Starts ok but stalls over 1200 rpm

#1

Starts ok but stalls over 1200 rpm

Hello, I am working on a friends, 2001 F350 4x4 with manual trans.

The owner of the truck said it started stalling intermittently a few weeks ago. It now will start fine and idle all day, however if you accelerate much past 1200 rpm it will stall. If you snap the throttle it will stall. This all occurs under no load.

That being said the owner recently changed oil and filter,fuel filter,IPC sensor and CPS.

I scanned it today and only code that appeared was P1670 (Electronic feedback signal not detected). I cleared it and it reappeared after a few stalls. I disconnected IDM and ECM, checked the circuits per Alldata and ended up with, replace PCM at end of troubleshooting guide.

My question, could a defective IPR be causing this issue? I am still reluctant to declare a bad ECM especially since we can't find one, dealer said discontinued.

Oh, I did look at fuel flow into bowl and it looked good, will do a pressure test later if need be.

Thanks Bill

The owner of the truck said it started stalling intermittently a few weeks ago. It now will start fine and idle all day, however if you accelerate much past 1200 rpm it will stall. If you snap the throttle it will stall. This all occurs under no load.

That being said the owner recently changed oil and filter,fuel filter,IPC sensor and CPS.

I scanned it today and only code that appeared was P1670 (Electronic feedback signal not detected). I cleared it and it reappeared after a few stalls. I disconnected IDM and ECM, checked the circuits per Alldata and ended up with, replace PCM at end of troubleshooting guide.

My question, could a defective IPR be causing this issue? I am still reluctant to declare a bad ECM especially since we can't find one, dealer said discontinued.

Oh, I did look at fuel flow into bowl and it looked good, will do a pressure test later if need be.

Thanks Bill

#2

Hello, I am working on a friends, 2001 F350 4x4 with manual trans.

The owner of the truck said it started stalling intermittently a few weeks ago. It now will start fine and idle all day, however if you accelerate much past 1200 rpm it will stall. If you snap the throttle it will stall. This all occurs under no load.

That being said the owner recently changed oil and filter,fuel filter,IPC sensor and CPS.

I scanned it today and only code that appeared was P1670 (Electronic feedback signal not detected). I cleared it and it reappeared after a few stalls. I disconnected IDM and ECM, checked the circuits per Alldata and ended up with, replace PCM at end of troubleshooting guide.

My question, could a defective IPR be causing this issue? I am still reluctant to declare a bad ECM especially since we can't find one, dealer said discontinued.

Oh, I did look at fuel flow into bowl and it looked good, will do a pressure test later if need be.

Thanks Bill

The owner of the truck said it started stalling intermittently a few weeks ago. It now will start fine and idle all day, however if you accelerate much past 1200 rpm it will stall. If you snap the throttle it will stall. This all occurs under no load.

That being said the owner recently changed oil and filter,fuel filter,IPC sensor and CPS.

I scanned it today and only code that appeared was P1670 (Electronic feedback signal not detected). I cleared it and it reappeared after a few stalls. I disconnected IDM and ECM, checked the circuits per Alldata and ended up with, replace PCM at end of troubleshooting guide.

My question, could a defective IPR be causing this issue? I am still reluctant to declare a bad ECM especially since we can't find one, dealer said discontinued.

Oh, I did look at fuel flow into bowl and it looked good, will do a pressure test later if need be.

Thanks Bill

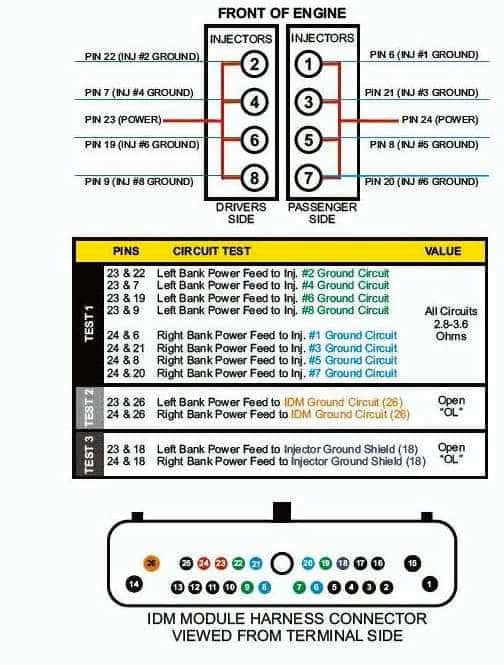

The following tests should be performed with the key off, the IDM harness disconnected from the module and all other harness connectors plugged in (connectors to valve covers, etc.). Measurements are taken by probing the female terminals from the connector face (where it would normally plug into the IDM module).

