A4LD/3L Frankentranny

#1

A4LD/3L Frankentranny

If you've ever spent much time researching the A4LD, then you've run across the Rebuild Diary and the Frankentranny threads over at ExplorerForum. The "Frankentranny" name was created by Brain as he leveraged off the earlier work by Glacier991. This thread fills in a little around those ground breaking works. Whereas those projects were based on the A4LD/4L as found in Explorers, here we target the 3 liter (3L) application as can be found on particular 2WD Aerostars.

Mine is not the original 1989 tranny but a remanufactured unit already upgraded with a few Torrington bearings in place of the original thrust washers. That swap occurred a dozen years, and 100K miles ago. The shop said of the original that there were fragments of thrust washer in the pan. Most probably this was the rear wave washer.

My current situation was that in the summer of 2012, returning from a drive-about, the 12yr/100K tranny would let loose when dropping down from overdrive, say under moderate throttle to begin a pass. Pondering the future of the van to possibly include a 4L engine swap, I had to consider whether to do a cheap overhaul, or rebuild to 4L specs. It was initially planned to do the overhaul but, in the background, procure or build a A4LD/4L. Long-short after getting into the tear-down for the cheap overhaul, and seeing the failure mode, it put me over the line and I merged the overhaul with the upgrade to 4L specs. Just for clarity, in the current time frame the bellhousing and engine still remain 3L Vulcan. If I swap in a 4L, I then merely change the bellhousing.

For those just tuning in, the Aerostar shipped with the A4LD tranny till about '94-95, then had a year or so with the 4RxxE series, then got the five speed 5RxxE series in the last year of production. The A4LD is visually distinct from the 4R/5R in that the A4LD has a vacuum modulator bolted to the side. In the A4LD its the mechanical governor and modulator that influence shift points, although overdrive is controlled electronically. In the earlier A4LD, one needs to specify whether it is 3L or 4L. For visual recognition, it's the bellhousing that mates to either the 3L Vulcan or the 4L Cologne.

The nemesis of the earlier A4LD was the use of brass/copper thrust washers, whereas the later versions and especially the 4R/5R used radial needle bearings (aka Torringtons). In several places, the 5R also introduced more axial needle bearings instead of sleeve bushings.

In the later 4R/5R nomenclature, the torque rating is swept up into the '44' number for 440 lb-ft, and '55' for 550 lb-ft (750 Nm). These are tend to be assigned to 3L and 4L engine applications. Not coincidentally, the 4R is a 4-speed, and the 5R is a 5-speed. The 'E' suffix basically means that Electronics determine the rotation speed of the components and resulting responses.

The difference between A4LD 3L torque and 4L torque capability shows up in the disk packs and the number of pinions in the planetary gear sets. For instance, early A4LD 3L apps implemented the reverse planet with 3 pinions in an aluminum cage. In the same location, the 4L apps got 6 pinions in a steel cage.

A 4L tranny case is likely to be stamped "750 NM", possibly on the outside, possibly inside at the rear. The aluminum shell is the same between the ratings, but there are differences in parts attached to the shell, and Ford considers these parts as integral to the case. Hence within the A4LD family there is a 3L case and a 4L case. Within the 4R & 5R family, there is a 44 case and a 55 case. And of course an A4LD case is different from a 4R/5R case, because of the modulator attachment port is present on the A4 and the output speed sensor port is present on the 4R/5R.

What's inside is an entirely different matter, hence Frankentranny. In Frankentranny projects, we steal the later 4R/5R goodies and stuff then into the older A4LD case. If we were to use the later nomenclature we would call my result a '4R55' with a xR44 bell. IOWs: 4 speeds, 550 ft-lb rating, no electronic control other than the OD & TC lock, updated pump & bell.

The bottom line benefit to the retrofit is that you get to retain your older ecu/ecm that doesn't know how to work the newer trannies. The dark side of this swap capability is that you never know what's inside your tranny. Worst case, a 4L style bellhousing conceals 3L parts inside.

