The "I hate FTE" shop truck build

#46

Notmeofficer, If I remember correctly, you are the gentleman I bought a pair of fenders from for my '73. I remember seeing your shop and c couple of your projects. I had the blue green bronco. That is, of course, supposing I am not seeing things! I read throughout the thread and am enjoying your work.

Small world of Ford truck owners!!!!

#47

#51

#52

If you're curious, I fixed the steering; turns out the adjustment nut on the spool bolt was not snugged down properly, it was simply on a tight spot. I snugged it down properly, and backed it off the requisite quarter turn. Valve is completely leak free, ram is close to that, and the pump works perfect.

Ok.. its Thanksgiving.. and momma day for all of those of us who are married.. but Ill sneak in some time today on the FTE truck

Today... rear tank install

and... worked on the door logos for the truck.. experimented with different paints for lettering for an old school "aged" look. All the paint will be mat..so I also experimented with flattening it out old school using talc (which unlike cornstarch does not absorb water)... by using a marble in the spray gun it keeps the talc in suspension

Heres the logo

Also got both tanks all done in the Oregon Oakie build truck.. which sounds easy peasey.. but Im not sure some understand.. parts come off our trucks pretty easily with air guns but take finesse to go back on correctly.. a lifetime of use makes some parts not the exact fit they were brand new (like they ever were) going back on.. doing it correctly.. adding the tank insulation.. getting the lines to line up properly.. detail detail detail.. that will never get seen.

Save a turkey eat tofu.. pics later

postscript..

I forgot to add .. "Mater".. Mater is a favorite around my shop.. my wife is a Disney aficionado and has run every Disney race there ever has been... over 100 marathons,, so when I told her select something Disney I can use for my builds and Ill incorporate it.. Mater immediately came up.. which lead to the "Son of Mater" tow truck build sitting in the back of the shop...(and she happily rode around in when it was running on seven cylinders when I brought it home.. now it has a hotrod 460 puller motor in it))

The first order of business was getting all the doo-dads.. the non functional stacks and a rats nest of mismatched markers off it (but I have coveted the original ford upper markers.. they are real and not repo's)

And here the body is blasted and the dented corners have all been repaired from a lifetime of towing.. cut them out and added formed diamond plate

Frame blasted and painted.. every piece new or "news'd" underneath...

I had to build the shop crane in the background just to get the body off.. which led me to buy a forklift.. the sickness never stops

Of course it has the signature Ford headliner that is in all my builds (which is Ford fleece material that I stretch over the plastic aftermarket headliners)

but..I digress.. and another build for another day

If you're married and your smart.. incorporate your significant other into your builds and when the checking account gets drained there wont be any sparks... well.. maybe just a couple... ;-)

Goals this month.. get the FTE truck to rolling chassis if at all possible.. AIRBAGIT is slowing me down with sending me the wrong parts over and over for lowering...

#54

OK ... I was able to install the rear tank before momma started cooking.. but the fresh corn cake smell plied me away.. so no more truckensteining for the day

Note to self.. I forgot that FORD tanks only like to get installed from the bottom ..which I figured out after scratching everything... ok.. no sweat.. there will be a number of coats of flat before Im done

I used sound deadening strips for the tank mounting points top and bottom.... the original fiber stuff is hard to source...and falls apart over time... sound deadening mat is asphalt based.. sticks well,, doesnt absorb water or munge and provides a decent barrier between the tank and the strap.

I had to remove the trailer hitch to put the tank up in the hole.. that took the most time...

Its family time.... truck dreams put to bed for now...

Thanksgiving at my place is a safe zone for the turkeys... they live here... we dont eat them..

Note to self.. I forgot that FORD tanks only like to get installed from the bottom ..which I figured out after scratching everything... ok.. no sweat.. there will be a number of coats of flat before Im done

I used sound deadening strips for the tank mounting points top and bottom.... the original fiber stuff is hard to source...and falls apart over time... sound deadening mat is asphalt based.. sticks well,, doesnt absorb water or munge and provides a decent barrier between the tank and the strap.

I had to remove the trailer hitch to put the tank up in the hole.. that took the most time...

Its family time.... truck dreams put to bed for now...

Thanksgiving at my place is a safe zone for the turkeys... they live here... we dont eat them..

