Broken Rocker Arm Bolt / Throttle Linkage

#1

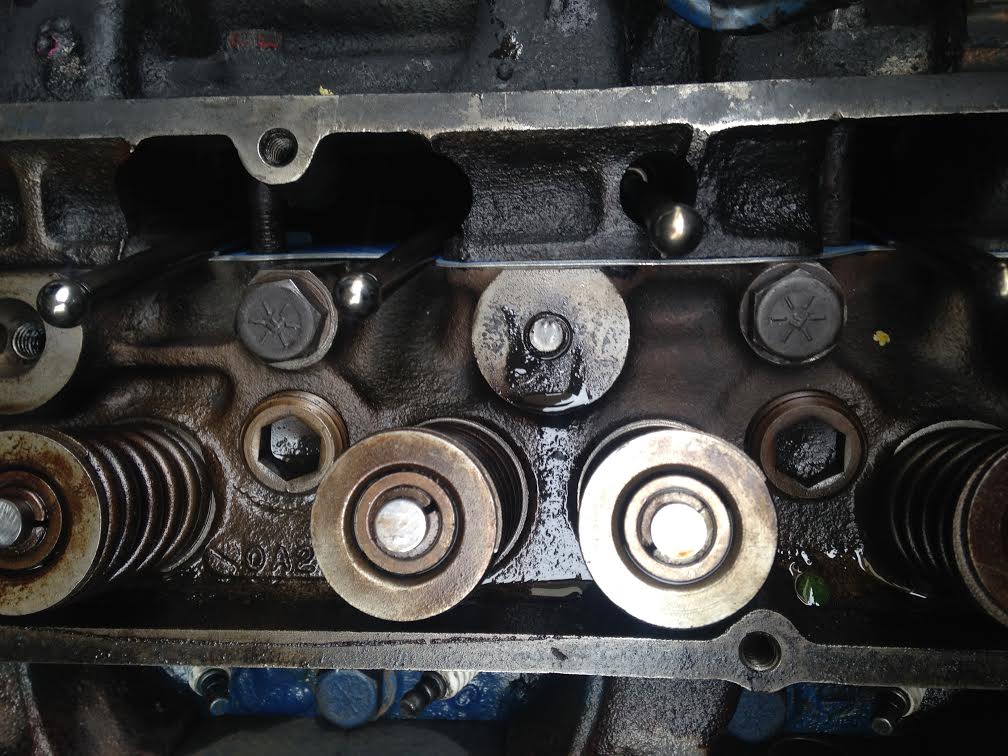

Was putting the rocker arms back on my FE360 and apparently my torque wrench is broken. I took a bit too long to realize I was torquing the bolts way beyond 45 ft lbs (even though I had it set correctly on the torque wrench). Long story short it ended up snapping one of my rocker arms bolts in the head  I tested my torque wrench by attempting to tighten my head bolts (which are @ 90 ft lbs) and it would even click when I got the head bolt to move.

I tested my torque wrench by attempting to tighten my head bolts (which are @ 90 ft lbs) and it would even click when I got the head bolt to move.

Here are some photos to show what I am talking about. I took some vice grips and squeezed the bolt as tight as possible and had no luck. It is really stuck in there. I purchased some replacement bolts, but am stuck until I can get this old one out. I am unsure of what to do.

As for the throttle linkage: The throttle linkage probably did its job well at one point in time, but the ball / socket is worn out. This causes the ball to fall out of the socket all the time. I am unsure if I can buy a new linkage, find one at a pickapart, etc. I am not sure as to whether or not this is the original linkage.

Oh, I also got my hands on a 1967 Ford Truck AM Radio after a 2-month search. Only ones I could find, people wanted $100+. Found one on CL for good price.

Only ones I could find, people wanted $100+. Found one on CL for good price.

I tested my torque wrench by attempting to tighten my head bolts (which are @ 90 ft lbs) and it would even click when I got the head bolt to move.

I tested my torque wrench by attempting to tighten my head bolts (which are @ 90 ft lbs) and it would even click when I got the head bolt to move.Here are some photos to show what I am talking about. I took some vice grips and squeezed the bolt as tight as possible and had no luck. It is really stuck in there. I purchased some replacement bolts, but am stuck until I can get this old one out. I am unsure of what to do.

As for the throttle linkage: The throttle linkage probably did its job well at one point in time, but the ball / socket is worn out. This causes the ball to fall out of the socket all the time. I am unsure if I can buy a new linkage, find one at a pickapart, etc. I am not sure as to whether or not this is the original linkage.

