1985 F150 302 holley problems

#212

You can use a vacuum gauge if you like, I am not arguing that point. But what makes good vacuum? The faster the engine runs, with the butterflies closed as much as they can be.

What I am saying is you can "hear" what the vacuum guage would tell you. You adjust the the mixture screws till it runs the smoothest/fastest, and then adjust your idle speed if you need to. Then you adjust the mixture screws again, and tweak the idle speed if needed. When the engine runs the smoothest and highest rpm, and is at a reasonable idle speed, that should be the highest vacuum reading. Tuning by "ear" like this gets you very close.

What I am saying is you can "hear" what the vacuum guage would tell you. You adjust the the mixture screws till it runs the smoothest/fastest, and then adjust your idle speed if you need to. Then you adjust the mixture screws again, and tweak the idle speed if needed. When the engine runs the smoothest and highest rpm, and is at a reasonable idle speed, that should be the highest vacuum reading. Tuning by "ear" like this gets you very close.

#213

Kyre,

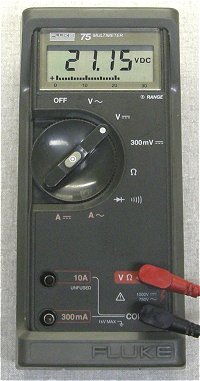

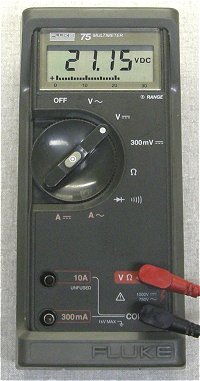

It is an old term for a Volt Ohm Meter.

Most would call them a DMM (digital MultiMeter) now.

Amps, Ohms, AC & DC Voltage, Capacitance, Continuity, diode check, etc.

My newer one even has a thermocouple.

My basic Fluke 75 has been serving well since the early '80's

I actually like my analog Simpson 260-6M best for hunting short or open wires.

It reacts much faster than the newer MeterMan 33XR

It is an old term for a Volt Ohm Meter.

Most would call them a DMM (digital MultiMeter) now.

Amps, Ohms, AC & DC Voltage, Capacitance, Continuity, diode check, etc.

My newer one even has a thermocouple.

My basic Fluke 75 has been serving well since the early '80's

I actually like my analog Simpson 260-6M best for hunting short or open wires.

It reacts much faster than the newer MeterMan 33XR

I do have a INNOVA 3306, would that be of any help?

#214

#215

Hey everyone, Been a while since I came here, a lot has happened.

But I wanted to give everyone an update.

A buddy of mine came over, tested the vacuum and said the vacuum looks fine on it, that was right after my last post here.

Since then I have just thrown parts at it when I have the time to spend with it.

To date, here is the list of things I have changed and tried.

Re built carburetor

new fuel pump

took Ignition control module to advance tested as good.

new plugs/wires

new Ignition coil

new egr valve

new timing chain, gears

So far that is what I have into it. Today I decided to play around a bit and took the multimeter around the engine, found that the MAP sensor vacuum port was not connected, nor was there even a vacuum line running to it, so I have to assume that it never had one. key was in the "ON" position during the testing.

I tested the 3 wires going into the MAP sensor to check for 4.7 volts, and found that no live wires are active at the MAP sensor on any of the 3 wires.

Traced the wires back, 2 go to the Throttle control, the last into the firewall. So having no power present, I then looked around for a fuse that may be blown but found none (under driver side dash).

Is it possible that this truck ran fine without the map sensor ever working or vacuum hooked up? or could it be that the map sensor was working, with vacuum line unhooked, but failure in the wire to the map sensor caused it to stop working?

I am not going to bother you guys about this much, I plan on throwing parts at it till I get it fixed then posting results here.

Thanks for all your help on this page as I know it was as frustrating for you as it was for me.

But I wanted to give everyone an update.

A buddy of mine came over, tested the vacuum and said the vacuum looks fine on it, that was right after my last post here.

Since then I have just thrown parts at it when I have the time to spend with it.

To date, here is the list of things I have changed and tried.

Re built carburetor

new fuel pump

took Ignition control module to advance tested as good.

new plugs/wires

new Ignition coil

new egr valve

new timing chain, gears

So far that is what I have into it. Today I decided to play around a bit and took the multimeter around the engine, found that the MAP sensor vacuum port was not connected, nor was there even a vacuum line running to it, so I have to assume that it never had one. key was in the "ON" position during the testing.

I tested the 3 wires going into the MAP sensor to check for 4.7 volts, and found that no live wires are active at the MAP sensor on any of the 3 wires.

