1955 ford c600

#16

I put everything back together yesterday and after an hour of bleeding i finally got a good hard pedal. However while driving it i have a really hard pedal and im fairly sure the booster isn't getting the proper vacuum it should so im going to check the valve on the fire wall to make sure its working properly, my hunch is that it isn't.

Today i built a brake light box for it and went ahead and pulled all the old wiring out and ran new wiring. I cut some holes in the box with my plasma cutter and picked up some lights and grommets from work.

I also had to mount a push button style brake light switch on the brake pedal as i decided to go away from the pressure activated switch, in my opinion that's just one extra failure point in the hydraulic system.

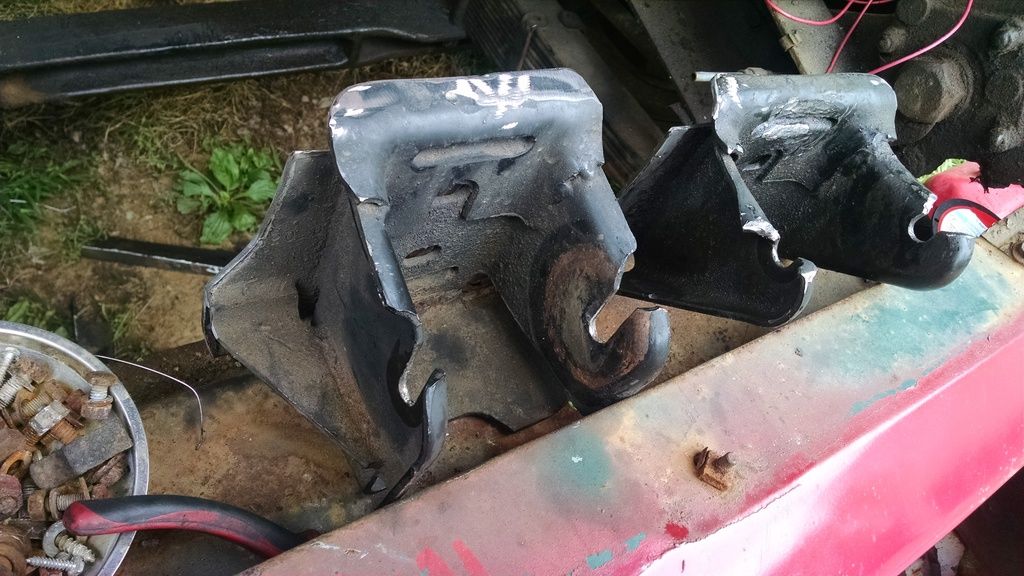

Ignore my horrible looking welds, it wasn't a matter of making it pretty it was simply a matter of getting my gun in there to put a couple tacks on it to hold haha. Im actually embarrassed to even post the pic but i know how much you guys like pictures.

I drove it around for about another mile tonight and the wheel cylinders do not seem to be leaking, im very happy that i was able to hone the cylinders and fix the leaking. It saved me lots of money, time, and i learnt some valuable info in the process.

I have no decided exactly what im going to do with the truck. One thing i know is im going to be swapping a diesel of some sort into the truck, most likely a cummins. Im very familiar with them and i feel most comfortable swapping a cummins. I plan to go next week to pick up an eaton 5 speed transmission witch will be perfect to put behind the cummins.

I am heading to my local big rig junk yard in the morning to hopefully pick up two air ride seats and a couple stacks. It currently has a very nice bench seat but i want the full big rig experience! Im going to mount an electric air compressor somewhere and a tank to control the seats, and air horns when i ad them. Once i put the cummins in i will most likely mount an air pump on the engine for future air operated things like air brakes!

As for my plans with the truck, well i never really create a game plan, i have had multiple projects in the last couple years, one of them being a 1975 tandem axle dodge that started out as a rust bucket i pulled from a field and one day i through another axle under it. So i figure i will just play this one by ear as well, i guess you will just have to stick to the thread to see what happens!

Cruising for the night.

The tandem axle dodge, probably the only one you will see, and if you see it another feller in knoxville tn now owns it. Just consider yourself lucky to know the person who built it!

And how it looked the day i got it

I believe my next plan of action is going to be removing some of the leafs. I will never haul something heavy enough to require the amount of leafs this truck has. I use to think the statement "rides like a log wagon" was simply a joke but i now know it is very possible to have something ride that rough.

