UPDATED Fuel Injector Top O-Rings/Seals ~ The Whole Story

#1

UPDATED Fuel Injector Top O-Rings/Seals ~ The Whole Story

UPDATE 6/21/15:

There Have Been a Huge Number of Sellers Pop up on ebay Selling Low Quality O-Rings and Cheap, Soft Steel Tools Which Fail During Install, or Within 10K Miles. Go with a good brand tool like HHC Diesel or Alliant Power or This could happen to you:

GOOD TOOL:

BAD TOOL:

Also, the Bostech/Cardone Nipple Cups are made of soft steel, are slightly small and wear prematurely. So I recommend re-using your OEM nipple cups or waiting for HHC Diesel's BulletProof Nipple Cups to Come out.

This is a Write-Up on the Top Fuel Injector Seals & The Nipple Cup O-Rings in the High Pressure Oil Rail

If you find a leak at one of your top injector seals you probably have a leaky nipple cup also... Don't learn the hard way like I did

~How to Diagnose and Replace~

Fact 1:

The top injector O-Rings can be easily replaced. You do not have to replace the whole injector as Ford would do.

Fact 2:

There are O-Rings behind the the Ball Tubes/Nipple Cups in the High Pressure Oil Rail. They are serviceable and easily replaced with the proper tool. YOU DO NOT HAVE TO REPLACE THE ENTIRE OIL RAIL AS FORD WOULD FOR $500 a PIECE!

Fact 3:

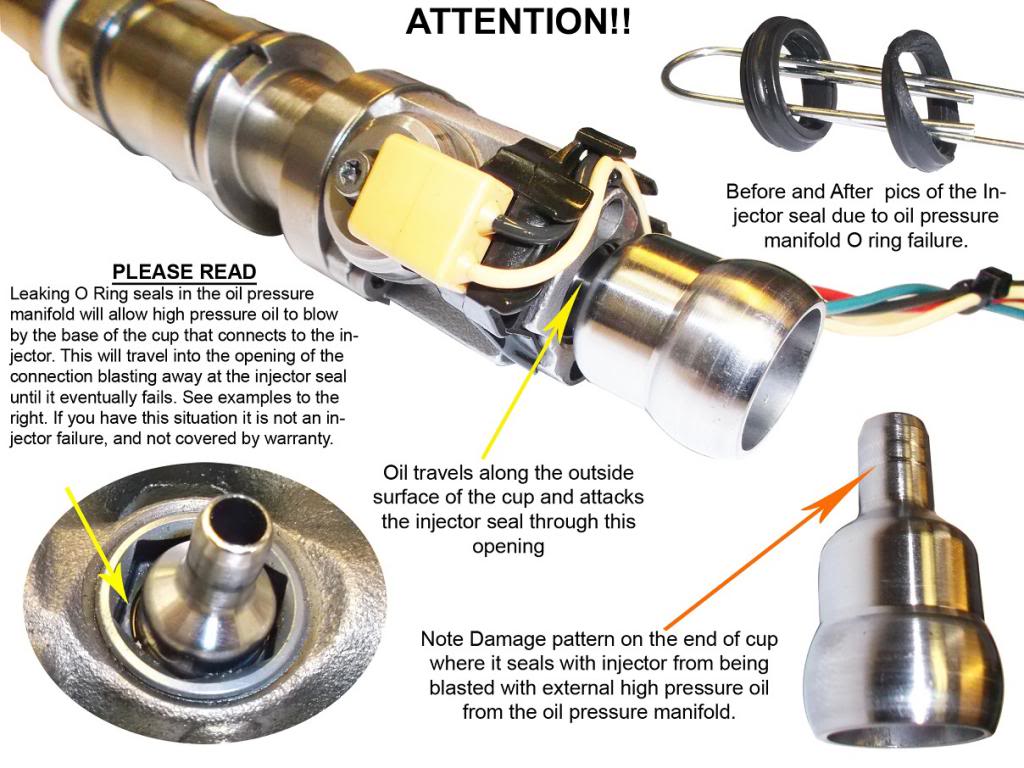

A Leak that shows up in your top injector O-Ring is probably actually originating above at the nipple cup seal. The high pressure oil actually follows the body of the nipple cup and attacks the top of the top injector O-Ring. This can be easily diagnosed by inspecting your old top injector O-Ring, if the top looks eroded, but the bottom looks fine, you have a leak at the nipple cup.

