Power brakes conversion

#1

Power brakes conversion

Hi

I'm new to the forum and have a 71 f100 Ranger XLT. I'm wanting to convert it to power brakes. I have all of the stuff to put disc brakes on the fron and figured I would do it all at once. My question is that I was wondering what all I need to put a power brake booster in the truck. I know I need some brackets to mount it but is there anything else? I'd be willing to buy the parts I need from someone on here if they have extras around. Thanks!

I'm new to the forum and have a 71 f100 Ranger XLT. I'm wanting to convert it to power brakes. I have all of the stuff to put disc brakes on the fron and figured I would do it all at once. My question is that I was wondering what all I need to put a power brake booster in the truck. I know I need some brackets to mount it but is there anything else? I'd be willing to buy the parts I need from someone on here if they have extras around. Thanks!

#2

1967 power brake booster is an odd - ball compared to '68-'72. Any booster from '68-'72 donor should work just fine in your application.

Some, but not all, Dentside ('73-'79 trucks) boosters will work without having to also change to Dentside Pedal (s) and pedal hanger.

From the donor vehicle, you can get the booster to turn in for the core charge on a newly rebuilt booster. You'll need the booster to firewall mounting brackets and the plastic tube the goes between the back of the booster to the engine side of the firewall. You can also grab the (4) 3/8"-16 mounting bolts or, you could use new mounting bolts.

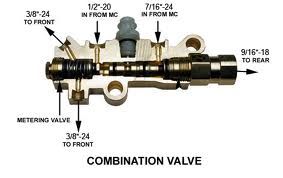

Your truck will currently have a drum/drum pressure differential valve (it's mounted inside the left frame rail, just rearward of the steering gear box). You'll need to replace it with a disc/drum combination valve. Unfortunately, getting a new OEM combination valve for these trucks is difficult to come by and usually expensive if you do find one. There are generic aftermarket ones available based on General Motors combination valves. An OEM ford truck wrecking yard donor may work or it may not. MuscleCarResearch.com does offer valve rebuild parts for some Ford brake valves.

I'm currently in the process of installing '77 F-100 front beams/discs on my '69 F-100 short bed Ranger but, a couple of years ago, I added a dual-diaphragm booster from a '75 F-350. The booster input rod on it attached directly to the pin on my existing '69 brake pedal.

Your current drum/drum pressure differential valve should look very similar to this.

This is the disc/drum combination valve I grabbed from the F-350 I got my booster/mounting brackets from.

This is the disc/drum combination valve that was on the '77 F-100 I got the I-beams/disc brakes from.

Some, but not all, Dentside ('73-'79 trucks) boosters will work without having to also change to Dentside Pedal (s) and pedal hanger.

From the donor vehicle, you can get the booster to turn in for the core charge on a newly rebuilt booster. You'll need the booster to firewall mounting brackets and the plastic tube the goes between the back of the booster to the engine side of the firewall. You can also grab the (4) 3/8"-16 mounting bolts or, you could use new mounting bolts.

Your truck will currently have a drum/drum pressure differential valve (it's mounted inside the left frame rail, just rearward of the steering gear box). You'll need to replace it with a disc/drum combination valve. Unfortunately, getting a new OEM combination valve for these trucks is difficult to come by and usually expensive if you do find one. There are generic aftermarket ones available based on General Motors combination valves. An OEM ford truck wrecking yard donor may work or it may not. MuscleCarResearch.com does offer valve rebuild parts for some Ford brake valves.

I'm currently in the process of installing '77 F-100 front beams/discs on my '69 F-100 short bed Ranger but, a couple of years ago, I added a dual-diaphragm booster from a '75 F-350. The booster input rod on it attached directly to the pin on my existing '69 brake pedal.

Your current drum/drum pressure differential valve should look very similar to this.

This is the disc/drum combination valve I grabbed from the F-350 I got my booster/mounting brackets from.

This is the disc/drum combination valve that was on the '77 F-100 I got the I-beams/disc brakes from.

#3

Booster, bracket, and MC off a '75 F150.... Prop valve from Wilwood, custom prop valve bracket and lines. I believe the OEM prop valve is a piece of crap.. I've never had any luck with them.

Compare to the pic above and note how much more flat the booster is and that it projects higher than the firewall seam.

I lucked out and there was a '70 parked next to the donor so I managed to do a test fit in the salvage yard.

