1949 F4 V8 to Mercedes diesel build thread

#122

This is the master cylinder and booster that I ordered from Rock Auto. The MC is a new Motorcraft part for a 2011-12 F250-F550. The booster is rebuilt for the same application. This MC and booster combination is also correct for the disc brakes I am installing on the front.

I would like to make some fittings to press onto the MC in place of the reservoir so I can mount the reservoir on the inner fender and run hoses to the MC under the floor. I will also have to fab a bracket to mount the MC and booster slightly behind the position of the original MC.

#124

Fred, I modified the engine crossmember so I could install the Mercedes motor mount shocks. The bracket on the front left side of the photo and the half round notch on the back right side of the photo are the mounts I had to add to the crossmember. I originally intended to just use the Mercedes motor mounts without the shocks, but the motor mounts are so soft, I was told that they would not be able to handle the engine vibration without them. I also finished drilling all of the bolt holes to fasten the crossmember into the frame. I am machining a stainless fitting to TIG weld into the air intake ell at the turbo. This will be for crankcase ventilation that will be drawn from the valve cover thru an oil catch can, to separate oil vapor, into the turbo. I will post more photos when I get that finished, maybe tomorrow evening.

Thanks, Mark

#126

I did get some more work done on the truck today . I made new bushings for the front springs, cleaned up all the shackle bolts, made sure the grease passage was open and replaced the zerks in the bolts. I had two sets of bolts, so I was able to find enough that had very little wear. I then reinstalled the axle. The ball for the draglink on the axle was about .003" out of round, so I polished it in the lathe and reinstalled it. The ball on the pitman arm had a little more wear, but I was able to polish it also. I also had two draglinks so I pick the best ball seats out of the two and reassembled the draglink on the truck. I found out when I reinstalled it that it was on backwards when I got the truck. Another good reason to have a shop manual! I also did some needle scaling on the frame where I removed the original motor mount arms, so I can repaint the front of the frame and the new crossmember. I didn't take any photos to post, so I guess none of this really happened

. I made new bushings for the front springs, cleaned up all the shackle bolts, made sure the grease passage was open and replaced the zerks in the bolts. I had two sets of bolts, so I was able to find enough that had very little wear. I then reinstalled the axle. The ball for the draglink on the axle was about .003" out of round, so I polished it in the lathe and reinstalled it. The ball on the pitman arm had a little more wear, but I was able to polish it also. I also had two draglinks so I pick the best ball seats out of the two and reassembled the draglink on the truck. I found out when I reinstalled it that it was on backwards when I got the truck. Another good reason to have a shop manual! I also did some needle scaling on the frame where I removed the original motor mount arms, so I can repaint the front of the frame and the new crossmember. I didn't take any photos to post, so I guess none of this really happened .

.

Thanks!

. I made new bushings for the front springs, cleaned up all the shackle bolts, made sure the grease passage was open and replaced the zerks in the bolts. I had two sets of bolts, so I was able to find enough that had very little wear. I then reinstalled the axle. The ball for the draglink on the axle was about .003" out of round, so I polished it in the lathe and reinstalled it. The ball on the pitman arm had a little more wear, but I was able to polish it also. I also had two draglinks so I pick the best ball seats out of the two and reassembled the draglink on the truck. I found out when I reinstalled it that it was on backwards when I got the truck. Another good reason to have a shop manual! I also did some needle scaling on the frame where I removed the original motor mount arms, so I can repaint the front of the frame and the new crossmember. I didn't take any photos to post, so I guess none of this really happened

. I made new bushings for the front springs, cleaned up all the shackle bolts, made sure the grease passage was open and replaced the zerks in the bolts. I had two sets of bolts, so I was able to find enough that had very little wear. I then reinstalled the axle. The ball for the draglink on the axle was about .003" out of round, so I polished it in the lathe and reinstalled it. The ball on the pitman arm had a little more wear, but I was able to polish it also. I also had two draglinks so I pick the best ball seats out of the two and reassembled the draglink on the truck. I found out when I reinstalled it that it was on backwards when I got the truck. Another good reason to have a shop manual! I also did some needle scaling on the frame where I removed the original motor mount arms, so I can repaint the front of the frame and the new crossmember. I didn't take any photos to post, so I guess none of this really happened .

