351m tuning project

#16

#17

tbear853 - that's quite a story - thanks for sharing your experience. I'm impressed you did all that bearing work without pulling the engine! I'll definitely keep my eye on the oil pressure. After hearing stories like yours, I was anxious to get a real gauge on there. Much to my relief, I'm running about 70 psi when cold with 10W-40. Once the engine is warm, it settles in around 35 psi at idle and then heads to about 60 psi from 1500 RPM and above. I'll keep my fingers crossed.

#18

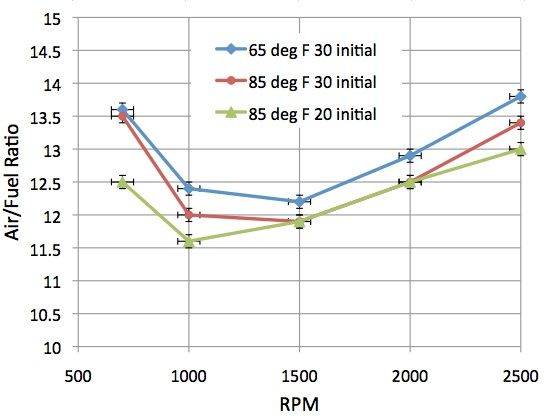

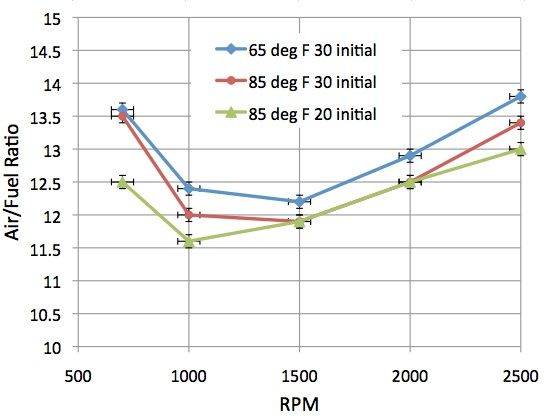

Today I backed off the initial timing (still using manifold vacuum for the advance) to 20 degrees (about 8 with vacuum advanced plugged) compared with the 32 I noted a few posts ago. This dropped the idle a bit so I had to tweak the screw to get back to 700 - 750 RPM. This seemed to make it slightly richer at idle and just above - probably need to tweak the idle mixture screws. Here's a slow RPM scan of the AFR after this change (green curve).

#19

tbear853 - that's quite a story - thanks for sharing your experience. I'm impressed you did all that bearing work without pulling the engine! I'll definitely keep my eye on the oil pressure. After hearing stories like yours, I was anxious to get a real gauge on there. Much to my relief, I'm running about 70 psi when cold with 10W-40. Once the engine is warm, it settles in around 35 psi at idle and then heads to about 60 psi from 1500 RPM and above. I'll keep my fingers crossed.

My first thought was the "Slick 50" was responsible, but Brownie felt like that was why I made it home .... but I still "don't know".

I'll enjoy your thread now ..... Good Luck .....

#20

Very cool; thanks for sharing this information. What kind of flow rates does the sensor report at idle and various other conditions (uphill under load, cruise, etc)?

Are you running an electric or mechanical pump (sorry if I missed it), and where specifically in the fuel system is the inline sensor placed? All of that information is really useful to me; you're the first person I've talked to that has any practical experience with that sensor.

Are you running an electric or mechanical pump (sorry if I missed it), and where specifically in the fuel system is the inline sensor placed? All of that information is really useful to me; you're the first person I've talked to that has any practical experience with that sensor.

