1973 f250 brake booster upgrade

#1

1973 f250 brake booster upgrade

I have a 1973 f250 4x4. I upgraded the front axle to a dana 60 with dual piston calipers from a 1977 f250 crew cab to get rid of the drum brakes. I want to upgrade the brake booster, from the original, to the one that will fit for dual piston calipers so my brakes work properly. Which year would I be able to use to make it work? I bought a booster for a 77 f250 crew but the shaft is much shorter and will not work. Any ideas from someone who has done this before. I had heard something about using a F350 assembly, but could not find it on the threads. Would I need to get the pedals from the truck also? Thanks

#2

Join Date: Jun 2014

Location: Oakhust NJ Jersey Shore

Posts: 3,208

Likes: 0

Received 2 Likes

on

2 Posts

The brake booster should be fine, I don't see why it would not give you enough assist because the discs, if anything it should work better you will have less travel in the pedal. Do you mean the master cylinder? That wont work for discs from drums, you need a hold off valve to let the rear shoes get ready to touch the drum before the front activate, some are built in the master and others have proportioning valves that you can add in, companies make adjustable typeswhich is what you would like to have, so you can set it for a nice level stop, not dragging your *** or dipping the front spilling your coffee in your lap! You should be able to find a master cylinder for that year with disc's and it will bolt right on. Then get the adjustable valve and your done.

#3

If you have a single diaphragm brake booster, upgrading to a dual diaphragm unit will make the dual piston calipers easier to apply.