Diagnosis and Repair

Parts Required:

Step 1:

Determine that you actually have a high pressure oil leak. This has been covered quite a bit, but I do have a video on this below.

It should be noted that many people are driving around with small HPO leaks that don't keep them from starting or running. The only way to really find all of the leaks in your HPO system is to test with a higher pressure source such as a Nitrogen bottle instead of shop air. Your HPO system runs at 3500+ PSI under WOT, so 100PSI is nothing and will only show you major leaks. A Nitrogen bottle will get you to around 1000 PSI. Lucky for us shop air will find the leaks big enough to keep up from starting and running. Leaks at the nipple cup seal actually can't be heard with shop air, Believe me I went though this 3 separate times for failed Top injector seals and never heard a leak once I replaced the Top seals, only to have the same seals fail weeks later. This is why I'm writing this post, so that others can easily diagnose a bad nipple cup seal.

This is an old video I did, but It's pretty accurate.

Step 2:

Determine that your leak is at one of your top injectors. You will feel/hear air coming out around the top of the injector under the oil rail. I made a video of one of my leaks, but an air leak is hard to catch on video

Step 3:

Replace your top injector O-Ring or Seal. The best way to explain this is in a video. Once you get the hang of it, it is actually quite easy. I have done it with the injector still in the engine, but I DON'T RECOMMEND THIS It is much more difficult, frustrating and time consuming trying to get the retaining clip out lying on top of the engine. I think the rear injectors would be near impossible. You already have the o-ring kit, just pull the injector out.

Step 4:

Examine your O-ring. If it looks like it is eroded from the top(nipple cup side) Down, you need to replace your nipple cup seal also. The bottom will have a nice smooth, flat, undamaged surface where as the top looks sand blasted. You may even find little bits of rubber o-ring all around the retaining clip and metal beveled keeper ring.

Step 5:

Replace one or all of your Nipple Cup Seals. If one is bad, the others may be failing also. Give your nipples a wiggle, if they feel loose at all, replace them. You don't want to get stuck somewhere you can't fix it. You should feel a snugness and resistance as you wiggle the nipples. The ball of the cup seals against and o-ring, so if it doesn't feel like it's contacting rubber you probably have at least a small leak.MAKE SURE YOU USE A LOT OF OIL ON ALL OF THE PARTS WHEN YOU REASSEMBLE! Sometimes the rings don't fully seat until the oil rails have been pressurized for the first time.

The Best Way to Explain the Process is With a Video:

The Tool Used to Remove the Nipple Cup and Replace the Seal:

DO NOT BUY A CHEAP TOOL AND O-RINGS OFF EBAY. THEY WILL FAIL LIKE THIS:

Bostech and Cardone Do Sell Replacement Nipple Cups, but They Are Soft Steel and Many are .0005" Smaller on the Ball End and Many are Reporting Leaks and Failures. HHC Diesel Will Have Their BulletProof Cups out This Summer

Step 6:

Put it all back together. If you have never had your oil rails off before there are a couple things to note;

1: It takes quite a bit of cranking to purge the air out of the HPO system once re-assembled. I like to unplug the FICM relay and use the Ignition pigtail to the positive battery terminal if I didn't pull any injectors.

2: If you had one or more injectors out, you need to re-prime the fuel system and purge any air BEFORE the FICM tries to fire the injectors. In this case I use the key to prime both the HPO and Fuel System. I unplug the Glow plug relay connectors then just cycle the key on and off cranking for about 20 seconds a time. Cycling the key ON/OFF is the important part here! This Turns the Fuel Pump On and Off to purge the air By the time the Oil Rail has purged enough air out to develop the 600PSI needed to tell the FICM to fire the injectors, you will have turned the fuel pump on and off at least 5 times and enough to purge the air out of the fuel lines.

Sometimes the nipple cup seals do not fully seat until the oil rails have been primed and fully pressurized for the first time. Don't freak out if you air test the system right after install and still hear a leak. run the truck for a bit and the leaks will most likely go away. If not, your nipple cups are bad or you didn't so something right... Like using excessive oil on every part when installing the new seals.

