390 Crankshaft

#136

#137

Good Morning All,

Thanks John, I am getting closer. I am still waiting for the block (cam bearing) should be done by the end of the day, hopefully. Then I will have the rotating assembly balanced. I kind a like the new machine shop, his shop is a mess, there is engine block and cylinder heads everywhere, and there is just enough room to close the garage door!... But the guy ask for the pressure plate to do the balancing, he also told me than some of the tooth on the flywheel were a little bit worn and he can flip it over. I told him I want everything ready in 2 weeks, for my vacation, I will be rebuilding the engine with the help of my step father (he is building a woody version of a model A).

So I am still looking for some part, essentially a carburetor and a distributor. I am a bit confuse with all the vacuum system, vacuum advance or mechanical, etc...

I was looking for a Holley 4180c, from Redroad's advice, but I have a hard time finding one, and the rebuild one are expensive! I was thinking maybe I could go with an Edelbrock, like 1406 600CFM? I looked on Ebay and I saw a lot of used one, make me think maybe there are not that good!

Any opinion will be appreciated.

Thanks

Thanks John, I am getting closer. I am still waiting for the block (cam bearing) should be done by the end of the day, hopefully. Then I will have the rotating assembly balanced. I kind a like the new machine shop, his shop is a mess, there is engine block and cylinder heads everywhere, and there is just enough room to close the garage door!... But the guy ask for the pressure plate to do the balancing, he also told me than some of the tooth on the flywheel were a little bit worn and he can flip it over. I told him I want everything ready in 2 weeks, for my vacation, I will be rebuilding the engine with the help of my step father (he is building a woody version of a model A).

So I am still looking for some part, essentially a carburetor and a distributor. I am a bit confuse with all the vacuum system, vacuum advance or mechanical, etc...

I was looking for a Holley 4180c, from Redroad's advice, but I have a hard time finding one, and the rebuild one are expensive! I was thinking maybe I could go with an Edelbrock, like 1406 600CFM? I looked on Ebay and I saw a lot of used one, make me think maybe there are not that good!

Any opinion will be appreciated.

Thanks

#138

Good Morning All,

Thanks John, I am getting closer. I am still waiting for the block (cam bearing) should be done by the end of the day, hopefully. Then I will have the rotating assembly balanced. I kind a like the new machine shop, his shop is a mess, there is engine block and cylinder heads everywhere, and there is just enough room to close the garage door!... But the guy ask for the pressure plate to do the balancing, he also told me than some of the tooth on the flywheel were a little bit worn and he can flip it over. I told him I want everything ready in 2 weeks, for my vacation, I will be rebuilding the engine with the help of my step father (he is building a woody version of a model A).

So I am still looking for some part, essentially a carburetor and a distributor. I am a bit confuse with all the vacuum system, vacuum advance or mechanical, etc...

I was looking for a Holley 4180c, from Redroad's advice, but I have a hard time finding one, and the rebuild one are expensive! I was thinking maybe I could go with an Edelbrock, like 1406 600CFM? I looked on Ebay and I saw a lot of used one, make me think maybe there are not that good!

Any opinion will be appreciated.

Thanks

Thanks John, I am getting closer. I am still waiting for the block (cam bearing) should be done by the end of the day, hopefully. Then I will have the rotating assembly balanced. I kind a like the new machine shop, his shop is a mess, there is engine block and cylinder heads everywhere, and there is just enough room to close the garage door!... But the guy ask for the pressure plate to do the balancing, he also told me than some of the tooth on the flywheel were a little bit worn and he can flip it over. I told him I want everything ready in 2 weeks, for my vacation, I will be rebuilding the engine with the help of my step father (he is building a woody version of a model A).

So I am still looking for some part, essentially a carburetor and a distributor. I am a bit confuse with all the vacuum system, vacuum advance or mechanical, etc...

I was looking for a Holley 4180c, from Redroad's advice, but I have a hard time finding one, and the rebuild one are expensive! I was thinking maybe I could go with an Edelbrock, like 1406 600CFM? I looked on Ebay and I saw a lot of used one, make me think maybe there are not that good!

Any opinion will be appreciated.