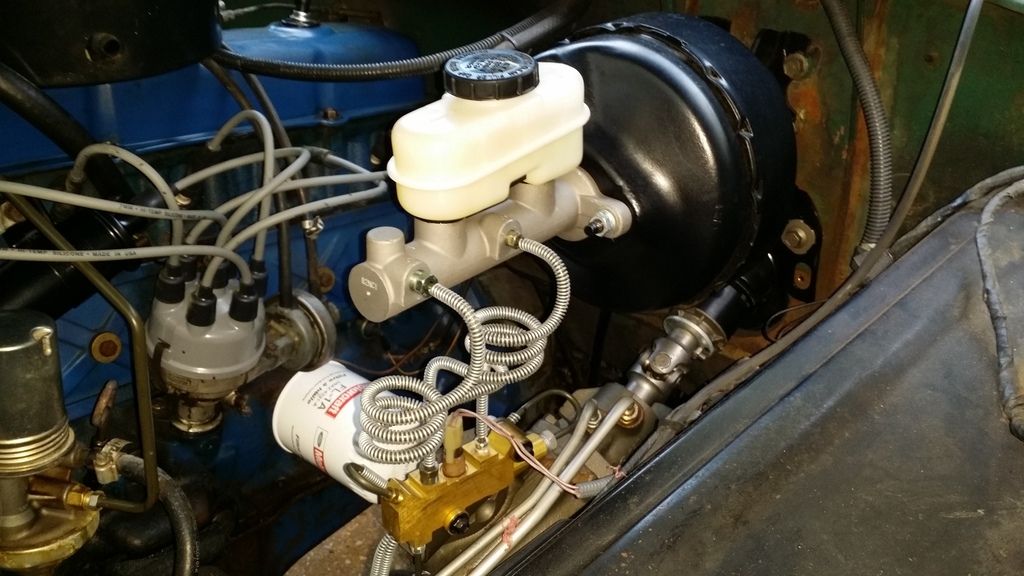

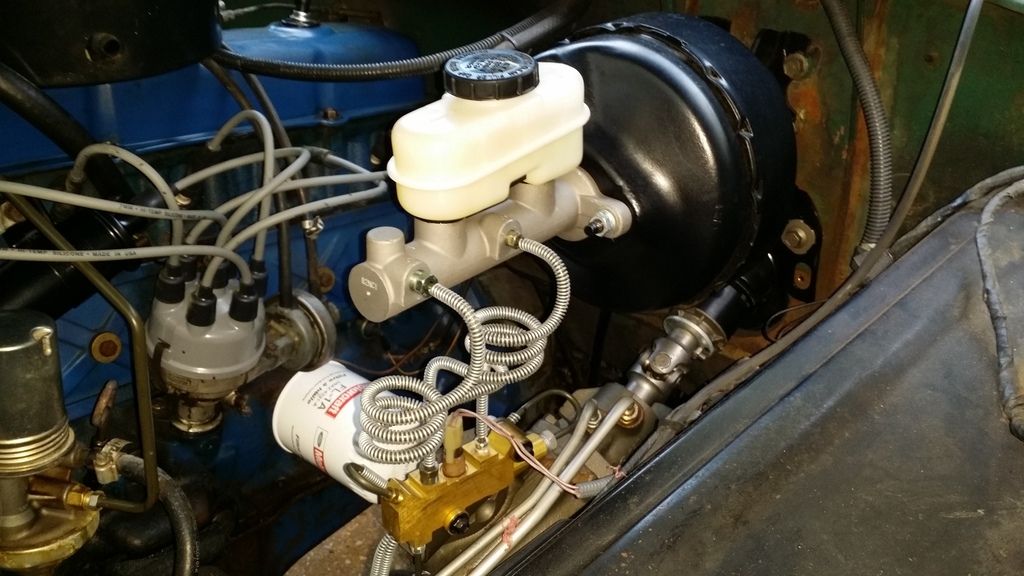

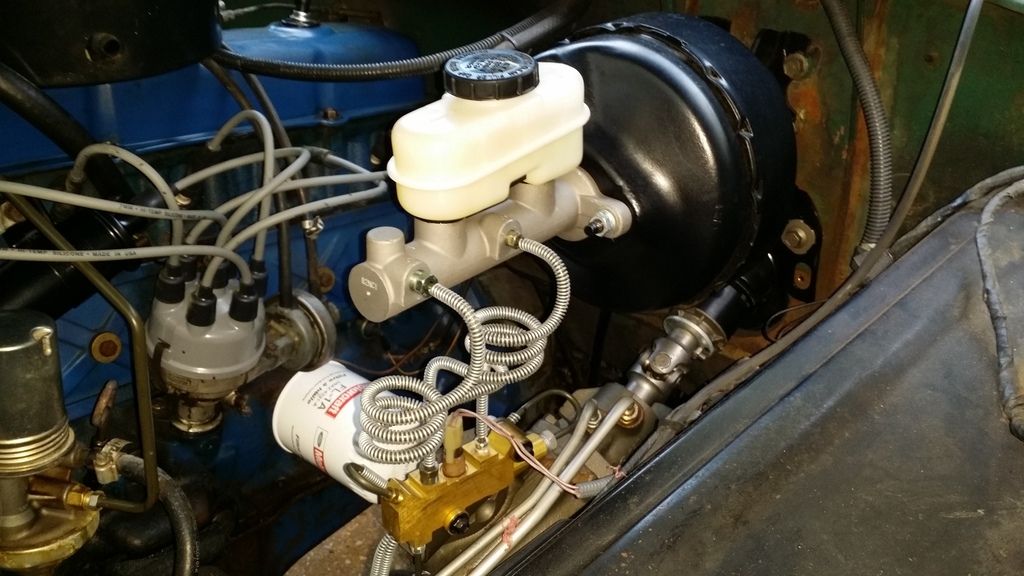

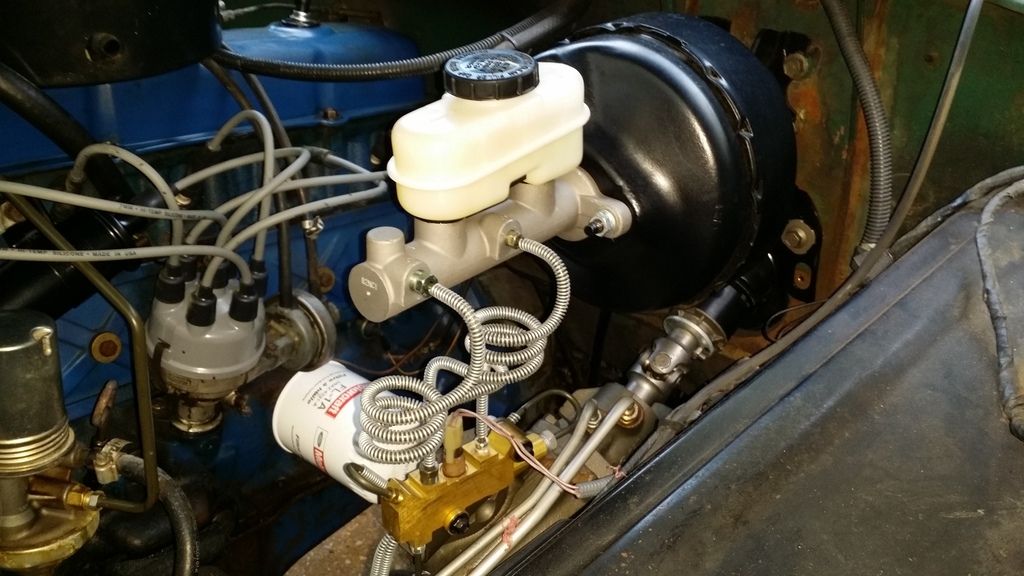

1975 F350 dual diaphragm Bendix booster in my truck. --I have an F100 with single piston front calipers but, the booster was originally on a truck with twin-piston front calipers.

1975 F350 dual diaphragm Bendix booster in my truck. --I have an F100 with single piston front calipers but, the booster was originally on a truck with twin-piston front calipers.

#4

#5

#6

Join Date: Jun 2014

Location: Oakhust NJ Jersey Shore

Posts: 3,208

Likes: 0

Received 2 Likes

on

2 Posts

If you have a single diaphragm brake booster, upgrading to a dual diaphragm unit will make the dual piston calipers easier to apply.

1975 F350 dual diaphragm Bendix booster in my truck. --I have an F100 with single piston front calipers but, the booster was originally on a truck with twin-piston front calipers.

1975 F350 dual diaphragm Bendix booster in my truck. --I have an F100 with single piston front calipers but, the booster was originally on a truck with twin-piston front calipers.