Step 7:

If you just replaced all of your nipple cups & O-rings and All of your injector O-rings, have yourself a beer and rest assured that your HPO system is solid and won't develop leaks for a long time....

My Story (Why I had to do this):

I had a high pressure oil leak at one of my top injector O-Rings so I replaced it. When I replaced my head gaskets a few weeks later I decided to go ahead and replace the rest of them while I had all of the injectors out. I drive long hard miles for my work generally towing something, Within 10,000 miles the same O-ring that had failed before failed again (catastrophically; the beveled keeper ring had shattered into a few pieces and the O-Ring was in 2 pieces that I could find). I replaced it thinking it was a fluke or something. Then within 2 weeks of heavy driving I had 2 more develop leaks bad enough that I had a Hot no start situation. (Luckily I had shut it off in a Walmart parking lot and was able to go in and buy their mid sized air compressor and the biggest inverter they had to air test my HPO system right there in the parking lot). I had developed leaks at 2 more injectors on that same rail side. I fixed them right there in the parking lot(1500mi from home). I was pissed, naturally, and sent a long email to the company I ordered the O-rings from thinking they were inferior. They forwarded my email straight to Bostech and within 24hrs the general manager replied via email. His name is Brian and he is actually a very nice, very knowledgeable on the 6.0L engine. He sent me all kinds of information and pictures(some of which I have included above) and we even ended up talking on the phone for almost an hour about the nipple cup seals, and all of the other known problems on the 6.0L. I didn't even know there were O-Rings in the oil rail and based on the limited information I see on it in the forums not too many people do either, hence this write-up.

Here is what a catastrophically failed O-Ring looks like. The O-ring was in at least 2 pieces, the keeper ring was shattered into at least 2 pieces and the C-clip was all bent and deformed:

There Have Been a Huge Number of Sellers Pop up on ebay Selling Low Quality O-Rings and Cheap, Soft Steel Tools Which Fail During Install, or Within 10K Miles. Go with a good brand tool like HHC Diesel or Alliant Power or This could happen to you:

GOOD TOOL:

BAD TOOL:

Also, the Bostech/Cardone Nipple Cups are made of soft steel, are slightly small and wear prematurely. So I recommend re-using your OEM nipple cups or waiting for HHC Diesel's BulletProof Nipple Cups to Come out.

If you find a leak at one of your top injector seals you probably have a leaky nipple cup also... Don't learn the hard way like I did

~How to Diagnose and Replace~

Fact 1:

The top injector O-Rings can be easily replaced. You do not have to replace the whole injector as Ford would do.

Fact 2:

There are O-Rings behind the the Ball Tubes/Nipple Cups in the High Pressure Oil Rail. They are serviceable and easily replaced with the proper tool. YOU DO NOT HAVE TO REPLACE THE ENTIRE OIL RAIL AS FORD WOULD FOR $500 a PIECE!

Fact 3:

A Leak that shows up in your top injector O-Ring is probably actually originating above at the nipple cup seal. The high pressure oil actually follows the body of the nipple cup and attacks the top of the top injector O-Ring. This can be easily diagnosed by inspecting your old top injector O-Ring, if the top looks eroded, but the bottom looks fine, you have a leak at the nipple cup.

Diagnosis and Repair

Parts Required:

- Injector O-Ring kits that include the top injector seal and a new retaining "C-Clip"

There are 2 major manufacturers that produce these;- ~Bostech Industries - Part# ISK102

- ~Alliant Power - Part#Ap0002

- Nipple Cup / Ball Tube Removal Tool: Don't Buy the Cheap Ebay Ones!!! They Break and Strip