Today i built a brake light box for it and went ahead and pulled all the old wiring out and ran new wiring. I cut some holes in the box with my plasma cutter and picked up some lights and grommets from work.

I also had to mount a push button style brake light switch on the brake pedal as i decided to go away from the pressure activated switch, in my opinion that's just one extra failure point in the hydraulic system.

Ignore my horrible looking welds, it wasn't a matter of making it pretty it was simply a matter of getting my gun in there to put a couple tacks on it to hold haha. Im actually embarrassed to even post the pic but i know how much you guys like pictures.

I drove it around for about another mile tonight and the wheel cylinders do not seem to be leaking, im very happy that i was able to hone the cylinders and fix the leaking. It saved me lots of money, time, and i learnt some valuable info in the process.

I have no decided exactly what im going to do with the truck. One thing i know is im going to be swapping a diesel of some sort into the truck, most likely a cummins. Im very familiar with them and i feel most comfortable swapping a cummins. I plan to go next week to pick up an eaton 5 speed transmission witch will be perfect to put behind the cummins.

I am heading to my local big rig junk yard in the morning to hopefully pick up two air ride seats and a couple stacks. It currently has a very nice bench seat but i want the full big rig experience! Im going to mount an electric air compressor somewhere and a tank to control the seats, and air horns when i ad them. Once i put the cummins in i will most likely mount an air pump on the engine for future air operated things like air brakes!

As for my plans with the truck, well i never really create a game plan, i have had multiple projects in the last couple years, one of them being a 1975 tandem axle dodge that started out as a rust bucket i pulled from a field and one day i through another axle under it. So i figure i will just play this one by ear as well, i guess you will just have to stick to the thread to see what happens!

Cruising for the night.

The tandem axle dodge, probably the only one you will see, and if you see it another feller in knoxville tn now owns it. Just consider yourself lucky to know the person who built it!

And how it looked the day i got it

I believe my next plan of action is going to be removing some of the leafs. I will never haul something heavy enough to require the amount of leafs this truck has. I use to think the statement "rides like a log wagon" was simply a joke but i now know it is very possible to have something ride that rough.

#17

Well i guess its time to update the thread once again. We will pick up where we left off.

The next day i got up and headed to the big rig junk yard where i found plenty of air ride seat candidates but we were to far apart on a good price on some of them so i ended up passing on the seats for now. However i did strike gold on the stacks, i picked up 2 5" chrome stacks for cheap. The next day i fabbed up brackets and mounted them.

After building a 2" y pipe and running pipe i fired it up. The ole y block v8 screamed like an old Detroit. I was very pleased with the sound. I took it for a quick spin and not long after driving it started smoking real bad. Now this was the first bit of smoke i had seen since the old booster was replaced. The smoke got worse and even after un hooking the booster to find a bone dry vacuum hose i came to the conclusion that i had either broke a ring or completly lost a valve seal. Surprisingly no blow by but i was not concerned with a compression check as i had plans on pulling the engine.

So i got on the ball to find a donor truck and just happened to come across a trade on a 96 dodge 3500 that i had been trying to sell for a while, the trade consisted of a 95 dodge 2500 cummins, an 01 cummins parts truck, and some cash. I took the trade as i was in need of the parts truck.

I immediately pulled the y block v8 and 4 speed transmission.

I am currently trying to sell the engine and transmission still bolted together for $200 for everything. If anyone is interested im located in east tn and i need to move it quick. I dont want it sitting around i will haul it to the scrap yard if it doesnt sell soon.

Back to the story.

I then began tearing into the dodge. Now this is a vp44 truck so the computer is a must. A lot of people don't prefer a 24 valve swap because of the wiring and the computer. I personally enjoy the challenge, once im done and will be able to run a programmer to tune my truck i will be very happy. The truck is a 5 speed 4x4 truck so i will be keeping the 5 speed transmission until i can find a 2x4 nv4500 to run behind the cummins. Now if i have done my math correctly, with the nv4500's over drive gearing of .73:1 and the steep gearing of the 2 speed rear end, coupled with the large diameter tires, i should be around 2100 rpm at 65 mph. That is perfect highway cruising speed for this old truck and personally i think i will see rather impressive fuel mileage numbers out of it.