Compare to the pic above and note how much more flat the booster is and that it projects higher than the firewall seam.

I lucked out and there was a '70 parked next to the donor so I managed to do a test fit in the salvage yard.

#4

#5

The biggest problem with OEM Ford brake valves is previous owners and their lack of proper maintenance in not keeping the brake fluid clean from not changing the fluid at regular intervals.

DOT 3, 4 and 5.1 brake fluid is hygroscopic. This is just a term that means the fluid will absorb moisture from the air --even in a sealed brake system. Brake fluid molecules are too large to seep through the walls of the flexible brake lines but air molecules are small enough to pass through them. On the older conventional style MCs (cast iron body with the large lift-off lid), the lid is vented so that air is present on top of the seal. Air (and the moisture content in the air) eventually gets past the cover seal and into the brake fluid in the MC's reservoirs.

DOT 3, 4 and 5.1 brake fluid should be changed every 18-24 months. These brake fluids can absorb up to 2% of moisture in the brake system per year. The moisture content in the fluid keeps accumulating, if not changed regularly, and anything ferrous in the system will begin to corrode. The rust scale and debris begins to settle out in the system and gets deposited in brake components such as the MC, caliper and wheel cylinder bores and in the brake valve passages and its internal valve components. This gums up the valve to where its internal components get sticky and don't operate freely or, they do move and then get stuck.

Prior to 1967, Ford vehicles had a single reservoir MC. If there was a failure of a wheel cylinder, hard brake line, flexible brake line, wheel cylinder or caliper piston, all the brakes of the vehicle were lost. Beginning in 1967, federal mandate required domestic auto manufacturers to install tandem MCs, where the brake system was split between the primary (front) and the secondary (rear) brake circuits. If there was a failure in the secondary brake circuit, for example, the primary side, while somewhat limited, would still operate to stop the vehicle.

In a vehicle with all-wheel drums, a pressure differential valve was used to sense for a balance between the primary and secondary sides of the system. Pressure coming out of a tandem MC's primary and secondary ports will be equal. Inside the brake valve body is a small piston or valve spool that has fluid pressure being applied to each end of the spool, when you press down on the brake pedal, and the equal fluid pressure applied will keep the spool centered, as long as the primary and secondary pressures are acting equally on the ends of the spool.

If, for example, there is a component failure of the secondary side (a blown rear wheel cylinder for example), the pressure of the secondary side, on the end of the pressure differential valve spool, will be low compared the the pressure being applied to the other end of the valve spool by the primary side. This imbalance in brake fluid pressure will cause the higher pressure side of the primary circuit to force the pressure differential valve spool over to block off the fluid passage of the secondary side. This blockage is designed to help reduce the amount of fluid loss from the secondary side of the MC, since the primary MC piston also uses the pressure build up of the secondary piston to help the primary piston build its line pressure. The shift of the spool will also close the switch contacts that will illuminate the brake warning light on the dash to alert the driver that a brake system malfunction has occurred.

In the Ford trucks that were factory equipped with front disc brakes and rear drum brakes, a combination valve was used. This valve body contained (3) brake functions.

The primary side of the disc/drum combination valve body contains a metering valve (it is also known as a 'hold-off' valve). Disc brakes react immediately when you press down on the brake pedal. Drum brake shoes have to first overcome the tension of the retracting springs before the shoes can begin to move towards the inner friction surfaces of the drums. The metering valve has a coil spring that holds the valve closed to the primary brakes, until a certain pressure level is reached to overcome the tension of the spring and push the valve open, in order to let the brake fluid start flowing to the front calipers. This slight delay of applying the front discs is designed so that both the front and rear brakes apply at the same time.

The disc/drum combination valve also has the same safety feature of a pressure differential spool, like the drum/drum pressure differential valve has, to sense for equal pressure being applied to the primary and secondary brake circuits.

