Cylinder head find, bust or a treasure?

#16

The machine shop is done with the head and I should be able to pick it up tomorrow.

I aquirred a "new to me" offy c to add to the mixmix with studs. Have some felpro intake/ exhaust gaskets ready but are their better options?

Pretty sure I'll have to get some pushrods too. But am not 100% on that yet.

I've never done a head change before but am not scared of it since I recently picked up a used 325i and no longer am required to have the truck back together daily. I Plan on following a Haynes manual for the install but is their anything that I should pay particular attention to. Best head gasket, should I use new head bolts, any solvents or soaking/trimming of the gaskets recommended?

I aquirred a "new to me" offy c to add to the mixmix with studs. Have some felpro intake/ exhaust gaskets ready but are their better options?

Pretty sure I'll have to get some pushrods too. But am not 100% on that yet.

I've never done a head change before but am not scared of it since I recently picked up a used 325i and no longer am required to have the truck back together daily. I Plan on following a Haynes manual for the install but is their anything that I should pay particular attention to. Best head gasket, should I use new head bolts, any solvents or soaking/trimming of the gaskets recommended?

#17

The biggest issue you'll run into when installing the head is how heavy it is. It's a LONG reach out into the engine bay with that head in your hands. Trying to put it out there without damaging the headgasket is not easy. Granted, having an engine hoist negates all that since you can just chain it up and swing it out.

If you don't have one, this is how I did it:

If you don't have one, this is how I did it:

#19

I picked up a #260 gasket, thanks. Still waiting on the head though. They said it'd be done, its not, you all know the story.

Anyways, I'm trying to make sure that I'm ready when it is done and the only thing that I'm questioning is pushrods.

Will I need to or would it be wise for me to get some new and stronger pushrods?

Anyways, I'm trying to make sure that I'm ready when it is done and the only thing that I'm questioning is pushrods.

Will I need to or would it be wise for me to get some new and stronger pushrods?

#20

You really should get a push rod length checking tool. With a head that is unknown ( as far as the amount it has been decked in the past ) you might need custom length pushrods to keep the correct valvetrain geometry. I wouldn't buy new ones until you confirm the length that is needed.

#21

I agree that the lengths will have to be determined and I will be borrowing a length tool to figure that out. What I'm asking is if its worth it to buck up and get chromoly versus steel? I know that the chromoly is more expensive but don't really know the benefits, if it's worth it or needed.

#22

#23

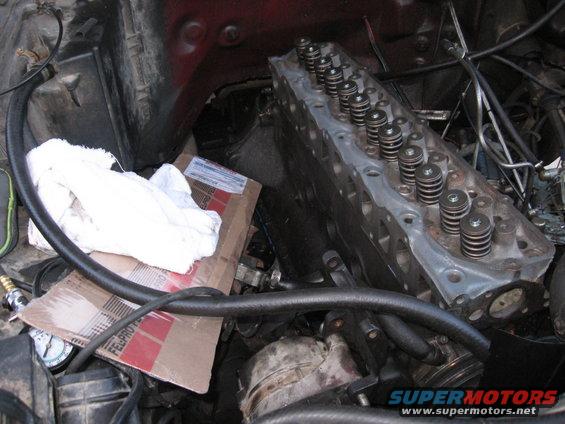

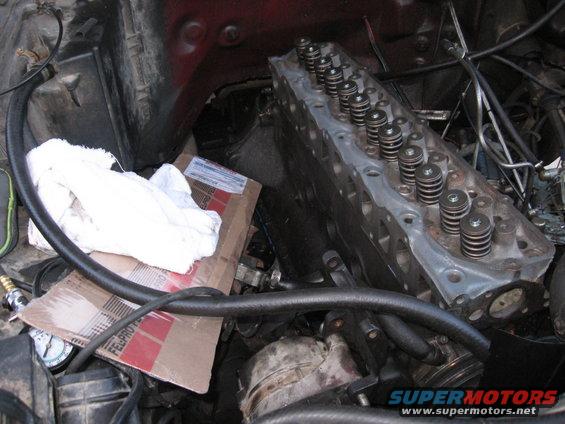

I made some headway today as far as getting this done. My guy has been ill and I've been patient.

The head is cleaned up, reseated and done as far as machining goes.

The issues delaying now:

1: the machinists can't find 1.73 rocker arms that fit the 7/16 studs. Switch to 3/8 or are they available in 7/16th?

2: roller tipped or full roller? He claims about $100 difference and durability as a bonus. Any performance advantage worth $100 for tipped versus full roller?

3: the previously stated pushrod length that I will deal with later. Race shops everywhere here in Charlotte so I'll be able to get some off a shelf somewhere when I need them. Pushrod length check tool to be acquired. Gonna cross my fingers and hope new 3/8 will clear or that the passages had already previously been cut. Thanks for the heads up on that.

The head is cleaned up, reseated and done as far as machining goes.

The issues delaying now:

1: the machinists can't find 1.73 rocker arms that fit the 7/16 studs. Switch to 3/8 or are they available in 7/16th?

2: roller tipped or full roller? He claims about $100 difference and durability as a bonus. Any performance advantage worth $100 for tipped versus full roller?

3: the previously stated pushrod length that I will deal with later. Race shops everywhere here in Charlotte so I'll be able to get some off a shelf somewhere when I need them. Pushrod length check tool to be acquired. Gonna cross my fingers and hope new 3/8 will clear or that the passages had already previously been cut. Thanks for the heads up on that.

#24

#27

#29

That lifts me out of a deep depression. I almost cried when it happened. I was all set to get everything back together and measure the pushrods for ordering.

That's what I get for trying to save a buck. It was the first one I attempted so I'm not risking anymore. I will be ordering the comp cams 1823-16 rockers now that pmuller had suggested as they fit the 7/16th. I found an 8 pack of rockers and they sell singles on amazon so I won't have to buy 16 of them. I'll just have to save up a little longer now.

That's what I get for trying to save a buck. It was the first one I attempted so I'm not risking anymore. I will be ordering the comp cams 1823-16 rockers now that pmuller had suggested as they fit the 7/16th. I found an 8 pack of rockers and they sell singles on amazon so I won't have to buy 16 of them. I'll just have to save up a little longer now.