Thanks

The 4180C is a great carb with many advantages but building one from scratch for your motor will take time .. I suggest if you find one for a manual trans get it and spend the time building it right .. Then compare it against the 1406 and see how you like it .. Get the 1406 first and will run ot of the box and get you going .. Get the strip kit with it so you can dial it in ..

#139

#140

Hi guys,

Yes I am still alive!!!

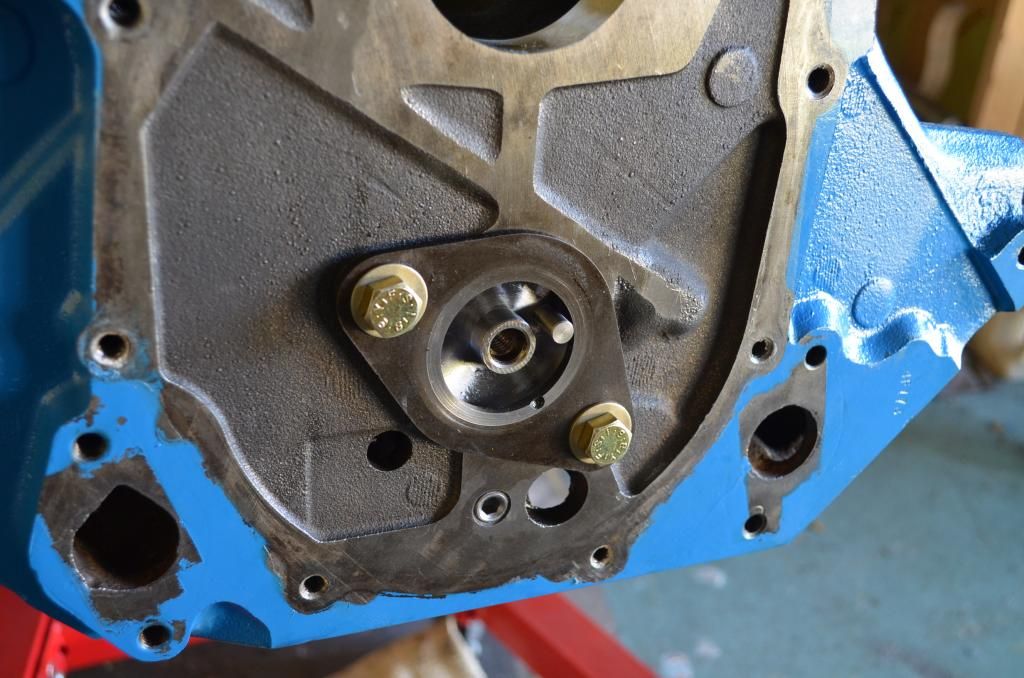

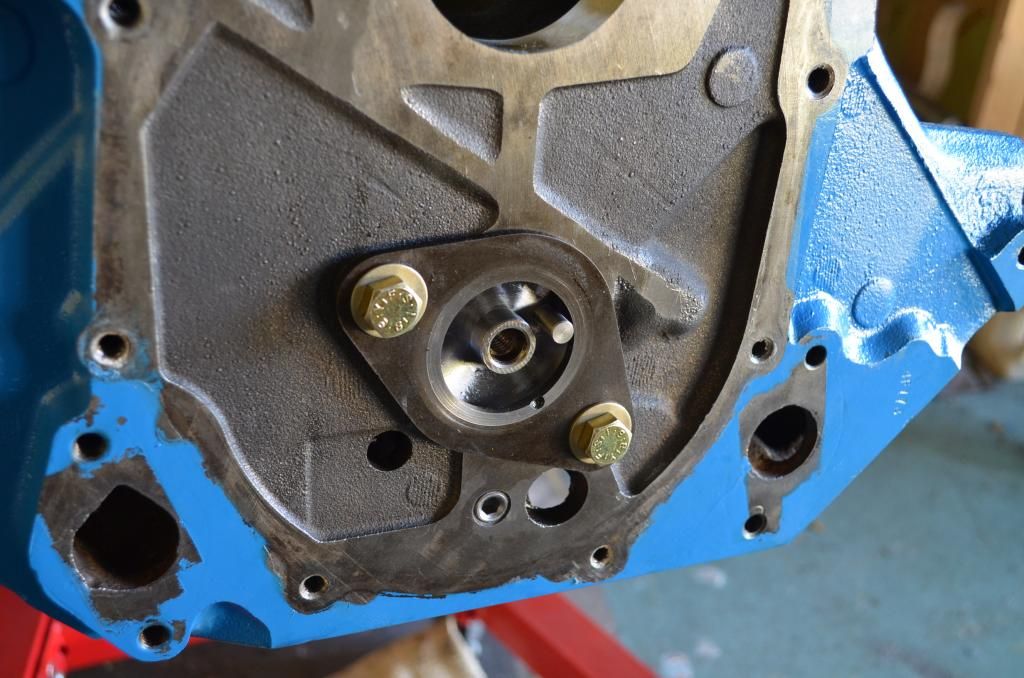

i finally got my block back! ready for the reassembly... I did not gave up! I finally was able to work and see the progress...

The shop did a good job, they convert all the small freeze plug by a 3/4 NPF plug. It make life easier and you know you won't have a to worry about plug popping out...

He put the cam bearing and check the clearance for the main journal on the crank (who need to be polish).

I washed the block thoroughly with hot water to take all the debris out...dried the block with compressed air, sprayed WD40 on the machined part. Clean the block and insert the brass freeze plug with black RTV around the edge.

After that I cleaned the block with denatured alcohol, masked the block with tape, and started to prime and paint.

Here is the result:

<a href="http://s1072.photobucket.com/user/laurentlesage/media/DSC_0431_zps211ebe91.jpg.html" target="_blank"><img src="http://i1072.photobucket.com/albums/w364/laurentlesage/DSC_0431_zps211ebe91.jpg" border="0" alt=" photo DSC_0431_zps211ebe91.jpg"/></a>

<a href="http://s1072.photobucket.com/user/laurentlesage/media/DSC_0434_zpsdaecf568.jpg.html" target="_blank"><img src="http://i1072.photobucket.com/albums/w364/laurentlesage/DSC_0434_zpsdaecf568.jpg" border="0" alt=" photo DSC_0434_zpsdaecf568.jpg"/></a>

<a href="http://s1072.photobucket.com/user/laurentlesage/media/DSC_0437_zps6e23a23d.jpg.html" target="_blank"><img src="http://i1072.photobucket.com/albums/w364/laurentlesage/DSC_0437_zps6e23a23d.jpg" border="0" alt=" photo DSC_0437_zps6e23a23d.jpg"/></a>

