Rear end options

#17

I am worn out from battling this thing. Mechanics shop I talked to discussed it and they said would be doing essentially what I am doing, but they don't think that the bearing, considering how much of it has fallen out, could be holding the axle in place against the sliding hammer or the sledge.

As I am fond of saying to my friends....Argggggg.

As I am fond of saying to my friends....Argggggg.

#18

....long day at work today. Finally got out of there 3 hours later than usual.

Ok, the Ford 9-inch differential in the following photo is a Traction-Lok 4-pinion unit with 31-spline axle gears.

I figure your differential is a 2-pinion, 28-spline open (single track) differential. Doesn't matter. The pinion shaft shown running through the middle of this differential would be the very same configuration on your differential. It's obvious with this shaft running through the center that the splined ends of the axles would not be meeting each other. They would be separated by the shaft between them.

In link below; on the left is an internal look at a 9-inch 2-pinion open (single track) differential. The one on the right is an internal look at a Ford 9-inch 4-pinion Traction-Lok differential. You can see the same common pinion shaft running all the way through both.

http://ultrastang.com/ustang/Images/image/32-m.jpg

A look at the internal 4-pinion arrangement of a Traction-Lok differential. Shown are the 4 pinion gears, long pinion shaft, the two short pinion shafts and the center block.

http://ultrastang.com/ustang/Images/image/31-m.jpg

I'm not an expert on Ford rear ends but, Ford 8-inch and 9-inch rear ends is a subject I do know a great deal about. My website is geared toward the vintage Mustang or related Ford owner but, any 9-inch 3rd member will fit in any 9-inch rear end housing (car or truck) so long as the 3rd members axle gear spline count matches the axle spline count of the vehicle the 3rd member is being put into.

Open (single track) differentials primarily came with a 2-pinion arrangement but there were some 4-pinion open differentials.

The '57-'68 Ford Equalok only came with 2 pinion gears.

The '69-'86 Ford Traction-Lok differential could have 2 pinion gears or a much stronger 4 pinion arrangement.

Some Ford 9-inch information from my website.

1. The Ford 9-inch Rear End

2. Differential Types

3. Third Member I.D. Codes

4. Third Member Cases

Unfortunately, if you were banging on something, up inside the differential to dislodge the stuck axle from the housing, it wasn't the stuck axle you were banging on. --it was that pinion shaft running through the center of the differential that was getting abused.

Ok, the Ford 9-inch differential in the following photo is a Traction-Lok 4-pinion unit with 31-spline axle gears.

I figure your differential is a 2-pinion, 28-spline open (single track) differential. Doesn't matter. The pinion shaft shown running through the middle of this differential would be the very same configuration on your differential. It's obvious with this shaft running through the center that the splined ends of the axles would not be meeting each other. They would be separated by the shaft between them.

In link below; on the left is an internal look at a 9-inch 2-pinion open (single track) differential. The one on the right is an internal look at a Ford 9-inch 4-pinion Traction-Lok differential. You can see the same common pinion shaft running all the way through both.

http://ultrastang.com/ustang/Images/image/32-m.jpg

A look at the internal 4-pinion arrangement of a Traction-Lok differential. Shown are the 4 pinion gears, long pinion shaft, the two short pinion shafts and the center block.

http://ultrastang.com/ustang/Images/image/31-m.jpg

I'm not an expert on Ford rear ends but, Ford 8-inch and 9-inch rear ends is a subject I do know a great deal about. My website is geared toward the vintage Mustang or related Ford owner but, any 9-inch 3rd member will fit in any 9-inch rear end housing (car or truck) so long as the 3rd members axle gear spline count matches the axle spline count of the vehicle the 3rd member is being put into.

Open (single track) differentials primarily came with a 2-pinion arrangement but there were some 4-pinion open differentials.

The '57-'68 Ford Equalok only came with 2 pinion gears.

The '69-'86 Ford Traction-Lok differential could have 2 pinion gears or a much stronger 4 pinion arrangement.

Some Ford 9-inch information from my website.

1. The Ford 9-inch Rear End

2. Differential Types

3. Third Member I.D. Codes

4. Third Member Cases

Unfortunately, if you were banging on something, up inside the differential to dislodge the stuck axle from the housing, it wasn't the stuck axle you were banging on. --it was that pinion shaft running through the center of the differential that was getting abused.

#19

#20

_That is my suggestion too. I'm sure there is more damage inside the gears you can't see now. That's the way things go some times , just get another one and chalk this up as a learning experience , we have all been there.__

_That is my suggestion too. I'm sure there is more damage inside the gears you can't see now. That's the way things go some times , just get another one and chalk this up as a learning experience , we have all been there.__ __JIM

__JIM.

#21

Now is the time to rent a pickup to pick up a rear end for my pickup.

Will be checking at a couple of salvage parts stores in San Antonio.

Guess main things - make sure the dimensions are the same and verify that I can pull the axles on both sides. That would be appropriate to find a rear end, get it home and be in the same situation.

Will be checking at a couple of salvage parts stores in San Antonio.

Guess main things - make sure the dimensions are the same and verify that I can pull the axles on both sides. That would be appropriate to find a rear end, get it home and be in the same situation.