Mine is not the original 1989 tranny but a remanufactured unit already upgraded with a few Torrington bearings in place of the original thrust washers. That swap occurred a dozen years, and 100K miles ago. The shop said of the original that there were fragments of thrust washer in the pan. Most probably this was the rear wave washer.

My current situation was that in the summer of 2012, returning from a drive-about, the 12yr/100K tranny would let loose when dropping down from overdrive, say under moderate throttle to begin a pass. Pondering the future of the van to possibly include a 4L engine swap, I had to consider whether to do a cheap overhaul, or rebuild to 4L specs. It was initially planned to do the overhaul but, in the background, procure or build a A4LD/4L. Long-short after getting into the tear-down for the cheap overhaul, and seeing the failure mode, it put me over the line and I merged the overhaul with the upgrade to 4L specs. Just for clarity, in the current time frame the bellhousing and engine still remain 3L Vulcan. If I swap in a 4L, I then merely change the bellhousing.

For those just tuning in, the Aerostar shipped with the A4LD tranny till about '94-95, then had a year or so with the 4RxxE series, then got the five speed 5RxxE series in the last year of production. The A4LD is visually distinct from the 4R/5R in that the A4LD has a vacuum modulator bolted to the side. In the A4LD its the mechanical governor and modulator that influence shift points, although overdrive is controlled electronically. In the earlier A4LD, one needs to specify whether it is 3L or 4L. For visual recognition, it's the bellhousing that mates to either the 3L Vulcan or the 4L Cologne.

The nemesis of the earlier A4LD was the use of brass/copper thrust washers, whereas the later versions and especially the 4R/5R used radial needle bearings (aka Torringtons). In several places, the 5R also introduced more axial needle bearings instead of sleeve bushings.

In the later 4R/5R nomenclature, the torque rating is swept up into the '44' number for 440 lb-ft, and '55' for 550 lb-ft (750 Nm). These are tend to be assigned to 3L and 4L engine applications. Not coincidentally, the 4R is a 4-speed, and the 5R is a 5-speed. The 'E' suffix basically means that Electronics determine the rotation speed of the components and resulting responses.

The difference between A4LD 3L torque and 4L torque capability shows up in the disk packs and the number of pinions in the planetary gear sets. For instance, early A4LD 3L apps implemented the reverse planet with 3 pinions in an aluminum cage. In the same location, the 4L apps got 6 pinions in a steel cage.

A 4L tranny case is likely to be stamped "750 NM", possibly on the outside, possibly inside at the rear. The aluminum shell is the same between the ratings, but there are differences in parts attached to the shell, and Ford considers these parts as integral to the case. Hence within the A4LD family there is a 3L case and a 4L case. Within the 4R & 5R family, there is a 44 case and a 55 case. And of course an A4LD case is different from a 4R/5R case, because of the modulator attachment port is present on the A4 and the output speed sensor port is present on the 4R/5R.

What's inside is an entirely different matter, hence Frankentranny. In Frankentranny projects, we steal the later 4R/5R goodies and stuff then into the older A4LD case. If we were to use the later nomenclature we would call my result a '4R55' with a xR44 bell. IOWs: 4 speeds, 550 ft-lb rating, no electronic control other than the OD & TC lock, updated pump & bell.

The bottom line benefit to the retrofit is that you get to retain your older ecu/ecm that doesn't know how to work the newer trannies. The dark side of this swap capability is that you never know what's inside your tranny. Worst case, a 4L style bellhousing conceals 3L parts inside.

Last edited by RojoStar; 02-27-2013 at 11:45 AM. Reason: new info

#2

The rap sheet

Tear-down of my 12 yr / 100K tranny revealed that the thrust washers, Torrington bearings and original gears were actually in remarkably good shape and could have put in another equal number of years and miles. However, there were 7 problems, some normal maintenance but two pushed the mission from cheap overhaul into Frankentranny. The mission creep was partially influenced by the 50-50 chance I will swap in a 4L engine within 2 years and also because I had already procured an updated bellhousing. If I could to the upgrade now, its one more item off my bucket list.