Now before i pulled this engine i did infact fire it up. The feller i got it from wasnt sure if it was a running engine because someone had robbed parts off of it. So after i found a dead lift pump to be the culprit of no fuel, it fired right up with install of a holley blue.

Tomorrow is D Day. I will be finishing up pulling the cummins out of the dodge and i will begin my first mock ups of it in the coe. I think i have a good game plan and i will keep the forum updated as i move on.

The next day i got up and headed to the big rig junk yard where i found plenty of air ride seat candidates but we were to far apart on a good price on some of them so i ended up passing on the seats for now. However i did strike gold on the stacks, i picked up 2 5" chrome stacks for cheap. The next day i fabbed up brackets and mounted them.

After building a 2" y pipe and running pipe i fired it up. The ole y block v8 screamed like an old Detroit. I was very pleased with the sound. I took it for a quick spin and not long after driving it started smoking real bad. Now this was the first bit of smoke i had seen since the old booster was replaced. The smoke got worse and even after un hooking the booster to find a bone dry vacuum hose i came to the conclusion that i had either broke a ring or completly lost a valve seal. Surprisingly no blow by but i was not concerned with a compression check as i had plans on pulling the engine.

So i got on the ball to find a donor truck and just happened to come across a trade on a 96 dodge 3500 that i had been trying to sell for a while, the trade consisted of a 95 dodge 2500 cummins, an 01 cummins parts truck, and some cash. I took the trade as i was in need of the parts truck.

I immediately pulled the y block v8 and 4 speed transmission.

I am currently trying to sell the engine and transmission still bolted together for $200 for everything. If anyone is interested im located in east tn and i need to move it quick. I dont want it sitting around i will haul it to the scrap yard if it doesnt sell soon.

Back to the story.

I then began tearing into the dodge. Now this is a vp44 truck so the computer is a must. A lot of people don't prefer a 24 valve swap because of the wiring and the computer. I personally enjoy the challenge, once im done and will be able to run a programmer to tune my truck i will be very happy. The truck is a 5 speed 4x4 truck so i will be keeping the 5 speed transmission until i can find a 2x4 nv4500 to run behind the cummins. Now if i have done my math correctly, with the nv4500's over drive gearing of .73:1 and the steep gearing of the 2 speed rear end, coupled with the large diameter tires, i should be around 2100 rpm at 65 mph. That is perfect highway cruising speed for this old truck and personally i think i will see rather impressive fuel mileage numbers out of it.

Now before i pulled this engine i did infact fire it up. The feller i got it from wasnt sure if it was a running engine because someone had robbed parts off of it. So after i found a dead lift pump to be the culprit of no fuel, it fired right up with install of a holley blue.

Tomorrow is D Day. I will be finishing up pulling the cummins out of the dodge and i will begin my first mock ups of it in the coe. I think i have a good game plan and i will keep the forum updated as i move on.

#18

I have a 56 COE that I want to put a diesel in, I had bought a BT to put in but after much measuring and study it looked like I would loose real estate in the cab. The Cummins is a wider, taller and longer engine than the old V8. It looked like the tranny and shifter would end up at the back of the cab and dog house would fill the cab. My alternative is a V8 diesel like the old 7.3 pre power stroke. A tight fit but doable. They are about the size of a 429/460 and will squeeze in with minable cutting. Good luck in your project.

#19

I finally got around to getting everything ready to get the Cummins in. I boxed the frame and cut the motor mounts out of the Dodge. The Dodge measured 2' 3" wide and the ford frame measured 2' 4". After I boxed the frame and put the motor mounts on it brought my measurements to right at 2' 3" wide. Today I squeezed the Cummins in. Didn't have to cut the floor or the cab at all. I did end up notching the front cross member, but I'll box it back in. I believe I'm gonna have to notch the cab cross memeber just a little and scoot the engine back just a little to get some extra space for the radiator.

#21

#23

As for radiator I'm going to run the ford radiator. It's not very wide but it is very thick, in going to run electric fans, they are more efficient than the manual fan and should help keep everything good and cool. If I can fit the Dodge radiator with out to much fabrication then I will go ahead and use it. I haven't fully decided on the radiator because it all depends on how much room I end up with. As for an intercooler. I plan to run with out one at first like the factory first gens were. I have drove plenty of these engines and I don't worry to much about the temps. I will how ever have gauges on both water temp and egt to keep a close eye, and if my egts run to high then I will be mounting the intercooler behind the cab with electric fans and scoops to grab air from underneath the cab and force it into the intercooler fins.

