Another Cummins Swap...

#76

#77

The following users liked this post:

#78

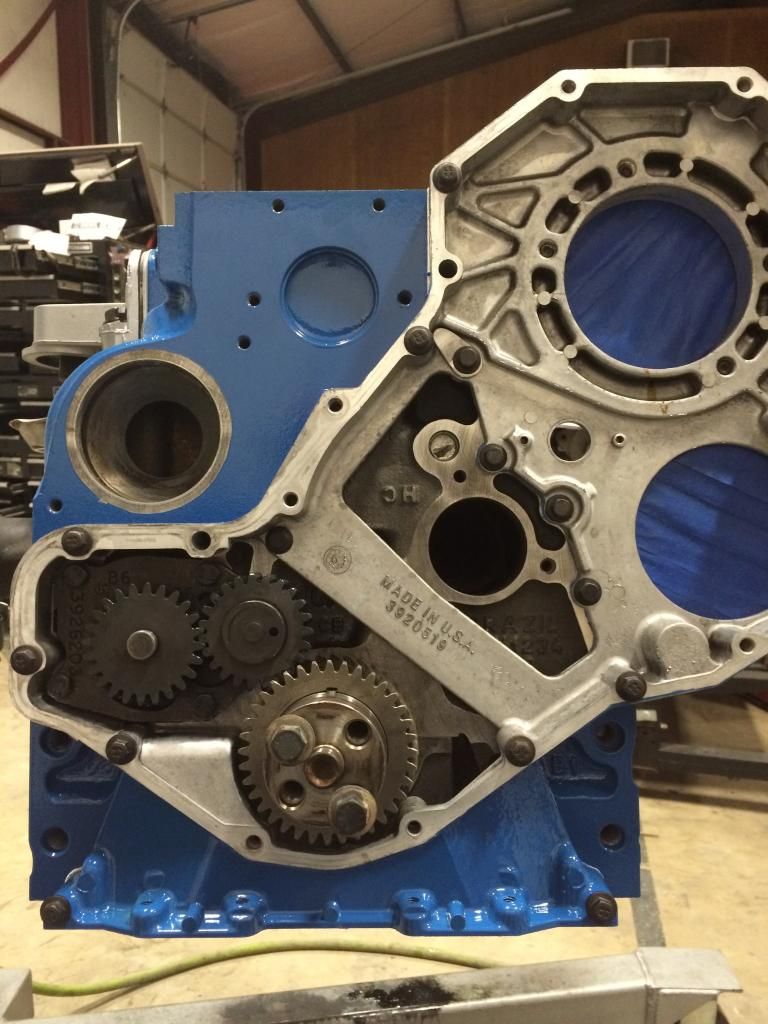

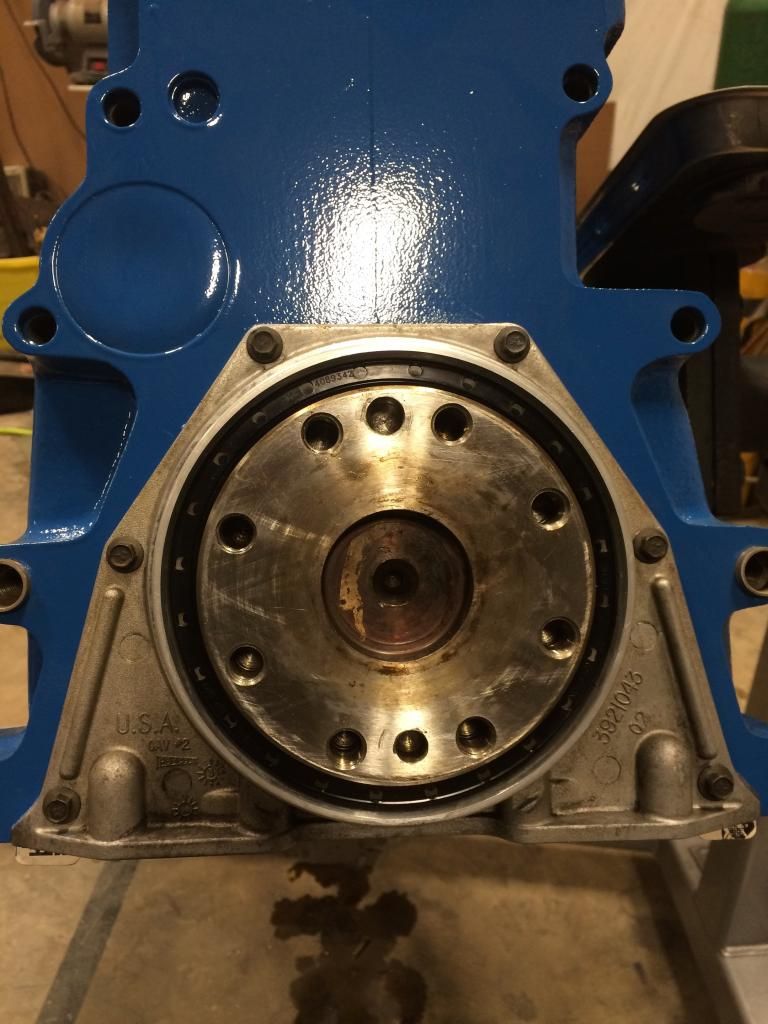

Got a little done today. Still dont have my correct cam bushing so couldn't complete front gear train. First up, I got the oil cooler/filter housing installed

Not a lot of people use these anymore but I like them, makes installing the plug while compressing the relief valve spring easy