#55

Ok.. some blasting

Blasting always reveals the sins underneath

In my case I found that one of the inner fenders has some stress cracks in it.. as well as broken radiator support spot welds to the core...easy to understand after a lifetime of moving around... I welded them up better than the factory (because I had the time and wasnt a robot... they will never break again)

I have a BB-950 (Badboys Blaster) with AMERICAN made 1/8" inch tips and a 10hp two stage air compressor... I runs constantly when blasting but does an admirable job... I open blast but this year I took a bed liner out of one of the parts trucks and made it my blast area... now with a screen I can recycle about 80 percent of the material. Before with Chinese junk "wear out" immediately blast tips and open blasting I was using way too much material.. now the pot lasts for about thirty minutes of blasting... two pots does everything you see in these pictures... its the crevices and corners that take the most time... the paint comes off like butter. I have an extra set of OEM plastic add on fender liners and Ill probably put a set on during the build up. I have also used the aftermarket ones and I fought them and fought them with a hair dryer and still arent happy with them (my tow truck had them and the inner fenders were still like new)

The sheetmetal was really nice on this truck and the inner surface rust from a life of getting hit with road gunge came right off

I like very understated sheet metal so I filled the F-250 badge holes... and did a little hammer and dolly work taking out the little ding you can spot on the lower right front fender area above the bodyline... a couple of light taps and it popped right out,,no filler needed (which I always prefer). I also removed all the trim studs and will make a decision today whether Im going to put trim back on..or not. Ive never liked the way Ford attaches their trim and I have an idea in the back of my mind to use bolts from the back side and finish with stainless acorn cap nuts.. a little detail.. in my mind anyway

Time consuming mind numbing slowness of a build....

Rough finish with a flap disc.. a little work with a mini scotchbrite grinder and you will never know something was done

More of the same today....

Blasting always reveals the sins underneath

In my case I found that one of the inner fenders has some stress cracks in it.. as well as broken radiator support spot welds to the core...easy to understand after a lifetime of moving around... I welded them up better than the factory (because I had the time and wasnt a robot... they will never break again)

I have a BB-950 (Badboys Blaster) with AMERICAN made 1/8" inch tips and a 10hp two stage air compressor... I runs constantly when blasting but does an admirable job... I open blast but this year I took a bed liner out of one of the parts trucks and made it my blast area... now with a screen I can recycle about 80 percent of the material. Before with Chinese junk "wear out" immediately blast tips and open blasting I was using way too much material.. now the pot lasts for about thirty minutes of blasting... two pots does everything you see in these pictures... its the crevices and corners that take the most time... the paint comes off like butter. I have an extra set of OEM plastic add on fender liners and Ill probably put a set on during the build up. I have also used the aftermarket ones and I fought them and fought them with a hair dryer and still arent happy with them (my tow truck had them and the inner fenders were still like new)

The sheetmetal was really nice on this truck and the inner surface rust from a life of getting hit with road gunge came right off

I like very understated sheet metal so I filled the F-250 badge holes... and did a little hammer and dolly work taking out the little ding you can spot on the lower right front fender area above the bodyline... a couple of light taps and it popped right out,,no filler needed (which I always prefer). I also removed all the trim studs and will make a decision today whether Im going to put trim back on..or not. Ive never liked the way Ford attaches their trim and I have an idea in the back of my mind to use bolts from the back side and finish with stainless acorn cap nuts.. a little detail.. in my mind anyway

Time consuming mind numbing slowness of a build....

Rough finish with a flap disc.. a little work with a mini scotchbrite grinder and you will never know something was done

More of the same today....

#57

As to hydroboost and 4wdb... Some people have proportioning issues.. A proportioning valve can solve this.. Or adaping a master from a 4wdb vehicle... P series Chevy vans.. F 450s.. Etc.. But that's a bit of trial and error..adapting or making fittings .. Pushrod length..etc

There is a company that makes a hydroboost conversion specifically for our trucks with all new parts (with brakes I like new parts as stopping in an emergency is the most important thing to me about vehicle operation)... They however specifically say it's not for 4wdbs... Because of the factory proportioning in the unit itself . I think I might use a Clark 5 speed in my 79 f350 tow truck resto "son of mater" ... It has the f600 parking brake on the drive shaft... But..another build thread for another day

Hydro is absolutely a great conversion and high priority on this build and the Oregon oakie truck 4 wd I'm building too

My stuff are all built as driver trucks..not purdy queens.. I want it clean and sano..I want it to run excellently.. I don't like chrome..

Thanks

I agree with the Hydroboost being a great mod and will be the next mod done to my truck. I also agree with NEW parts when it comes to brakes. I had thought about doing a JY conversion, but figured that a NEW, engineered SYSTEM for my application would be a better option for me. I would not want something to malfunction that I may have overlooked with my wife or kids in the truck. I have done TONS of research and talked to all of the major companies that offer conversions and have settled on one to work with. I will do a complete review of the kit as well as install thread when it goes in. They offer a complete kit, that will bolt in to my truck as well as support if needed.

