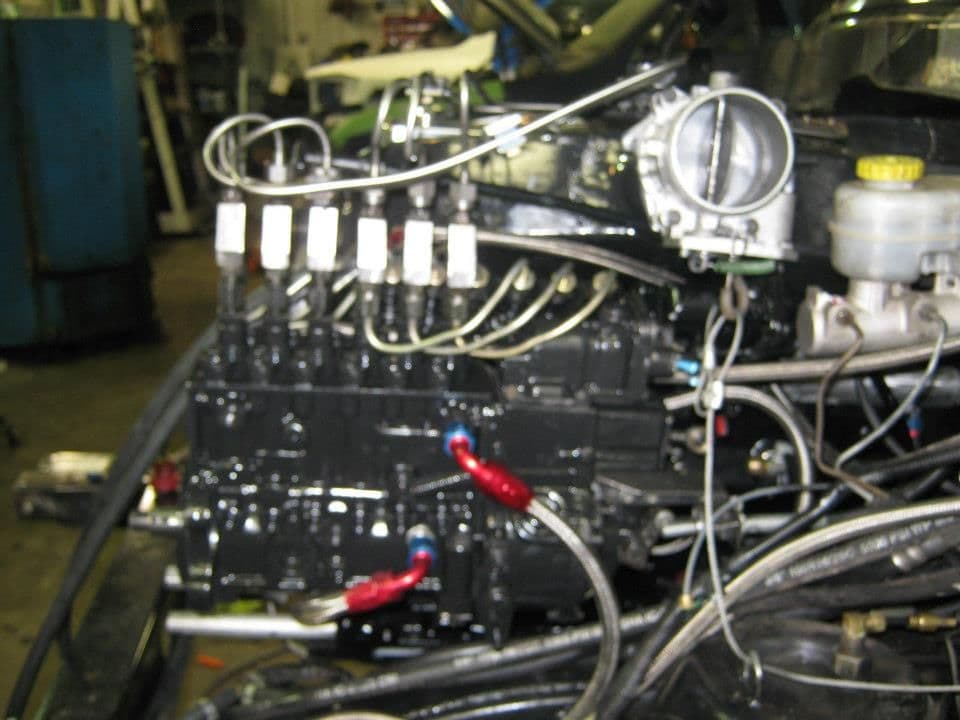

6.4 truck swap to a navistar inline 6 dt360 - project

#106

the dodge p7100 is 12 mm.

plunger face area:

95.03 mm2 - a pump

113.10 mm2 - p7100

This does sort of beg the question; why can a p-pump be turned up to almost 1000 hp, but the a-pump is only capable of 200 hp (or so many say, anyways) ???

Maybe the cam profile is way taller on the p7100?

I know someone said the rack travel is part of the problem, but now that I'm thinking about it, if the rack is wide open, then why still only pushing so little fuel?

Is there some secret relief screw or something that nobody knows about to make these things (a pumps) put out? It seems like they could, but I really don't know much about them, and everyone seems to say they are not that great.

#108

Should I, or should I not, get upgraded valve springs for higher back pressure?

I have no plans to rev over 3000 RPM, but don't want to grenade valve train from high back pressure from a VVT turbo.

#109

"I've never seen a 360 with a p7100 on it. I am putting one on it. The 190HP motor came with the smaller A pump. Check your part #s. The A shouldn't be made to go more than 180 ccs for reliable daily driving. We are putting a P7100 off a 97 dodge on ours. The injectors (still juggling wheter 5x14 or 4x18), .093 lines, and holders are coming from a small tractor pulling shop in Nebraska. Most of the pump parts are Scheids and Haisley sourced. The S400 is gonna be in the 74mm range. Send a PM for more info. Is this going in a truck as well or a tractor?"

Ih Dt360 Upgrades - Competition Diesel.Com - Bringing The BEST Together

And then somewhere else, it is stated that the a-pump can flow 700 CC's.

I hate the internet sometimes for trying to track down information like this.

At this point, I can only assume that the a-pump CAN flow lots of fuel, but since diesel shops recommend the p-7100 dodge cummins pump conversion, the a-pump must be very unfriendly for street driving when turned up.

At first, I did want to run 2 a-pumps, the original, and an additional one belt driven with an actuator to adjust timing. I found all the little high pressure fittings to make it work, but a diesel shop said the ultimate problem would be that the vibrations would cause leaks and I would constantly have fuel leaks.