Torqued and completed assy.

Not a lot of people use these anymore but I like them, makes installing the plug while compressing the relief valve spring easy

Torqued and completed assy.

#79

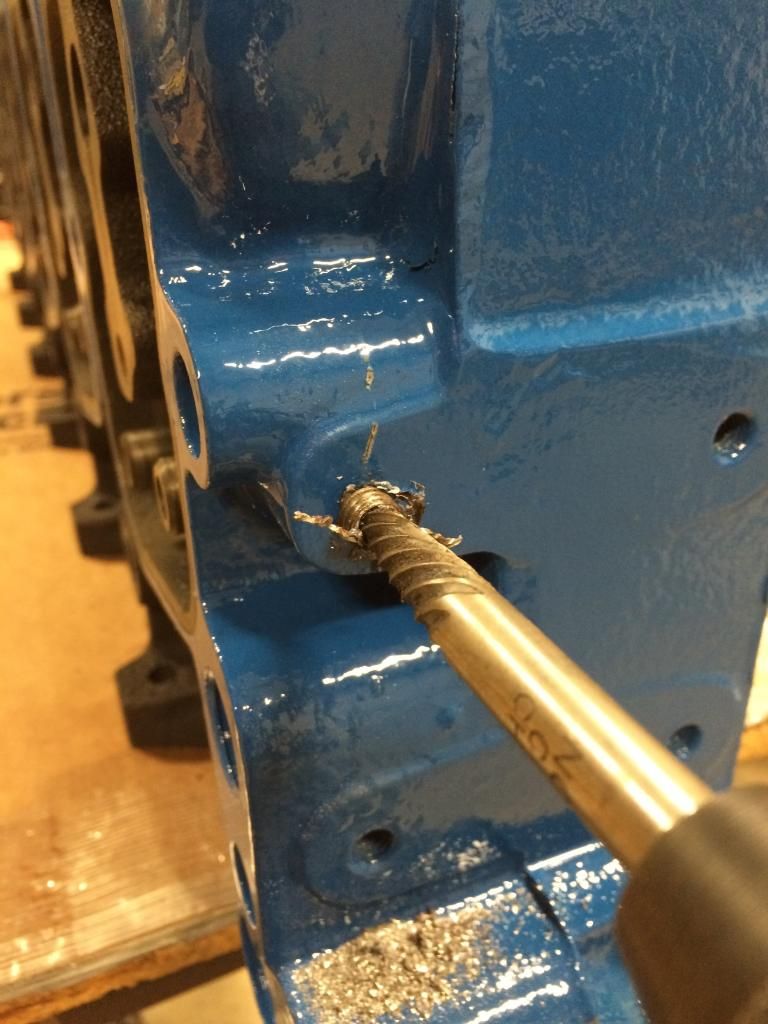

A few pics so everyone doesn't jump me about it. Building a tab for the KDP

Drill the hole before cutting

All burrs and sharp edges removed

My KDP protrudes a little so a little offset makes for a better fit. Low tech metal fab