#7

Trending Topics

#8

brake booster

I updated the MC and proportioning valve for a dual piston disk setup. When I hit the pedal, it goes almost to the floor with the engine running, and it is not grabbing the wheels hard. I have to push with a lot of force. The brake pedal is hard with the engine off. I assume the brake booster, that was for the original drum setup, is not up to the task, or is bad. So the 77 F350 has the same long rod to reach to the brake pedal as the current one that came with my 73 F250? The brake booster for the 77 crew cab has a short rod going to the pedal, about 5-6 inchs. The one on my truck reaches about 10 inches. Or do I need to the the brake pedal off of the F350? I do have a 79 F350 in a local pick n pull, so if that would work, I could get the brake pedal from that.

#9

Oh man, I've been looking off and on for a newer style MC with plastic reservoir. Been wanting to eliminate that nasty break fluid leaking on crap and ruining paint.

I already have the f350 booster. Anything special about the 1995 explorer to know when getting a MC? Engine size matter at all? Any changes to pushrod needed?

I already have the f350 booster. Anything special about the 1995 explorer to know when getting a MC? Engine size matter at all? Any changes to pushrod needed?

#10

#11

Aside from the booster, the biggest thing that will affect braking performance is the bore diameter of the MC.

The larger the MC bore diameter, the more volume of fluid it will move but, at a reduced output pressure. The pedal will have less forward travel, will likely feel hard to push and it will be more difficult to bring the vehicle to a stop within a reasonable distance.

A smaller MC bore diameter will generate more output pressure but, will have more pedal travel and the pedal will feel less firm.

A typical manual brake system will have around a 6:1 leverage ratio between the brake pedal pin location where the MC input rod attaches to and the pivot point (fulcrum) of the brake pedal, to where the pedal mounts to the pedal hanger.

A typical power brake pedal ratio is around 4:1. With the brakes being boosted, it doesn't need the extra leverage. A high leverage rate on a boosted system will make the brakes overly sensitive to the application of the brake pedal.

Brake engineers design the brake system for a particular vehicle so that all of the individual parts work together as a matched system. But, there are always compromises that have to be made. This is generally done with the MC bore diameter and what the average person can comfortably apply reasonable pressure on the brake pedal, to bring the vehicle to a stop in an acceptable distance.

However, in reference to a brake booster, it doesn't know what type of brakes are on the vehicle. It doesn't know if the vehicle has drums all the way around, if it has discs front/drums rear or, if there are disc brakes all the way around. In simple terms, a brake booster is just a force multiplier. --it takes a smaller input force, applied by the driver through the brake pedal, and multiplies the output of that force being applied to the MC and ultimately, on the brakes themselves.

In the case of the Bumpside trucks ('67-'72), none of the F100s came with factory front discs. They were ALL equipped from the factory with 4-wheel drum brakes. Power (drum) brakes were optional on them.

Disc brakes (manual or power) were only (optionally) available on the F250 and F350s beginning in 1968, but not on the F100s.

1967 was the first year Ford (and all other domestic auto manufacturers) went to split brake systems with tandem MCs.