Here's the rap sheet:

* Front seal leaking. 'Tiz normal. Covered by routine rebuild.

* Friction bands getting a little worn. 'Tiz normal. Covered by routine rebuild. fyi, while still serviceable, new bands mic'd at 70 mils.

* As predicted by the Explorer forum crowd, the star washer providing input into the overdrive sun gear was exhibiting some distress, along with the corresponding output lugs on overdrive drum.

* O-ring failure on the center support snout. NOT normal. This is the smoking gun, the reason why we are here.

* More smoking. Intermediate clutch steel is discolored and/or coated. I think this is burnt tranny oil due to slippage due to the o-ring failure.

* Thrust washer wear, between the reverse hub and the end of the inner race. Disturbing. fyi, 4R/5R has a Torrington bearing here. Frankentranny gets a new hub compatible with the Torrington.

* Output shaft bushing wear. Catches my attention. 5R has a roller bearing here. More on that later.

* Shattered bearing on the output shaft snout . Houston, we got a problem. Fyi, this is the earlier end style possibly 3L only, and the 4R/5R has a roller bearing here. Frankentranny gets a roller style shaft but this requires updating the OD hub / center shaft because the roller has a smaller ID.

Here's the rap sheet:

* Front seal leaking. 'Tiz normal. Covered by routine rebuild.

* Friction bands getting a little worn. 'Tiz normal. Covered by routine rebuild. fyi, while still serviceable, new bands mic'd at 70 mils.

* As predicted by the Explorer forum crowd, the star washer providing input into the overdrive sun gear was exhibiting some distress, along with the corresponding output lugs on overdrive drum.

* O-ring failure on the center support snout. NOT normal. This is the smoking gun, the reason why we are here.

* More smoking. Intermediate clutch steel is discolored and/or coated. I think this is burnt tranny oil due to slippage due to the o-ring failure.

* Thrust washer wear, between the reverse hub and the end of the inner race. Disturbing. fyi, 4R/5R has a Torrington bearing here. Frankentranny gets a new hub compatible with the Torrington.

* Output shaft bushing wear. Catches my attention. 5R has a roller bearing here. More on that later.

* Shattered bearing on the output shaft snout . Houston, we got a problem. Fyi, this is the earlier end style possibly 3L only, and the 4R/5R has a roller bearing here. Frankentranny gets a roller style shaft but this requires updating the OD hub / center shaft because the roller has a smaller ID.

Last edited by RojoStar; 09-28-2017 at 12:39 PM. Reason: FB pic link repair

#3

The mods

It's tough to keep the pieces clear, so here is concise gallery of the tranny in order front to back. Washers and/or bearings are known by their locations in the machine, numbered 1 thru 11. However, there is a challenge to match up position numbers with vendor part numbers. I won't help you on the research because your application and situation might not match mine, and then you would kill me.

* Case and Bellhousing. Frankentranny gets the bell housing from the 4R44 to match with a new 4R pump while providing compatibility to my 3 bolt starter. If a 4L engine swap happens, then the either the 4R55 or 5R55 bell just bolt up and be compatible with the 4R pump.