#21

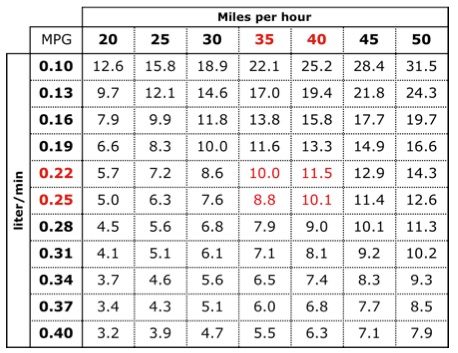

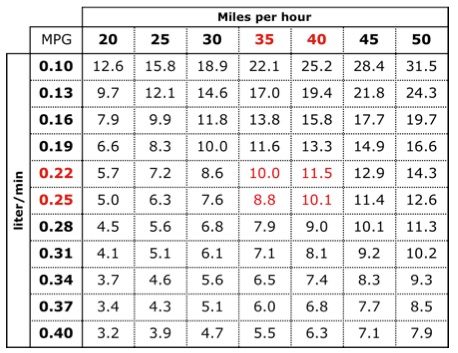

You're welcome. I was asking myself the same question the other day. Going uphill to HF it was showing roughly 0.26 l/min and downhill it was 0.21 l/min with trying to hold a steady 35 MPH. I took one measurement at idle which was ~0.1 l/min but it seems to bounce around a far bit. Because I was curious what these numbers mean in terms of MPG, I made this chart which I have on my clipboard in the truck:

I'm running a mechanical pump which recently came from NAPA. The sensor is underneath the cab on the driver's side where I have a valve to switch between the tanks. I looked at putting it under the hood, but thought it would be better to keep it in a cooler place. One half the electrical box I used is attached with a nut to the threads sticking through from the seat belt bolt. My first post in this thread has a few pictures of it.

I'm running a mechanical pump which recently came from NAPA. The sensor is underneath the cab on the driver's side where I have a valve to switch between the tanks. I looked at putting it under the hood, but thought it would be better to keep it in a cooler place. One half the electrical box I used is attached with a nut to the threads sticking through from the seat belt bolt. My first post in this thread has a few pictures of it.

#22

Hey that chart is pretty cool. That must be how the new vehicles work with a digital mpg display. Keep up the good work.

Last weekend I made some jetting changes and monitored A/F ratios. I went from #73 primaries and #79 secondaries to #72 and #76. AFR at idle was able to adjust from around 12.5 to 13.4 and runs well with peak vacuum. Wide open went from 12.0 to about 12.6. Cruise went from low 13s to low 14s. The carb had #75s and #81s out of the box.

I did a little internet research and the general idea is keep the loaded AFRs such as wide open around 12.5 and cruise can be right at stoic or 14.7 or a bit higher. The closer you can get to 14.7 the better for economy except at full throttle. Although I am running a different engine and carb it should still be similar to your 351m. I am using a Road Demon 725 CFM with vacuum secondaries on a mild cam 460. My timing curve is 38 degrees total mechanical plus initial all in around 2500 rpm and running full manifold vacuum advance. Haven't checked for an increase in mileage yet since I have been towing and city driving a lot lately. Previous to this I got 7-8 mpg consistently.

Last weekend I made some jetting changes and monitored A/F ratios. I went from #73 primaries and #79 secondaries to #72 and #76. AFR at idle was able to adjust from around 12.5 to 13.4 and runs well with peak vacuum. Wide open went from 12.0 to about 12.6. Cruise went from low 13s to low 14s. The carb had #75s and #81s out of the box.

I did a little internet research and the general idea is keep the loaded AFRs such as wide open around 12.5 and cruise can be right at stoic or 14.7 or a bit higher. The closer you can get to 14.7 the better for economy except at full throttle. Although I am running a different engine and carb it should still be similar to your 351m. I am using a Road Demon 725 CFM with vacuum secondaries on a mild cam 460. My timing curve is 38 degrees total mechanical plus initial all in around 2500 rpm and running full manifold vacuum advance. Haven't checked for an increase in mileage yet since I have been towing and city driving a lot lately. Previous to this I got 7-8 mpg consistently.

#23

#24

Very cool. That's interesting information on the sensor. As I mentioned earlier, I'm using that same sensor (just the sensor, not the module) on another project, and was hoping to find someone who had tried it. This is a rotary sensor in which a veined armature passes a Hall effect sensor. The sensor emits pulses; each pulse represents one volume of fuel that has gone past since the last pulse. This is called a "K-factor."

The unfortunate part, however, is that the volume of fuel represented by each pulse depends on flow rate. But flow rate is what you're trying to measure in the first place. If you know the flow rate such that you could qualify the sensor's output, there wouldn't be a need for the sensor in the first place. I've researched a variety of sensor manufacturers, all have the same chicken-and-egg problem, and I haven't had success in getting an explanation.