Well it feel really good to finally work in the assembly after waiting for almost 6 month, spending so much time in cleaning and researching part! Finally, now I can think about cranking the engine in the next few month...

Yes I am still alive!!!

i finally got my block back! ready for the reassembly... I did not gave up! I finally was able to work and see the progress...

The shop did a good job, they convert all the small freeze plug by a 3/4 NPF plug. It make life easier and you know you won't have a to worry about plug popping out...

He put the cam bearing and check the clearance for the main journal on the crank (who need to be polish).

I washed the block thoroughly with hot water to take all the debris out...dried the block with compressed air, sprayed WD40 on the machined part. Clean the block and insert the brass freeze plug with black RTV around the edge.

After that I cleaned the block with denatured alcohol, masked the block with tape, and started to prime and paint.

Here is the result:

<a href="http://s1072.photobucket.com/user/laurentlesage/media/DSC_0431_zps211ebe91.jpg.html" target="_blank"><img src="http://i1072.photobucket.com/albums/w364/laurentlesage/DSC_0431_zps211ebe91.jpg" border="0" alt=" photo DSC_0431_zps211ebe91.jpg"/></a>

<a href="http://s1072.photobucket.com/user/laurentlesage/media/DSC_0434_zpsdaecf568.jpg.html" target="_blank"><img src="http://i1072.photobucket.com/albums/w364/laurentlesage/DSC_0434_zpsdaecf568.jpg" border="0" alt=" photo DSC_0434_zpsdaecf568.jpg"/></a>

<a href="http://s1072.photobucket.com/user/laurentlesage/media/DSC_0437_zps6e23a23d.jpg.html" target="_blank"><img src="http://i1072.photobucket.com/albums/w364/laurentlesage/DSC_0437_zps6e23a23d.jpg" border="0" alt=" photo DSC_0437_zps6e23a23d.jpg"/></a>

Well it feel really good to finally work in the assembly after waiting for almost 6 month, spending so much time in cleaning and researching part! Finally, now I can think about cranking the engine in the next few month...

