TLDR; need somebody to check my numbers

#1

TLDR; need somebody to check my numbers

Math time! with a 97 351 W

ok so im going to run pacesetter 70-2223's (with a 1 5/8 inch primary and a 3in collector) on my 97 f250 351W

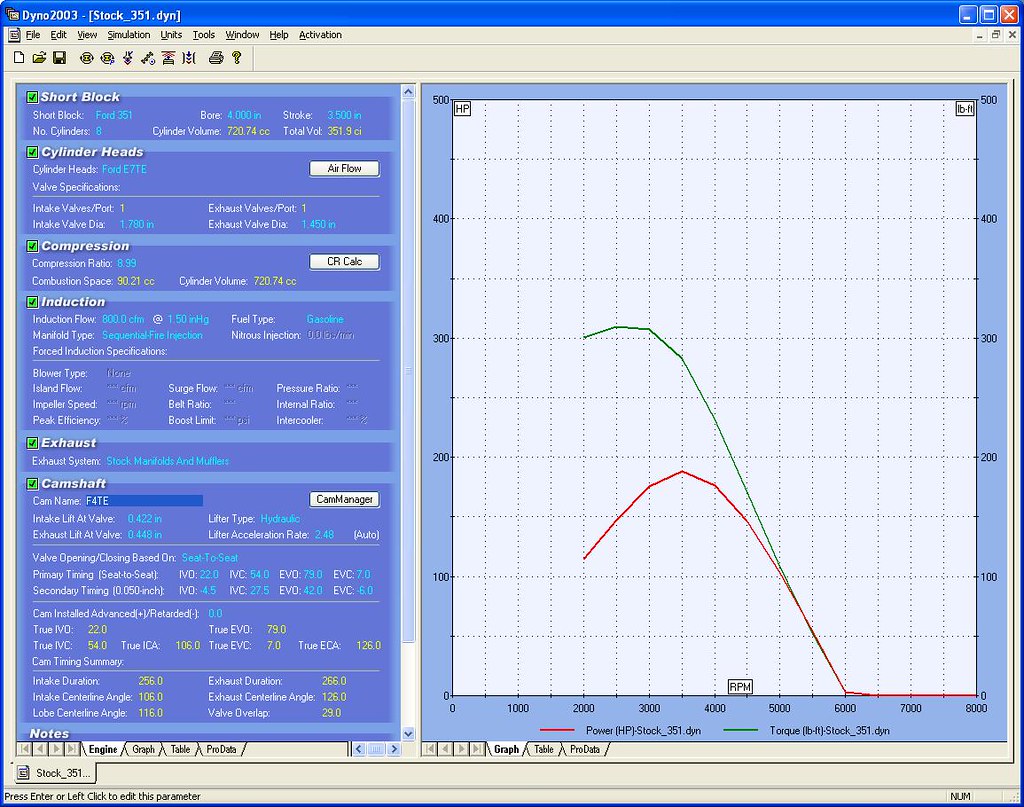

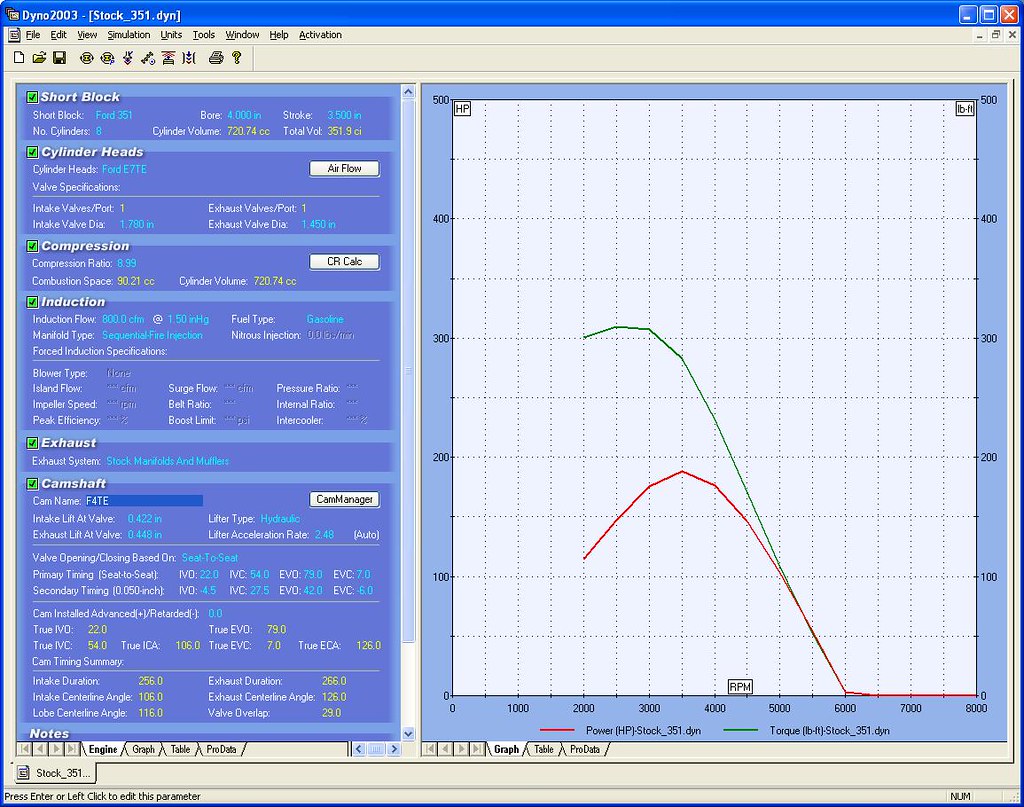

now this truck according to a dyno graph i found (credit to conanski)