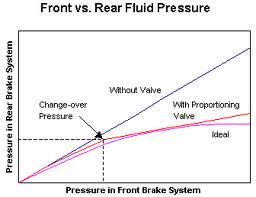

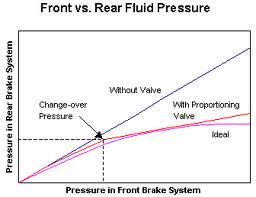

The 3rd feature of the disc/drum combination valve is the proportioning valve in the secondary side of the valve body assembly. This valve has a calibrated coil spring that holds the valve open so that pressure to the rear brakes will rise at the same rate as the pressure being applied to the front brakes, under normal driving conditions. In a panic stop situation though, there's a sudden shift in vehicle weight from the rear to the front of the vehicle. This shift places more downward force on the front tires but, at the same time, unloads the weight over the rear tires. The unloading of the rear would cause the rear brakes to easily lock up if the rate of fluid pressure rise was not controlled through the restriction of the proportioning valve. Once the secondary pressure reaches a predetermined amount (known as the 'knee point'), the sudden rise of hydraulic pressure of the secondary circuit overcomes the tension of the coil spring and forces the valve to restrict the fluid passage to slow the rate of pressure rise to the rear brakes, in proportion to the linear rise of pressure being applied on the front brakes.

