Rear end options

#31

#33

While the Dana 44 was the most common, 1963/66's could also have the Dana 60.2, 1966/67's could also have the Dana 60.3.

Some 1977/79 F100/150's also came with Dana 44 rear axles with or without Limited Slip.

#34

Join Date: Feb 2006

Location: North Pole, Alaska

Posts: 2,708

Likes: 0

Received 151 Likes

on

131 Posts

No, you don't have to pull the axle housing from the truck. Just unbolt and pull the carrier from the housing. That is why the 9 inch is known as the "poor man's quick change" rearend for dragstrip and racetrack. Just pull the axles to clear the carrier, and unbolt the carrier and replace with a new one, and done.

#35

1959/67 F100 9" was not available with Limited Slip. If Limited Slip was specified, Ford installed Dana rear axles.

While the Dana 44 was the most common, 1963/66's could also have the Dana 60.2, 1966/67's could also have the Dana 60.3.

Some 1977/79 F100/150's also came with Dana 44 rear axles with or without Limited Slip.

While the Dana 44 was the most common, 1963/66's could also have the Dana 60.2, 1966/67's could also have the Dana 60.3.

Some 1977/79 F100/150's also came with Dana 44 rear axles with or without Limited Slip.

A 9-inch Equalok or a Traction-Lok 3rd member could have been taken from an early Bronco or even a passenger car and installed in a Ford F-100 rear end housing that originally had an open differential. --so long as the axle gear spline count matches the axle spline count of the vehicle the 3rd member is being installed in, it's a direct fit. The driving pinion yoke is the only thing that differs. Passenger car driving pinion yokes tend to be longer than the yokes on the trucks but, that can be swapped out to be compatible with the existing drive shaft.

Lots of time has passed since these vehicles were new and not all still have the same exact equipment they had when they rolled off the assembly line. If something, such as an Equalok or Traction-Lok, for example, was added and you know the difference in the two, you're better equipped to know what you have and a better idea of what's needed to refurbish it.

What's listed in the Ford master parts catalog is an account of the way it was in its OEM configuration but, years later, it doesn't necessarily mean that's what's actually on/in a particular vehicle now.

#36

Join Date: Jul 2011

Location: On the Edge of the Desert

Posts: 8,601

Likes: 0

Received 137 Likes

on

121 Posts

Speaking if the equa-loc and traction-loc, how do you tell them apart?

I bought what was said to be a traction loc, but also said to be genuine ford from a '64.

I'm looking to put it in my 71 with 4.11 gears, 31s and a strong 351.

I've heard the equa-loc is only worth it's weight in scrap, and that the trac-loc was a much better unit.

How do I tell them apart?

I bought what was said to be a traction loc, but also said to be genuine ford from a '64.

I'm looking to put it in my 71 with 4.11 gears, 31s and a strong 351.

I've heard the equa-loc is only worth it's weight in scrap, and that the trac-loc was a much better unit.

How do I tell them apart?

#37

Speaking if the equa-loc and traction-loc, how do you tell them apart?

I bought what was said to be a traction loc, but also said to be genuine ford from a '64.

I'm looking to put it in my 71 with 4.11 gears, 31s and a strong 351.

I've heard the equa-loc is only worth it's weight in scrap, and that the trac-loc was a much better unit.

How do I tell them apart?

I bought what was said to be a traction loc, but also said to be genuine ford from a '64.

I'm looking to put it in my 71 with 4.11 gears, 31s and a strong 351.

I've heard the equa-loc is only worth it's weight in scrap, and that the trac-loc was a much better unit.

How do I tell them apart?

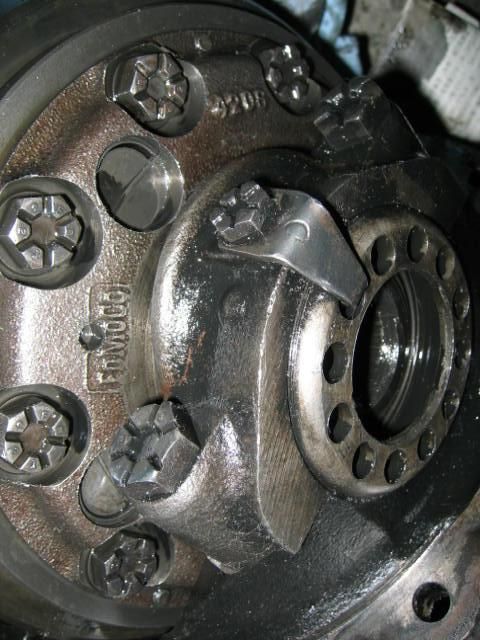

On the outside, the Equa-Lok differential has a rather rough looking casting, compared to a '70-'86 Traction-Lok differential casting, which has a machined surface on the ring gear bolt head side. The '69 Traction-Lok also has a fairly rough casting but, the 4 large holes on the left half make it easy to spot that it's a '69 Traction-Lok differential and not a '68 and earlier Equa-Lok.

