Probably a silly question - brake line installation

#1

Probably a silly question - brake line installation

Progress is slow in a cold, dark, garage with no electricity, but I am making a small bit of headway on brake lines. On each connection I try to take apart the hex nut on the line fitting crumbles to rust when touched by the wrenches. With vice grips and rechargeable trouble lite I have removed the lines along the rear axle housing. - Now, here is my question, when the new lines with new fittings are installed onto the new wheel cylinder, should the line feel tight when the fitting is threaded all the way into the female connection on the wheel cylinder?

With the fitting snug into the wheel cylinder and threaded all the way up, I can still slip the line end in and out a little bit. This will surely leak under pressure. Does the flared bit on the end of the line have to be up against the threaded fitting when the threads first catch? Perhaps this is necessary for the flare to be 'compressed' as the fitting is threaded and tightened. On the other end of the line where they go into a "splitter block" mounted on the axle housing, the lines feel good and tight.

Please pardon my ignorance on this matter. I am not a mechanic and I have no experience in fitting steel lines to wheel cylinders. thanks in advance for any help you may provide.

With the fitting snug into the wheel cylinder and threaded all the way up, I can still slip the line end in and out a little bit. This will surely leak under pressure. Does the flared bit on the end of the line have to be up against the threaded fitting when the threads first catch? Perhaps this is necessary for the flare to be 'compressed' as the fitting is threaded and tightened. On the other end of the line where they go into a "splitter block" mounted on the axle housing, the lines feel good and tight.

Please pardon my ignorance on this matter. I am not a mechanic and I have no experience in fitting steel lines to wheel cylinders. thanks in advance for any help you may provide.

#2

#3

#4

The nut is supposed to "crush" the double flare (you are using properly double flared lines aren't you? Single flares are not safe to use on brakes.) Also be sure the flare angle matches the seat angle, there are two different angles commonly used on flared lines. Here a good basic chart to identify the right flares:

<cite>http://www.fedhillusa.com/webnuts/common%20flares6.pdf</cite><cite class="_Rm">

Double flares are somewhat difficult for the average DIYer to form correctly especially with the average inexpensive flaring tool commonly available. Eastwood sells a tool that is likely to work sucessfully in the home shop if you carefully follow the directions, but it is 199.00.