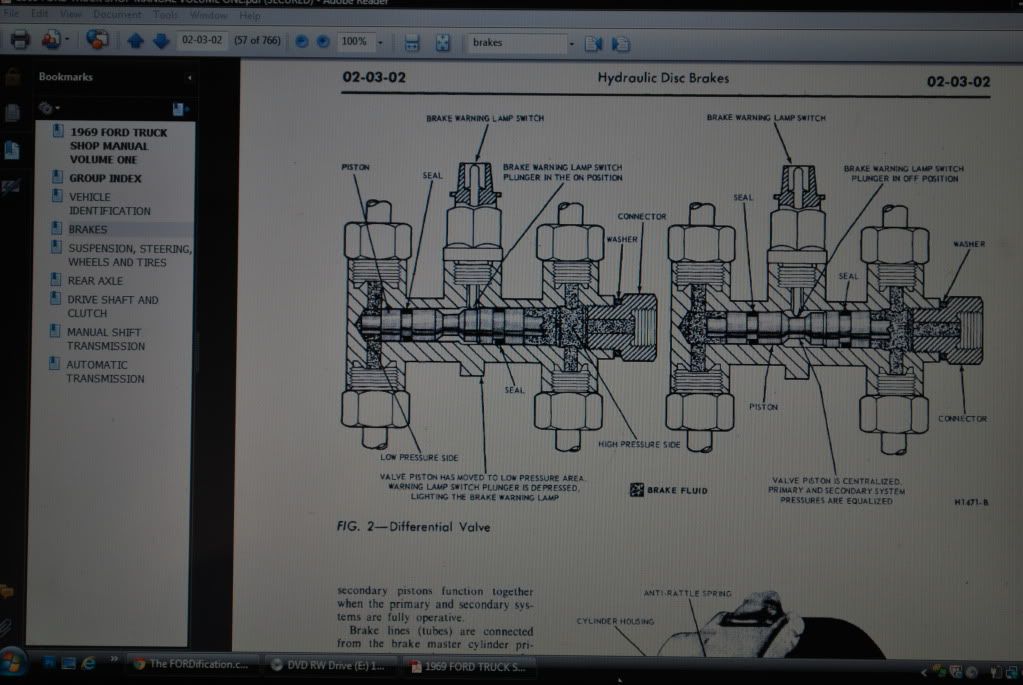

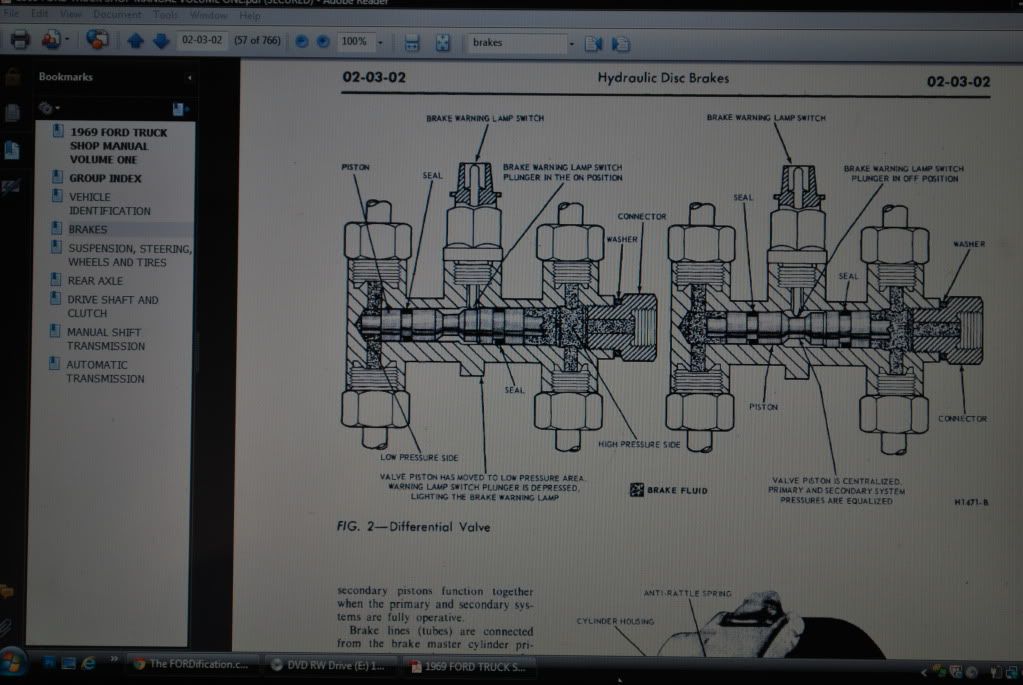

This is an internal look at a drum/drum pressure differential valve.

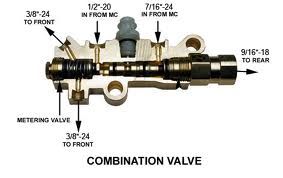

This is a cutaway view of an actual (Dentside) Ford truck disc/drum combination valve (like the one from the '77 F-100 I had posted a picture of earlier in this thread --the primary side is on the left. Secondary side is on the right. Pressure differential valve spool is in the center of the valve body assembly).

This is a cutaway of a valve like the one I had posted earlier that I pulled from a '75 F-350 1-ton truck. (The metering valve of the primary circuit is on the left. Pressure differential valve is in the center. Proportioning valve is on the right).

Graph example of the pressure rise in a brake system and the curve ('knee-point') of the secondary side pressure reduction, relative to the primary side, of a proportional valve.

A booster, like HiO posted, has a bell crank (cantilever) style input linkage with a bracket that mounts the booster higher up on the firewall. The booster is a single diaphragm unit with an overall outside (flange) dimension of 11". The actual diaphragm diameter though is 9-3/4".

Pictured is a similar booster I pulled from a '78/'79 F-150. You'll notice that the input rod is actually a flat bar on this particular unit. A person would need the brake pedal and pedal hanger from the '78/'79 Dentside to make this particular unit work in a Bumpside truck.

The '75 F-350 1-ton Bendix booster I installed in my truck is an 8-3/4" dual-diaphragm unit. It doesn't mount high up like the bell crank (cantilever) booster and it's thicker (front to back) than the single-diaphragm bell crank booster but, it came out of a 1-ton truck that had a big-block and clearance between the engine and the edge of the booster wasn't a problem. --currently, I have a 240 so, definitely no clearance issues between the dual-diaphragm booster and my inline six engine. Eventually, a fuel injected 5.0L H.O. engine will take the place of the 240. I don't expect any clearance issues with it either.

By comparison, a single-diaphragm 11" diameter cantilever booster has an effective diaphragm surface area of 9-3/4" of vacuum on one side and atmospheric pressure on the other, to act upon. By contrast, a dual-diaphragm booster, like the one I installed on my truck, has two surfaces of 8-3/4" each. If the two diaphragms of it were combined into one single diaphragm, you would have a single-diaphragm booster that was 17-1/2" in diameter. That would be a monstrous booster!

The Wilwood manually-adjustable proportioning valve is a nice looking unit. However, it does not contain two of the three features of an OEM disc/drum combination valve. It doesn't have a metering (hold-off) valve to control the primary brake circuit and, it does not contain the safety feature of a pressure differential valve to limit fluid loss to the MC, in the event of a brake system failure.

http://www.wilwood.com/Images/Master...179_dwg-lg.jpg

Of all the systems of a vehicle, the brakes are without a doubt THE most important system. Yet, many people don't understand the various components of a brake system, what they do, how they function or what specific components apply to a particular brake setup. A lack of maintenance (not changing the brake fluid regularly) leads to troubles with the brake valves malfunctioning --particularly when the brakes are being converted to discs or when the brake system is opened up to change a MC or other components.