One thing that you touched on that I have discovered is the master cylinder is critical. A lot of people that do this mod (as myself) currently have front disc/rear drum but will be going to rear disc in the future requiring either a change now, or in the future. One of the most popular master cylinders for this application is the 1977-1982 master cylinder off of a Corvette. This one will accommodate any combination of brakes and is very common on Hydroboost setups because of its flexibility. Although I am not crazy about all the chrome (I too want sano, but not a show truck), I will be going with CPP's MCPV-1 master cylinder as it also accommodates any braking configuration, but also has a built in proportioning valve, to clean up the install.

#58

Built not bought...!!! way to go

Ok.. its Thanksgiving.. and momma day for all of those of us who are married.. but Ill sneak in some time today on the FTE truck

Today... rear tank install

and... worked on the door logos for the truck.. experimented with different paints for lettering for an old school "aged" look. All the paint will be mat..so I also experimented with flattening it out old school using talc (which unlike cornstarch does not absorb water)... by using a marble in the spray gun it keeps the talc in suspension

Heres the logo

Also got both tanks all done in the Oregon Oakie build truck.. which sounds easy peasey.. but Im not sure some understand.. parts come off our trucks pretty easily with air guns but take finesse to go back on correctly.. a lifetime of use makes some parts not the exact fit they were brand new (like they ever were) going back on.. doing it correctly.. adding the tank insulation.. getting the lines to line up properly.. detail detail detail.. that will never get seen.

Save a turkey eat tofu.. pics later

postscript..

I forgot to add .. "Mater".. Mater is a favorite around my shop.. my wife is a Disney aficionado and has run every Disney race there ever has been... over 100 marathons,, so when I told her select something Disney I can use for my builds and Ill incorporate it.. Mater immediately came up.. which lead to the "Son of Mater" tow truck build sitting in the back of the shop...(and she happily rode around in when it was running on seven cylinders when I brought it home.. now it has a hotrod 460 puller motor in it))

The first order of business was getting all the doo-dads.. the non functional stacks and a rats nest of mismatched markers off it (but I have coveted the original ford upper markers.. they are real and not repo's)

And here the body is blasted and the dented corners have all been repaired from a lifetime of towing.. cut them out and added formed diamond plate

Frame blasted and painted.. every piece new or "news'd" underneath...

I had to build the shop crane in the background just to get the body off.. which led me to buy a forklift.. the sickness never stops

Of course it has the signature Ford headliner that is in all my builds (which is Ford fleece material that I stretch over the plastic aftermarket headliners)

but..I digress.. and another build for another day

If you're married and your smart.. incorporate your significant other into your builds and when the checking account gets drained there wont be any sparks... well.. maybe just a couple... ;-)

Goals this month.. get the FTE truck to rolling chassis if at all possible.. AIRBAGIT is slowing me down with sending me the wrong parts over and over for lowering...

Ok.. its Thanksgiving.. and momma day for all of those of us who are married.. but Ill sneak in some time today on the FTE truck

Today... rear tank install

and... worked on the door logos for the truck.. experimented with different paints for lettering for an old school "aged" look. All the paint will be mat..so I also experimented with flattening it out old school using talc (which unlike cornstarch does not absorb water)... by using a marble in the spray gun it keeps the talc in suspension

Heres the logo

Also got both tanks all done in the Oregon Oakie build truck.. which sounds easy peasey.. but Im not sure some understand.. parts come off our trucks pretty easily with air guns but take finesse to go back on correctly.. a lifetime of use makes some parts not the exact fit they were brand new (like they ever were) going back on.. doing it correctly.. adding the tank insulation.. getting the lines to line up properly.. detail detail detail.. that will never get seen.

Save a turkey eat tofu.. pics later

postscript..

I forgot to add .. "Mater".. Mater is a favorite around my shop.. my wife is a Disney aficionado and has run every Disney race there ever has been... over 100 marathons,, so when I told her select something Disney I can use for my builds and Ill incorporate it.. Mater immediately came up.. which lead to the "Son of Mater" tow truck build sitting in the back of the shop...(and she happily rode around in when it was running on seven cylinders when I brought it home.. now it has a hotrod 460 puller motor in it))

The first order of business was getting all the doo-dads.. the non functional stacks and a rats nest of mismatched markers off it (but I have coveted the original ford upper markers.. they are real and not repo's)

And here the body is blasted and the dented corners have all been repaired from a lifetime of towing.. cut them out and added formed diamond plate

Frame blasted and painted.. every piece new or "news'd" underneath...

