First Round Of Mods ... Have Questions

#31

Got it. Drivers side manifold about an inch before it goes into the up-pipe.

Obviously i'll figure it out once i start driving but off hand what are some normal EGT temps? Like around town, just driving your truck, no towing temps?

My other question is for boost. Kit says to cut the MAP line, install T, get boost readings off there. Do this?

Obviously i'll figure it out once i start driving but off hand what are some normal EGT temps? Like around town, just driving your truck, no towing temps?

My other question is for boost. Kit says to cut the MAP line, install T, get boost readings off there. Do this?

Also as far as EGTs go, your thinking about it wrong. My Egts get up to 1150 in town, its all about if your getting up to 1220 for extended periods. If you stay under 1220, your fine. What its doing in town isnt a direct reflection of what itll do towing. When towing theres more load your engine is under and more fuel youll be dumping at higher rpms at lower speeds. So your turbo will spool faster at lower speeds towing. When unloaded your rpms rise slower, and have to dump in less fuel to get u moving. But less fuel=less exhaust to spool turbo. My egts rise faster in town then towing. So now that ive confused the crap out of you, dont worry about how fast they rise, just were they stop. If your hitting 1220 in town, on flat level pavement, even flooring it, you may have an issue.

#32

Ok. Another question.

Just cut my entire stock exhaust off the truck. Only thing still attached is the downpipe. Cut the clamps off the heatshield they have around it and realized how close the downpipe is to the wires on the side of the transmission.

Am i suppose to put the old heatshield around the new downpipe to prevent it from melting these wires or is that a non-issue?

Oh, and the factory downpipe is a pancake. I didn't realize it was that constricted.

The transmission also took a dump, so i think i'm going to buy a tru-cool transmission cooler as well.

On the bright side removing the transmission seems to be a hell of a lot easier with the exhaust out of the way. Haha.

Just cut my entire stock exhaust off the truck. Only thing still attached is the downpipe. Cut the clamps off the heatshield they have around it and realized how close the downpipe is to the wires on the side of the transmission.

Am i suppose to put the old heatshield around the new downpipe to prevent it from melting these wires or is that a non-issue?

Oh, and the factory downpipe is a pancake. I didn't realize it was that constricted.

The transmission also took a dump, so i think i'm going to buy a tru-cool transmission cooler as well.

On the bright side removing the transmission seems to be a hell of a lot easier with the exhaust out of the way. Haha.

#33

Ok. Another question.

Just cut my entire stock exhaust off the truck. Only thing still attached is the downpipe. Cut the clamps off the heatshield they have around it and realized how close the downpipe is to the wires on the side of the transmission.

Am i suppose to put the old heatshield around the new downpipe to prevent it from melting these wires or is that a non-issue?

Oh, and the factory downpipe is a pancake. I didn't realize it was that constricted.

The transmission also took a dump, so i think i'm going to buy a tru-cool transmission cooler as well.

On the bright side removing the transmission seems to be a hell of a lot easier with the exhaust out of the way. Haha.

Just cut my entire stock exhaust off the truck. Only thing still attached is the downpipe. Cut the clamps off the heatshield they have around it and realized how close the downpipe is to the wires on the side of the transmission.

Am i suppose to put the old heatshield around the new downpipe to prevent it from melting these wires or is that a non-issue?

Oh, and the factory downpipe is a pancake. I didn't realize it was that constricted.

The transmission also took a dump, so i think i'm going to buy a tru-cool transmission cooler as well.

On the bright side removing the transmission seems to be a hell of a lot easier with the exhaust out of the way. Haha.

Define tranny took a dump.

#34

I reused the heat shield, it wont fit all the way around the pipe, so just put it on the side of the pipe that the tranny is on to prevent it front directly touching the hot pipe itself. And just use metal hose clamps to reattach it to the pipe.

Define tranny took a dump.

Define tranny took a dump.

I have another thread on it. OD "Off" light started flashing.

P1728 - Transmission Slip Error.