#141

#142

Well vacation are over, back to work now.

I had enough time to be able to put some part together. And since this is my first time putting an engine together, I check, re-check, and re re check everything.

Hugh, my step father helped me, he have done this before which

I got the MSD distributor, I still need to get a steel gear to replace the iron one installed from factory.

All the plugs (3/4 npt) are in, I drilled a 0.030 hole on the plug who sit behind the distributor, to lubricate the gear.

We also checked all end gap ring, the top rings have 0.020, and the second rings have 0.022.

Today I tried to install the oil pan and realized I have a clearance problem, after some research it is a common issue with the ARP bolt kit.

I wrote to ARP and hopefully they will send me 2 bolt with a shorter head.

Also I bought an engine bolt kit from ARP, and it misses the long bolt going in the timing cover. I used the old one for now, we'll see what the guys from ARP have to say about that.

I had enough time to be able to put some part together. And since this is my first time putting an engine together, I check, re-check, and re re check everything.

Hugh, my step father helped me, he have done this before which

I got the MSD distributor, I still need to get a steel gear to replace the iron one installed from factory.

All the plugs (3/4 npt) are in, I drilled a 0.030 hole on the plug who sit behind the distributor, to lubricate the gear.

We also checked all end gap ring, the top rings have 0.020, and the second rings have 0.022.

Today I tried to install the oil pan and realized I have a clearance problem, after some research it is a common issue with the ARP bolt kit.

I wrote to ARP and hopefully they will send me 2 bolt with a shorter head.

Also I bought an engine bolt kit from ARP, and it misses the long bolt going in the timing cover. I used the old one for now, we'll see what the guys from ARP have to say about that.

#143

Going backward now!

I am ready to bring the pistons back, the first machine sold me the 381NP030, they are too short, deck clearance is 0.130'', way too much the CR will be in the low 8:1!

So I spot 2 different pistons:

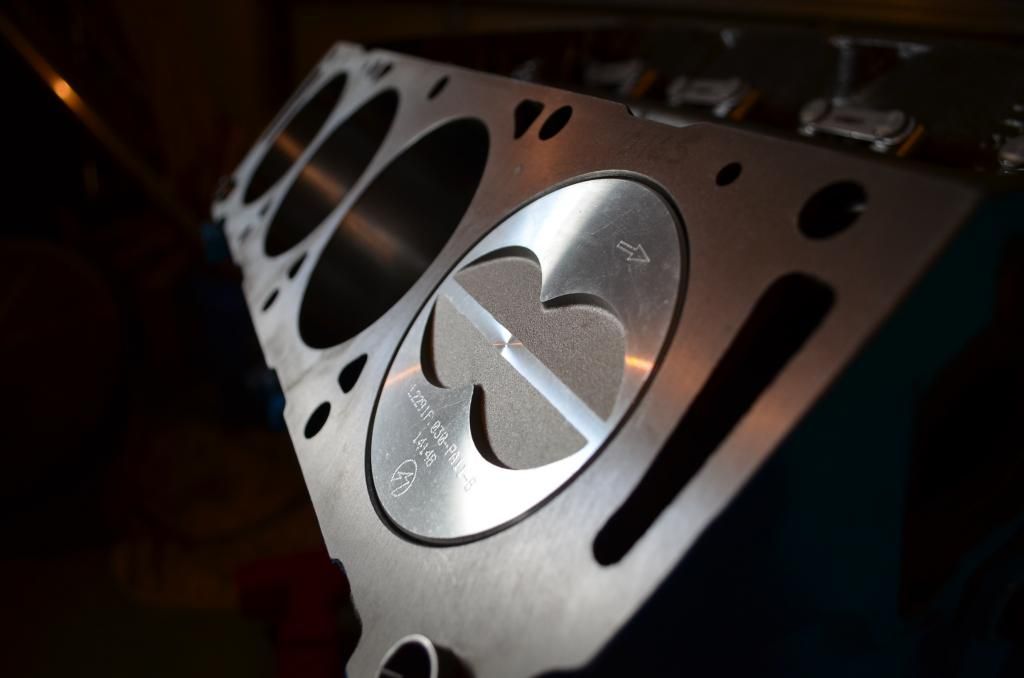

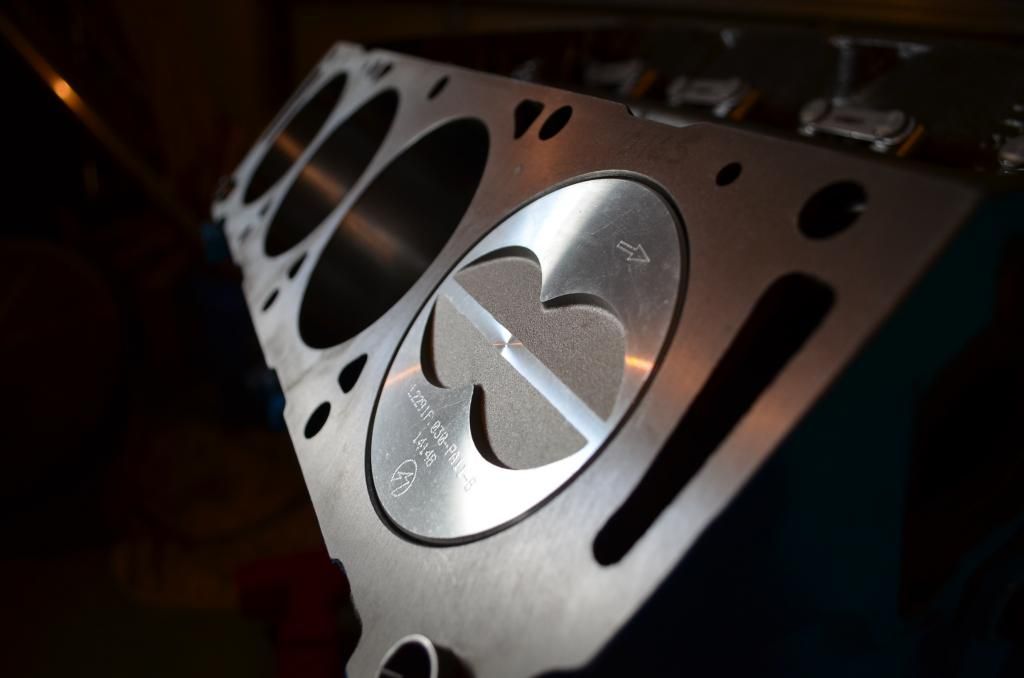

- L2291F030 from Speed Pro, those will match the actual weight of the 381NP030 (784gr.) but CR will be around 9.6:1, I will have a deck clearance of 0.014'', squish will be 0.054'' with 0.040 gasket.

Advantage: no need to rebalance the crank

Inconvenient: I will have to use premium gas with a CR of 9.6:1

- KB150-030 from Keith Black, those are 665 gr., CR will be 9.1:1, deck clearance will be 0.01, squish will be 0.050'' with 0.040 gasket. I could also use the 0.027 gasket ($200/pair) and have a perfect squish.

Advantage: I could use cheap gas I think.

Inconvenient: I will have to rebalance the crank....

I have to say, I don't know which way to go, but I know it is not too late to do it right.

I am a bit concern about the fact the shop had to drill a few hole in the pressure plate for the balancing and now it might be totally off if I go with the KB!

And in the same time, it is not going to be a daily driver, I am not going to race, and I already spend enough money in machine shop!!!

What you guys will do?

Thanks

I am ready to bring the pistons back, the first machine sold me the 381NP030, they are too short, deck clearance is 0.130'', way too much the CR will be in the low 8:1!

So I spot 2 different pistons:

- L2291F030 from Speed Pro, those will match the actual weight of the 381NP030 (784gr.) but CR will be around 9.6:1, I will have a deck clearance of 0.014'', squish will be 0.054'' with 0.040 gasket.

