Any riggers here (as in blocks, cable, cranes, winches)?

#1

Any riggers here (as in blocks, cable, cranes, winches)?

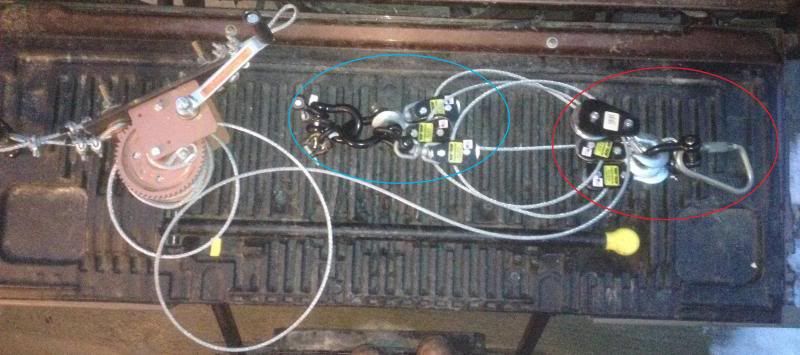

Just curious about something... I have 6 blocks that I am working on rigging up in the same line. One is direction changing and the other 5 are running the load - 2 fixed/3 moving.

I have 2 options with connecting all the blocks - use them all as separate blocks through a big shackle in sets of 3 fixed on top and 3 moving on the bottom. Or I can take all the blocks apart, get longer bolts, and put the 5 blocks together as two units with 2 sheaves on one and 3 sheaves on the other (6th block isn't the same as the other 5) - sort of like this:

http://www.byrnerentals.com/Crane-Blk-1843SHA.gif

I am well within the capacity of the blocks, even a single one, the goal is to make moving the load a lot easier, not more load. I tried with a 2:1 ratio without any luck, went to a 4:1 and I got the set up to work, but it was way hard. So now I'm up to a 6:1.

If I stack the blocks that would hold them, and the cable, together a lot better (not spaghetti as much) when not in use, but I am thinking that being locked together may bind up the cable - the the first sheave closest to the winch would pull towards the winch and leave the last sheave would be further out = angled pull, not straight with the load. Thoughts?

I have 2 options with connecting all the blocks - use them all as separate blocks through a big shackle in sets of 3 fixed on top and 3 moving on the bottom. Or I can take all the blocks apart, get longer bolts, and put the 5 blocks together as two units with 2 sheaves on one and 3 sheaves on the other (6th block isn't the same as the other 5) - sort of like this:

http://www.byrnerentals.com/Crane-Blk-1843SHA.gif

I am well within the capacity of the blocks, even a single one, the goal is to make moving the load a lot easier, not more load. I tried with a 2:1 ratio without any luck, went to a 4:1 and I got the set up to work, but it was way hard. So now I'm up to a 6:1.

If I stack the blocks that would hold them, and the cable, together a lot better (not spaghetti as much) when not in use, but I am thinking that being locked together may bind up the cable - the the first sheave closest to the winch would pull towards the winch and leave the last sheave would be further out = angled pull, not straight with the load. Thoughts?

#2

How much weight are you trying to move? It's amazing what I've dragged with a double blocked 1.5 ton chain block or 2 of them double blocked. The last big pull I was part of we had 5 blocks attached right to the piece of equip we were pulling each were double blocked into the wall across from the equip. Starts to become a rats nest...

How far do you have to pull?

How far do you have to pull?

#3

#4

#6

#7

Something like this link shows, the ones Ive seen have a bigger spacing between holes, so it holds your blocks further apart, which helps with tangling.

Stainless Steel NFPA Rigging Plate

Stainless Steel NFPA Rigging Plate

Trending Topics

#8

Thanks for the idea. I know what you're talking about, and I thought about something similar. However, that isn't getting me around the "loose blocks" syndrome. They would all still be able to swing freely. It may be a wasted effort anyway because the loose cable is going to flop around on its own regardless, its just the blocks seemed to make the tangling worse.

When it is all set up in use and tension is on the line it is fine - no tangling issues there, although I could relocate the fixed end as one of the cable clamps always seems to ride on the block next to it and the cable passing through. When its not set up is when it gets tangled.

When it is all set up in use and tension is on the line it is fine - no tangling issues there, although I could relocate the fixed end as one of the cable clamps always seems to ride on the block next to it and the cable passing through. When its not set up is when it gets tangled.

#9

All my rigging experience is from working underground, if we need to mount something we just drill a hole and install a rated eye bolt/mounting beam/lifting lug, lol, pretty easy we can space them out, etc.

Only other thing I could think of is maybe beefing up to a ratchet chain block or something so you could get away with using one block or none...?

Only other thing I could think of is maybe beefing up to a ratchet chain block or something so you could get away with using one block or none...?

#10

At some point I am going to get an electric winch. That would make things a ton easier. Until then I am making do. I think the extra 2 blocks I added today will do the trick to ease up the effort, it just turns in to a mess quick. I used to store that winch with one block. I could crank the cable all the way in like how you lock up a power winch for storage, but I think if I do that now all the windings through the stacked blocks will set a permanent bend in the cable and kink it.

The original power source was a come-along, but it fell apart after 2 uses. The crank winch holds up better. It is a ton easier to lower the load also. It just doesnt have the "power" the come-along did with the lever. With a 4:1 reduction I could raise the load ok. Lowering was another issue as the pawl had to be reset with each drop of the cable to control it. With the crank winch I crank backwards to lower, no pawl to release.

Ive never used a chain hoist. That may be another route. A power winch would be a lot easier than the rest of the options, though.

The original power source was a come-along, but it fell apart after 2 uses. The crank winch holds up better. It is a ton easier to lower the load also. It just doesnt have the "power" the come-along did with the lever. With a 4:1 reduction I could raise the load ok. Lowering was another issue as the pawl had to be reset with each drop of the cable to control it. With the crank winch I crank backwards to lower, no pawl to release.

Ive never used a chain hoist. That may be another route. A power winch would be a lot easier than the rest of the options, though.

#11

I have 2 options with connecting all the blocks - use them all as separate blocks through a big shackle in sets of 3 fixed on top and 3 moving on the bottom. Or I can take all the blocks apart, get longer bolts, and put the 5 blocks together as two units with 2 sheaves on one and 3 sheaves on the other (6th block isn't the same as the other 5)

So now I'm up to a 6:1.

Thoughts?

So now I'm up to a 6:1.

Thoughts?

5:1 or 6:1 is right at the peak, before diminishing return. Loss of mechanical advantage.

These are my set-ups away from work:

On my block & tackle: rope and sheaves are good for 400, hooks are good for 2000 lbs., snaps are good for 750, 1/4" shackle is good for 1000 lbs., and 1/4" quick link is 880 lbs. But, my whole set-up is only good for 400 lbs.

My chain hoist (that I found at a flea market for $40 bucks): is good for 1 ton.

Hope this helped you out with a little info,

Thread

Thread Starter

Forum

Replies

Last Post

Jimmy Dean

General NON-Automotive Conversation

16

01-13-2009 07:56 PM