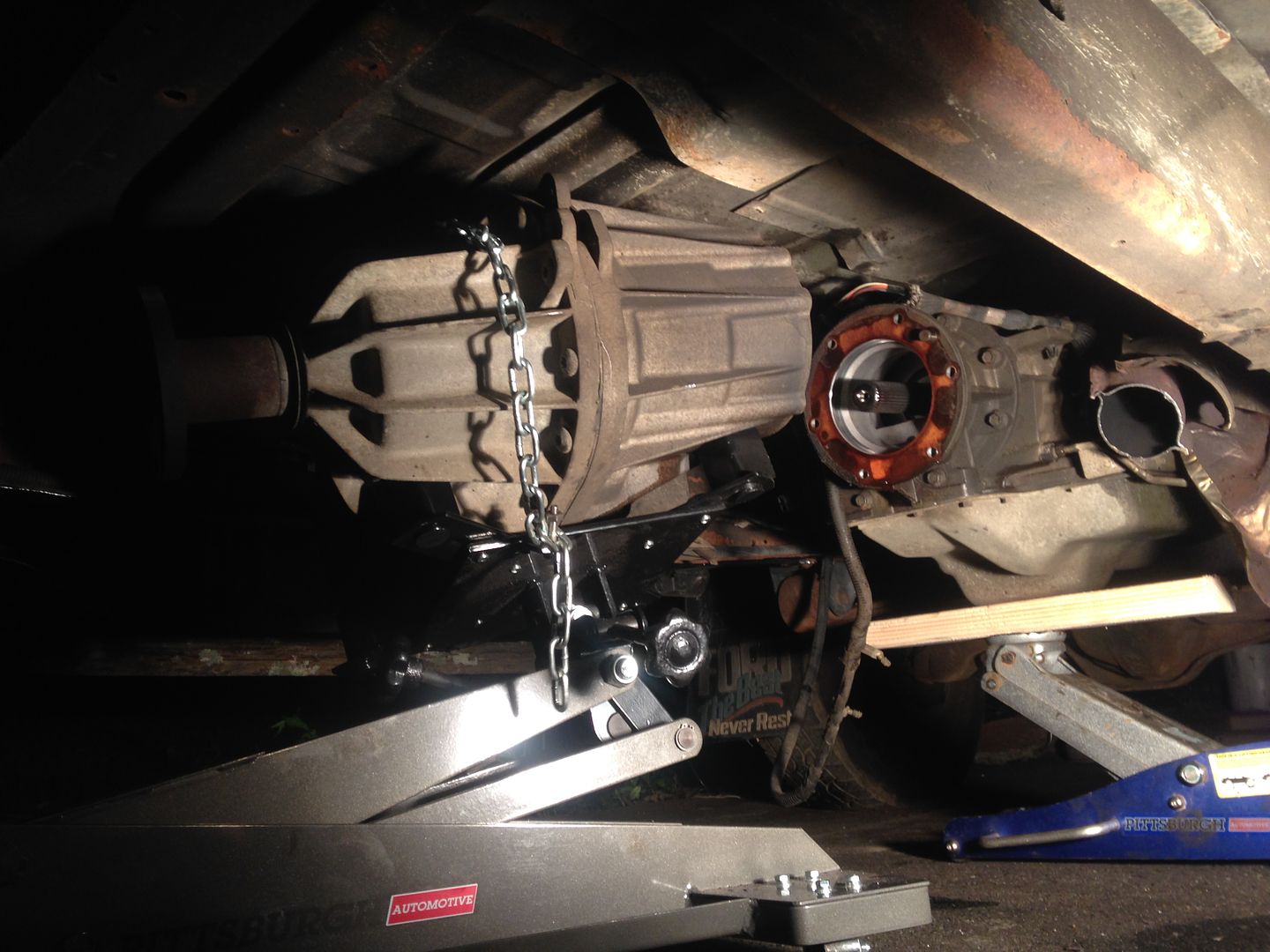

Think the torque converter took a dump. It's currently like halfway out.

Gives me a chance to needle scale the entire frame and transmission tunnel and then paint it. I've been wanting to do that for a while now and now that all of this is out of the way it's perfect timing.

#35

Probably overthinking this but i've been looking at places on the exhaust manifold to drill and tap for the EGT probe.

The easiest place i think would be on the drivers side manifold on the top of it pretty much right behind the very first cylinder (closest to the front of the truck.)

Picture related. Is this a good spot? Closing to the up-pipe would be a lot harder to drill and tap.

The easiest place i think would be on the drivers side manifold on the top of it pretty much right behind the very first cylinder (closest to the front of the truck.)

Picture related. Is this a good spot? Closing to the up-pipe would be a lot harder to drill and tap.

#36

#37

No clue on the recall. When drilling the manifold u can drill upside down from the bottom up so all the fillings drop out. Also the tiny amount of shrapnel that will fall inside wont hurt the turbo, if assuming you ever build up enough pressure to push them all the way up to the turbo. The manifold is cast steel wich creates small crumbles of metal instead of long strands when drilled. So there's no large pieces to destroy the turbo. Once u drill the hole tap it, and u can take a magnet to the outside of the manifold from the bottom where the files would have dropped and move it up to the hole. From there put a vacuum up to the hole. After that you've done all u can do.

#38

#40

WOW, great thread guys. I have a crappy E-bay EGT gauge on the way. Chomping at the bit for downpipe and 6637 filter mod, but times are tuff..haha. Fortunately the truck already has the TS chip. I don't know what the tunes are but I know in pos 1 it is a complete dog. I noticed the other day that my TC is locked in 3&4 until I touch the brake.

Where are you guys getting trans temp from?

Where are you guys getting trans temp from?

#42

#43