In link below are two Traction-Lok 3rd members. The one on the left is a '69 version (note 2 of the 4 holes showing near the ring gear bolt heads). '70-up Traction-Lok differential on right has a machined surface compared to '69 TL unit on left. Aside from the lack of holes, an Equa-Lok's rougher surface casting will look more like the '69 unit on the left.

http://i1287.photobucket.com/albums/...ps6e68fd46.jpg

Another '69 Traction-Lok showing the holes and the rather rough looking casting:

Inside, an Equa-lok will have 3 friction discs and 5 ears or, tabs sticking out around the perimeter of those discs. If the differential halves were split open and you were looking down on top of it, the silhouette of the discs inside would look similar to the shape of a turtle. There's also a large conical (Belleville) spring that applies pressure to the clutches.

Equa-Lok internals:

http://www.kevinstang.com/elock3.jpg

Inside a Traction-Lok, there are 4 clutch discs with four tabs around the perimeter and a square center block with 4 small coil springs and a stamped plate that applies pressure (no Belleville spring).

4 'tabs' on a Traction-Lok clutch disc/plate (Equa-Lok will have 5) :

http://diyford.com/wp-content/uploads/2013/10/379.jpg

The internal parts of the Traction-Lok can be seen here:

http://www.ultrastang.com/ustang/Images/image/31-m.jpg

'69 (4 hole) differential casting failure shown in following link.

http://www.kevinstang.com/bn33.jpg

#38

No, you don't have to pull the axle housing from the truck. Just unbolt and pull the carrier from the housing. That is why the 9 inch is known as the "poor man's quick change" rearend for dragstrip and racetrack. Just pull the axles to clear the carrier, and unbolt the carrier and replace with a new one, and done.

1. disconnect drive shaft;

2. Drain rear-end;

3. remove the bolts in the face of the differential;

4. then ease out?

When I ease this unit out, what type of weight should I expect

#39

When I ease this unit out, what type of weight should I expect[/QUOTE]

.

I don't know how heavy it is just don't have any body parts in the way it can hurt. But it is best to check the gears out before using it , you don't want to damage the splines on an axle after doing all that work.

.

.

I don't know how heavy it is just don't have any body parts in the way it can hurt. But it is best to check the gears out before using it , you don't want to damage the splines on an axle after doing all that work.

.

#40

You'll be able to get a 9/16" socket on all but the bottom two nuts that holds the 3rd member to the housing. (10 in all).

The 3rd member will weigh close to 70 lb.

When you go to refill, you'll need 3 bottles of gear oil. It will take all of the first two bottles and half of the 3rd.

#41

A co-worker made reference to needing the a 1.5 inch socket or larger for one bolt. Dang need a drawing in front of me, but isn't that the large bolt that you can see when take the axle/u-joints out? This nut won't have to come out yet, correct.

This will sound dense of me - but what is the third member?

This will sound dense of me - but what is the third member?

#42

#43

#44

Axles are out and getting new bearings pressed on;

Would need to remove the brake lines from the housing - no big deal;

Would need to find me another place for my jack stands to support the truck - probably not a big deal;

disconnect the shocks;

undo the u-bolts.

Are there any challenges on getting it lined up properly.

Would at least give me a chance to clean it up all "pretty and nice (:"

Would need to remove the brake lines from the housing - no big deal;

Would need to find me another place for my jack stands to support the truck - probably not a big deal;

disconnect the shocks;

undo the u-bolts.

Are there any challenges on getting it lined up properly.

Would at least give me a chance to clean it up all "pretty and nice (:"

#45

Two days after I bought my truck, the right rear wheel cylinder blew. I also discovered the MC was leaking brake fluid down the inside of the firewall.

I pulled the wheels off and began stripping the brake components off to start the rebuild process. It wasn't necessary to pull the rear end housing out from under the truck but, I figured while I was replacing brake components, axle bearings, axle seals, etc., might as well ****** the rear end out, pressure wash it inside and out, bead blast, prime and repaint it. Had to make a new 3/16" hard brake line too. The original line was pretty surface pitted (weak spots that could cause the line to blow out).

The rear end housing after I got it all cleaned, put back together and re-installed under my '69 F-100 Ranger.

I pulled the wheels off and began stripping the brake components off to start the rebuild process. It wasn't necessary to pull the rear end housing out from under the truck but, I figured while I was replacing brake components, axle bearings, axle seals, etc., might as well ****** the rear end out, pressure wash it inside and out, bead blast, prime and repaint it. Had to make a new 3/16" hard brake line too. The original line was pretty surface pitted (weak spots that could cause the line to blow out).

The rear end housing after I got it all cleaned, put back together and re-installed under my '69 F-100 Ranger.