Swap ends and hit it again

Presto

Installed

All interior bolts get a dose of this for security

Drill the hole before cutting

All burrs and sharp edges removed

My KDP protrudes a little so a little offset makes for a better fit. Low tech metal fab

Swap ends and hit it again

Presto

Installed

All interior bolts get a dose of this for security

Last edited by xringonly; 03-08-2015 at 09:04 PM. Reason: double pic

#83

#84

Comming together nicely. Good decision on the loctite. What ever you do do not forget the loctite on the harmonic damper bolts. Learned the hard way and shredded that $30.00 belt. I honestly would use Loctite on all the bolts you encounter even the oil galley / water galley soft plugs.

It's expensive but when you get to the intake through bolts and injectors I recommend loctite 37397 and primer 37509. I had three injectors leaking from the nozzle hold down nuts. The injector builder used what appeared to be black RTV and did not torque the nuts down properly. I tore them down cleaned everything with a brass brush and acetone. And went back together with that loctite torquing to 30 ft lbs on the nozzle nut. No leaks now. The only downside is you have to let it cure for 3 days before running.

It's expensive but when you get to the intake through bolts and injectors I recommend loctite 37397 and primer 37509. I had three injectors leaking from the nozzle hold down nuts. The injector builder used what appeared to be black RTV and did not torque the nuts down properly. I tore them down cleaned everything with a brass brush and acetone. And went back together with that loctite torquing to 30 ft lbs on the nozzle nut. No leaks now. The only downside is you have to let it cure for 3 days before running.

#85

Comming together nicely. Good decision on the loctite. What ever you do do not forget the loctite on the harmonic damper bolts. Learned the hard way and shredded that $30.00 belt. I honestly would use Loctite on all the bolts you encounter even the oil galley / water galley soft plugs.

It's expensive but when you get to the intake through bolts and injectors I recommend loctite 37397 and primer 37509. I had three injectors leaking from the nozzle hold down nuts. The injector builder used what appeared to be black RTV and did not torque the nuts down properly. I tore them down cleaned everything with a brass brush and acetone. And went back together with that loctite torquing to 30 ft lbs on the nozzle nut. No leaks now. The only downside is you have to let it cure for 3 days before running.

It's expensive but when you get to the intake through bolts and injectors I recommend loctite 37397 and primer 37509. I had three injectors leaking from the nozzle hold down nuts. The injector builder used what appeared to be black RTV and did not torque the nuts down properly. I tore them down cleaned everything with a brass brush and acetone. And went back together with that loctite torquing to 30 ft lbs on the nozzle nut. No leaks now. The only downside is you have to let it cure for 3 days before running.

#86

I have a question for the experienced folks out there. All the swaps I have seen are using the dodge engine, mine is the commercial version and has the 15 qt pan. I want to use this pan if I can because of the larger capacity even if have to modify it a little. Does anyone have experience with this? If I have to modify so much that I loose most of the capacity advantage I would like to know now.

Thanks, Carl

Thanks, Carl

#87

Amazon sells them both.

I have a question for the experienced folks out there. All the swaps I have seen are using the dodge engine, mine is the commercial version and has the 15 qt pan. I want to use this pan if I can because of the larger capacity even if have to modify it a little. Does anyone have experience with this? If I have to modify so much that I loose most of the capacity advantage I would like to know now.

Thanks, Carl

Thanks, Carl

Can you post a picture of the pan, also the front profile like your looking straight at the engine. The dodge pan is 12 quarts I am curious where the extra 3 quarts are in the pan.

#89

#90