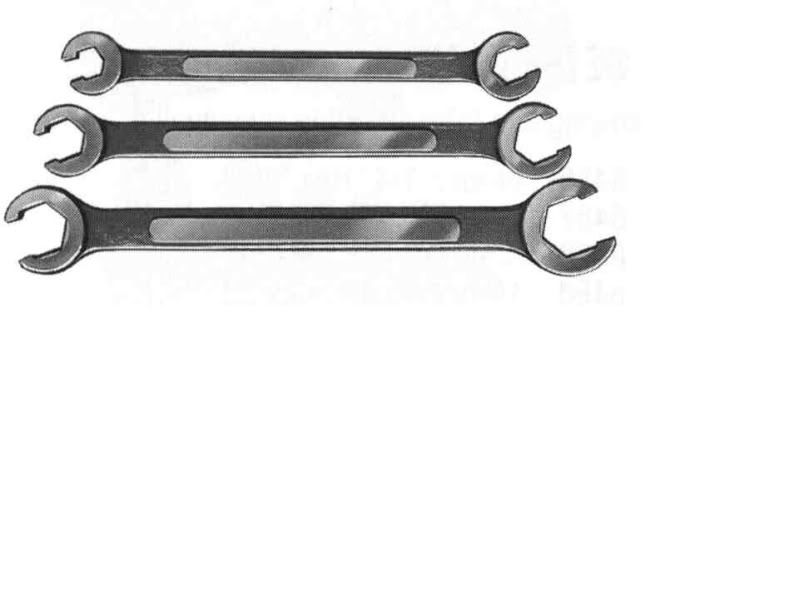

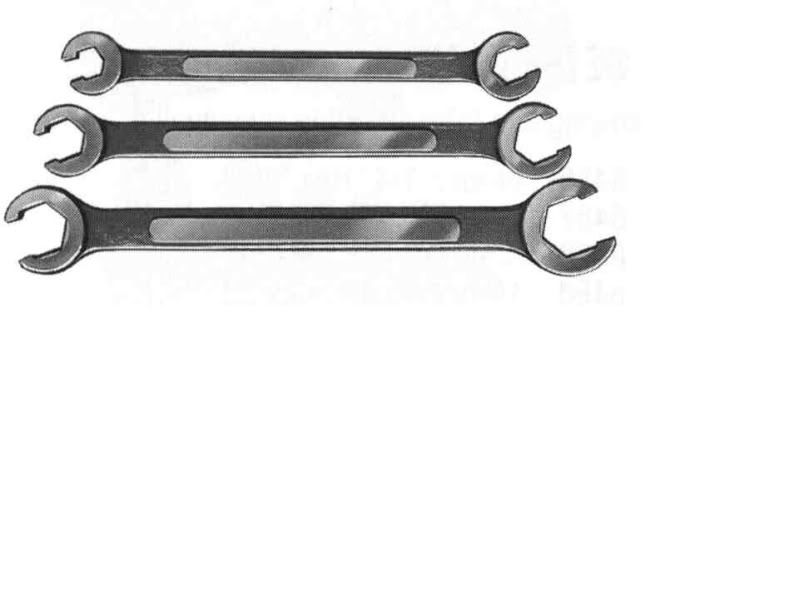

The alternative is to use preflared brake lines from the auto parts store. They are sold in lengths of 6" increments, and they sell joiner fittings for joining two lines. Buy the closest next longer length line or combo of two lines, the extra couple inches of length can be taken up with larger radius bend or an S bend in the line. (DO NOT make a loop or tall hump in the line though) By careful planning you can often use a needed junction block, or residual valve as a joiner. Always use a line bending tool to make your bends so you don't kink or crush it. DON'T try to unbend a mistake, buy a new piece of line and try again, it's not expensive and brakes are too important to try to save a buck or two. I like to buy a package of 1/16" TIG or uncoated brazing rod at my local DIY store, and use it to bend a pattern to follow when bending the tubing. The wire will hold it's shape but is easily bent over a round object or with the fingers, and can be straightened and rebent until you are satisfied with the shape. The last 3-4" of the line should enter straight into the fitting so the nut can be started with just your fingers. Hint: buy a couple fitting wrenches for tightening and loosening the line fittings. They look like heavy weight box wrench with one section of the box cut out. Avoid using open end, adjustable wrenches, or (heaven forbid) pliers on tube fittings! They aren't expensive and you won't need but a couple sizes.

If you still can't get the nuts to tighten in the wheel cylinders with correct flares, The wheel cylinder fitting is likely rusted up. Buy new wheel cylinders, if the lines need replacing, the wheel cylinders likely do too, and it's the perfect time to do it. They are available at your local NAPA store and aren't expensive.

Typical fitting wrenches: Like open end wrenches you get two sizes in each wrench, use two fitting wrenches when screwing fittings together.

</cite>

<cite class="_Rm"> </cite>

</cite>

<cite>http://www.fedhillusa.com/webnuts/common%20flares6.pdf</cite><cite class="_Rm">

Double flares are somewhat difficult for the average DIYer to form correctly especially with the average inexpensive flaring tool commonly available. Eastwood sells a tool that is likely to work sucessfully in the home shop if you carefully follow the directions, but it is 199.00.