The problem shows up after everything is buttoned up and it's time to bleed the system out. Both the drum/drum and disc/drum valves have pressure differential valves that are sensing for an imbalance between the primary and secondary brake circuits. A brake component failure isn't the only thing that can trip the warning light on the dash. Trying to bleed the brakes out too fast, by applying too much pressure too quickly on the brake pedal, will easily cause a pressure imbalance (differential) in the brake system. The pressure differential spool inside the valve body doesn't know the difference between a legitimate differential caused by a component failure or, if an imbalance is being caused by the system being bled out. It just knows there's an imbalance in the system and it's doing its job of shifting over to turn the brake warning light on.

Since many don't have a clear understanding of the various brake components, what their function is and what they do, they just see a warning light staying on, assume the valve must be bad and replace it with something else or worse, take the valve out and don't install anything in its place. If you take care of the brake system (keep the fluid clean) and know what the valve does, you'll know what to do to correct the problem of re-centering the valve to turn the warning light off and to restore normal brake operation to the entire system.

This simple valve lock tool can save you from a lot of trouble when it comes time to bleed the brake system. It won't re-center a pressure differential valve spool that's already shifted off-center but, it will keep a spool that's already centered from getting off-center.

https://www.musclecarresearch.com/brake-valve-tool

Before anyone starts re-engineering their brakes components, I would advise to do your homework and understand what the different components are and how they apply, or don't apply to a particular brake system, before you just start changing things up. Your life, or the people's life in the oncoming lane may very well depend on it.

DOT 3, 4 and 5.1 brake fluid is hygroscopic. This is just a term that means the fluid will absorb moisture from the air --even in a sealed brake system. Brake fluid molecules are too large to seep through the walls of the flexible brake lines but air molecules are small enough to pass through them. On the older conventional style MCs (cast iron body with the large lift-off lid), the lid is vented so that air is present on top of the seal. Air (and the moisture content in the air) eventually gets past the cover seal and into the brake fluid in the MC's reservoirs.

DOT 3, 4 and 5.1 brake fluid should be changed every 18-24 months. These brake fluids can absorb up to 2% of moisture in the brake system per year. The moisture content in the fluid keeps accumulating, if not changed regularly, and anything ferrous in the system will begin to corrode. The rust scale and debris begins to settle out in the system and gets deposited in brake components such as the MC, caliper and wheel cylinder bores and in the brake valve passages and its internal valve components. This gums up the valve to where its internal components get sticky and don't operate freely or, they do move and then get stuck.

Prior to 1967, Ford vehicles had a single reservoir MC. If there was a failure of a wheel cylinder, hard brake line, flexible brake line, wheel cylinder or caliper piston, all the brakes of the vehicle were lost. Beginning in 1967, federal mandate required domestic auto manufacturers to install tandem MCs, where the brake system was split between the primary (front) and the secondary (rear) brake circuits. If there was a failure in the secondary brake circuit, for example, the primary side, while somewhat limited, would still operate to stop the vehicle.

In a vehicle with all-wheel drums, a pressure differential valve was used to sense for a balance between the primary and secondary sides of the system. Pressure coming out of a tandem MC's primary and secondary ports will be equal. Inside the brake valve body is a small piston or valve spool that has fluid pressure being applied to each end of the spool, when you press down on the brake pedal, and the equal fluid pressure applied will keep the spool centered, as long as the primary and secondary pressures are acting equally on the ends of the spool.

If, for example, there is a component failure of the secondary side (a blown rear wheel cylinder for example), the pressure of the secondary side, on the end of the pressure differential valve spool, will be low compared the the pressure being applied to the other end of the valve spool by the primary side. This imbalance in brake fluid pressure will cause the higher pressure side of the primary circuit to force the pressure differential valve spool over to block off the fluid passage of the secondary side. This blockage is designed to help reduce the amount of fluid loss from the secondary side of the MC, since the primary MC piston also uses the pressure build up of the secondary piston to help the primary piston build its line pressure. The shift of the spool will also close the switch contacts that will illuminate the brake warning light on the dash to alert the driver that a brake system malfunction has occurred.

In the Ford trucks that were factory equipped with front disc brakes and rear drum brakes, a combination valve was used. This valve body contained (3) brake functions.