Traced the wires back, 2 go to the Throttle control, the last into the firewall. So having no power present, I then looked around for a fuse that may be blown but found none (under driver side dash).

Is it possible that this truck ran fine without the map sensor ever working or vacuum hooked up? or could it be that the map sensor was working, with vacuum line unhooked, but failure in the wire to the map sensor caused it to stop working?

I am not going to bother you guys about this much, I plan on throwing parts at it till I get it fixed then posting results here.

Thanks for all your help on this page as I know it was as frustrating for you as it was for me.

#216

Hey everyone, Been a while since I came here, a lot has happened.

But I wanted to give everyone an update.

A buddy of mine came over, tested the vacuum and said the vacuum looks fine on it, that was right after my last post here.

Since then I have just thrown parts at it when I have the time to spend with it.

To date, here is the list of things I have changed and tried.

Re built carburetor

new fuel pump

took Ignition control module to advance tested as good.

new plugs/wires

new Ignition coil

new egr valve

new timing chain, gears

So far that is what I have into it. Today I decided to play around a bit and took the multimeter around the engine, found that the MAP sensor vacuum port was not connected, nor was there even a vacuum line running to it, so I have to assume that it never had one. key was in the "ON" position during the testing.

I tested the 3 wires going into the MAP sensor to check for 4.7 volts, and found that no live wires are active at the MAP sensor on any of the 3 wires.

Traced the wires back, 2 go to the Throttle control, the last into the firewall. So having no power present, I then looked around for a fuse that may be blown but found none (under driver side dash).

Is it possible that this truck ran fine without the map sensor ever working or vacuum hooked up? or could it be that the map sensor was working, with vacuum line unhooked, but failure in the wire to the map sensor caused it to stop working?

I am not going to bother you guys about this much, I plan on throwing parts at it till I get it fixed then posting results here.

Thanks for all your help on this page as I know it was as frustrating for you as it was for me.

But I wanted to give everyone an update.

A buddy of mine came over, tested the vacuum and said the vacuum looks fine on it, that was right after my last post here.

Since then I have just thrown parts at it when I have the time to spend with it.

To date, here is the list of things I have changed and tried.

Re built carburetor

new fuel pump

took Ignition control module to advance tested as good.

new plugs/wires

new Ignition coil

new egr valve

new timing chain, gears

So far that is what I have into it. Today I decided to play around a bit and took the multimeter around the engine, found that the MAP sensor vacuum port was not connected, nor was there even a vacuum line running to it, so I have to assume that it never had one. key was in the "ON" position during the testing.

I tested the 3 wires going into the MAP sensor to check for 4.7 volts, and found that no live wires are active at the MAP sensor on any of the 3 wires.

Traced the wires back, 2 go to the Throttle control, the last into the firewall. So having no power present, I then looked around for a fuse that may be blown but found none (under driver side dash).

Is it possible that this truck ran fine without the map sensor ever working or vacuum hooked up? or could it be that the map sensor was working, with vacuum line unhooked, but failure in the wire to the map sensor caused it to stop working?

I am not going to bother you guys about this much, I plan on throwing parts at it till I get it fixed then posting results here.

Thanks for all your help on this page as I know it was as frustrating for you as it was for me.

Clean around the spark plugs HEAVILY before you touch them. if the rocker arms show nothing strange, then do a compression test! (keep the spark plugs in order to aid in inspection later. If one plug is fouled, then keep an eye on that cylinder.

Clean around the spark plugs HEAVILY before you touch them. Dirt always hides next to the spark plug waiting to jump into the cylinder! I heavily clean with as many things as i think possible before removing a spark plug. Engine degreaser, compressed air, even a squirt bottle with water can help flush the dust and little rocks hiding around the spark plug Before I remove them.

Throwing parts can work, but vacuum gauge, and compression test are KEY steps to diagnostic of engines.

I really hope someone else would have replied by now, but nobody else seems to have. I pray you fix what the problem is and it goes easily for you. Remember first of all safety, and do as many diagnostics as possible. Start simple, spark, fuel compression, then try to pull the valve covers to see anything weird. Good luck and take care!

Thread

Thread Starter

Forum

Replies

Last Post

william11

1948 - 1956 F1, F100 & Larger F-Series Trucks

2

03-18-2016 02:20 PM

StarFox

Fuel Injection, Carburetion & Fuel System

1

03-20-2011 07:07 PM

59INA40

1961 - 1966 F-100 & Larger F-Series Trucks

12

05-12-2009 09:34 PM

ihateminimumwage

Fuel Injection, Carburetion & Fuel System

6

04-16-2008 07:24 PM

smisage

1980 - 1986 Bullnose F100, F150 & Larger F-Series Trucks

1

08-24-1999 02:27 PM