The alternative is to use preflared brake lines from the auto parts store. They are sold in lengths of 6" increments, and they sell joiner fittings for joining two lines. Buy the closest next longer length line or combo of two lines, the extra couple inches of length can be taken up with larger radius bend or an S bend in the line. (DO NOT make a loop or tall hump in the line though) By careful planning you can often use a needed junction block, or residual valve as a joiner. Always use a line bending tool to make your bends so you don't kink or crush it. DON'T try to unbend a mistake, buy a new piece of line and try again, it's not expensive and brakes are too important to try to save a buck or two. I like to buy a package of 1/16" TIG or uncoated brazing rod at my local DIY store, and use it to bend a pattern to follow when bending the tubing. The wire will hold it's shape but is easily bent over a round object or with the fingers, and can be straightened and rebent until you are satisfied with the shape. The last 3-4" of the line should enter straight into the fitting so the nut can be started with just your fingers. Hint: buy a couple fitting wrenches for tightening and loosening the line fittings. They look like heavy weight box wrench with one section of the box cut out. Avoid using open end, adjustable wrenches, or (heaven forbid) pliers on tube fittings! They aren't expensive and you won't need but a couple sizes.

If you still can't get the nuts to tighten in the wheel cylinders with correct flares, The wheel cylinder fitting is likely rusted up. Buy new wheel cylinders, if the lines need replacing, the wheel cylinders likely do too, and it's the perfect time to do it. They are available at your local NAPA store and aren't expensive.

Typical fitting wrenches: Like open end wrenches you get two sizes in each wrench, use two fitting wrenches when screwing fittings together.

</cite>

<cite class="_Rm">

</cite>

</cite>

#5

If you look inside the wheel cylinder, there should be a cone looking insert. The double flared end on the brake line that Ax mentioned should crush onto the cone to form a tight seal. when tight, you won't be able to move the metal brake line around. This website has a pretty good image ....relatively far down the page: Brake Fundamentals Training Manual | Wingate Motors

Dan

Dan

#6

I have this tool for the double flare formation, it is a 2 step process and works great. It only cost about $20.00 and allows you to buy bulk brake line.

One thing that comes to mind with your loose fit is that it is imperative that the threads are not cross-threaded. Cross-threading is really easy to do with these connections. I have had to take mannnnny breaks just trying to get one to align right. good luck and I hope this helps.

.........Roger

#7

I have this tool for the double flare formation, it is a 2 step process and works great. It only cost about $20.00 and allows you to buy bulk brake line.

One thing that comes to mind with your loose fit is that it is imperative that the threads are not cross-threaded. Cross-threading is really easy to do with these connections. I have had to take mannnnny breaks just trying to get one to align right. good luck and I hope this helps.

.........Roger

I'd suggest buying at least one premade line, carefully examine the flare and keep it handy to use as a reference for comparing any you make against it. If it's not perfect, cut it off and do it over.

Trending Topics

#8

#9

I must be lucky,, I purchased this contraption about 2 years ago, at the suggestion of a parts store buddy, while needing to replace every line on a 2004 darkside Silverado of my wife's uncle. The lines at the anti-lock gizmo were all shot and leaking. I suspect because of the brine and salt used to treat the snow covered roads and the fact that the lines are bare and not protected with any special coatings.

I had 1 leaker that couldn't be fixed with extra torque and had to redo the flair.

since then I have replaced 1 on my 2000 darkside Silverado with no problems.

Did a complete brake system on my 1951 Ford F5,,,no leaks.

Just 2 weeks ago on my sons 2000 ford F150 rear brakes also no problem.

If I have figured correctly that's about 21 flares with only one leaker.

I don't file the ends just used a small tubing cutter and flared em up as the cut is not part of the mating/sealing surface.

I am not a professional auto mechanic and know enough to be dangerous but I have had great success with mine.

If you live close to me, I would be more than happy to loan them to you.

However, please,, don't forget about taking extra care on proper alignment as they are easy to cross-thread,,, just ask me how I know...

.....Roger

I had 1 leaker that couldn't be fixed with extra torque and had to redo the flair.

since then I have replaced 1 on my 2000 darkside Silverado with no problems.

Did a complete brake system on my 1951 Ford F5,,,no leaks.

Just 2 weeks ago on my sons 2000 ford F150 rear brakes also no problem.