The primary side of the disc/drum combination valve body contains a metering valve (it is also known as a 'hold-off' valve). Disc brakes react immediately when you press down on the brake pedal. Drum brake shoes have to first overcome the tension of the retracting springs before the shoes can begin to move towards the inner friction surfaces of the drums. The metering valve has a coil spring that holds the valve closed to the primary brakes, until a certain pressure level is reached to overcome the tension of the spring and push the valve open, in order to let the brake fluid start flowing to the front calipers. This slight delay of applying the front discs is designed so that both the front and rear brakes apply at the same time.

The disc/drum combination valve also has the same safety feature of a pressure differential spool, like the drum/drum pressure differential valve has, to sense for equal pressure being applied to the primary and secondary brake circuits.

The 3rd feature of the disc/drum combination valve is the proportioning valve in the secondary side of the valve body assembly. This valve has a calibrated coil spring that holds the valve open so that pressure to the rear brakes will rise at the same rate as the pressure being applied to the front brakes, under normal driving conditions. In a panic stop situation though, there's a sudden shift in vehicle weight from the rear to the front of the vehicle. This shift places more downward force on the front tires but, at the same time, unloads the weight over the rear tires. The unloading of the rear would cause the rear brakes to easily lock up if the rate of fluid pressure rise was not controlled through the restriction of the proportioning valve. Once the secondary pressure reaches a predetermined amount (known as the 'knee point'), the sudden rise of hydraulic pressure of the secondary circuit overcomes the tension of the coil spring and forces the valve to restrict the fluid passage to slow the rate of pressure rise to the rear brakes, in proportion to the linear rise of pressure being applied on the front brakes.

This is an internal look at a drum/drum pressure differential valve.

This is a cutaway view of an actual (Dentside) Ford truck disc/drum combination valve (like the one from the '77 F-100 I had posted a picture of earlier in this thread --the primary side is on the left. Secondary side is on the right. Pressure differential valve spool is in the center of the valve body assembly).

This is a cutaway of a valve like the one I had posted earlier that I pulled from a '75 F-350 1-ton truck. (The metering valve of the primary circuit is on the left. Pressure differential valve is in the center. Proportioning valve is on the right).

Graph example of the pressure rise in a brake system and the curve ('knee-point') of the secondary side pressure reduction, relative to the primary side, of a proportional valve.

A booster, like HiO posted, has a bell crank (cantilever) style input linkage with a bracket that mounts the booster higher up on the firewall. The booster is a single diaphragm unit with an overall outside (flange) dimension of 11". The actual diaphragm diameter though is 9-3/4".

Pictured is a similar booster I pulled from a '78/'79 F-150. You'll notice that the input rod is actually a flat bar on this particular unit. A person would need the brake pedal and pedal hanger from the '78/'79 Dentside to make this particular unit work in a Bumpside truck.

The '75 F-350 1-ton Bendix booster I installed in my truck is an 8-3/4" dual-diaphragm unit. It doesn't mount high up like the bell crank (cantilever) booster and it's thicker (front to back) than the single-diaphragm bell crank booster but, it came out of a 1-ton truck that had a big-block and clearance between the engine and the edge of the booster wasn't a problem. --currently, I have a 240 so, definitely no clearance issues between the dual-diaphragm booster and my inline six engine. Eventually, a fuel injected 5.0L H.O. engine will take the place of the 240. I don't expect any clearance issues with it either.

By comparison, a single-diaphragm 11" diameter cantilever booster has an effective diaphragm surface area of 9-3/4" of vacuum on one side and atmospheric pressure on the other, to act upon. By contrast, a dual-diaphragm booster, like the one I installed on my truck, has two surfaces of 8-3/4" each. If the two diaphragms of it were combined into one single diaphragm, you would have a single-diaphragm booster that was 17-1/2" in diameter. That would be a monstrous booster!

The Wilwood manually-adjustable proportioning valve is a nice looking unit. However, it does not contain two of the three features of an OEM disc/drum combination valve. It doesn't have a metering (hold-off) valve to control the primary brake circuit and, it does not contain the safety feature of a pressure differential valve to limit fluid loss to the MC, in the event of a brake system failure.

http://www.wilwood.com/Images/Master...179_dwg-lg.jpg

Of all the systems of a vehicle, the brakes are without a doubt THE most important system. Yet, many people don't understand the various components of a brake system, what they do, how they function or what specific components apply to a particular brake setup. A lack of maintenance (not changing the brake fluid regularly) leads to troubles with the brake valves malfunctioning --particularly when the brakes are being converted to discs or when the brake system is opened up to change a MC or other components.