TEST 1:

Tools: DVOM

Measure the resistance between each power feed and each injector’s ground circuit at the IDM harness connector.

There is one power feed for each cylinder bank.

TEST 2:

Tools: DVOM

Measure the resistance between each power feed and ground. This should indicate an open circuit. If resistance is present check for damaged valve cover gasket connectors and the wiring beneath the valve cover gaskets UVCH).

TEST 3:

Tools: Flash Light / Hand-Held Mirror

Check for damaged injector wiring harness; Measure the resistance between the each injector power feed and the ground shield for the

injector wires.

WARNING: The wires to the injectors are shielded wire, DO NOT pierce injector wires, doing so will permanently damage the harness.

NOTE: Nominal solenoid resistance for Powerstroke injectors is 2.9 Ohms.

This test measures entire circuit resistance which includes wire and valve cover connector resistance. All readings for the vehicle should be consistent between each circuit.

NOTE: This test checks for injector circuits that are shorted to ground, which will cause immediate and permanent damage to the IDM module.

NOTE: The resistance between these pins should be open (infinity), indicating no path to ground. This should indicate an open circuit. If resistance is present inspect the wiring harness for damage.

Found this somewhere...

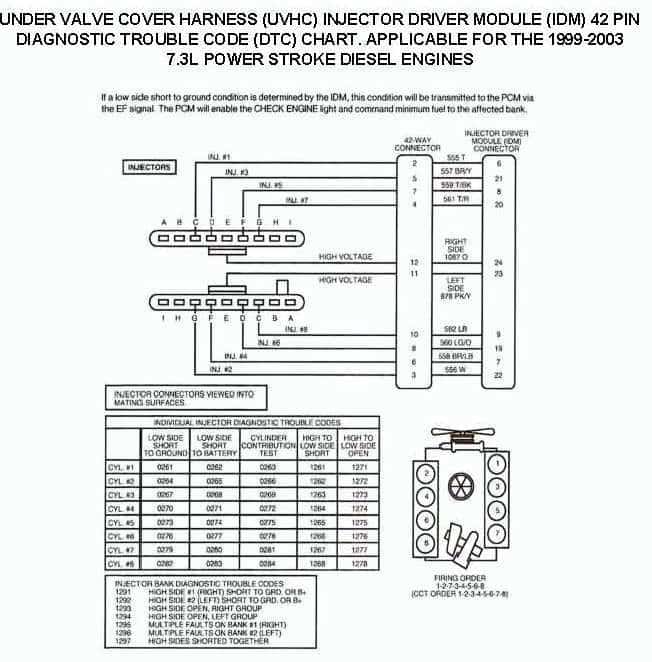

FORD INJECTOR DRIVER (IDM) MODULE / UVCH & DIAGNOSTICS:

The IDM module can fail as a result of an internal failure or be damaged by other malfunctioning components on the vehicle. In order to assist in the diagnosis of the IDM module and ensure the replacement module is not damaged when installed, the following tests and procedures should be performed.

Injector Resistance and Wiring Tests:

The IDM module can fail as a result of an internal failure or be damaged by other malfunctioning components on the vehicle. In order to assist in the diagnosis of the IDM module and ensure the replacement module is not damaged when installed, the following tests and procedures should be performed.