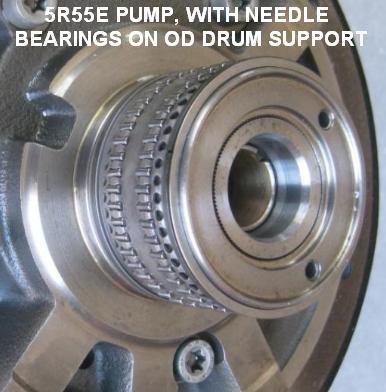

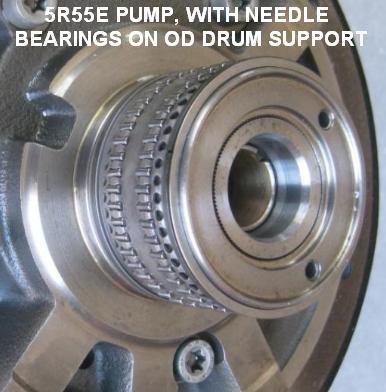

* Pump, with washer #1. Frankentranny gets the pump from the 4R. We took a pass on the 5R pump, which has roller bearings on the snout to support the heavier 5R overdrive drum. Reason was that we are always going to operate the tranny as a 4-speed, therefore did not need to swap in the heavier duty drum.. The pump arrived without the snout split rings but this was covered by the "master" overhaul kit. The o-ring in the pump gear caught my attention, but don't know (yet) what my A4LD pump has here. Be aware that the Explorerforum crowd mentioned a mod to the holes and channels in the bellhousing. I'll consider it if I ever get hold of the TSB. Washer #1 stays a washer, no choice.

* Overdrive drum, aka coast drum, front view left. No change here although those distressed output lugs and the pump bushing might motivate me to go to the 5R drum and pump someday.

* Overdrive gear set, with sun gear. The star washer was replaced as per Explorerforum recommendations.

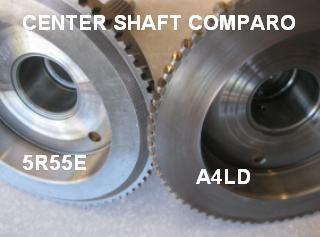

* OD hub and center shaft. The original had the 0.438 dia snout. It is required to reconstruct this part unit using a center shaft with 0.392 so that it can pilot into the new output shaft roller bearings.

* Center support, front side left. As installed left. The original A4LD design had washers #3 & #4 front and back, but my 12yr/100K reman had already been changed over to Torrington's. No change here other than replace the (broken) o-rings. fyi, 5R has roller bearings on the snout.

* Intermediate drum, front side left. Right shows washer #5 (probably). This was only washer remaining that could have been migrated to a Torrington needle bearing, but wasn't. The reason is that there was nothing broken in this area and I had no motivation to procure a compatible drum and possibly a forward clutch.

* Forward clutch. Front left. Bearing #6. No change here.

* Forward ring gear, rear side, showing bearing #7. A new hub was brought in to assure compatibility with a new planet.

* Forward planet. 4 pinion, rear view left. This was replaced by a 6 pinion unit, left unit in the right pic.

* Input shell. Holds sun gears mating to forward & reverse planets, washer #8 show in the rear view in the right pic. This washer goes to a Torrington which is centered by the new 6-pinion reverse planetary gear.

{Edit: During assembly I ran into a problem involving the input shell. It needed to be updated also. See post #5 for details.}

* Reverse planet, 3 pinion aluminum, showing washer #8 an #9. This was replaced by a 6 pinion steel unit, compatible with a Torrington on each side, right side right pic.

* Reverse hub ring gear, front side left. Right shows the evil washer. To solve the disturbing wear found on my washer #10, this hub end gets replaced by one compatible with Torrington bearings. Possibly my #10 was misbehaving because after the wave washer to case was removed from behind the inner race, then the load on #10 increased at the front of the race.

* Reverse brake drum. A replacement is required so as to be compatible with the Torrington above. In place of a sleeve bushing and 10 spring&rollers, we get needle bearings and 26 lug sprag, right side with hub and Torrington in place.

* Reverse inner race. This is where you might find the notorious wave washer. Even though mine tranny has already been revised, the race needs to get pulled because it's 2.5" OD not compatible with the new sprags on the reverse drum. Fyi, I fetched a 2.7" OD race from my another case using the Sonnax tool and observed that the wave washer had barely been brushed.

* You'll find washer #11 "outside" at the rear of the case. No other choice.

* Mentioned before, the A4LD has a bushing on the output of the case, while the 4R/5R has a roller bearing. The roller bearing has a larger OD and would require an overbore for the larger race. Frankentranny took a pass, because we would have to find a machine shop. Speculations elsewhere guess that the bushing style can take more abuse than a roller bearing and would fail more gracefully. The same speculators thought the style difference may be motivated by fuel savings.

