you get it out.

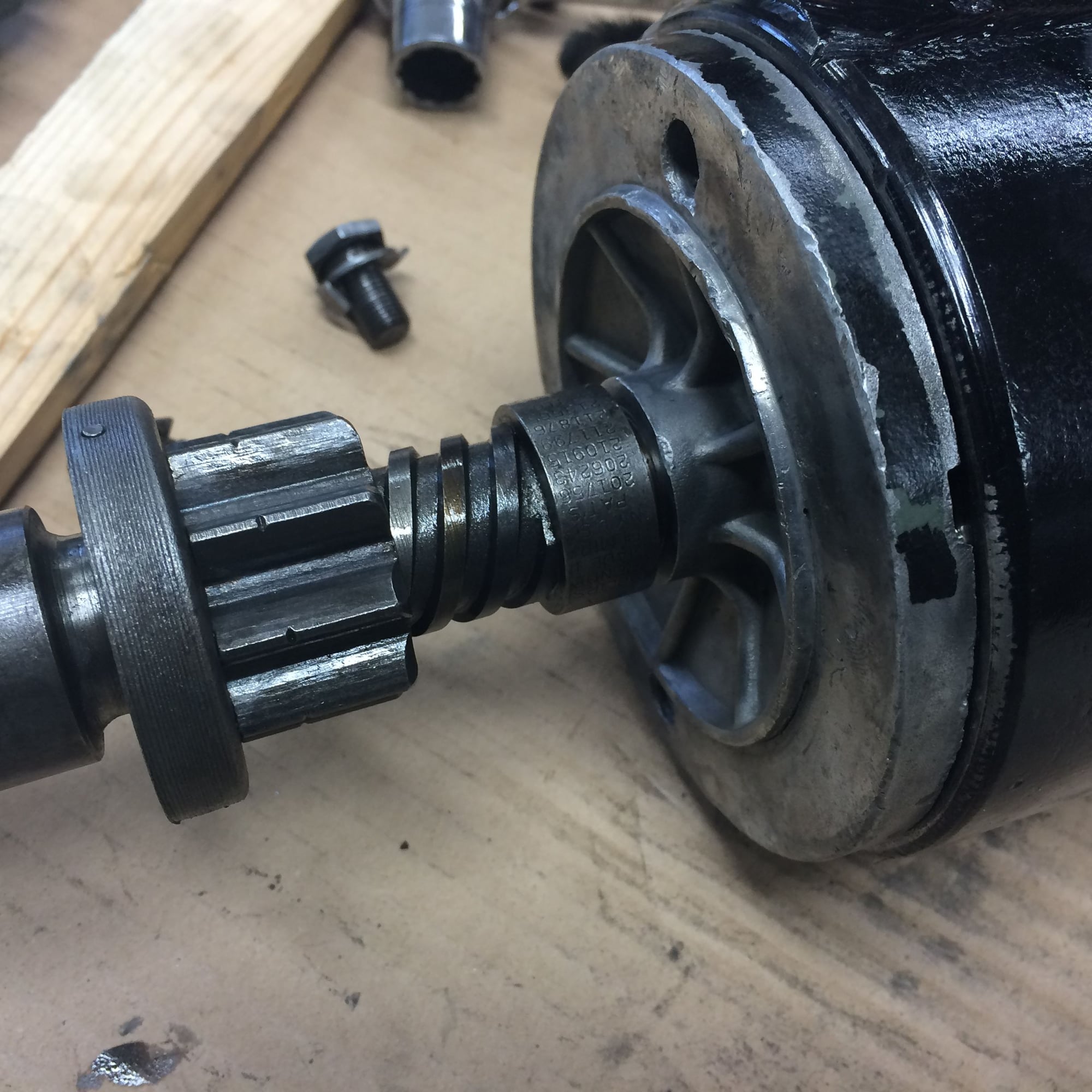

You have to "manipulate" the starter to get the Bendix to clear as it comes out. Otherwise very easy.

Just two mounting bolts that ran through the starter. One ran through an angle bracket that bolts to the pan with one of the pan bolts. Supports the end of the starter.

The mounting bolts also hold the starter together. You can thread a couple nuts on to hold things together once you get it out.

You have to "manipulate" the starter to get the Bendix to clear as it comes out. Otherwise very easy.

#22

So I did what I think is a correct voltage drop test. Voltage at battery was 6.36. Voltage on crank on battery to relay pole 6.36. Voltage on crank on starter relay pole around 5.9. Voltage on starter motor pole on crank 4.85. So I think I am losing about 1.5 volts across the connections. Did I do my tests correctly and does my starter motor cable sound like the culprit?

JB

JB

#23

#25

For example: Disable engine from starting. Place one probe on the negative post of the battery, place the other on a clean, unpainted surface on the starter. Crank the engine over for a few seconds. Ideally we want to see zero volts, but up to +0.2 (two tenths) of a volt is considered acceptable. This positive voltage represents the amount of voltage drop in the circuit being tested. Doesn't sound like much, but it is. And of course, this is cumulative. Testing the positive side of the starter circuit is done the same way. A total of +0.4 volts or so is the limit.

Each individual connection can be tested to see where the bottleneck is - say between the battery post and the battery terminal, or the terminal and cable, etc.

#28

If you form an edge tapping them in you may have to remove that but, I have never reamed them either.

You can press them in with a vise if you don't have an actual press. Bushing driver with hammer.

If the shaft doesn't spin freely after getting them in you probably rolled a little lip on it. take it out with emery cloth or edge of a knife.

You can press them in with a vise if you don't have an actual press. Bushing driver with hammer.

If the shaft doesn't spin freely after getting them in you probably rolled a little lip on it. take it out with emery cloth or edge of a knife.

#30