I had to build the shop crane in the background just to get the body off.. which led me to buy a forklift.. the sickness never stops

Of course it has the signature Ford headliner that is in all my builds (which is Ford fleece material that I stretch over the plastic aftermarket headliners)

but..I digress.. and another build for another day

If you're married and your smart.. incorporate your significant other into your builds and when the checking account gets drained there wont be any sparks... well.. maybe just a couple... ;-)

Goals this month.. get the FTE truck to rolling chassis if at all possible.. AIRBAGIT is slowing me down with sending me the wrong parts over and over for lowering...

#59

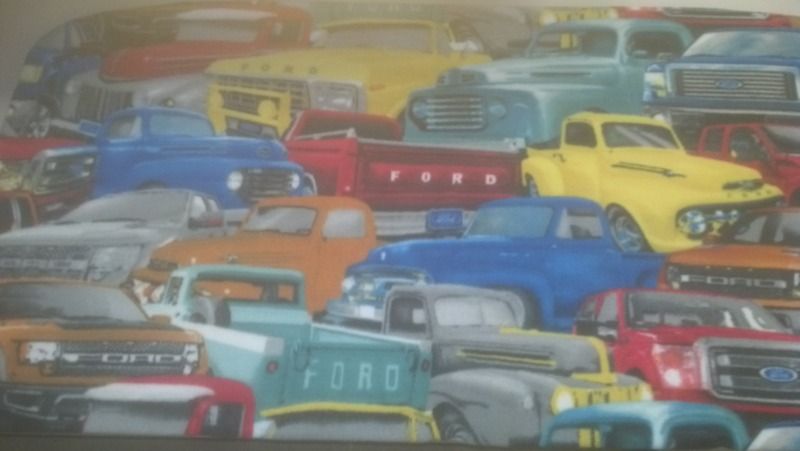

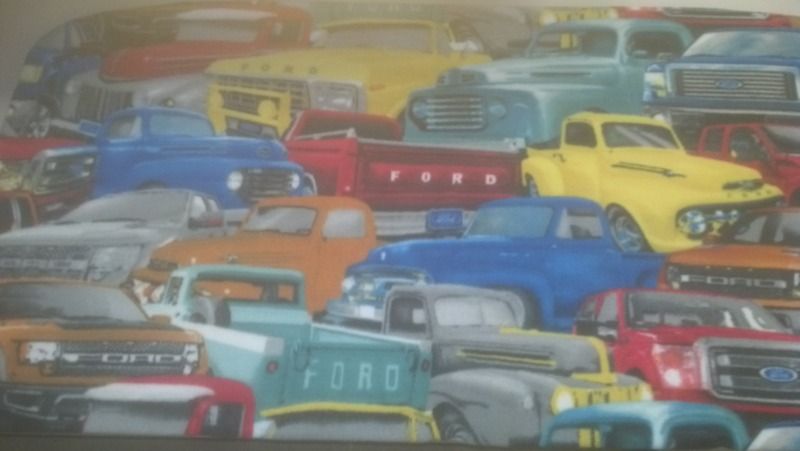

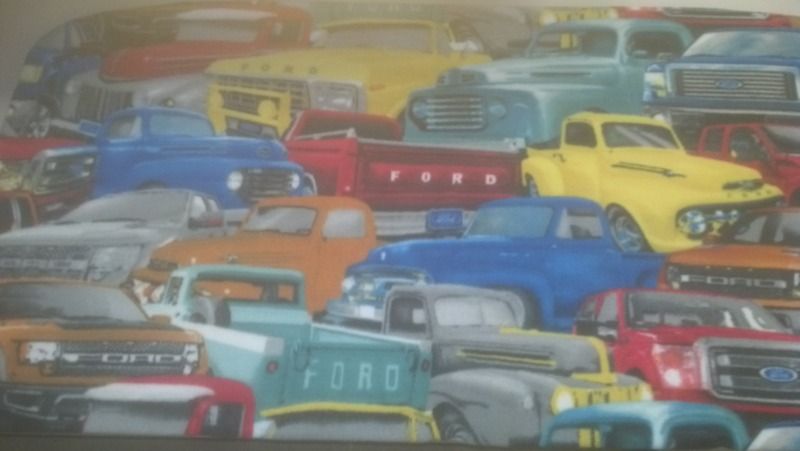

I gotta say that I really like this truck and that Ford fleece headliner. Would really like to see the completed project. If it were my truck, I'd keep those old flareside taillights that are at the top of the cab. They look awesome on there. Also I find it particularly hard to find anything Ford related that shows either a dentside or a bullnose truck let alone both in the same print. That fleece is awesome. Keep up the good work on both builds.

https://www.fabric.com/buy/0308399/p...-allover-multi

And we are in agreement with the ford tailights... as well as the gumball.. which I rebuilt and found a NOS lens for.. I love hearing the motor wiring and the lights going around super slow