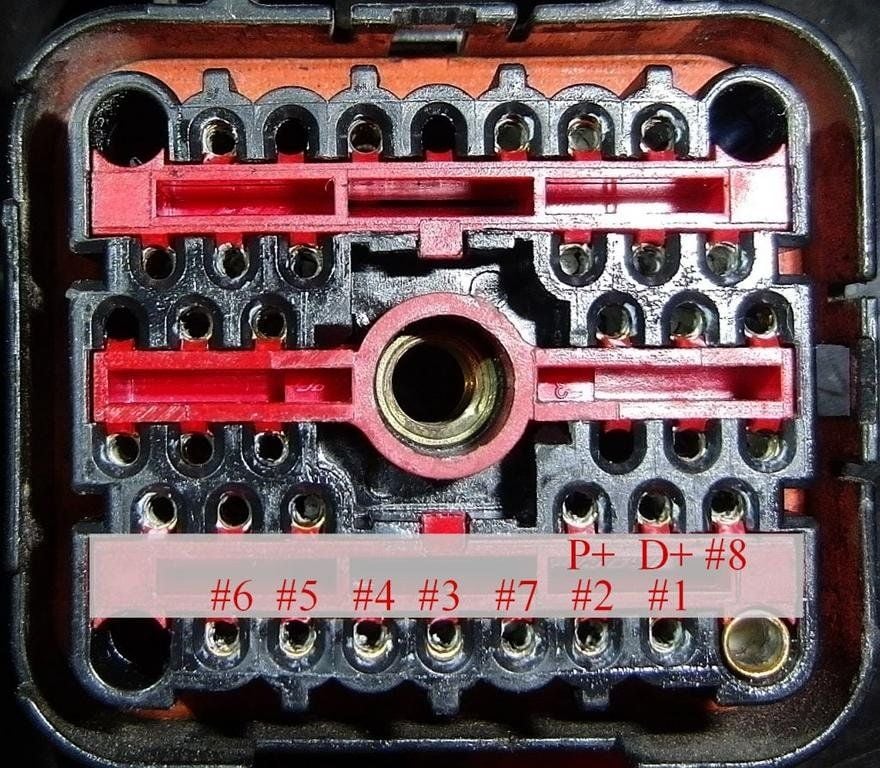

A common failure found on the Powerstroke 7.3L injection system is faulty electrical wiring between the IDM module and the fuel injectors. The wiring passes through connectors which are molded into the valve cover gaskets (see Figures 1 and 2).

The following test ensures the wiring between the IDM module and injectors are within specification. This procedure will also test for defective injector solenoid(s). By measuring the resistance (ohms) between each injector’s power-feed and ground circuit, the total circuit and wiring resistance can be verified. This ensures that there are no shorted or open circuits to the injectors.

IDM Wiring Circuit Testing Procedure:

The following tests should be performed with the key off, the IDM harness disconnected from the module and all other harness connectors plugged in (connectors to valve covers, etc.). Measurements are taken by probing the female terminals from the connector face (where it would normally plug into the IDM module).

TEST 1: Use a multi-meter to measure the resistance between each power feed and each injector’s ground circuit at the IDM harness connector.

Note: There is one power feed for each cylinder bank.

TEST 2: Measure the resistance between each power feed and ground. This should indicate an open circuit. If resistance is present check for damaged valve cover gasket connectors and the wiring beneath the valve cover gaskets.

TEST 3: Check for damaged injector wiring harness; Measure the resistance between the each injector power feed and the ground shield for the injector wires.

** WARNING: The wires to the injectors are shielded wire, DO NOT pierce injector wires, doing so will permanently damage the harness.

** WARMING: Wire Loom wrapped in RED tape has up to 110 vdc. Use caution!

Nominal solenoid resistance for Powerstroke injectors is 2.9 Ohms.

This test measures entire circuit resistance which includes wire and valve cover connector resistance. All readings for the vehicle should be consistent between each circuit.

This test checks for injector circuits that are shorted to ground, which will cause immediate and permanent damage to the IDM module. The resistance between these pins should be open (infinity), indicating no path to ground. This should indicate an open circuit. If resistance is present inspect the wiring harness for damage.

NOTE: Always consult vehicle specific service and diagnostic information. Visual Inspection – Wiring Harness & Connectors Inspect the connectors at the valve cover gaskets for damage and proper fit. Over time the connectors can become brittle and crack. Wiggling the connectors while performing the tests on the previous page can help detect intermittent connections. If the electrical tests indicate there is a problem remove the valve cover and inspect the Injector harnesses.

The following users liked this post:

#3

Thanks for the great info Thomas, it is much appreciated. I have already checked the circuits for the EF signal, they checked out.

I monitored the ICP pressure with scan tool and pressure was around 600 at idle but never went above 700 before stalling at about 1200 rpm. What pressure should I be seeing at this engine speed. Do you or anyone have specs for ICP pressure vs engine rpms?

I can't seem to get a possible defective IPR out of my mind.

I monitored the ICP pressure with scan tool and pressure was around 600 at idle but never went above 700 before stalling at about 1200 rpm. What pressure should I be seeing at this engine speed. Do you or anyone have specs for ICP pressure vs engine rpms?

I can't seem to get a possible defective IPR out of my mind.

#4

Thanks for the great info Thomas, it is much appreciated. I have already checked the circuits for the EF signal, they checked out.

I monitored the ICP pressure with scan tool and pressure was around 600 at idle but never went above 700 before stalling at about 1200 rpm. What pressure should I be seeing at this engine speed. Do you or anyone have specs for ICP pressure vs engine rpms?

I can't seem to get a possible defective IPR out of my mind.

I monitored the ICP pressure with scan tool and pressure was around 600 at idle but never went above 700 before stalling at about 1200 rpm. What pressure should I be seeing at this engine speed. Do you or anyone have specs for ICP pressure vs engine rpms?

I can't seem to get a possible defective IPR out of my mind.