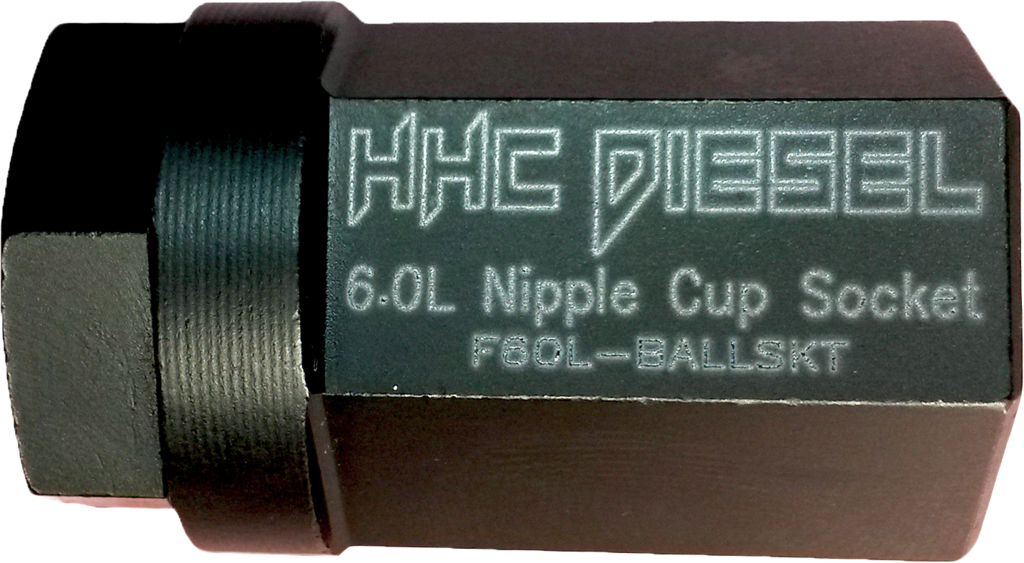

- HHC Diesel - Part# F60L-BALLSKT (lifetime Warranty w/ 1/2" Square Drive)

- Alliant Power:

- Bostech - Part # ISK607 XDP Sponsor Link

- HHC Diesel - Part# F60L-BALLSKT (lifetime Warranty w/ 1/2" Square Drive)

- Replacement Nipple Cup O-Rings: Many of these are now on the market, but not all are created equal. The cheap tools and O-Rings on ebay have left many people stranded and needing to re-do the job less than 10,000 miles later. YOU NEED A HEAVY DUTY O-RING!! Only 2 Companies I would recommend right now:

~HHC Diesel - F60L-BALLSEAL ~Alliant Power - - New Nipple Cups. ONLY IF YOURS ARE WORN BEYOND REPAIR. Many People have had Bostech/Cardone Nipple Cups Fail Due to a Diameter Which is Slightly Smaller Than OEM and They are Soft Steel. I Recommend Re-Using Your OEM CUPS or Waiting for HHC Diesel's Bulletproof Nipple Cups. A little Grooving on the Nipple Tip is Normal and Not an Issue. It is Wear on the Top of the Ball (the part closest to the nipple end) that you have to watch out for. Even half a thousandth (.0005") is enough to cause premature nipple cup seal failure.

Step 1:

Determine that you actually have a high pressure oil leak. This has been covered quite a bit, but I do have a video on this below.

It should be noted that many people are driving around with small HPO leaks that don't keep them from starting or running. The only way to really find all of the leaks in your HPO system is to test with a higher pressure source such as a Nitrogen bottle instead of shop air. Your HPO system runs at 3500+ PSI under WOT, so 100PSI is nothing and will only show you major leaks. A Nitrogen bottle will get you to around 1000 PSI. Lucky for us shop air will find the leaks big enough to keep up from starting and running. Leaks at the nipple cup seal actually can't be heard with shop air, Believe me I went though this 3 separate times for failed Top injector seals and never heard a leak once I replaced the Top seals, only to have the same seals fail weeks later. This is why I'm writing this post, so that others can easily diagnose a bad nipple cup seal.

This is an old video I did, but It's pretty accurate.

Step 2:

Determine that your leak is at one of your top injectors. You will feel/hear air coming out around the top of the injector under the oil rail. I made a video of one of my leaks, but an air leak is hard to catch on video

Step 3:

Replace your top injector O-Ring or Seal. The best way to explain this is in a video. Once you get the hang of it, it is actually quite easy. I have done it with the injector still in the engine, but I DON'T RECOMMEND THIS It is much more difficult, frustrating and time consuming trying to get the retaining clip out lying on top of the engine. I think the rear injectors would be near impossible. You already have the o-ring kit, just pull the injector out.

Step 4:

Examine your O-ring. If it looks like it is eroded from the top(nipple cup side) Down, you need to replace your nipple cup seal also. The bottom will have a nice smooth, flat, undamaged surface where as the top looks sand blasted. You may even find little bits of rubber o-ring all around the retaining clip and metal beveled keeper ring.