The problem shows up after everything is buttoned up and it's time to bleed the system out. Both the drum/drum and disc/drum valves have pressure differential valves that are sensing for an imbalance between the primary and secondary brake circuits. A brake component failure isn't the only thing that can trip the warning light on the dash. Trying to bleed the brakes out too fast, by applying too much pressure too quickly on the brake pedal, will easily cause a pressure imbalance (differential) in the brake system. The pressure differential spool inside the valve body doesn't know the difference between a legitimate differential caused by a component failure or, if an imbalance is being caused by the system being bled out. It just knows there's an imbalance in the system and it's doing its job of shifting over to turn the brake warning light on.

Since many don't have a clear understanding of the various brake components, what their function is and what they do, they just see a warning light staying on, assume the valve must be bad and replace it with something else or worse, take the valve out and don't install anything in its place. If you take care of the brake system (keep the fluid clean) and know what the valve does, you'll know what to do to correct the problem of re-centering the valve to turn the warning light off and to restore normal brake operation to the entire system.

This simple valve lock tool can save you from a lot of trouble when it comes time to bleed the brake system. It won't re-center a pressure differential valve spool that's already shifted off-center but, it will keep a spool that's already centered from getting off-center.

https://www.musclecarresearch.com/brake-valve-tool

Before anyone starts re-engineering their brakes components, I would advise to do your homework and understand what the different components are and how they apply, or don't apply to a particular brake system, before you just start changing things up. Your life, or the people's life in the oncoming lane may very well depend on it.

#6

#7

I remember someone from another forum that had this same style (cantilever/bell crank) booster and the pedal pin hole of the input rod (or, the flat bar) wouldn't line up with the pedal pin in their Bumpside but, I can't remember who it was that was showing photos of it or what model truck they had (?).

....I see in your last photo a pair of front sway bar bushing brackets. Have you put the bar on your truck yet? I believe we have the same style sway bar (mine came from a '78 F-250 Camper Special).

I've been trying to find a rear sway bar from a Dentside F-150 or from a '78/'79 F-150 Bronco but, I'm not having any luck locating one so far. I know the Dentside rear frame rails are wider than the Bumpside but, I don't see why 2" frame spacers couldn't be used or, for that matter, I could make my own offset end links with Heim joint rod ends to attach it.

Trending Topics

#8

#9

In your case you can probably make it work if you get the pedal and pedal hanger from the '78.

#10

Good to know, HiO.

I remember someone from another forum that had this same style (cantilever/bell crank) booster and the pedal pin hole of the input rod (or, the flat bar) wouldn't line up with the pedal pin in their Bumpside but, I can't remember who it was that was showing photos of it or what model truck they had (?).

....I see in your last photo a pair of front sway bar bushing brackets. Have you put the bar on your truck yet? I believe we have the same style sway bar (mine came from a '78 F-250 Camper Special).

I've been trying to find a rear sway bar from a Dentside F-150 or from a '78/'79 F-150 Bronco but, I'm not having any luck locating one so far. I know the Dentside rear frame rails are wider than the Bumpside but, I don't see why 2" frame spacers couldn't be used or, for that matter, I could make my own offset end links with Heim joint rod ends to attach it.

I remember someone from another forum that had this same style (cantilever/bell crank) booster and the pedal pin hole of the input rod (or, the flat bar) wouldn't line up with the pedal pin in their Bumpside but, I can't remember who it was that was showing photos of it or what model truck they had (?).

....I see in your last photo a pair of front sway bar bushing brackets. Have you put the bar on your truck yet? I believe we have the same style sway bar (mine came from a '78 F-250 Camper Special).

I've been trying to find a rear sway bar from a Dentside F-150 or from a '78/'79 F-150 Bronco but, I'm not having any luck locating one so far. I know the Dentside rear frame rails are wider than the Bumpside but, I don't see why 2" frame spacers couldn't be used or, for that matter, I could make my own offset end links with Heim joint rod ends to attach it.

On the rear, I totally lucked out and found a '70 with a rear ADDCO swaybar and quickly harvested the parts.. Along the way I spied rear swaybars... some use offset end links while others endlink mounts were custom fabricated.