* Governor. Front view, rear. No change.

* Output shaft. This was converted from bushing snout style to roller bearing style. It took three attempts for the salvage yard to ship me to correct shaft. My application required roller snout, 2WD, 3 oiling holes (for the sun gear bushings) and speedo threads starting 6-1/2 inches from the rear. The "6" stamp on the shaft indicates that there are this many worm teeth(*) interleaved around the shaft. (Worm teeth: There's an oxy for you, but have you every seen the movie Dune?)

* Here is the other half of the speedo equation. Orange color coding tells me I have 20 cog teeth, which is a mighty fine match to my 4.10 diff and 215/65-15 tires.

A color chart is available on line, probably over at Exploreforum. Tan = 19 teeth, good for larger dia tires or longer gearing. Purple = 21 teeth.

*Servos. Frankentranny gets migrated to the 5R design by replacing the A4LD's BB position with AB components and the AB position with ZC components. Fyi, every servo plunger/piston I have taken out was sloppy, barely sealing against the cover, whereas every (new) replacement plunger sealed tightly. Conclusion: always replace your plunger/piston, they are guaranteed to wear out.

******************

Thank you for not asking me any questions about your transmission problems. I'm just a monkey typing randomly on the keyboard.

Last edited by RojoStar; 09-28-2017 at 12:52 PM. Reason: FB pic link repair

#5

Misc topics that came up

* The input shell needed updating

During assembly, after stacking up the new internals from the rear of the case up to the center support, it was found that the stack was too tall and the center support snap ring did not seat into its groove in the case to lock down in the stack.

Investigation considered the distance from the center support reference shelf to points further down in the stack. A brass bar was dropped down from the CS reference point and scribed. Then the stack was removed and rebuilt using the old gears and washers. Then the brass bar was scribed again. The difference in the scribe points revealed that the stack was 0.100" taller and this was due to the rear planet assembly. The input shell was pushed forward by this amount.

So how to make up this difference before reaching the center support snap ring?

A search of the parts catalog revealed that the input shell should get updated when bearings are swapped in for the original washers. The new input shell is 0.0.50 shorter. Another 0.020" was gained by swapping in a thinner bearing #4 at the rear of the center support.

Now I haven't said whether the original tranny was in/out of spec, or whether the end play is the same for the A4LD versus the 4R/5R. I'll just say that now the center support snap ring seats correctly now and that the rear of the tranny is now 0.030" tighter than it was.

Left: Input shell w/sun, washer app. Right: Input shell, bearing app.

* Cheap pump alignment tool

When assembling the pump to the bellhousing, we need to guarantee that the pump shaft is in the center of the hole. Otherwise the torque converter, concentric with the shaft, will force a gap in the fluid seal and/or wear into the sleeve bearing. The factory has an alignment tool, although I can't see why you couldn't use the converter as the alignment tool. Third parties also sell tools for upwards of $100 new. Elsewhere, some guy figured out that a PVC coupling, 1" Sch40, is a perfect standin for the real tools. You'll only need to file down the internal ridge. So spend $1 or $100, your choice.

Pump shaft dia: 1.287

PVC ID: 1.320, less if you leave a little ridge.

TC shaft OD: 1.610

PVC OD: 1.654

* Weights

Empty A4/4R/5R tranny: 118 lbs.

Empty torque converter: 27 lbs.

Fluid within the tranny + TC: 13 lbs.

Total: 158 lbs.

Don't let it fall on you.

* Costs

Rebuild kit: $150

Parts + TC: $1000

Tools: $150

Shipping: $100

Fluid: $50

Total: $1450

During assembly, after stacking up the new internals from the rear of the case up to the center support, it was found that the stack was too tall and the center support snap ring did not seat into its groove in the case to lock down in the stack.

Investigation considered the distance from the center support reference shelf to points further down in the stack. A brass bar was dropped down from the CS reference point and scribed. Then the stack was removed and rebuilt using the old gears and washers. Then the brass bar was scribed again. The difference in the scribe points revealed that the stack was 0.100" taller and this was due to the rear planet assembly. The input shell was pushed forward by this amount.