If I have figured correctly that's about 21 flares with only one leaker.

I don't file the ends just used a small tubing cutter and flared em up as the cut is not part of the mating/sealing surface.

I am not a professional auto mechanic and know enough to be dangerous but I have had great success with mine.

If you live close to me, I would be more than happy to loan them to you.

However, please,, don't forget about taking extra care on proper alignment as they are easy to cross-thread,,, just ask me how I know...

.....Roger

#10

I used a "cheap" double flare kit for years, and it worked fine. I use a mastercool kit now but only because I wanted the ability to make GM fuel line ends.

I have found the trick to perfect double flares is to not overdo the 2nd step with the cone. Use the die to make the bubble, use the cone to fold it in but do not fully crush it. Install the line and the cone on the wheel cylinder or whatever you will connect to will complete the double flare with as an exact match to it.

I have found the trick to perfect double flares is to not overdo the 2nd step with the cone. Use the die to make the bubble, use the cone to fold it in but do not fully crush it. Install the line and the cone on the wheel cylinder or whatever you will connect to will complete the double flare with as an exact match to it.

#11

Thanks, everyone, what a wealth of knowledge!

I am using new "pre bent" lines from a "kit" that included all of the lines for a '51 Ford F1. I have installed new shoes, springs, and wheel cylinders (ordered for a '51 Ford F1). When I removed the rubber cap from the part of the wheel cylinder that protrudes out of the back plate (where the lines attach), I can push the flared end of the steel line about 1/2 - 1 inch into the threaded hole. I have treaded the "nut" into the hole and it goes all the way in (no more threads exposed) and bottoms out. But the line is not tight. I can still push the line in and out, for perhaps a distance of 1/2 inch.

Today I went back and had another go at it. I took the threaded nut out and pulled the line out of the wheel cylinder. The flared end of the line appears as it did before it was installed. I tried to straighten the end of the line a little (it seemed fairly straight for about two inches from the end of the line) and I inserted it again. Same result. The nut threaded up, turned easily all the way until no threads were showing. It bottomed out and still the flared end isn't "crushed" against anything and I can still push / pull the line in and out (not all the way out, of course) through the threaded nut.

I ordered these parts some years ago and I installed the parts that go inside the brake drum at that time. In all ways (fit and appearance) the new parts seemed to be proper replacements for the original parts. Retirement, home sale, a move, storage issues, and a new "retirement" job put the project on hold for about 3 years. I have just discovered that another new part (fuel line) purchased a few years ago is not the one that was ordered or the one identified on the invoice. What are the chances that wheel cylinders I have are not the right ones even though they fit well and seemed to be nearly the same as the originals that were removed?

I seem to have a talent for making simple things difficult. - I really appreciate the help and the support from the FTE forum followers. - THANKS AGAIN!

Today I went back and had another go at it. I took the threaded nut out and pulled the line out of the wheel cylinder. The flared end of the line appears as it did before it was installed. I tried to straighten the end of the line a little (it seemed fairly straight for about two inches from the end of the line) and I inserted it again. Same result. The nut threaded up, turned easily all the way until no threads were showing. It bottomed out and still the flared end isn't "crushed" against anything and I can still push / pull the line in and out (not all the way out, of course) through the threaded nut.

I ordered these parts some years ago and I installed the parts that go inside the brake drum at that time. In all ways (fit and appearance) the new parts seemed to be proper replacements for the original parts. Retirement, home sale, a move, storage issues, and a new "retirement" job put the project on hold for about 3 years. I have just discovered that another new part (fuel line) purchased a few years ago is not the one that was ordered or the one identified on the invoice. What are the chances that wheel cylinders I have are not the right ones even though they fit well and seemed to be nearly the same as the originals that were removed?

I seem to have a talent for making simple things difficult. - I really appreciate the help and the support from the FTE forum followers. - THANKS AGAIN!