#24

Got some more work done today. I got the motor mounts welded into the frame. They fit perfectly almost like they were made for it. The engine is in on its own.

I sprayed the engine down with a couple cans of engine degreaser and broke out the pressure washer to get the engine cleaned up. It cleaned up really well.

I test fit some of the front body parts and also test fitted the radiators. The ford radiator is gonna fit best of course but the Dodge radiator would fit with some work so I'm still tossing around both ideas.

I got plenty of pics for everyone to look through. I did end up having to cut out the cab cross member but I'm gonna scoot it back about an inch and patch it back in. Along with the floor. It looks like the factory dog house is gonna fit right back on like it should.

I sprayed the engine down with a couple cans of engine degreaser and broke out the pressure washer to get the engine cleaned up. It cleaned up really well.

I test fit some of the front body parts and also test fitted the radiators. The ford radiator is gonna fit best of course but the Dodge radiator would fit with some work so I'm still tossing around both ideas.

I got plenty of pics for everyone to look through. I did end up having to cut out the cab cross member but I'm gonna scoot it back about an inch and patch it back in. Along with the floor. It looks like the factory dog house is gonna fit right back on like it should.

#25

#26

This truck has a stack of 12 leaf springs on each side under the truck. Although tittled as a c600 I believe that is incorrect. Based on a lot of my research Dayton wheels came on c700 and up. So I'm guessing it's a c700 or c800.

When I sat the engine in the leafs springs didn't compress at all. Having 12 leaf springs that's plenty for this engine. If I remember correctly the first gen Dodge trucks only had 6 leafs under each side. I plan to remove some leafs from the front end to make it ride a little better with some blocks to keep it the same height.

It was sitting on the cross member but it was keeping the engine tilted forward so I cut it out and I'm going to redesign the cross member so that it has a notch to allow the engine to sit down about 2" more in the rear. The Dodges don't even have a cross member under the Bell housing. They have the motor mounts welded to the frame and in front of that they have a welded in cross member. The transmission has a cross member under the tail housing of the transmission and the front of the transmission simply bolts to the back of the Cummins.

When I sat the engine in the leafs springs didn't compress at all. Having 12 leaf springs that's plenty for this engine. If I remember correctly the first gen Dodge trucks only had 6 leafs under each side. I plan to remove some leafs from the front end to make it ride a little better with some blocks to keep it the same height.

It was sitting on the cross member but it was keeping the engine tilted forward so I cut it out and I'm going to redesign the cross member so that it has a notch to allow the engine to sit down about 2" more in the rear. The Dodges don't even have a cross member under the Bell housing. They have the motor mounts welded to the frame and in front of that they have a welded in cross member. The transmission has a cross member under the tail housing of the transmission and the front of the transmission simply bolts to the back of the Cummins.

#27

Looks good. I gotta admit it I didn`t think it would go in there but it fits. The stock radiator may not have the capacity for the diesel. Ford used 2 sizes in there trucks back then depending on engine size. I found one from a 55 tandem with the linclon engine which is taller and still bolts in to the stock mts . This is in a F100 with a 427. It cools just fine. I did get it recored 3 yrs ago as it survived in the pickup for 30 yrs before springing a leak. Just an idea for you.

#28

It has been quite some time sense i last updated my post. I have been so busy with the swap i haven't had time. But i have taken lots of pictures so you guys are in luck.

After i got the engine sat in the next line of business was to get the trans in. I was able to pull the trans and transfer case from the parts truck and put it in the ford with in about 3 hours.

It got lots of degreaser and pressure washing to get all the oil off of it.

It went in just fine.

After that i began building the trans cross member. The easiest way i could think to do it was to take a factory dodge cross member out of a 96 3500 (i just happen to have one laying around) and cut the ends off of it where its suppose to wedge in the frame on the dodge, i welded plates on the ends, drilled holes and then welded 2" square tubing to the bottom of the frame with holes drilled in them, i ended up doing that because it got my spacing just right to get the engine sitting a little down in the back but not too much. The reason i didn't use the 2001 dodge cross member is because its slightly wider and covers more of the trans and transfer case, so i figured the more stuff i can get to the easier it will be to work on later on down the road.