I was going to mount the 2nd pump beside the original pump, and put little "T"'s on the original pump lines, for the 2nd pump to flow into.

I think it would have worked great, I could have set the stock pump to 10* of timing, and the 2nd pump idle speed would be way lower than the primary pump, so it wouldn't even kick in at idle, enabling really great low noise idling. It probably would have run great, maybe even better than a modded pump . But, I don't want the headaches of leaking fuel fittings, and that sounds like the main issue that is guaranteed to happen, so that is why I ditched that idea.

I bet it would end up being cheaper running 2 a-pumps than the p-pump and all the modifications, but sounds less reliable if it's gonna leak fuel everywhere.

Ih Dt360 Upgrades - Competition Diesel.Com - Bringing The BEST Together

And then somewhere else, it is stated that the a-pump can flow 700 CC's.

I hate the internet sometimes for trying to track down information like this.

At this point, I can only assume that the a-pump CAN flow lots of fuel, but since diesel shops recommend the p-7100 dodge cummins pump conversion, the a-pump must be very unfriendly for street driving when turned up.

At first, I did want to run 2 a-pumps, the original, and an additional one belt driven with an actuator to adjust timing. I found all the little high pressure fittings to make it work, but a diesel shop said the ultimate problem would be that the vibrations would cause leaks and I would constantly have fuel leaks.

I was going to mount the 2nd pump beside the original pump, and put little "T"'s on the original pump lines, for the 2nd pump to flow into.

I think it would have worked great, I could have set the stock pump to 10* of timing, and the 2nd pump idle speed would be way lower than the primary pump, so it wouldn't even kick in at idle, enabling really great low noise idling. It probably would have run great, maybe even better than a modded pump . But, I don't want the headaches of leaking fuel fittings, and that sounds like the main issue that is guaranteed to happen, so that is why I ditched that idea.

I bet it would end up being cheaper running 2 a-pumps than the p-pump and all the modifications, but sounds less reliable if it's gonna leak fuel everywhere.

#110

Like something like this is what I was thinking, "T" the 2 pumps together at every injection line, and that way you can set the timing different on both pumps, and achieve more fuel without fancy pumps.

Granted, any money saved from not buying a fancy p7100 and drive gear setup would be spend on injection lines and parts, mounting, etc.

But, if it didn't leak fuel everywhere, I think it would be a lot nicer to drive than a modded pump, but what do I know.

Also a-pumps are cheap, like give away cheap, and modded p7100 pumps are not cheap, at all, so if one did manage to make dual a-pumps run in this fashion, it could be very cheap to run. I still think if the injection lines would work without leaking, this would be a better more reliable and cost effective setup. Maybe not for a dodge where they came with a p7100 on it already, but a dt where it costs money to put a p7100 on it.

The only downside to the 2nd pump I can think of is the drive belt or chain, and the possiblity of leaking injection lines, which I'm told is GOING to happen for sure, because of vibrations. Other than that, I think it would be far superior to a modded p7100.

#111

Current issue trying to find out: valve springs.

Through all of the dt360 threads I've seen, I haven't read about valve spring problems.

The dirty truth in the matter seems to be that I can't seem to find mild springs.

Theres springs available, but they are racing ones with way more force than anyone would want unless your upgrading everything. Enough to snap stock rockers,

So until I can find springs that can handle more than 40 psi of back pressure, but not destroy stuff, looks like this could get stuck at a 250 hp ish truck

Through all of the dt360 threads I've seen, I haven't read about valve spring problems.

The dirty truth in the matter seems to be that I can't seem to find mild springs.

Theres springs available, but they are racing ones with way more force than anyone would want unless your upgrading everything. Enough to snap stock rockers,

So until I can find springs that can handle more than 40 psi of back pressure, but not destroy stuff, looks like this could get stuck at a 250 hp ish truck

#112

Any of you guys know much about valves and springs?

Just thinking out loud here....

Exhaust valve 1.76" cummins, 1.455" DT360...

Stock 12 valve cummins seem to be able to handle 50 psi and 3500 RPM on stock springs, which are 150 lbs of tension when seated.

Some interesting things I've read along my way, boost does not in and of itself, need stronger springs. When the exhaust valve closes, there is pressure trying to force it open, but the cylinder also has pressurized exhaust in it too! So it's not like there could be 80 psi of back pressure, and 0 psi cylinder pressure.