The only solution I can think of is to use a sensor with a relatively flat K-factor vs. flow rate curve within the range of operation, and this sensor appeared to be a good candidate, which your results seem to confirm.

http://www.digisavant.com/PDF/FS-3400AH-Spec.pdf

That's the sensor's data sheet. It implies a constant K-factor for flow rates between 4 and 30 LPH, or 0.07 and 0.5 LPM. Your results seem to show that an engine falls within this range under normal operating conditions, which makes sense as this sensor is advertised for automotive applications.

The reason I ask about fuel pump style is because a mechanical pump pushes fuel in a pulsed motion, which from what I've read, can have adverse effects on the sensor output's stability. To address that issue, I've seen folks take measures to increase the run of straight line after the sensor, and in some cases add a fluid dampener in the path. The other solution is to use an electric pump which moves fuel in a continuous motion. I happen to be going down the latter path, so I'm curious to see how much of an improvement it offers, if any.

Again, nice work. As for this:

That's obviously not what this thread is about. This thread is about experimentation and optimizing one specific technology, not "what's the absolute best way to improve your fuel mileage." Why not tell him to sell the truck and buy a Ford Escort? That would be just as irrelevant as what you keep spamming. I for one find this thread extremely useful. Quit raining on the guy's parade.

The unfortunate part, however, is that the volume of fuel represented by each pulse depends on flow rate. But flow rate is what you're trying to measure in the first place. If you know the flow rate such that you could qualify the sensor's output, there wouldn't be a need for the sensor in the first place. I've researched a variety of sensor manufacturers, all have the same chicken-and-egg problem, and I haven't had success in getting an explanation.

The only solution I can think of is to use a sensor with a relatively flat K-factor vs. flow rate curve within the range of operation, and this sensor appeared to be a good candidate, which your results seem to confirm.

http://www.digisavant.com/PDF/FS-3400AH-Spec.pdf

That's the sensor's data sheet. It implies a constant K-factor for flow rates between 4 and 30 LPH, or 0.07 and 0.5 LPM. Your results seem to show that an engine falls within this range under normal operating conditions, which makes sense as this sensor is advertised for automotive applications.

The reason I ask about fuel pump style is because a mechanical pump pushes fuel in a pulsed motion, which from what I've read, can have adverse effects on the sensor output's stability. To address that issue, I've seen folks take measures to increase the run of straight line after the sensor, and in some cases add a fluid dampener in the path. The other solution is to use an electric pump which moves fuel in a continuous motion. I happen to be going down the latter path, so I'm curious to see how much of an improvement it offers, if any.

Again, nice work. As for this:

That's obviously not what this thread is about. This thread is about experimentation and optimizing one specific technology, not "what's the absolute best way to improve your fuel mileage." Why not tell him to sell the truck and buy a Ford Escort? That would be just as irrelevant as what you keep spamming. I for one find this thread extremely useful. Quit raining on the guy's parade.

#25

Last weekend I made some jetting changes and monitored A/F ratios. I went from #73 primaries and #79 secondaries to #72 and #76. AFR at idle was able to adjust from around 12.5 to 13.4 and runs well with peak vacuum. Wide open went from 12.0 to about 12.6. Cruise went from low 13s to low 14s. The carb had #75s and #81s out of the box.

I did a little internet research and the general idea is keep the loaded AFRs such as wide open around 12.5 and cruise can be right at stoic or 14.7 or a bit higher. The closer you can get to 14.7 the better for economy except at full throttle. Although I am running a different engine and carb it should still be similar to your 351m. I am using a Road Demon 725 CFM with vacuum secondaries on a mild cam 460. My timing curve is 38 degrees total mechanical plus initial all in around 2500 rpm and running full manifold vacuum advance. Haven't checked for an increase in mileage yet since I have been towing and city driving a lot lately. Previous to this I got 7-8 mpg consistently.

#26

FMC400 - you've definitely spent some time looking at flow meters and this one in particular. I was curious how well it worked at low speeds which you've touched on. It wasn't clear from your post, but it sounds like your measuring the pulses with something other than the readout I have?