Advantage: no need to rebalance the crank

Inconvenient: I will have to use premium gas with a CR of 9.6:1

- KB150-030 from Keith Black, those are 665 gr., CR will be 9.1:1, deck clearance will be 0.01, squish will be 0.050'' with 0.040 gasket. I could also use the 0.027 gasket ($200/pair) and have a perfect squish.

Advantage: I could use cheap gas I think.

Inconvenient: I will have to rebalance the crank....

I have to say, I don't know which way to go, but I know it is not too late to do it right.

I am a bit concern about the fact the shop had to drill a few hole in the pressure plate for the balancing and now it might be totally off if I go with the KB!

And in the same time, it is not going to be a daily driver, I am not going to race, and I already spend enough money in machine shop!!!

What you guys will do?

Thanks

#144

Let's say you go 100,000 miles and you get 12 miles per gallon ..

100,000/12 = 8,333. 3 gallons

average savings of regular over premium gas let's say $0.07

8,333.3 x .07 = $583.3

What will be the total costs to do the changes ?

It looks like you would only be breaking even at best ..

So it looks like L2291F030 from Speed Pro to me

100,000/12 = 8,333. 3 gallons

average savings of regular over premium gas let's say $0.07

8,333.3 x .07 = $583.3

What will be the total costs to do the changes ?

It looks like you would only be breaking even at best ..

So it looks like L2291F030 from Speed Pro to me

#145

HI John,

Yes, looking at it this way, the choice is obvious!

I just come back from the first machine shop, they told me they don't understand why Speed Pro advertise the 381NP for FE block since it bring the CR very low.

They reimburse me and purpose me to buy the H304P30, I told them I would prefer to get the L2291F030, then they told me I will need a bigger bore clearance since they are forged piston! They said I should bring my block and they will bore it a bit bigger for forged piston at no cost! If I go that way I have to take everything apart but it will cost me the price of the new piston.

Well now I am going to look at the H304P30, the weight is 840gr., 56gr heavier than the 381NP (I don't know if you can take that much weight to match 784gr.), they have 12.8cc which will bring the CR at 9.1:1, deck clearance will be 0.031'' and the squish will be 0.071'' (seems a bit high).

Now I am going to see Doc Dan. the other machine shop and ask him his opinion...

The guy from Speed Pro, I just talk on the phone, said I should definitely have a bigger bore clearance for forged piston.

Yes, looking at it this way, the choice is obvious!

I just come back from the first machine shop, they told me they don't understand why Speed Pro advertise the 381NP for FE block since it bring the CR very low.

They reimburse me and purpose me to buy the H304P30, I told them I would prefer to get the L2291F030, then they told me I will need a bigger bore clearance since they are forged piston! They said I should bring my block and they will bore it a bit bigger for forged piston at no cost! If I go that way I have to take everything apart but it will cost me the price of the new piston.

Well now I am going to look at the H304P30, the weight is 840gr., 56gr heavier than the 381NP (I don't know if you can take that much weight to match 784gr.), they have 12.8cc which will bring the CR at 9.1:1, deck clearance will be 0.031'' and the squish will be 0.071'' (seems a bit high).

Now I am going to see Doc Dan. the other machine shop and ask him his opinion...

The guy from Speed Pro, I just talk on the phone, said I should definitely have a bigger bore clearance for forged piston.

#146

Well, finally got some luck. I receive the new set of piston (L2291F+30) and their size is spot on with enough bore clearance. No need to re-bore the cylinder, that is great news! I just need the shop to match the weight of the first piston and then I will be ready for assembly.

Since I didn't know if I will have to bring the block to a machine shop, I took everything apart again. I order new timing cover gasket and oil pan gasket.