Sorry but i dont have any pics of it bolted into the frame right now.

I then moved onto fabing up drive shafts and u joints, i kinda figured i would have to buy a ******* joint but thankfully the ford uses the exact same u joint as the dodge.

Ford cap on the left dodge on the right.

The driveshaft was easy to because i had a spare driveshaft out of a single cab long bed 2500 that was the exact length i needed it to be. It bolted right in just how it should have.

Then i built my shifter, i first built a shifter using metal linkages but it was too hard to tell what gear you were in, shifted just fine but i didnt like how you couldnt really feel what the other stick under the seat was trying to do so i scrapped it and built a bent shifter after all. Also while i was in there i cleaned and bed linerd the floor.

Then i moved on to mounting my alternator and belt driven vacuum pump witch came off a ford power stroke. I had to build brackets for both, i currently dont have any pictures of the vacuum pump bracket but it took place of the tensioner and it actually pivots on two bolts to tighten and loosen the belt. I had to build a bent bracket to mount my wilson 1 wire alternator but i got it all in there.

I decided to run a third gen manifold too keep the turbo from hitting the floor and to get the exhaust under the cab cross member. Surprisingly the truck doesnt have a raspy high rpm with the third gen manifold like a normal third gen does.

After that came time for radiator, wiring, and getting it all how i wanted. I built a battery box and mounted the battery under the hood, all my wiring is in wire loom and sealed off from the outside world. The radiator i ran is out of an 89 dodge w150 with the biggest gas engine they offered.