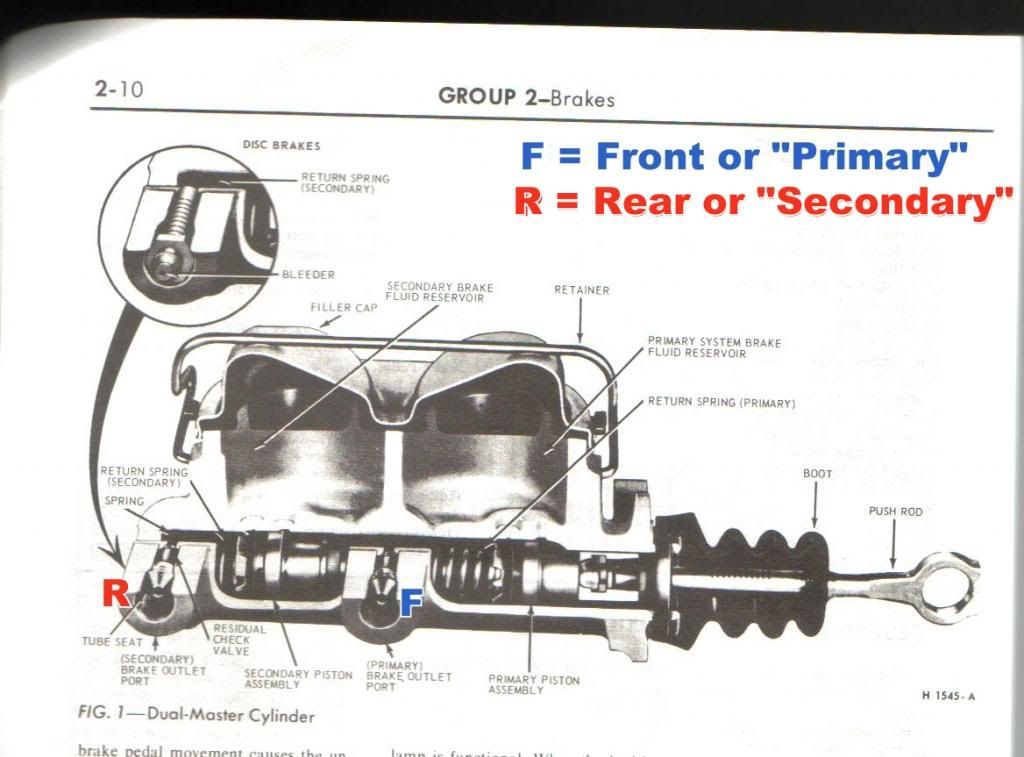

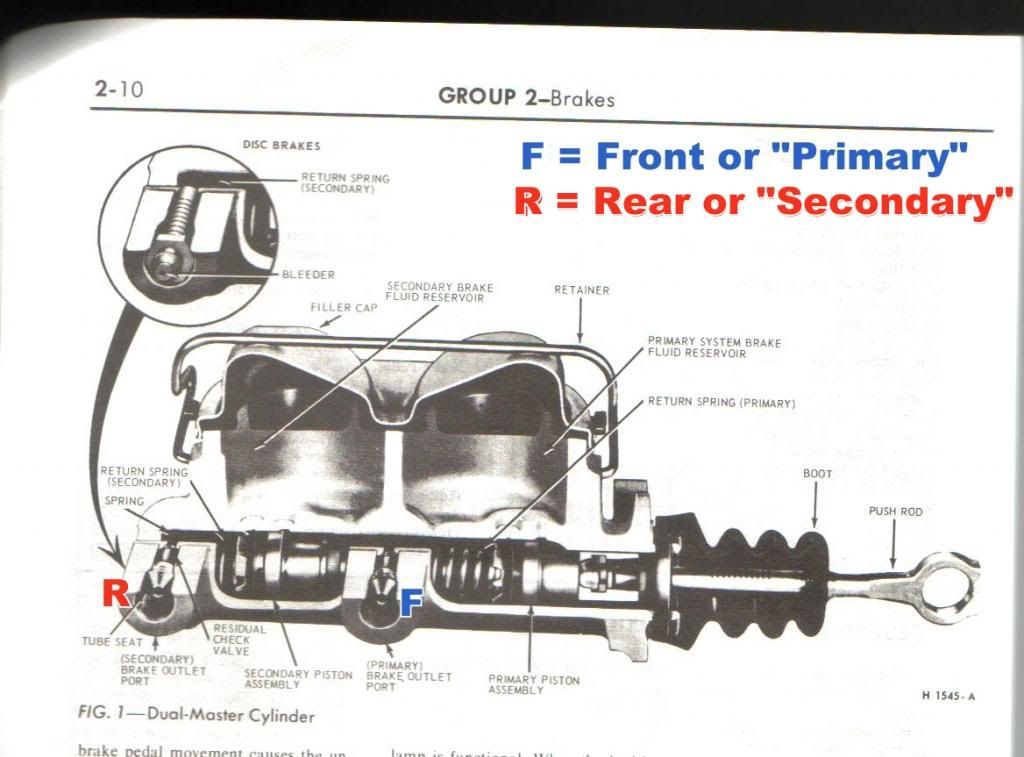

This is a cutaway view of a typical drum/drum manual brake MC.

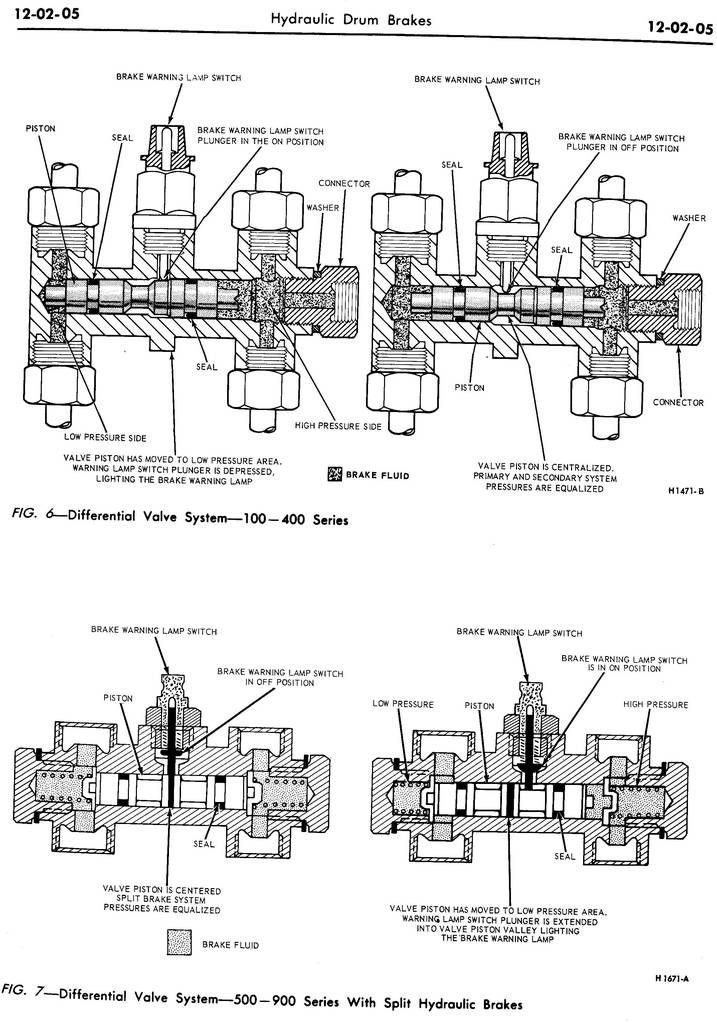

1967 was also when the brake pressure differential valve first came into use. In 1967, the plastic brake switch on the valve only had one pin and a single wire going to it. From 1968-up, the brake switch had two pins and two wires going to the switch.