#12

Wondering if you have FRONT wheel cylinders on there instead of rears. They are different. Your brake line should not go in more than 1/2 inch. Look into the threaded port.....is there a small cone shaped seat for the brake line flare to fit up against?

Also, pictures of what you are working with would help us help you.

Also, pictures of what you are working with would help us help you.

#13

Sounds like you need longer brake line nuts. Have to cut off the flare, install the longer nuts, and redo the double flare.

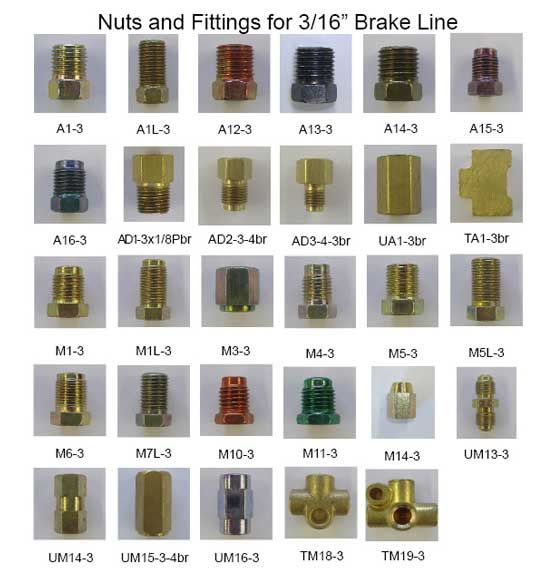

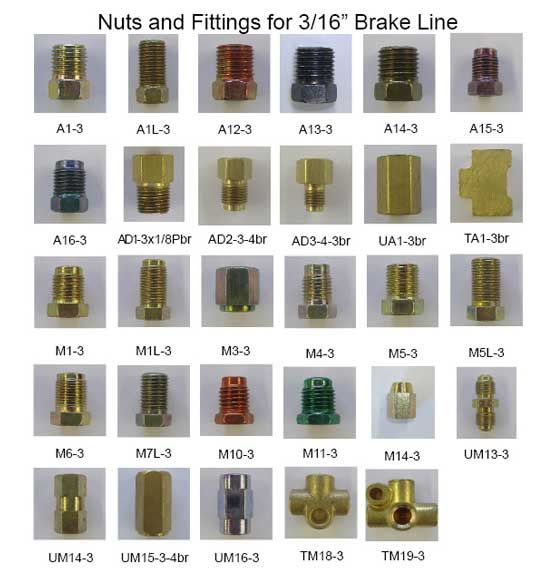

If you have the A1-3 on a 3/16" line you need the A1L-3. Most sections of brake line sold at parts stores have one of each size on them if you need to pirate the nuts or just use their lines if you can get the right length.

If you have the A1-3 on a 3/16" line you need the A1L-3. Most sections of brake line sold at parts stores have one of each size on them if you need to pirate the nuts or just use their lines if you can get the right length.

#14

#15

Grumble, grumble . . . . why would the firm selling me the wheel cylinders AND the brake line kit sell parts that would not match up?!? I suppose that is possible. I think I will pull off one of the wheel cylinders and try fitting one of the lines I have not attached while the wheel cylinder is off the truck. I could do this back at my house at the kitchen table where it is warm and there is good light.

On the front wheels it is the rubber hose that threads right into the wheel cylinder with the other end of the hose taking the steel line with the flared fitting.. Not sure I remember that so clearly from four years ago, but I don't think the threads on the rubber hose are the same as for the rear wheel cylinders and I think the fittings for the front wheels will use a copper "crush washer" for a leak tight seal.

Thanks again for everyone's help.

On the front wheels it is the rubber hose that threads right into the wheel cylinder with the other end of the hose taking the steel line with the flared fitting.. Not sure I remember that so clearly from four years ago, but I don't think the threads on the rubber hose are the same as for the rear wheel cylinders and I think the fittings for the front wheels will use a copper "crush washer" for a leak tight seal.

Thanks again for everyone's help.