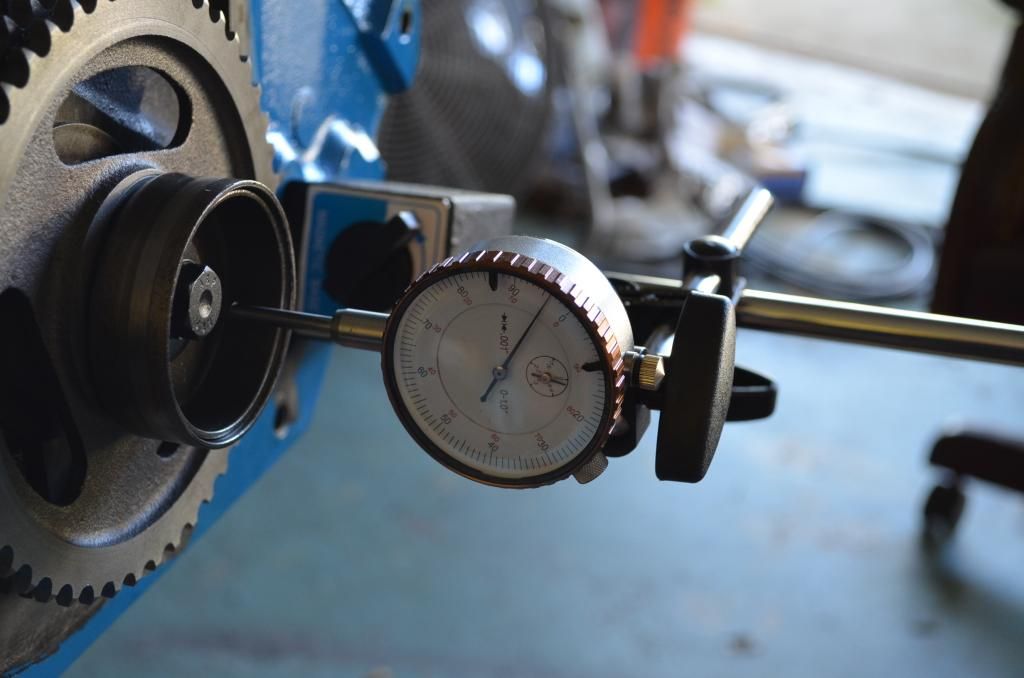

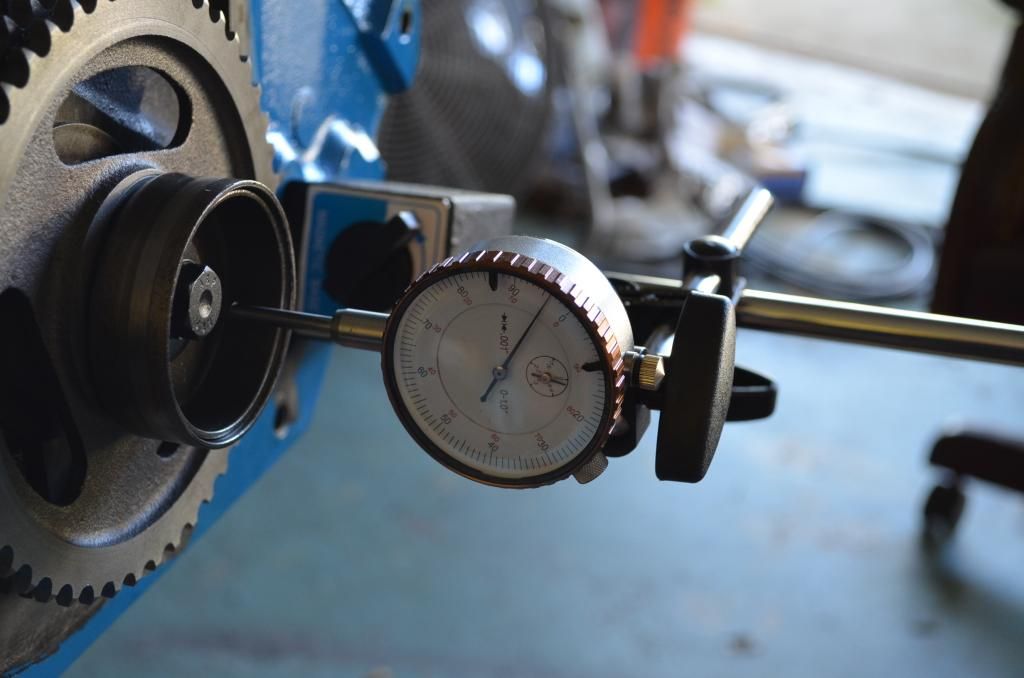

This time I had my dial indicator in hand and I was able to check the cam end play, between 0.004'' and 0.005'' which is within Ford spec.