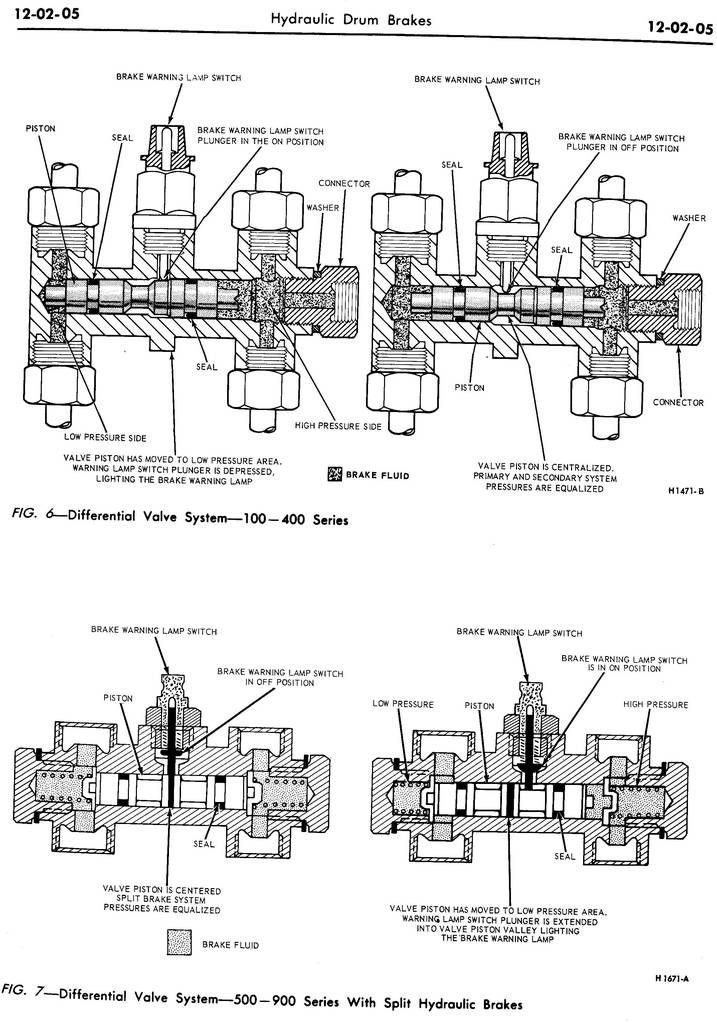

Pressure coming out of the primary (front brake) circuit and secondary (rear brake) circuit of the MC is equal. The equal pressure is passed through the pressure differential brake valve and this pressure is equally applied across both ends of the pressure differential valve spool, inside the valve body. The balance in pressure keeps the pressure differential valve spool centered.

If, for example, there's a rear wheel cylinder failure or, a ruptured flexible brake hose or hard line rupture, there will be an imbalance in brake pressure in the secondary vs. primary brake circuits when the brakes are applied. This imbalance will place a higher pressure on the primary side of the pressure differential brake valve spool. The higher brake fluid pressure of the good side will force the spool over to the failed side.

The plastic brake switch, sticking out of the pressure differential valve body, has a pin inside the valve body that resides in a narrow 'hour glass' portion of the valve spool. When primary and secondary brake pressures are not equal, the spool will shift over to the failed side. The brake switch pin will ride up the 'ramp' on the valve spool, which closes the switch contacts.

The closed contacts of the switch will illuminate the red brake warning light on the dash.

This is the drum/drum pressure differential brake valve from my '69 F100.

This is an internal view of the drum/drum pressure differential valve. (upper half of diagram).