#11

The front bar has not yet been installed. I'm putting it off until more weight (water, battery, headlights, etc.) is over the front tires. It'll be one of the last things to do. Got mine off a 2WD SuperCab CS.

On the rear, I totally lucked out and found a '70 with a rear ADDCO swaybar and quickly harvested the parts.. Along the way I spied rear swaybars... some use offset end links while others endlink mounts were custom fabricated.

On the rear, I totally lucked out and found a '70 with a rear ADDCO swaybar and quickly harvested the parts.. Along the way I spied rear swaybars... some use offset end links while others endlink mounts were custom fabricated.

I've looked at some aftermarket rear sway bars but, I just prefer to use Ford parts where I can. The main problem is just finding it.

#12

Good luck on your hunt.

#13

The Ford rear sway bar I'm looking for has a curve in the middle to fit around the 'hump' on the back of the 9-inch rear end housing.

OEM rear sway bar pictured below from a '78/'79 F-150 Bronco with a 9-inch rear end. Notice curve in center that fits around the hump on the back of a 9-inch rear end housing.

#14

1967 power brake booster is an odd - ball compared to '68-'72.

1967 only: master cylinders, power brake boosters, brake and clutch pedals, bracket under the dash they suspend from, Brake Pressure Differential Valves and switch.

Any booster from '68-'72 donor should work just fine in your application.

Some, but not all, Dentside ('73-'79 trucks) boosters will work without having to also change to Dentside Pedal (s) and pedal hanger (s).

without having to also change to Dentside Pedal (s) and pedal hanger (s).

AFAIK, the pedal hangers do not have to be swapped.

From the donor vehicle, you can get the booster to turn in for the core charge on a newly rebuilt booster. You'll need the booster to firewall mounting brackets and the plastic tube the goes between the back of the booster to the engine side of the firewall. You can also grab the (4) 3/8"-16 mounting bolts or, you could use new mounting bolts.

Your truck will currently have a drum/drum pressure differential valve (it's mounted inside the left frame rail, just rearward of the steering gear box). You'll need to replace it with a disc/drum combination valve.

Unfortunately, getting a new OEM combination valve for these trucks is difficult to come by and usually expensive if you do find one.

1967 only: master cylinders, power brake boosters, brake and clutch pedals, bracket under the dash they suspend from, Brake Pressure Differential Valves and switch.

Any booster from '68-'72 donor should work just fine in your application.

Some, but not all, Dentside ('73-'79 trucks) boosters will work

without having to also change to Dentside Pedal (s) and pedal hanger (s).

without having to also change to Dentside Pedal (s) and pedal hanger (s). AFAIK, the pedal hangers do not have to be swapped.

From the donor vehicle, you can get the booster to turn in for the core charge on a newly rebuilt booster. You'll need the booster to firewall mounting brackets and the plastic tube the goes between the back of the booster to the engine side of the firewall. You can also grab the (4) 3/8"-16 mounting bolts or, you could use new mounting bolts.

Your truck will currently have a drum/drum pressure differential valve (it's mounted inside the left frame rail, just rearward of the steering gear box). You'll need to replace it with a disc/drum combination valve.

Unfortunately, getting a new OEM combination valve for these trucks is difficult to come by and usually expensive if you do find one.

1973/79 F100 2WD: Manual disc brakes were standard equipment, power disc brakes were optional.

D3TZ-2B257-A .. Brake Pressure Differential Valve / Marked: D3TA-2B254-AA / Obsolete

1973/74 F100 2WD & F250 2WD with single piston caliper disc brakes.

-------------------------------------------------------------------------------

D5TZ-2B257-B .. Brake Pressure Differential Valve / Marked: D5TA-2B524-FA or FB / Obsolete

1975/79 F100/150 2WD/4WD / 1975/79 E100/150 / 1975/79 F250 2WD with single piston caliper disc brakes / 1976/79 F250 4WD / 1978/79 Bronco / 1979 F350 4WD

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1968/72 F100/350: There is one brake and clutch pedal, one bracket they suspend from. Manual or power brakes, 2WD or 4WD makes no difference.

1973/79 F100/350: There are TWENTY TWO different brake pedals, NINETEEN different master cylinders, SEVENTEEN different P/B boosters and SEVEN different clutch pedals, I kid you not!

Whatever booster and master cylinder you use, the specific pedals must match.

#15