Oh, I also got my hands on a 1967 Ford Truck AM Radio after a 2-month search.

Only ones I could find, people wanted $100+. Found one on CL for good price.

Only ones I could find, people wanted $100+. Found one on CL for good price.

#2

I'd EZ-out that bolt... it's fat enough to be doable. Alternatively, weld a nut on it, let it cool, and then back it out.

On the throttle linkage, Summit sells replacement parts for "ball socket"-type linkages. Looks like the PO threaded the stud through the arm which is never a good idea cuz there's not enough meat.

On the throttle linkage, Summit sells replacement parts for "ball socket"-type linkages. Looks like the PO threaded the stud through the arm which is never a good idea cuz there's not enough meat.

#3

I'd EZ-out that bolt... it's fat enough to be doable. Alternatively, weld a nut on it, let it cool, and then back it out.

On the throttle linkage, Summit sells replacement parts for "ball socket"-type linkages. Looks like the PO threaded the stud through the arm which is never a good idea cuz there's not enough meat.

On the throttle linkage, Summit sells replacement parts for "ball socket"-type linkages. Looks like the PO threaded the stud through the arm which is never a good idea cuz there's not enough meat.

I will check out Summit's site and see what I can find.

Unfortionetly I do not own a welder, but I know someone close by who does. (Only problem is I can't drive the truck over there.

) I will see what I can do. I was going to attempt to EZ out it, but I think it is in there a bit too tight. I will attempt it anyways. Worst casenario I pay someone to come out and bring a welder box to weld a nut.

) I will see what I can do. I was going to attempt to EZ out it, but I think it is in there a bit too tight. I will attempt it anyways. Worst casenario I pay someone to come out and bring a welder box to weld a nut.Thanks for the advice,

Mister_King

#4

Here ya go on the linkage: http://www.summitracing.com/search/p...le-lever-studs

Btw, no that's not OEM for the pedal linkage side. IIRC, it was a configuration for 78/79s (maybe others) on the carb side.. I pirated the set up for my '70'

Good luck on the rocker stand bolt.... you'll get it done.

Btw, no that's not OEM for the pedal linkage side. IIRC, it was a configuration for 78/79s (maybe others) on the carb side.. I pirated the set up for my '70'

Good luck on the rocker stand bolt.... you'll get it done.

#5

Here ya go on the linkage: http://www.summitracing.com/search/p...le-lever-studs

Btw, no that's not OEM for the pedal linkage side. IIRC, it was a configuration for 78/79s (maybe others) on the carb side.. I pirated the set up for my '70'

Good luck on the rocker stand bolt.... you'll get it done.

Btw, no that's not OEM for the pedal linkage side. IIRC, it was a configuration for 78/79s (maybe others) on the carb side.. I pirated the set up for my '70'

Good luck on the rocker stand bolt.... you'll get it done.

Thanks for the link.

Thanks for the link.It to dark to do anything with the bolt as of rite now, but I will attempt to take care of it tomorrow. I appreciate the feedback.

Just curious, what would the original linkage from pedal to carburetor look like? I was thinking of going to a local pickapart and taking a reliable looking linkage of something there. (Maybe grab a rocker arm bolt while I'm there. Not too sure if these ones I purchased are actually OEM bolts.)

#6

The OEM linkage on an FE is a funky "trapeze" linkage". Basically a short linkage connected the pedal arm to the trapeze which, in turn, connected via another arm to the carburetor. It works very much like the Z-bar for the clutch.

Simplification was a goal so here is the 78/79 setup on my 73. The arm just unclips from the ball stud on the carb.

Here's a similar setup:

Simplification was a goal so here is the 78/79 setup on my 73. The arm just unclips from the ball stud on the carb.

Here's a similar setup:

#7

The OEM linkage on an FE is a funky "trapeze" linkage". Basically a short linkage connected the pedal arm to the trapeze which, in turn, connected via another arm to the carburetor. It works very much like the Z-bar for the clutch.

Simplification was a goal so here is the 78/79 setup on my 73. The arm just unclips from the ball stud on the carb.

Here's a similar setup:

Simplification was a goal so here is the 78/79 setup on my 73. The arm just unclips from the ball stud on the carb.

Here's a similar setup:

Trending Topics

#9

For the rocker bolt, get a nut big enough to sit down over the section of bolt sticking out and weld/tack it on. Let it cool, put a wrench on it and back it out. Works like a charm. HIO, just realized you already recommended this. Unfortunately I've had to do it a time or two. It works great though

#11

That rod won't stay on the ball because it is missing a part. There was a spring steel collar that wrapped around the rod end by the hole. The ball would pass through the collar,spreading it apart,then the ends of it would come back together BEHIND the ball. This collar might have fallen down on the intake ,bell housing, or top of tranny. I'll see if I can find a pic of one.