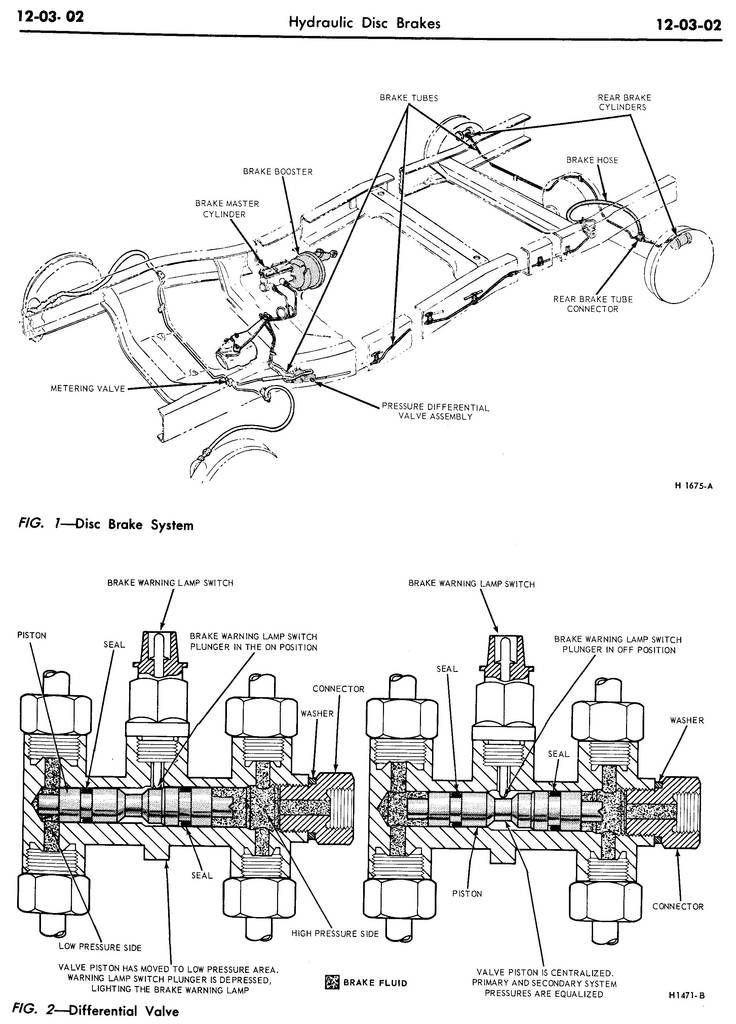

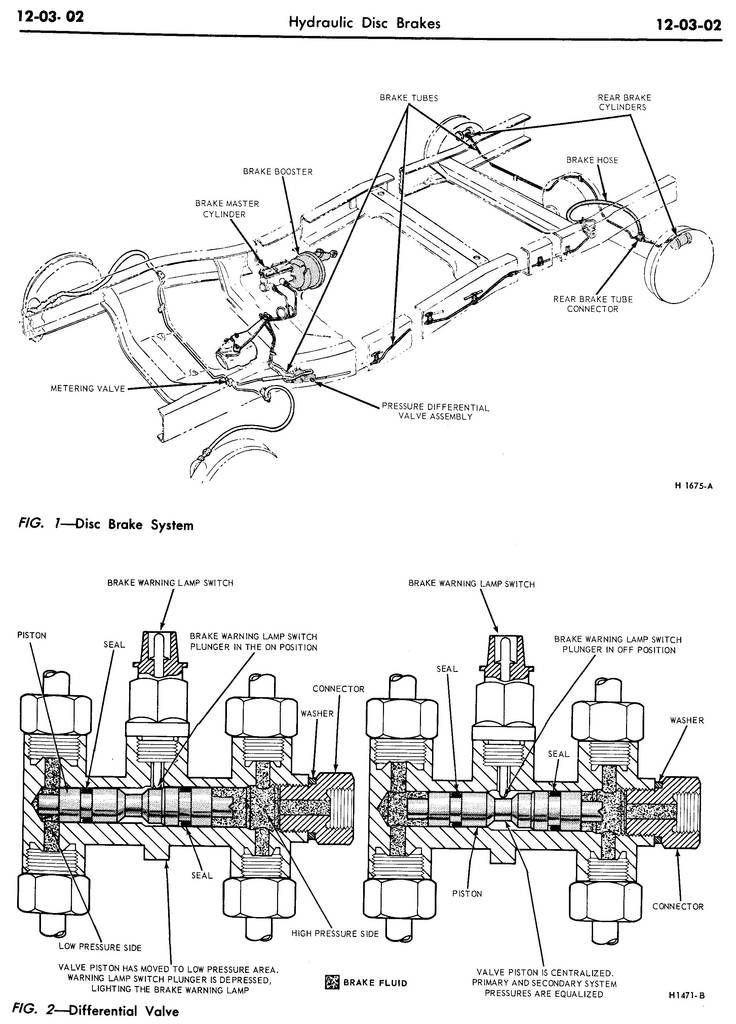

In the '68-'72 Bumpside F250/F350 trucks that had optional front discs, the same pressure differential valve that was used used on the all-wheel drum brake trucks was also used on the disc/drum trucks. The primary difference was a stand-alone metering (hold-off) valve the was plumbed, in series, to the front discs.

Stand-alone metering valve for the front disc brake circuit.

Diagram showing where the pressure differential and metering valves would be located on a Bumpside that had front discs.

In 1973, the F100-F350s came factory stock with manual front disc brakes --power was optional. SOME of the older style pressure differential brake valves, like the ones used on the Bumpsides, were used on the Dentsides too but, most of the brake valves used in the Dentsides had changed to multi-function disc brake valves or, commonly referred to as a disc/drum 'combination valve.'

People will also often reference this valve as a "proportioning valve." However, proportioning is only ONE function of this disc/drum combination valve (proportioning is NOT used on drum/drum brake systems).

The three functions of the disc/drum combination valve are: metering to the front disc brake circuit, pressure differential sensing between the primary and secondary brake circuits and proportioning to the rear drum brake circuit.

There were at least two combination disc/drum brake valves commonly used on the Dentsides. One was a brass valve manufactured by Weatherhead. The other was a cast iron combination valve manufactured by Kelsey-Hayes.

Example of the brass Weatherhead disc/drum combination brake valve. (this came off the 1975 F350 donor truck my dual diaphragm booster was taken from to put on my '69 F100).