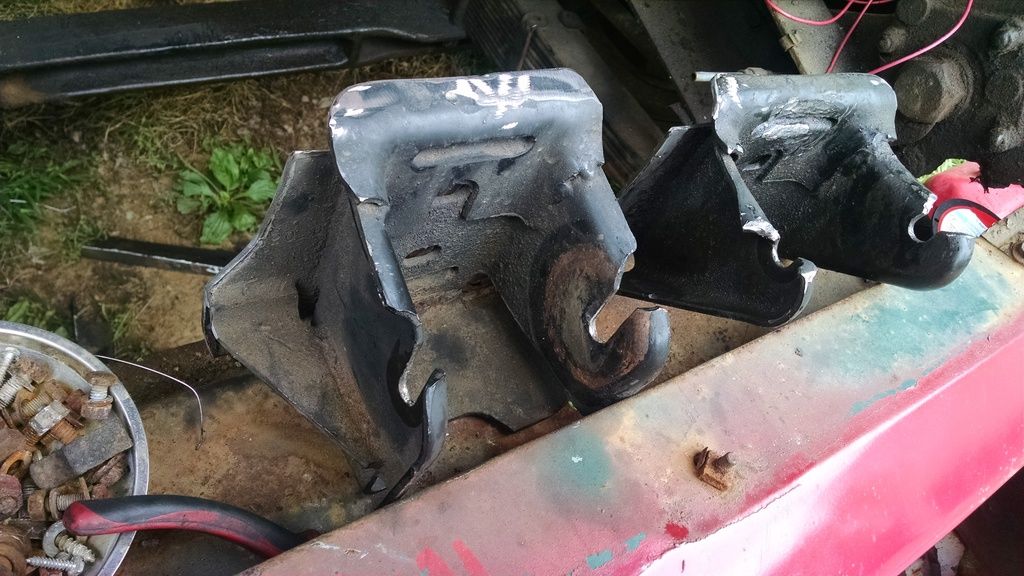

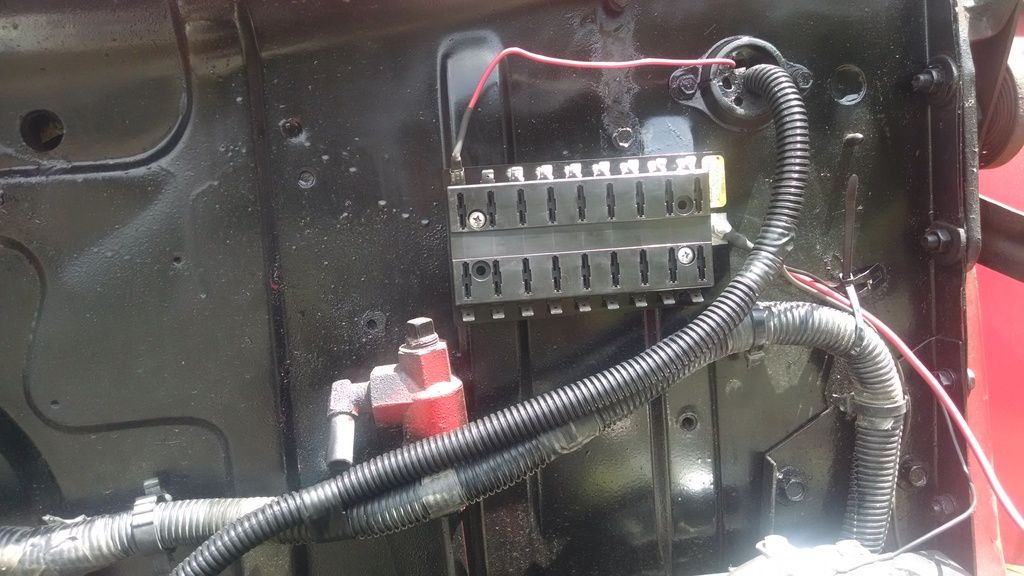

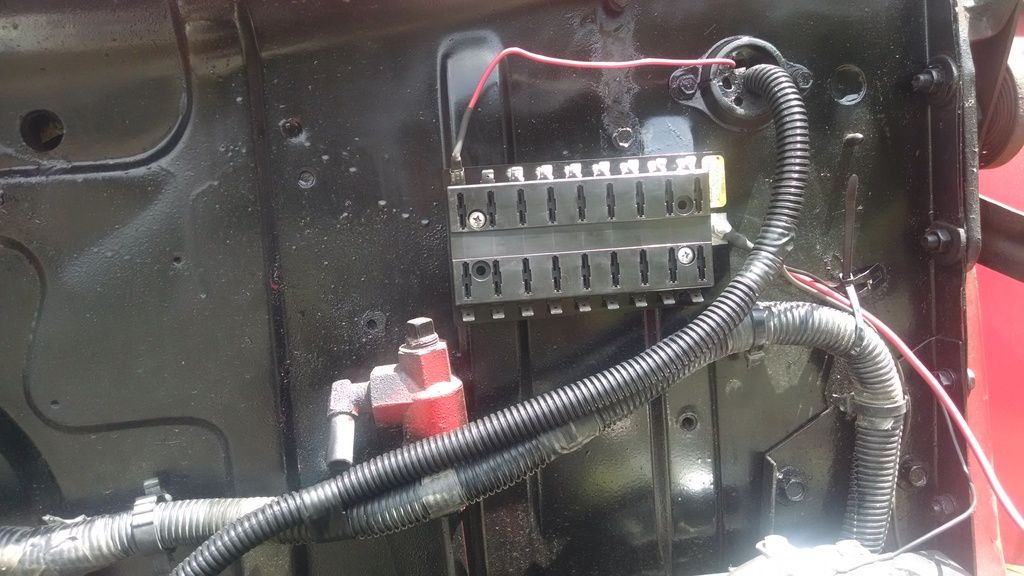

I installed a universal bwd fuse box.

The yard a mess

Stacks installed

As for my clutch i used a factory dodge hydraulic slave and master cylinder, i got rid of the factory ford clutch pedal and assembly and built my own pedal assembly, i mounted the master cylinder on the fire wall like it would be in the dodge and used a brake pedal out of a dodge truck as the clutch pedal.

Then it was time for its madden voyage, i had hick ups along the way, i kept slinging a belt cause of a slightly miss aligned alternator witch took some re bending of brackets to fix, and i kept getting air in the system causing random shut downs and hard starts due to a loose line on the suction side.

Im running a 60 gallon fuel tank off of a freightliner road commander mounted on the passenger side, you can see the tank in the stack pictures up there ^^.

Plenty of room for electric fans on the radiator and it cools just fine, truck doesnt get over 180* going down the road. No intercooler and so far no problems on that side either.

After all the hard work it successfully made the 8 mile round trip to the local O'Reilly auto parts

Now it was time to piddle with things, i started by building a gauge cluster. I took the factory ford cluster apart and was able to use most of it to make my new cluster with all my new gauges installed.