. Thanks!

#128

How the heck can you polish the ***** on a lathe?? Did you remove the ***** from their arms first?

#129

Joe, I would love to have it finished for Truckstock, but I don't there is any way I can.

Ross, The draglink was assembled correctly, it was just on backwards. I didn't know until reading the manual on how to adjust the draglink, that it made any difference which way you installed it. It supposedly takes more of the road shock out of the steering if properly installed. The ball on the spindle I removed and polished in the lathe, the pitman arm ball I just polished by hand holding the pitman arm my bench vise. Neither one are perfectly round, but they are smooth and they are smooth and tight after assembly.

Ross, The draglink was assembled correctly, it was just on backwards. I didn't know until reading the manual on how to adjust the draglink, that it made any difference which way you installed it. It supposedly takes more of the road shock out of the steering if properly installed. The ball on the spindle I removed and polished in the lathe, the pitman arm ball I just polished by hand holding the pitman arm my bench vise. Neither one are perfectly round, but they are smooth and they are smooth and tight after assembly.

#130

#131

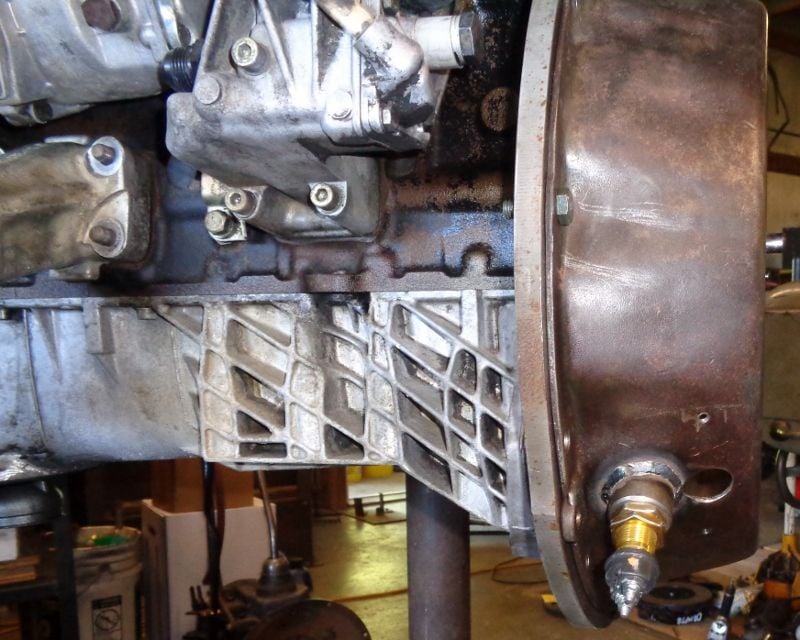

I had to fab a bracket for my engine stand to hold the Mercedes engine. I wanted to hold it from the side so I could work on any part of the engine. I didn't need that many bolts to hold it on the stand, but I had to drill all the holes for the studs , so I used them.

This is the threaded fitting and alignment hole that I added to the bellhousing for the inductive pickup for the tach. It sends a electrical impulse as each flywheel tooth passes it. I have a Dakota Digital control box that changes this impulse to a standard spark ignition tach signal.

you can see the flywheel teeth centered in the threaded hole for the inductive pickup, also the cover over the inspection hole.

This is the access hole in the bellhousing next to the inductive pickup the visually set the geartooth alignment

This is the inductive pickup for the tach installed

#132

460 Ford flywheel mounted on the Mercedes crankshaft. This flywheel is the same diameter as the Flathead V8 flywheel and was drilled for the same pressure plate.

FE series Ford starter.

The crank adapter with the pilot bearing. Note the 12 bolts holding the adapter to the Mercedes crank.

The crankshaft adapter to attach the 460 Ford flywheel and bellhousing adapter.

#135

One of my cars uses an inductive pickup on the flywheel for the tach, with just a single setscrew as the "trigger". The way the gap on the inductive pickup is set on those is to stick a piece of cardboard on the end of the transducer, with thickness matching desired gap, stick it in til it hits, then tighten the transducer down. The cardboard will just fall out when the engine cranks the first time.