The other style of combination brake valve seen on the Dentsides is this cast iron Kelsey-Hayes combination valve. (this valve was taken from the 1977 F100 donor truck my front disc brake suspension was taken from for my truck).

In years past, I had used the manually-adjustable proportioning valves, when I was doing a front disc or, an all wheel disc brake conversion on a vehicle. Anymore, I prefer to use a factory combination brake valve.

If you don't know what the proportioning valve pressure setting needs to be set at for your vehicle and, if you don't have a set of brake pressure gauges to tune the manual proportioning valve to that pressure setting, turning the ****, after some hard stops, is only a guess that it's anywhere close to being right. --maybe it is. Maybe it isn't. Chances are greater that it will be off the mark.

The brakes are the most important system of any vehicle. The ability for the vehicle to go or, to go fast, doesn't mean anything if you can't controllably stop that vehicle in a short distance. Brake systems aren't rocket science but, you need to know what the components are, what they do, where they do (or don't) apply and above all, just exercise a lot of common sense and don't short-cut things when you are modifying a brake system.

The larger the MC bore diameter, the more volume of fluid it will move but, at a reduced output pressure. The pedal will have less forward travel, will likely feel hard to push and it will be more difficult to bring the vehicle to a stop within a reasonable distance.

A smaller MC bore diameter will generate more output pressure but, will have more pedal travel and the pedal will feel less firm.

A typical manual brake system will have around a 6:1 leverage ratio between the brake pedal pin location where the MC input rod attaches to and the pivot point (fulcrum) of the brake pedal, to where the pedal mounts to the pedal hanger.

A typical power brake pedal ratio is around 4:1. With the brakes being boosted, it doesn't need the extra leverage. A high leverage rate on a boosted system will make the brakes overly sensitive to the application of the brake pedal.

Brake engineers design the brake system for a particular vehicle so that all of the individual parts work together as a matched system. But, there are always compromises that have to be made. This is generally done with the MC bore diameter and what the average person can comfortably apply reasonable pressure on the brake pedal, to bring the vehicle to a stop in an acceptable distance.

However, in reference to a brake booster, it doesn't know what type of brakes are on the vehicle. It doesn't know if the vehicle has drums all the way around, if it has discs front/drums rear or, if there are disc brakes all the way around. In simple terms, a brake booster is just a force multiplier. --it takes a smaller input force, applied by the driver through the brake pedal, and multiplies the output of that force being applied to the MC and ultimately, on the brakes themselves.

In the case of the Bumpside trucks ('67-'72), none of the F100s came with factory front discs. They were ALL equipped from the factory with 4-wheel drum brakes. Power (drum) brakes were optional on them.

Disc brakes (manual or power) were only (optionally) available on the F250 and F350s beginning in 1968, but not on the F100s.

1967 was the first year Ford (and all other domestic auto manufacturers) went to split brake systems with tandem MCs.

This is a cutaway view of a typical drum/drum manual brake MC.

1967 was also when the brake pressure differential valve first came into use. In 1967, the plastic brake switch on the valve only had one pin and a single wire going to it. From 1968-up, the brake switch had two pins and two wires going to the switch.

Pressure coming out of the primary (front brake) circuit and secondary (rear brake) circuit of the MC is equal. The equal pressure is passed through the pressure differential brake valve and this pressure is equally applied across both ends of the pressure differential valve spool, inside the valve body. The balance in pressure keeps the pressure differential valve spool centered.

If, for example, there's a rear wheel cylinder failure or, a ruptured flexible brake hose or hard line rupture, there will be an imbalance in brake pressure in the secondary vs. primary brake circuits when the brakes are applied. This imbalance will place a higher pressure on the primary side of the pressure differential brake valve spool. The higher brake fluid pressure of the good side will force the spool over to the failed side.

The plastic brake switch, sticking out of the pressure differential valve body, has a pin inside the valve body that resides in a narrow 'hour glass' portion of the valve spool. When primary and secondary brake pressures are not equal, the spool will shift over to the failed side. The brake switch pin will ride up the 'ramp' on the valve spool, which closes the switch contacts.

The closed contacts of the switch will illuminate the red brake warning light on the dash.

This is the drum/drum pressure differential brake valve from my '69 F100.

This is an internal view of the drum/drum pressure differential valve. (upper half of diagram).

In the '68-'72 Bumpside F250/F350 trucks that had optional front discs, the same pressure differential valve that was used used on the all-wheel drum brake trucks was also used on the disc/drum trucks. The primary difference was a stand-alone metering (hold-off) valve the was plumbed, in series, to the front discs.

Stand-alone metering valve for the front disc brake circuit.

Diagram showing where the pressure differential and metering valves would be located on a Bumpside that had front discs.

In 1973, the F100-F350s came factory stock with manual front disc brakes --power was optional. SOME of the older style pressure differential brake valves, like the ones used on the Bumpsides, were used on the Dentsides too but, most of the brake valves used in the Dentsides had changed to multi-function disc brake valves or, commonly referred to as a disc/drum 'combination valve.'

People will also often reference this valve as a "proportioning valve." However, proportioning is only ONE function of this disc/drum combination valve (proportioning is NOT used on drum/drum brake systems).

The three functions of the disc/drum combination valve are: metering to the front disc brake circuit, pressure differential sensing between the primary and secondary brake circuits and proportioning to the rear drum brake circuit.