So how to make up this difference before reaching the center support snap ring?

A search of the parts catalog revealed that the input shell should get updated when bearings are swapped in for the original washers. The new input shell is 0.0.50 shorter. Another 0.020" was gained by swapping in a thinner bearing #4 at the rear of the center support.

Now I haven't said whether the original tranny was in/out of spec, or whether the end play is the same for the A4LD versus the 4R/5R. I'll just say that now the center support snap ring seats correctly now and that the rear of the tranny is now 0.030" tighter than it was.

Left: Input shell w/sun, washer app. Right: Input shell, bearing app.

* Cheap pump alignment tool

When assembling the pump to the bellhousing, we need to guarantee that the pump shaft is in the center of the hole. Otherwise the torque converter, concentric with the shaft, will force a gap in the fluid seal and/or wear into the sleeve bearing. The factory has an alignment tool, although I can't see why you couldn't use the converter as the alignment tool. Third parties also sell tools for upwards of $100 new. Elsewhere, some guy figured out that a PVC coupling, 1" Sch40, is a perfect standin for the real tools. You'll only need to file down the internal ridge. So spend $1 or $100, your choice.

Pump shaft dia: 1.287

PVC ID: 1.320, less if you leave a little ridge.

TC shaft OD: 1.610

PVC OD: 1.654

* Weights

Empty A4/4R/5R tranny: 118 lbs.

Empty torque converter: 27 lbs.

Fluid within the tranny + TC: 13 lbs.

Total: 158 lbs.

Don't let it fall on you.

* Costs

Rebuild kit: $150

Parts + TC: $1000

Tools: $150

Shipping: $100

Fluid: $50

Total: $1450

Last edited by RojoStar; 09-28-2017 at 12:54 PM. Reason: FB pic link repair

#6

I'm gathering up another 4L tranny which temporarily has to sit on a cart behind a 3.2L SHO, while I work out PCM details, then later hook up to a SOHC. The translation between the xR55E guts and the 3L engine is the 3L bellhousing normally found on a xR44E and is compatible with the xRxxE pump. Someone out there, please save me the trouble of buying a xR44E + shipping, and then throwing away everything but the bell. So check your barn for a throw away tranny, and ship me the bell. Me thinks either a -CB or -CC works. Btw, current eBay'rs don't know what they are talking about.

#7

5R update

There were continuing troubles while in service.

The tranny was pulled again, twice, and the diagnosis led to me completing the update so that the internals are now completely 5R55E components, particularly the input roller bearings, but with the exception that the A4LD output shaft is retained for its speedo drive feature.

IOW's our build level is now...

- A4LD case and valve body

- 5R55E components except output shaft

- 3L bell

Back story...

Ever since the transmission was modified two years ago, there has been chronic trouble with loosing engagement while in top gear.

Ironically, this symptom was identical to an original problem that motivated the project, but the root cause was now different.

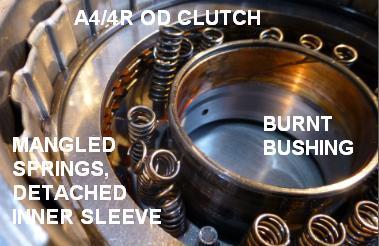

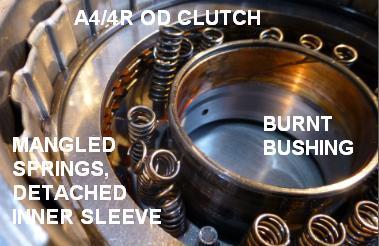

In November 2014, the tranny was pulled and inspected and it was found that the overdrive clutch drum had failed.

The inner sleeve of the piston retainer mechanism had separated from the inside barrel and so the clutch was inoperative.

There was evidence that the bushing between the pump and the OD drum inside diameter had overheated and begun smearing the pump barrel with copper alloy.

