So how hard is oil cooler o-ring's?

#1

So how hard is oil cooler o-ring's?

Well I backed the truck out of the station bay today and found a pretty good size oil spot. Pulled in back in and got underneath it. It appears to me like the oil cooler is leaking. So with that being said, how hard is it to replace the o rings on the oil cooler? Time wise what am I looking at?

#2

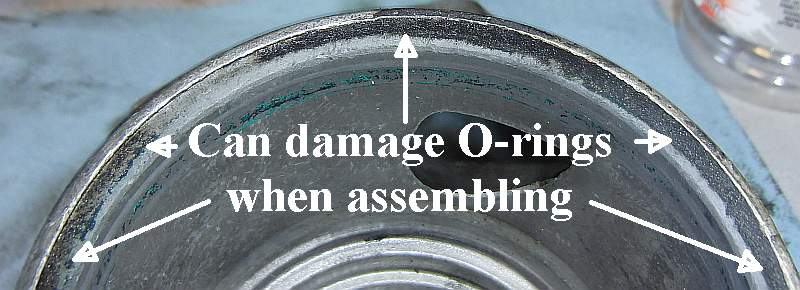

I can only speak with the water pump off,it was really easy,it was time consuming for me because I can get a little picky with cleaning,If I could of done one a second time it would took half the time.careful to lube orings & mating surfaces & clean the mounting surface well,there's been people that had to pull twice due to leaks & cut orings.

#4

#6

#7

Trending Topics

#8

from another thread

read: it's fffing impossible

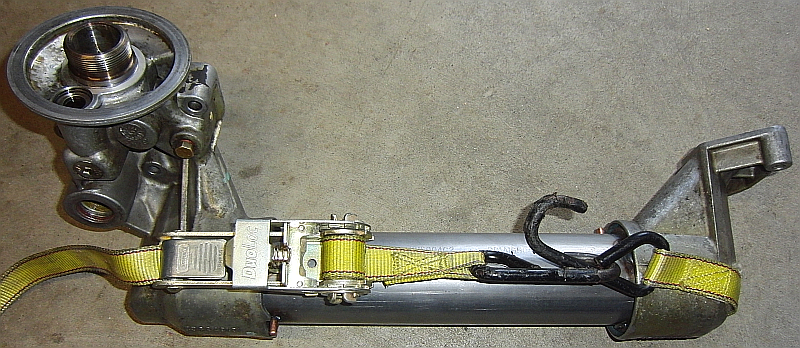

I have it back together. I just need to do a couple more flushes with distilled water and then top it back off one more time. The oil cooler was not a fun job. First, be prepared for oil to get absolutely everywhere. There is no avoiding it. Do the whole thing with a huge tarp underneath your work area if you care about oil spilling. No matter what way you hold the cooler, oil will leak out of it and drip. Second, no one told me what a miserable SOB that oil cooler is to put back together with new seals. No amount of manual persuasion would even come close. I had to stand the cooler on end, ready to be pushed together, on the pad of my floor jack. Then I ran a ratchet strap around the top of the cooler and underneath the jack. I pumped the jack up and it eventually was able to push both ends of the cooler back on. I had a piece of plywood between the pad and the bottom of the cooler, and the pressure from this destroyed the wood. So you either need to have a hydraulic press handy, or be prepared to improvise one. You are not getting the cooler back together without one.

#9

Join Date: Aug 2008

Location: Staten Island,hamilton ny

Posts: 802

Received 0 Likes

on

0 Posts

I have only done it with the motor out,as far as putting it together I used a ratchet strap to pull it together,it didnt go evenly and i used a soft faced hammer to even it out,didnt take much.When i went to install it one problem i found was it had compressed too much so i tapped both sides with a hammer a little looking to split the difference and bolted it up.I havent started it yet so at this point all i can say is im hopeful but the rathchet strap does work use some oil as a lubricant first before trying to squeeze

#10

Join Date: Aug 2008

Location: Staten Island,hamilton ny

Posts: 802

Received 0 Likes

on

0 Posts

#11

I have just recently (month ago) changed the oil cooler o rings on my 02.I had the kit from Bob (Diesel O rings) for a few years just waiting beings my truck has 316k on it.The removal of the cooler went good.I marked the end caps where they were installed from the factory so I would put them back in the same place.There are pins but I felt better with my own marks.Put the cooler in the vise and was able to tap both ends off with a rubber hammer.The o rings were not broke but flat and brittle.I set the new o rings in the sun while I cleaned the parts up.I lubed the o rings with Molycoat 55 o ring lube which I use on all o rings at the job.I put a 2x4 on the ground and used my weight (182lbs of me) and was able to press both ends right on.Not sure I was just lucky because I have read stories of this part being pretty tough for others and cutting o rings.I think the sun and good lube made it easier for me.

The re-install was a little tricky but with my wife holding the front end I got the two bolts started in the back end and then the front bolts were easy.The rest was just tightening all 4 bolts.

My block heater element had alot of calcium buildup on it so I pulled it out when I had the cooler out and cleaned it up with sandpaper.They are made of copper so I just shined it up and re-installed it.Seems to work fine the few times I have plugged it in the last several weeks.

Just take your time,clean the block surfaces and the cooler and i bet you will be ok.

The re-install was a little tricky but with my wife holding the front end I got the two bolts started in the back end and then the front bolts were easy.The rest was just tightening all 4 bolts.

My block heater element had alot of calcium buildup on it so I pulled it out when I had the cooler out and cleaned it up with sandpaper.They are made of copper so I just shined it up and re-installed it.Seems to work fine the few times I have plugged it in the last several weeks.

Just take your time,clean the block surfaces and the cooler and i bet you will be ok.

#12

#13

Thank you guys for all your suggestions and pointers. I order the parts from bob last night. I do have a 20 ton shop press so that will not be a problem. Where can I get this I ring lube? Apparently this has been leaking for a while because the under side of the truck is pretty nasty. I am hoping that it warms up a little before I have to do this.

So for cleaning up the lips on the ends should I us quad steel wool? Or sandpaper?

So for cleaning up the lips on the ends should I us quad steel wool? Or sandpaper?

#14

#15

Thank you guys for all your suggestions and pointers. I order the parts from bob last night. I do have a 20 ton shop press so that will not be a problem. Where can I get this I ring lube? Apparently this has been leaking for a while because the under side of the truck is pretty nasty. I am hoping that it warms up a little before I have to do this.

So for cleaning up the lips on the ends should I us quad steel wool? Or sandpaper?

So for cleaning up the lips on the ends should I us quad steel wool? Or sandpaper?