In my case, I'm pulling fuel through the sensor with about 3 - 4' of pipe/hose between it and the pump. I hadn't thought about the pumping action, but I agree that ~feet would seem enough to damp it out. On a related front, I have pondered transient effects when starting after sitting for awhile. For example, I see it flow quite a bit for a few seconds (filling up the line if it drained down?) and then drops off to zero for a few seconds and bounces around some until it settles down.

And thanks to all for the interest in this topic - it's great to have folks to share information with who like to experiment.

And thanks to all for the interest in this topic - it's great to have folks to share information with who like to experiment.

#27

FMC400 - you've definitely spent some time looking at flow meters and this one in particular. I was curious how well it worked at low speeds which you've touched on. It wasn't clear from your post, but it sounds like your measuring the pulses with something other than the readout I have?

Keep up the great work!

#28

I'm interested to see what sort of signal it produces on the oscilloscope. I've been thinking more about how to capture data electronically rather than trying to write points down on paper. The AFR has a 0 - 5V analog output and capturing a tach signal would be straightforward (I think). I'd head down this road if I could find an obvious path forward to capture the timing advance and the speed. Optical or magnetic transducers seem the place to start, but I need to do some more research and see if anyone out there in cyberspace has tackled these.

Work was all-consuming last week so I only got a few miles on the truck. Hopefully this weekend! I'm eager to change the jets, but I want to be methodical and get some data making one change at a time.

Work was all-consuming last week so I only got a few miles on the truck. Hopefully this weekend! I'm eager to change the jets, but I want to be methodical and get some data making one change at a time.

#29

Well I finally got a chance to put some miles on the truck this week. With the change I made below to the timing (30 degrees initial to 20 degrees initial both using manifold vacuum), the MPG dropped from 9 to 8.3. In doing some analysis of the data I have, I think a reasonable error bar is +-0.5 so this change is real. I also rechecked the AFR curve with a slow ramp and it's essentially the same as I posted below.

So now I have to think about why the MPG would drop with a change that I assumed would be better as it's closer to suggested initial timing. In hindsight, now I wish I had some sense of the change in engine power - maybe there's a way to use timed runs up one of the hills around here or pulling a loaded trailer.

At this point, I'm going to drop 2 jet sizes and start seeing what effect that has.

So now I have to think about why the MPG would drop with a change that I assumed would be better as it's closer to suggested initial timing. In hindsight, now I wish I had some sense of the change in engine power - maybe there's a way to use timed runs up one of the hills around here or pulling a loaded trailer.

At this point, I'm going to drop 2 jet sizes and start seeing what effect that has.

#30

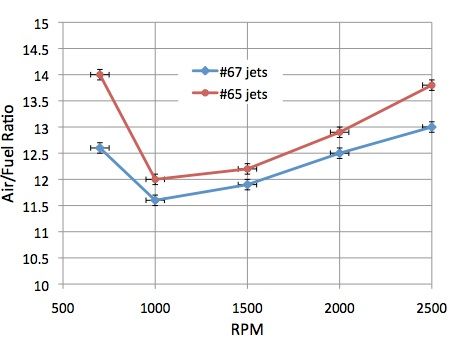

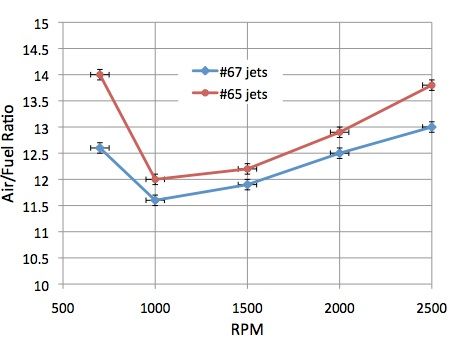

Yesterday I swapped the jets from #67 to #65 and did an AFR scan as shown in the plot. Now I can drop the idle RPM to 700 (before it was closer to 750) and get the idle AFR up to 14.0 with no discernible change in idle (before the idle was not smooth at this AFR). Going from 12.6 to 14.0 took just 1/8 turn on the screws. Given how little this changed the AFR, I'm temped to swap in some #63 jets I have. More importantly the question I have is how to 'flatten' the AFR curve - anybody have a suggestion for this?