This overheating was the cause of the inner sleeve detaching.

Note: these are A4/4R style components.

After the repair, symptoms continued and the transmission was pulled again after only 6 months.

This time, the same bushing on the OD drum had been chewed up badly.

Obviously, no coincidence.

Looking around, it was discovered first that bell housing gasket did not match the pump plate.

This eventually led to finding the mismatch between an A4 housing and the 4R/5R bell housing.

I do not know whether this is the root cause of the OD bushing problem.

Regardless, the pump and OD clutch were migrated to the 5R55E style featuring needle bearings,

much less sensitive to lubrication.

Previously, only the gear sets and washers had been upgraded to 5R55E, along with a newer style output shaft.

The conversion to 5R55E components has now been extended to pump & OD above, plus the center shaft, center support, intermediate/direct clutch and the forward clutch, featuring still more needle bearings instead of bushings.

*** Pump and compatible OD clutch drum

A 5R55E normally has a plastic washer between the pump and OD drum, but the A4/4R metal washer can be opened up by 0.050 so as to fit over the needle bearings.

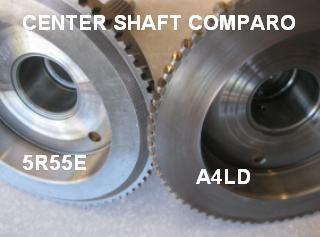

*** Center shaft and compatible OD ring gear

The center shaft assembly includes the OD ring gear, a sprag and a snap ring.

The A4LD has a thin metal sheet to retain the sprag inside the center shaft, whereas the 5R55E sprag snaps into the center shaft cavity and there is no retainer sheet.

The A4 and 5R OD ring gears are very similar but not the same, so an early A4 ring does not work quite properly with a 5R shaft. It will be too loose by the thickness of the missing retainer plate.

The 5R center shaft has the thinner snout so definitely requires the newer output shaft with internal needle bearings.

*** Center Support

The dimensions and style of the center support rear closely match that of the pump.

The A4/4R torrington bearing will not fit over the 5R55E needle bearings.

There is a 5R specific bearing with a larger ID.

At the front of the Center Support the A4 has the (56223) bearing centered on its inside diameter,

whereas the 5R has the (56223B) bearing centered by its outside diameter.

*** Direct/Intermediate clutch drum, compatible with new Center support

The direct/intermediate clutch drum fits over the barrel of the center support.

The needle bearings on the 5R center support require a larger inside diameter for the clutch drum.

A torrington bearing (not shown) replaces the A4 washer.

*** Forward clutch drum, compatible with new Center support

The front end of the forward clutch drum fits inside the barrel of the center support.

*** A4LD output shaft and compatible sungear

The A4LD output shaft is still retained, rather than migrating to some 4R/5R shaft.

This maintains support for the speedometer sensor and is compatible with the A4LD case that has the bushing at the rear rather than needle bearings as with the 4R/5R case.

To properly retain oil pressure in the 3-hole shaft, the input sungear needs to be the bushing style rather than the no-bushing style as in the 5R55E.

The tranny was pulled again, twice, and the diagnosis led to me completing the update so that the internals are now completely 5R55E components, particularly the input roller bearings, but with the exception that the A4LD output shaft is retained for its speedo drive feature.

IOW's our build level is now...

- A4LD case and valve body

- 5R55E components except output shaft

- 3L bell

Back story...

Ever since the transmission was modified two years ago, there has been chronic trouble with loosing engagement while in top gear.

Ironically, this symptom was identical to an original problem that motivated the project, but the root cause was now different.

In November 2014, the tranny was pulled and inspected and it was found that the overdrive clutch drum had failed.

The inner sleeve of the piston retainer mechanism had separated from the inside barrel and so the clutch was inoperative.

There was evidence that the bushing between the pump and the OD drum inside diameter had overheated and begun smearing the pump barrel with copper alloy.

This overheating was the cause of the inner sleeve detaching.

Note: these are A4/4R style components.