Step 5:

Replace one or all of your Nipple Cup Seals. If one is bad, the others may be failing also. Give your nipples a wiggle, if they feel loose at all, replace them. You don't want to get stuck somewhere you can't fix it. You should feel a snugness and resistance as you wiggle the nipples. The ball of the cup seals against and o-ring, so if it doesn't feel like it's contacting rubber you probably have at least a small leak.MAKE SURE YOU USE A LOT OF OIL ON ALL OF THE PARTS WHEN YOU REASSEMBLE! Sometimes the rings don't fully seat until the oil rails have been pressurized for the first time.

The Best Way to Explain the Process is With a Video:

The Tool Used to Remove the Nipple Cup and Replace the Seal:

DO NOT BUY A CHEAP TOOL AND O-RINGS OFF EBAY. THEY WILL FAIL LIKE THIS:

Bostech and Cardone Do Sell Replacement Nipple Cups, but They Are Soft Steel and Many are .0005" Smaller on the Ball End and Many are Reporting Leaks and Failures. HHC Diesel Will Have Their BulletProof Cups out This Summer

Step 6:

Put it all back together. If you have never had your oil rails off before there are a couple things to note;

1: It takes quite a bit of cranking to purge the air out of the HPO system once re-assembled. I like to unplug the FICM relay and use the Ignition pigtail to the positive battery terminal if I didn't pull any injectors.

Sometimes the nipple cup seals do not fully seat until the oil rails have been primed and fully pressurized for the first time. Don't freak out if you air test the system right after install and still hear a leak. run the truck for a bit and the leaks will most likely go away. If not, your nipple cups are bad or you didn't so something right... Like using excessive oil on every part when installing the new seals.

Step 7:

If you just replaced all of your nipple cups & O-rings and All of your injector O-rings, have yourself a beer and rest assured that your HPO system is solid and won't develop leaks for a long time....

My Story (Why I had to do this):

I had a high pressure oil leak at one of my top injector O-Rings so I replaced it. When I replaced my head gaskets a few weeks later I decided to go ahead and replace the rest of them while I had all of the injectors out. I drive long hard miles for my work generally towing something, Within 10,000 miles the same O-ring that had failed before failed again (catastrophically; the beveled keeper ring had shattered into a few pieces and the O-Ring was in 2 pieces that I could find). I replaced it thinking it was a fluke or something. Then within 2 weeks of heavy driving I had 2 more develop leaks bad enough that I had a Hot no start situation. (Luckily I had shut it off in a Walmart parking lot and was able to go in and buy their mid sized air compressor and the biggest inverter they had to air test my HPO system right there in the parking lot). I had developed leaks at 2 more injectors on that same rail side. I fixed them right there in the parking lot(1500mi from home). I was pissed, naturally, and sent a long email to the company I ordered the O-rings from thinking they were inferior. They forwarded my email straight to Bostech and within 24hrs the general manager replied via email. His name is Brian and he is actually a very nice, very knowledgeable on the 6.0L engine. He sent me all kinds of information and pictures(some of which I have included above) and we even ended up talking on the phone for almost an hour about the nipple cup seals, and all of the other known problems on the 6.0L. I didn't even know there were O-Rings in the oil rail and based on the limited information I see on it in the forums not too many people do either, hence this write-up.

Here is what a catastrophically failed O-Ring looks like. The O-ring was in at least 2 pieces, the keeper ring was shattered into at least 2 pieces and the C-clip was all bent and deformed:

Last edited by Maxium4x4; 06-21-2015 at 12:39 PM. Reason: Updates: Request by original author. (Max)

#2

#3

Great writeup Reps given

We need this one in the Tech Folder I havent seen anything like it in there

That Took alot of work to do this writeup Alone I know its very time consuming to get that anmount of info on here

The Only thing I would add and maybe I missed it But you can run with valve covers offf to check for leaks too However its alot of work to hook all stuff back up to get to a runable condition and Tie stuff like the Ficm and GPCM Back out the way

But Great Job!!!

