AC Bracket for a 1967 F100 300 engine underdash unit

#61

#62

Join Date: Aug 2003

Location: **** hole San Jose ca.

Posts: 7,592

Likes: 0

Received 9 Likes

on

9 Posts

The three 3/8" 30-35

The center large bolt is also listed in the manual

a long with all the rest time to but one.. Most 6 cyl.(85-100lbs)

Orich

#64

I have installed the 3 sheave pulley. The last sheave is 1/2 inch and I be leave I will be able to get it to line up to the compressor. I should be able to run a belt right to the 3rd sheave from the compressor, right? I can pivot the compressor with the bracket that I installed on the original bracket. I can get away without using an idler pulley or tensioner. Right? Or, am I missing something?

#66

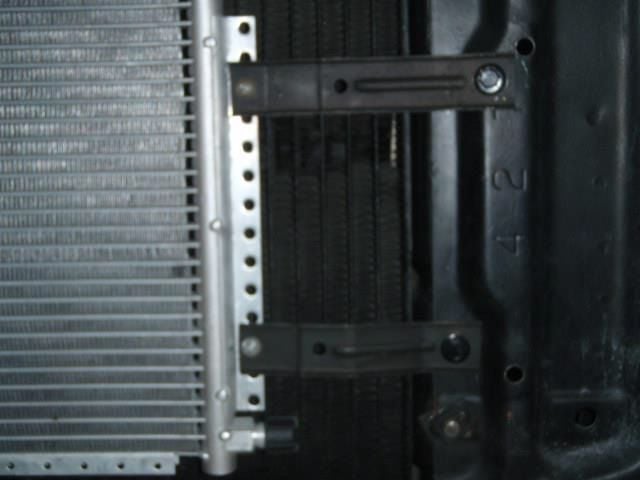

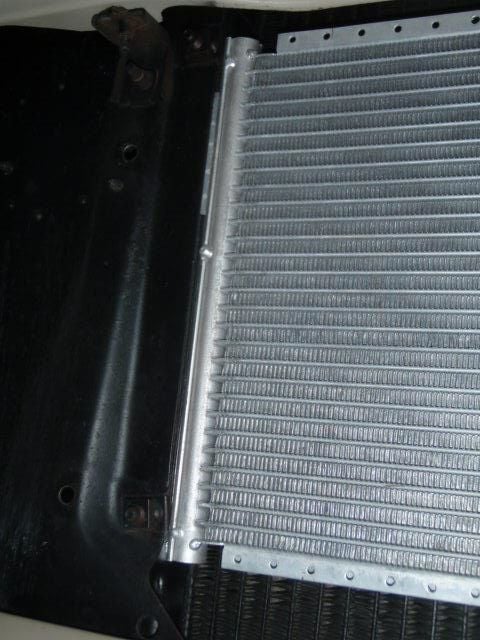

#67

I scrapped the idea of using the York to Sanden pivot bracket that I found on Ebay -- it didn't go out far enough--couldn't get the compressor to line up with the crank pulley. However, I found a a/c compressor bracket off of a 77 truck and I am just using the upper part of the mounting bracket/mounts a sanden compressor. This will sit on the original ac bracket that is correct for the 1967 model years that I found. I will be able to make the Sanden compressor pivot while using some other brackets that I found. I will post some more pictures in a few days.

#70

Well, I have been reading a lot of different installation instructions from different aftermarket vendors and I was wondering, do I need a binary switch? What does the binary switch do? Anyone have a good set of instructions (to address the hoses/lines that I am going to be running) that may apply for my set up.

#71

Well, I have been reading a lot of different installation instructions from different aftermarket vendors and I was wondering, do I need a binary switch? What does the binary switch do? Anyone have a good set of instructions (to address the hoses/lines that I am going to be running) that may apply for my set up.

#72

I have the components mapped out and I have a pretty good feel on how to run the hoses/lines now. At this point, I am more concerned about using an old evaporator with flare fittings and the new stuff (compressor, drier, condenser) that uses O-ring. I talked to the guys at Vintage Air and they indicated that the flare type fittings are not good for R134. I checked with a local ac guy that is going to crimp my hoses and he indicated that he uses R134 with flare fittings all of the time and even showed me a Gremlin that he installed both flare and O-ring type fittings. Anyone try to use R134 with flare fittings at the evaporator? I guess the concern, if I understood the Vintage Air guy correctly, is that R134 is a lighter gas than R12 and as a result, it is more susceptible of escaping.

I guess I can drain out the oil on the compressor and use R12 but I would rather not.

Anyone want to weigh in on this?

I guess I can drain out the oil on the compressor and use R12 but I would rather not.

Anyone want to weigh in on this?

#73

I think O-ring connections on A/C systems came about because they're quicker to put together on an assembly line --slide the connections together and slap the clip over the two joints, done.

From a durbility stand point though, I think the screwed flared connections are better.

Brake systems deal with high pressure (much higher than an A/C). Ever see any O-rings in a brake system? Under normal circumstances, a brake system would see pressures of several hundred pounds (pounds per square inch) to over 1,500 PSI in a panic stop situation.

Their flared connections are subjected to a lot of pressure yet, they rarely ever leak.

From a durbility stand point though, I think the screwed flared connections are better.

Brake systems deal with high pressure (much higher than an A/C). Ever see any O-rings in a brake system? Under normal circumstances, a brake system would see pressures of several hundred pounds (pounds per square inch) to over 1,500 PSI in a panic stop situation.

Their flared connections are subjected to a lot of pressure yet, they rarely ever leak.

#74

I think O-ring connections on A/C systems came about because they're quicker to put together on an assembly line --slide the connections together and slap the clip over the two joints, done.

From a durbility stand point though, I think the screwed flared connections are better.

Brake systems deal with high pressure (much higher than an A/C). Ever see any O-rings in a brake system? Under normal circumstances, a brake system would see pressures of several hundred pounds (pounds per square inch) to over 1,500 PSI in a panic stop situation.

Their flared connections are subjected to a lot of pressure yet, they rarely ever leak.

From a durbility stand point though, I think the screwed flared connections are better.

Brake systems deal with high pressure (much higher than an A/C). Ever see any O-rings in a brake system? Under normal circumstances, a brake system would see pressures of several hundred pounds (pounds per square inch) to over 1,500 PSI in a panic stop situation.

Their flared connections are subjected to a lot of pressure yet, they rarely ever leak.