After the repair, symptoms continued and the transmission was pulled again after only 6 months.

This time, the same bushing on the OD drum had been chewed up badly.

Obviously, no coincidence.

Looking around, it was discovered first that bell housing gasket did not match the pump plate.

This eventually led to finding the mismatch between an A4 housing and the 4R/5R bell housing.

I do not know whether this is the root cause of the OD bushing problem.

Regardless, the pump and OD clutch were migrated to the 5R55E style featuring needle bearings,

much less sensitive to lubrication.

Previously, only the gear sets and washers had been upgraded to 5R55E, along with a newer style output shaft.

The conversion to 5R55E components has now been extended to pump & OD above, plus the center shaft, center support, intermediate/direct clutch and the forward clutch, featuring still more needle bearings instead of bushings.

*** Pump and compatible OD clutch drum

A 5R55E normally has a plastic washer between the pump and OD drum, but the A4/4R metal washer can be opened up by 0.050 so as to fit over the needle bearings.

*** Center shaft and compatible OD ring gear

The center shaft assembly includes the OD ring gear, a sprag and a snap ring.

The A4LD has a thin metal sheet to retain the sprag inside the center shaft, whereas the 5R55E sprag snaps into the center shaft cavity and there is no retainer sheet.

The A4 and 5R OD ring gears are very similar but not the same, so an early A4 ring does not work quite properly with a 5R shaft. It will be too loose by the thickness of the missing retainer plate.

The 5R center shaft has the thinner snout so definitely requires the newer output shaft with internal needle bearings.

*** Center Support

The dimensions and style of the center support rear closely match that of the pump.

The A4/4R torrington bearing will not fit over the 5R55E needle bearings.

There is a 5R specific bearing with a larger ID.

At the front of the Center Support the A4 has the (56223) bearing centered on its inside diameter,

whereas the 5R has the (56223B) bearing centered by its outside diameter.

*** Direct/Intermediate clutch drum, compatible with new Center support

The direct/intermediate clutch drum fits over the barrel of the center support.

The needle bearings on the 5R center support require a larger inside diameter for the clutch drum.

A torrington bearing (not shown) replaces the A4 washer.

*** Forward clutch drum, compatible with new Center support

The front end of the forward clutch drum fits inside the barrel of the center support.

*** A4LD output shaft and compatible sungear

The A4LD output shaft is still retained, rather than migrating to some 4R/5R shaft.

This maintains support for the speedometer sensor and is compatible with the A4LD case that has the bushing at the rear rather than needle bearings as with the 4R/5R case.

To properly retain oil pressure in the 3-hole shaft, the input sungear needs to be the bushing style rather than the no-bushing style as in the 5R55E.

Last edited by RojoStar; 09-28-2017 at 02:11 PM. Reason: FB pic link repair

Trending Topics

#10

The calculated rating is after torque multiplication. Based on how stout it looks and which cars/trucks you find it in, and comparing it to other trannys I have around, the max engine torque is in the 250 to 280 ft-lb range. Electronic control can stretch it to slightly higher torque capacity by slewing/flaring and pulling back on engine power during shifts. However...

The valvebody (and case) used here is still the original A4LD, so the engine computer operates only the 4th gear (aka OverDrive) and the torque converter lock up and there is no 5th gear.

The valvebody (and case) used here is still the original A4LD, so the engine computer operates only the 4th gear (aka OverDrive) and the torque converter lock up and there is no 5th gear.

Thread

Thread Starter

Forum

Replies

Last Post

JacoFordCummins

Engine Swaps

45

11-04-2020 09:09 AM

PapaBearYuma

1973 - 1979 F-100 & Larger F-Series Trucks

35

10-24-2016 03:39 PM

Saturn5

1967 - 1972 F-100 & Larger F-Series Trucks

24

08-02-2014 10:37 AM

alpha/omega

Offroad & 4x4

295

05-15-2014 09:36 PM

96_F250_Deezal

Clutch, Transmission, Differential, Axle & Transfer Case

2

07-12-2013 02:10 PM