I reinstalled the crankshaft, and this time I checked all the bearing clearances with plasti gauge, I find out that they are all between 0.015'' and 0.02''

I found a steering column, from I believe a 1978 truck, the harness is outside the column when the original on my 74 was inside. I scored the column and steering wheel for $100. So I installed it with a new rag joint.

I also found a used dash pad, it seems faded by the sun with maybe one or 2 little scratches. I am thinking of using vinyl spray paint or maybe some black shoe shine. Picture coming soon.

Since I didn't know if I will have to bring the block to a machine shop, I took everything apart again. I order new timing cover gasket and oil pan gasket.

This time I had my dial indicator in hand and I was able to check the cam end play, between 0.004'' and 0.005'' which is within Ford spec.

I reinstalled the crankshaft, and this time I checked all the bearing clearances with plasti gauge, I find out that they are all between 0.015'' and 0.02''

I found a steering column, from I believe a 1978 truck, the harness is outside the column when the original on my 74 was inside. I scored the column and steering wheel for $100. So I installed it with a new rag joint.

I also found a used dash pad, it seems faded by the sun with maybe one or 2 little scratches. I am thinking of using vinyl spray paint or maybe some black shoe shine. Picture coming soon.

#147

I wanted to wish everyone a happy and healthy new year.

Also I wanted to thanks everyone on this forum for sharing all the good stuff, I learned so much from you guys!

Now for the update, I worked on the inside of the cab, installed new carpet and I put temporarily the door seal (I had rain running to the carpet). The cab still need a little work, but I am definitely close to be done with it, door panels are ready to go as soon as I install some speaker.

I had the new pistons match the weigh of the old one, in fact the machine shop ask me the rods and they took the weight on the small end. The pistons are in and the deck clearance is now 0.015'', much better. I reinstalled the oil pump, oil pan, timing cover, check the camshaft spec with the degree wheel and I found a the cam is advance of 0.5 degree, perfect!

I was thinking about going to adjustable roller rocker, PRW sell an entire kit on Ebay, I thought it might make my life easier going with adjustable for the installation.

Also I wanted to thanks everyone on this forum for sharing all the good stuff, I learned so much from you guys!

Now for the update, I worked on the inside of the cab, installed new carpet and I put temporarily the door seal (I had rain running to the carpet). The cab still need a little work, but I am definitely close to be done with it, door panels are ready to go as soon as I install some speaker.

I had the new pistons match the weigh of the old one, in fact the machine shop ask me the rods and they took the weight on the small end. The pistons are in and the deck clearance is now 0.015'', much better. I reinstalled the oil pump, oil pan, timing cover, check the camshaft spec with the degree wheel and I found a the cam is advance of 0.5 degree, perfect!

I was thinking about going to adjustable roller rocker, PRW sell an entire kit on Ebay, I thought it might make my life easier going with adjustable for the installation.

#150

Thanks Blue04.5 for the kind word.

Rockittsled, no I don't think I will do the dyno tune, I am sure it will be a really good thing but I heard it is a bit pricey.

I am using a hydraulic roller cam and apparently I don't have to do the break in with zinc supplement, but I decided to use some just to make sure. I will have Doc Dan, my machine shop guy, he will come when I will crank the engine for the first time to make sure everything is right.

But yeah I would like to know how many horse I will get!

What about those dyno test when you bring your truck, you put the rear wheel on a roller thing (sorry I don't know the name of that! ), is it close enough?

), is it close enough?

Rockittsled, no I don't think I will do the dyno tune, I am sure it will be a really good thing but I heard it is a bit pricey.

I am using a hydraulic roller cam and apparently I don't have to do the break in with zinc supplement, but I decided to use some just to make sure. I will have Doc Dan, my machine shop guy, he will come when I will crank the engine for the first time to make sure everything is right.

But yeah I would like to know how many horse I will get!

What about those dyno test when you bring your truck, you put the rear wheel on a roller thing (sorry I don't know the name of that!

), is it close enough?

), is it close enough?