<iframe name="lbIframe" class="grey" id="lbIframe" frameborder="0" style="display: none;"></iframe>

<iframe name="lbIframe" class="grey" id="lbIframe" frameborder="0" style="display: none;"></iframe>

#12

#13

like said , easiest is weld , have a plumber buddy ? they normally have a portable oxy/acetylene kit that will get job done . MIG is preferred .

if you drill /easy out be sure to cover area with old towel or something to catch the shavings . poke a hole in towel and put around broken stud .

good luck

if you drill /easy out be sure to cover area with old towel or something to catch the shavings . poke a hole in towel and put around broken stud .

good luck

#14

Call me chicken, but I never use an EZ out on an engine. They break easily and once that happens a machine shop won't even touch it. I threw away every EZ out I had so I wouldn't be tempted. Good luck, but consider yourself warned. I'm guessing you have a "turn handle to adjust" style torque wrench. They need returned to zero before storing or things like this happen.

#15

Join Date: Aug 2003

Location: **** hole San Jose ca.

Posts: 7,592

Likes: 0

Received 9 Likes

on

9 Posts

Hmm I see a lot of the "Sears" turn handle to adjust style torque wrenches,

at the loco Flea market and many other tools that have been returned to Sear.

Thiers store outlets thatselling all the

store returned items junk that's made overseas that fails.

These outlets sell to flea-market dealers./vendors.

They use to have monthly catalogs just for the Flea market seller-dealers of where to buy this all imported junk to good & bad crap tools too everything else.

I use to be delivered once a month to most all flea- market here in the SF Bay areas.

So you could have one of those junk adjustable style torque wrenches.

Did you realizes that the rocker bolts have one longer Bolt?

That only goes in one threaded boss, it's for the oil feed.

You may have put it in the wrong thread boss and bottomed out and broke seated into the bottom which will make it even harder to remove.

If it's not bottom out but just over tightened then I'd use a hammer and a flat end large bolt long enough to hit hard on the broken head stud. This will help releave any stress on the pulled threads from over tightening.

You can't just do a few light pecks but hit it harder each time you try to remove it with some vice grips.

Or center punch it real good a few time then with a small chisel make a starting indent and lightly try working it out.

Or cut a screw driver slot with a dermal cutting wheel disc if you have one then work it out..

There's has been very few broken studs, I could not get out.

You just have to go about the right ways. If first way don't work then go the the next best way with the tools you have.

Just don't screw up the boss surface for the rocker arm pedestal wher it can't be used.

Buy it's about 25-50 bucks to have a shop remove it if you took the head into them.

Welding a nut on with Mig or other electric types. A gas welder puts out to much heat

maybe just heat it up some also helps relieve stress tipping it on the head stud let cool and try removing it.

Keep us posted

Orich

at the loco Flea market and many other tools that have been returned to Sear.

Thiers store outlets thatselling all the

store returned items junk that's made overseas that fails.

These outlets sell to flea-market dealers./vendors.

They use to have monthly catalogs just for the Flea market seller-dealers of where to buy this all imported junk to good & bad crap tools too everything else.

I use to be delivered once a month to most all flea- market here in the SF Bay areas.

So you could have one of those junk adjustable style torque wrenches.

Did you realizes that the rocker bolts have one longer Bolt?

That only goes in one threaded boss, it's for the oil feed.

You may have put it in the wrong thread boss and bottomed out and broke seated into the bottom which will make it even harder to remove.

If it's not bottom out but just over tightened then I'd use a hammer and a flat end large bolt long enough to hit hard on the broken head stud. This will help releave any stress on the pulled threads from over tightening.

You can't just do a few light pecks but hit it harder each time you try to remove it with some vice grips.

Or center punch it real good a few time then with a small chisel make a starting indent and lightly try working it out.

Or cut a screw driver slot with a dermal cutting wheel disc if you have one then work it out..

There's has been very few broken studs, I could not get out.

You just have to go about the right ways. If first way don't work then go the the next best way with the tools you have.

Just don't screw up the boss surface for the rocker arm pedestal wher it can't be used.

Buy it's about 25-50 bucks to have a shop remove it if you took the head into them.

Welding a nut on with Mig or other electric types. A gas welder puts out to much heat

maybe just heat it up some also helps relieve stress tipping it on the head stud let cool and try removing it.

Keep us posted

Orich