here is the original thread for this image https://www.ford-trucks.com/forums/9...y-89-351w.html

shows that this trucks peak torque is at about 2800-3200 rpm im throwing in a wider band due to the differnece in age and cam between my motor and the one thats run on the sim (actually i have no idea what cam is in mine im just assuming its different) now if use the equation

peak torque rpm = primary pipe area (ppa) * 88200 / 1 cyl displacment

what we get is here is

1 5/8 * 88200 / (351/8) = rpm of max torque

which comes out to an rpm of 3267 since this doesn't quite match up with our peak torque rpm on the dyno we can assume that this header should widen out the power band a little as well as provide some gains on top of the peak torque rpm

no we need to focus on getting the fastest exhaust flow which is where i start to stumble ..i have no idea how hot the exhaust gases are coming down the pipes but If anybody can tell me the temps i can more acurately determing what size pipes i need coming down from the headers.. now i used the equation

engine size * rpm / 3456 = theroetical intake volume for a given rpm im going to use 3200 since thats the where i want to increase my power band around

****(correct me if this sounds wrong im doing this on a wing and a prayer here)*****

now i took my theoritical intake and mulitplied by a volumetirc efficency of about .72-.75 cause my motor is old and i have no idea how to calculate it actually with out somethings that i don't have

my cfm per minute was 234-264 depending on what i multiplied by

now i refrenced the chart on this page to determine what pipe size i needed for exhaust

How To Calculate Muffler Size and Exhaust Pipe Diameter | Exhaust Videos

and i came to the conclusion that for duals i should run betwen a 2 - 2.25 and for singles i should run 2.75 both of these setups where im trying to allow the most horsepower pushing down the pipe with the most amount of air flow

cause to be fair this motor probably won't be pushing 300 horses in its life with out some major head work..

ok so im going to run pacesetter 70-2223's (with a 1 5/8 inch primary and a 3in collector) on my 97 f250 351W

now this truck according to a dyno graph i found (credit to conanski)

here is the original thread for this image https://www.ford-trucks.com/forums/9...y-89-351w.html

shows that this trucks peak torque is at about 2800-3200 rpm im throwing in a wider band due to the differnece in age and cam between my motor and the one thats run on the sim (actually i have no idea what cam is in mine im just assuming its different) now if use the equation

peak torque rpm = primary pipe area (ppa) * 88200 / 1 cyl displacment

what we get is here is

1 5/8 * 88200 / (351/8) = rpm of max torque

which comes out to an rpm of 3267 since this doesn't quite match up with our peak torque rpm on the dyno we can assume that this header should widen out the power band a little as well as provide some gains on top of the peak torque rpm

no we need to focus on getting the fastest exhaust flow which is where i start to stumble ..i have no idea how hot the exhaust gases are coming down the pipes but If anybody can tell me the temps i can more acurately determing what size pipes i need coming down from the headers.. now i used the equation

engine size * rpm / 3456 = theroetical intake volume for a given rpm im going to use 3200 since thats the where i want to increase my power band around

****(correct me if this sounds wrong im doing this on a wing and a prayer here)*****

now i took my theoritical intake and mulitplied by a volumetirc efficency of about .72-.75 cause my motor is old and i have no idea how to calculate it actually with out somethings that i don't have

my cfm per minute was 234-264 depending on what i multiplied by

now i refrenced the chart on this page to determine what pipe size i needed for exhaust

How To Calculate Muffler Size and Exhaust Pipe Diameter | Exhaust Videos

and i came to the conclusion that for duals i should run betwen a 2 - 2.25 and for singles i should run 2.75 both of these setups where im trying to allow the most horsepower pushing down the pipe with the most amount of air flow

cause to be fair this motor probably won't be pushing 300 horses in its life with out some major head work..

#3

to many..

but im just got everything i wanted said done so i don't think ill be starting a new thread for a week or two most of the topics im running over while mining the past has alread been addressed by conanski and im finding him every-time i google certain things and come up with a fte thread

but im just got everything i wanted said done so i don't think ill be starting a new thread for a week or two most of the topics im running over while mining the past has alread been addressed by conanski and im finding him every-time i google certain things and come up with a fte thread

Thread

Thread Starter

Forum

Replies

Last Post

Tony G

Big Block V8 - 385 Series (6.1/370, 7.0/429, 7.5/460)

6

09-17-2003 08:04 AM

DeenHylton

Ford Inline Six, 200, 250, 4.9L / 300

10

05-02-2001 10:29 AM