I even installed a wait to start light

Both my headlights were taken apart and painted the headlight buckets, i installed new plugs on the back of the headlights and ran all to wiring out to a 2 prong plug for easy removal of the plug on the back of the headlight if it was to ever go bad.

Now im simply piddling around, wiring up my headlights cleaning up my wiring, and building gauge clusters. There is lots more to come for this truck though. Im gonna upload a video to you tube soon for everyone also!

After i got the engine sat in the next line of business was to get the trans in. I was able to pull the trans and transfer case from the parts truck and put it in the ford with in about 3 hours.

It got lots of degreaser and pressure washing to get all the oil off of it.

It went in just fine.

After that i began building the trans cross member. The easiest way i could think to do it was to take a factory dodge cross member out of a 96 3500 (i just happen to have one laying around) and cut the ends off of it where its suppose to wedge in the frame on the dodge, i welded plates on the ends, drilled holes and then welded 2" square tubing to the bottom of the frame with holes drilled in them, i ended up doing that because it got my spacing just right to get the engine sitting a little down in the back but not too much. The reason i didn't use the 2001 dodge cross member is because its slightly wider and covers more of the trans and transfer case, so i figured the more stuff i can get to the easier it will be to work on later on down the road.

Sorry but i dont have any pics of it bolted into the frame right now.

I then moved onto fabing up drive shafts and u joints, i kinda figured i would have to buy a ******* joint but thankfully the ford uses the exact same u joint as the dodge.

Ford cap on the left dodge on the right.

The driveshaft was easy to because i had a spare driveshaft out of a single cab long bed 2500 that was the exact length i needed it to be. It bolted right in just how it should have.

Then i built my shifter, i first built a shifter using metal linkages but it was too hard to tell what gear you were in, shifted just fine but i didnt like how you couldnt really feel what the other stick under the seat was trying to do so i scrapped it and built a bent shifter after all. Also while i was in there i cleaned and bed linerd the floor.

Then i moved on to mounting my alternator and belt driven vacuum pump witch came off a ford power stroke. I had to build brackets for both, i currently dont have any pictures of the vacuum pump bracket but it took place of the tensioner and it actually pivots on two bolts to tighten and loosen the belt. I had to build a bent bracket to mount my wilson 1 wire alternator but i got it all in there.

I decided to run a third gen manifold too keep the turbo from hitting the floor and to get the exhaust under the cab cross member. Surprisingly the truck doesnt have a raspy high rpm with the third gen manifold like a normal third gen does.

After that came time for radiator, wiring, and getting it all how i wanted. I built a battery box and mounted the battery under the hood, all my wiring is in wire loom and sealed off from the outside world. The radiator i ran is out of an 89 dodge w150 with the biggest gas engine they offered.

I installed a universal bwd fuse box.

The yard a mess

Stacks installed

As for my clutch i used a factory dodge hydraulic slave and master cylinder, i got rid of the factory ford clutch pedal and assembly and built my own pedal assembly, i mounted the master cylinder on the fire wall like it would be in the dodge and used a brake pedal out of a dodge truck as the clutch pedal.

Then it was time for its madden voyage, i had hick ups along the way, i kept slinging a belt cause of a slightly miss aligned alternator witch took some re bending of brackets to fix, and i kept getting air in the system causing random shut downs and hard starts due to a loose line on the suction side.

Im running a 60 gallon fuel tank off of a freightliner road commander mounted on the passenger side, you can see the tank in the stack pictures up there ^^.

Plenty of room for electric fans on the radiator and it cools just fine, truck doesnt get over 180* going down the road. No intercooler and so far no problems on that side either.

After all the hard work it successfully made the 8 mile round trip to the local O'Reilly auto parts

Now it was time to piddle with things, i started by building a gauge cluster. I took the factory ford cluster apart and was able to use most of it to make my new cluster with all my new gauges installed.

I even installed a wait to start light

Both my headlights were taken apart and painted the headlight buckets, i installed new plugs on the back of the headlights and ran all to wiring out to a 2 prong plug for easy removal of the plug on the back of the headlight if it was to ever go bad.

Now im simply piddling around, wiring up my headlights cleaning up my wiring, and building gauge clusters. There is lots more to come for this truck though. Im gonna upload a video to you tube soon for everyone also!