#23

A glimmer of hope - well at least in removing the axle. Old timer told me about using some sort of 25 pound weight with an all-thread bolt/washers/nuts and attaching the to the hole on the lug plate for pulling the backing plate nuts.

Loaning me his "tool" this weekend.

If rear end is messed up, same mechanic is pretty sure he can match me up with a replacement as well.

Loaning me his "tool" this weekend.

If rear end is messed up, same mechanic is pretty sure he can match me up with a replacement as well.

#24

#26

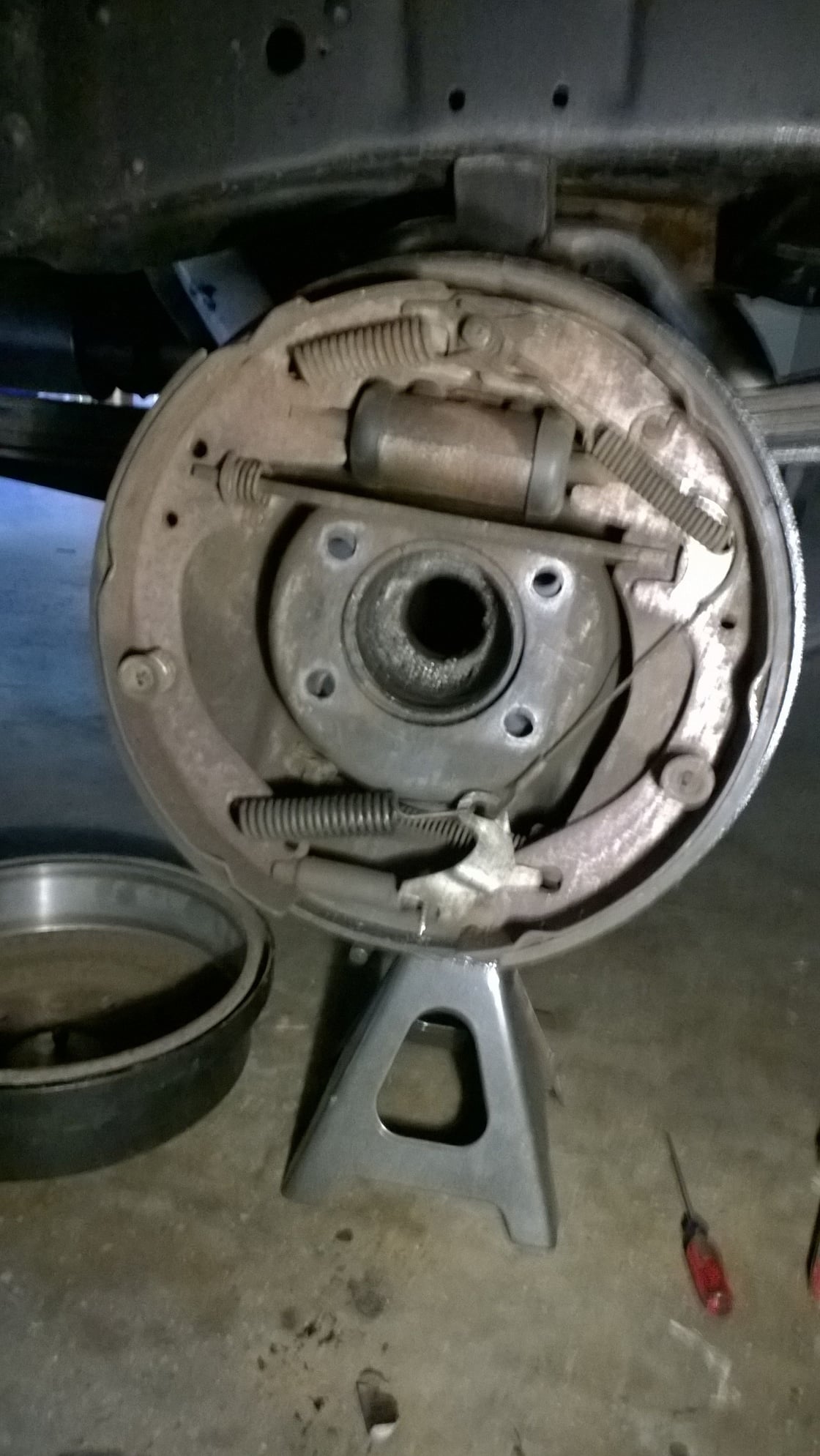

Well, the outer bearing race remained after the removal. A day or so of cutting with a dremel (and about 20 wheels) I was able to get that out. Polished up the opening, replaced the oil seals and am taking the axles down to a local auto repair place today to have the bearings replaced.

Then I will get to see/hear if I damaged the rear end.

Then I will get to see/hear if I damaged the rear end.

#29

#30

Basically, 36 inch 3/4 inch all thread;

3 x appropriate nuts;

3 x wide, thick washers;

Put one nut and wash on all thread and run it about 2-3 inches on bolt;

insert through hole on lug nut plate;

install another washer and nut to secure;

tighten down;

slide weight onto all thread;

place large washer and the other nut on end;

straddle slide hammer and slide away.

Turbo dog, probably will put it back together first and see if anything works after the pounding I subjected to earlier. Either way, the differential is in for some refurb (it leaks).