That being said, when the intake valve opens, pressure could release from the cylinder to the intake valve, backwards, and cylinder pressure could momentarily be low enough to allow the exhaust valve to creep open. As long as boost is present, the combustion chamber will be pressurized during the intake stroke, but a major problem would be when using a back pressure device like a VVT turbo, or exhaust brake, because then you can have large exhaust back pressure, with very little boost. In that situation, the exhaust valves need more spring, to stay shut.

Also learned that the valve springs have clamping force, and "over the nose" pressure. The clamping force is how many pounds the spring exerts on the valve when seated. The over the nose pressure is the force when the valve is open all the way.

For a high RPM non boosted engine, you'd want high over the nose pressure, to close the valve quickly, while a high boosted stock RPM engine would need high seat pressure, without increasing over the nose pressure. There is no point in increasing over the nose spring rate with stock RPM, all it will do is cause wear and tear for no reason.

If you are building a higher than stock RPM, higher than stock boosted engine, then you want higher over the nose rate, to close valves quicker and eliminate float, and also a higher seat pressure, to hold back exhaust pressure.

Whew. ok... if anyone wants to poke a hole in that theory, go right ahead lol.

Just thinking out loud here....

Exhaust valve 1.76" cummins, 1.455" DT360...

Stock 12 valve cummins seem to be able to handle 50 psi and 3500 RPM on stock springs, which are 150 lbs of tension when seated.

Some interesting things I've read along my way, boost does not in and of itself, need stronger springs. When the exhaust valve closes, there is pressure trying to force it open, but the cylinder also has pressurized exhaust in it too! So it's not like there could be 80 psi of back pressure, and 0 psi cylinder pressure.

That being said, when the intake valve opens, pressure could release from the cylinder to the intake valve, backwards, and cylinder pressure could momentarily be low enough to allow the exhaust valve to creep open. As long as boost is present, the combustion chamber will be pressurized during the intake stroke, but a major problem would be when using a back pressure device like a VVT turbo, or exhaust brake, because then you can have large exhaust back pressure, with very little boost. In that situation, the exhaust valves need more spring, to stay shut.

Also learned that the valve springs have clamping force, and "over the nose" pressure. The clamping force is how many pounds the spring exerts on the valve when seated. The over the nose pressure is the force when the valve is open all the way.

For a high RPM non boosted engine, you'd want high over the nose pressure, to close the valve quickly, while a high boosted stock RPM engine would need high seat pressure, without increasing over the nose pressure. There is no point in increasing over the nose spring rate with stock RPM, all it will do is cause wear and tear for no reason.

If you are building a higher than stock RPM, higher than stock boosted engine, then you want higher over the nose rate, to close valves quicker and eliminate float, and also a higher seat pressure, to hold back exhaust pressure.

Whew. ok... if anyone wants to poke a hole in that theory, go right ahead lol.

#113

#114

Heres a neat thingy showing how to get the 6.4 engine out :

http://www.aev.com/uploads/file/BodyOn64EngineMtnc.pdf

http://www.aev.com/uploads/file/BodyOn64EngineMtnc.pdf

#117

I already thought I found the vacuum pump on the drivers side fender well lol.

It has what looks like a motor, and vacuum lines going to it. Maybe I have 2?

Awesome, 2 is better than 1 lol.

#118

Could it be for the hubs if you have shift on the fly? It doesn't look like the vacuum pumps when doing a parts search. I'm sure someone with more knowledge than me on the subject.

Edit: It is the vacuum solenoid for the autolock hubs.

http://www.partsgeek.com/gbproducts/...FUEV7AodLmcAdQ

Edit: It is the vacuum solenoid for the autolock hubs.

http://www.partsgeek.com/gbproducts/...FUEV7AodLmcAdQ

#119

Could it be for the hubs if you have shift on the fly? It doesn't look like the vacuum pumps when doing a parts search. I'm sure someone with more knowledge than me on the subject.

Edit: It is the vacuum solenoid for the autolock hubs.

1999-2010 Ford F350 Super Duty 4WD Hub Locking Solenoid - Driveshaft & Axle - Dorman 99-10 F350 Super Duty 4WD Hub Locking Solenoid - 5365-05317197 - PartsGeek

Edit: It is the vacuum solenoid for the autolock hubs.

1999-2010 Ford F350 Super Duty 4WD Hub Locking Solenoid - Driveshaft & Axle - Dorman 99-10 F350 Super Duty 4WD Hub Locking Solenoid - 5365-05317197 - PartsGeek

Ah that makes perfect sense, don't know how I didn't think of that.