We need this one in the Tech Folder I havent seen anything like it in there

That Took alot of work to do this writeup Alone I know its very time consuming to get that anmount of info on here

The Only thing I would add and maybe I missed it But you can run with valve covers offf to check for leaks too However its alot of work to hook all stuff back up to get to a runable condition and Tie stuff like the Ficm and GPCM Back out the way

But Great Job!!!

#4

#5

Great writeup Reps given

We need this one in the Tech Folder I havent seen anything like it in there

That Took alot of work to do this writeup Alone I know its very time consuming to get that anmount of info on here

The Only thing I would add and maybe I missed it But you can run with valve covers offf to check for leaks too However its alot of work to hook all stuff back up to get to a runable condition and Tie stuff like the Ficm and GPCM Back out the way

But Great Job!!!

We need this one in the Tech Folder I havent seen anything like it in there

That Took alot of work to do this writeup Alone I know its very time consuming to get that anmount of info on here

The Only thing I would add and maybe I missed it But you can run with valve covers offf to check for leaks too However its alot of work to hook all stuff back up to get to a runable condition and Tie stuff like the Ficm and GPCM Back out the way

But Great Job!!!

I actually have a newer video I did with the valve covers off, but it was done after the leaks were fixed so there is no dramatic leak effect. If there is enough interest I'll add it in there.

#6

For pressure source please stick with Nitrogen or Argon gas not Oxygen.

Oxygen does not do well at any pressure with oil.

Oil and grease are particularly hazardous in the presence of oxygen

as they can ignite spontaneously and burn with explosive violence.

They should never be used to lubricate oxygen or enriched-air equipment.

Special lubricants which are compatible with oxygen must be used under

certain conditions.

Other that that I think this is a very good write-up. I just don't want to have to send Emails

to the moon is things go bad.

Sean

Oxygen does not do well at any pressure with oil.

Oil and grease are particularly hazardous in the presence of oxygen

as they can ignite spontaneously and burn with explosive violence.

They should never be used to lubricate oxygen or enriched-air equipment.

Special lubricants which are compatible with oxygen must be used under

certain conditions.

Other that that I think this is a very good write-up. I just don't want to have to send Emails

to the moon is things go bad.

Sean

#7

For pressure source please stick with Nitrogen or Argon gas not Oxygen.

Oxygen does not do well at any pressure with oil.

Oil and grease are particularly hazardous in the presence of oxygen

as they can ignite spontaneously and burn with explosive violence.

They should never be used to lubricate oxygen or enriched-air equipment.

Special lubricants which are compatible with oxygen must be used under

certain conditions.

Other that that I think this is a very good write-up. I just don't want to have to send Emails

to the moon is things go bad.

Sean

Oxygen does not do well at any pressure with oil.

Oil and grease are particularly hazardous in the presence of oxygen

as they can ignite spontaneously and burn with explosive violence.

They should never be used to lubricate oxygen or enriched-air equipment.

Special lubricants which are compatible with oxygen must be used under

certain conditions.

Other that that I think this is a very good write-up. I just don't want to have to send Emails

to the moon is things go bad.

Sean

I edited the first post to exclude testing the HPO system with O2.

That's the great thing about forums. More minds are better than 1 (or none o_O)

Trending Topics

#8

I have hears to some very scary storied about O2 and oils. I think one

of the worst is a LOX leak and having a vehicle tire run over it on

pavement that has some grease. If you lucky you get a POP if not you may

see flying tire. Or so the story goes. I just know what they teach in the section

on handling compressed gasses. Also with a high pressure tank you can have a

regulator fail and get more than you bargained for. I know of one dead and one badly

injured flight-line mechanics that found that out on a nose gear. 9,000 PSI from

the bottle blew the tire into little parts and shredded the wheel.

The lesson is always check the regulators and start at low pressure. ALWAYS!

Sean

of the worst is a LOX leak and having a vehicle tire run over it on

pavement that has some grease. If you lucky you get a POP if not you may

see flying tire. Or so the story goes. I just know what they teach in the section

on handling compressed gasses. Also with a high pressure tank you can have a

regulator fail and get more than you bargained for. I know of one dead and one badly

injured flight-line mechanics that found that out on a nose gear. 9,000 PSI from

the bottle blew the tire into little parts and shredded the wheel.

The lesson is always check the regulators and start at low pressure. ALWAYS!

Sean

#10