#5

Update

Yesterday the truck stalled every time I increased throttle over 1200 rpm or snapped the throttle. Today I disconnected the fuel heater wire and it revved fine, thought I was on to the problem until I shut it down and restarted. Now the problem is intermittent again as it was earlier.

I looked at the IPR data and was 7% at idle cold and 9% at operating temp.

Any ideas?

Thanks Bill

Yesterday the truck stalled every time I increased throttle over 1200 rpm or snapped the throttle. Today I disconnected the fuel heater wire and it revved fine, thought I was on to the problem until I shut it down and restarted. Now the problem is intermittent again as it was earlier.

I looked at the IPR data and was 7% at idle cold and 9% at operating temp.

Any ideas?

Thanks Bill

#7

Have you checked to ensure the Tin Nut is on the Valve? Sometimes they fall off allowing the Electromagnet to slide on the valve rather than operate the valve.

Trending Topics

#8

Thank you again Thomas for your help. I had the owner replace the IPR yesterday and that did not solve the problem unfortunately. The problem is intermittent and my feeling was that the IPR was sticking at times, but oh well no change.

The injectors are overdue for replacement and the owner is thinking that is the problem, however I am reluctant to agree. When it stalls it is as if the key was turned off.

I feel as though the injectors are losing voltage to fire and will monitor voltage tomorrow.

I am now thinking PCM or IDM as I have no codes to work with other than P1670.

The injectors are overdue for replacement and the owner is thinking that is the problem, however I am reluctant to agree. When it stalls it is as if the key was turned off.

I feel as though the injectors are losing voltage to fire and will monitor voltage tomorrow.

I am now thinking PCM or IDM as I have no codes to work with other than P1670.

#9

Thank you again Thomas for your help. I had the owner replace the IPR yesterday and that did not solve the problem unfortunately. The problem is intermittent and my feeling was that the IPR was sticking at times, but oh well no change.

The injectors are overdue for replacement and the owner is thinking that is the problem, however I am reluctant to agree. When it stalls it is as if the key was turned off.

I feel as though the injectors are losing voltage to fire and will monitor voltage tomorrow.

I am now thinking PCM or IDM as I have no codes to work with other than P1670.

The injectors are overdue for replacement and the owner is thinking that is the problem, however I am reluctant to agree. When it stalls it is as if the key was turned off.

I feel as though the injectors are losing voltage to fire and will monitor voltage tomorrow.

I am now thinking PCM or IDM as I have no codes to work with other than P1670.

If you can at least get these parameters and post back I would feel better about saying IDM.

V-PWR 10.5 VDC Minimum. (The CMP may fall out of the PCM circuit if vehicle voltage falls below 10.5v).

RPM 100 RPM Minimum (0 - CMP Suspect)

ICP 500 PSI or 3.4 MPAM Minimum the ICP should steadily climb during cranking. This indicates a healthy HPOP depending upon how high it climbs.

ICPv (KOEO) Spec 0.20v - 0.30v

FUEL PW: 1 MS - 6 MS (<1 / >6 IDM Suspect)

V-PWR - If indicating a low voltage condition, check battery voltage, charging system or power and ground circuits to the PCM.

DC% - Cranking NTE 20% / 65% is closed. (IPR Suspect)

2. RPM - Low RPM could be an indication of starting / charging system problems **

3. No RPM indicated with the engine cranking - could be CMP circuit fault, check for DTC’s.

4. ICP - A minimum of 500 PSI (3.4 mPa) is required before the injectors are enabled. No or low oil in the reservoir, system leakage, injector O-Rings, or faulty IPR could cause pressure loss.

Note: If no RPM signal is received, IPR duty cycle will default to 14%

5. FUEL PW - Even though a 1 to 6 mS FUEL PW is shown, it’s possible the IDM did not receive the signal due to a CI or FDCS circuit fault or internal IDM failure.

Hope this helps,

Tom

#11

I wanted to let everyone know who has followed this problem, that I believe I finally repaired the stalling issue.

I replaced the alternator on the 4th because though it was charging fine, the A/C voltage was climbing to about .5 to.6 volts @1000 rpm. The truck has been in service since Monday without any issues,so I feel confident this was the fix.

Thank you Tom for your help and support.

Bill

I replaced the alternator on the 4th because though it was charging fine, the A/C voltage was climbing to about .5 to.6 volts @1000 rpm. The truck has been in service since Monday without any issues,so I feel confident this was the fix.

Thank you Tom for your help and support.

Bill

Thread

Thread Starter

Forum

Replies

Last Post

akorcovelos

1999 - 2003 7.3L Power Stroke Diesel

1

09-07-2018 06:40 PM

C&MWreckerService

1999 - 2003 7.3L Power Stroke Diesel

6

10-17-2015 02:48 PM