There were at least two combination disc/drum brake valves commonly used on the Dentsides. One was a brass valve manufactured by Weatherhead. The other was a cast iron combination valve manufactured by Kelsey-Hayes.

Example of the brass Weatherhead disc/drum combination brake valve. (this came off the 1975 F350 donor truck my dual diaphragm booster was taken from to put on my '69 F100).

The other style of combination brake valve seen on the Dentsides is this cast iron Kelsey-Hayes combination valve. (this valve was taken from the 1977 F100 donor truck my front disc brake suspension was taken from for my truck).

In years past, I had used the manually-adjustable proportioning valves, when I was doing a front disc or, an all wheel disc brake conversion on a vehicle. Anymore, I prefer to use a factory combination brake valve.

If you don't know what the proportioning valve pressure setting needs to be set at for your vehicle and, if you don't have a set of brake pressure gauges to tune the manual proportioning valve to that pressure setting, turning the ****, after some hard stops, is only a guess that it's anywhere close to being right. --maybe it is. Maybe it isn't. Chances are greater that it will be off the mark.

The brakes are the most important system of any vehicle. The ability for the vehicle to go or, to go fast, doesn't mean anything if you can't controllably stop that vehicle in a short distance. Brake systems aren't rocket science but, you need to know what the components are, what they do, where they do (or don't) apply and above all, just exercise a lot of common sense and don't short-cut things when you are modifying a brake system.

#12

Oh man, I've been looking off and on for a newer style MC with plastic reservoir. Been wanting to eliminate that nasty break fluid leaking on crap and ruining paint.

I already have the f350 booster. Anything special about the 1995 explorer to know when getting a MC? Engine size matter at all? Any changes to pushrod needed?

I already have the f350 booster. Anything special about the 1995 explorer to know when getting a MC? Engine size matter at all? Any changes to pushrod needed?

A manual brake MC will come with an input rod but, a power brake MC will not.

The booster will have an adjustable output rod that fits into the back of the MC. --the length of the booster's output rod needs to be checked/adjusted for the engagement depth into the MC. The tip of the booster's output rod should not bottom out in the MC, when the brake pedal isn't being applied. There should be a .005"-.010" gap between the tip of the output rod to the MC primary piston.

How to adjust the booster output rod to the depth of the MC.

http://www.maximummotorsports.com/as.../MMBAK-1r1.pdf

There are two different versions of the '95 Explorer MC. In the photo below, you'll notice there's a 'rhino horn' at the front of the MC body. The MC I have was without cruise control.

There's also a version of this MC w/cruise control. On that version, the 'rhino horn' will be drilled and tapped for a pressure switch.

The bore diameter of this MC is 1.062" (1-1/16").

You'll have to have SAE double flare tools as well as ISO metric bubble flare tools to run the brake lines from the MC to the brake valve.

The primary port on this MC requires a 10 mm x 1.0 metric bubble flare fitting. The secondary port fitting is 12 mm x 1.0.

Engine size doesn't matter. Just use the MC part number from above and it will be just like the MC I have.

#13

Let me go ahead and stride against the grain and suggest you go hydroboost for the braking system; upgrading to the dual diaphragm booster is hit or miss as to how well it works. It's worked for some but several have been asking what they did wrong.

I have a 79 Bronco, but when I was trying to make the brakes somewhat less deadly, I wound up first replacing everything on the system, then swapping it with the F-250 "Upgrade", then with F-350 stuff, then with rear disks, etc, etc, etc.

ONLY when I went to the Hydroboost setup did I make things safe and reliable. In my particular case, I used the booster out of a 2004(?) F-350.

It's easy, I haven't read about anyone installing it and not having it work and it's pretty damn cool as well.

I have a 79 Bronco, but when I was trying to make the brakes somewhat less deadly, I wound up first replacing everything on the system, then swapping it with the F-250 "Upgrade", then with F-350 stuff, then with rear disks, etc, etc, etc.

ONLY when I went to the Hydroboost setup did I make things safe and reliable. In my particular case, I used the booster out of a 2004(?) F-350.

It's easy, I haven't read about anyone installing it and not having it work and it's pretty damn cool as well.

#14

Stand-alone metering valve

Thanks Ranger for the great in depth information. I have one question about the Stand-alone metering valve. I had 4 wheel drum, and now have dual pistons in the front, and still have drums in back. Should my truck have the extra metering valve installed? Is this something I should have or remove for the current setup? Also with the increased brake fluid flow, should my brake line size be increased? Thanks for all responses.

#15

73 brake booster

I found at Orielly's a brake booster for a 73 with dual piston calipers. Does anyone think that this will give me the extra boost I am missing? I did not know that a 73 had dual piston option.

Now the hydroboost sounds like a good option, but trying to find one that will work in my truck may be an issue. Is it hit and miss to try and find one, or is there a year range that will be a match? Will I need to take the entire system (pedal, booster, MC) off a donor truck? And will I need to make modifications?

Now the hydroboost sounds like a good option, but trying to find one that will work in my truck may be an issue. Is it hit and miss to try and find one, or is there a year range that will be a match? Will I need to take the entire system (pedal, booster, MC) off a donor truck? And will I need to make modifications?