Bleeding Hydraulic Lifters/ Adjusting Valves

#1

Bleeding Hydraulic Lifters/ Adjusting Valves

I am looking for some tips with bleeding and adjusting Hydraulic Lifters in a 300. I have a 300 in my my 84, it has a remanfactured long block, when the head was reman, the pressed in studs where replaced with threaded studs, so the lifters are now adjustable.

My first question is if there are any tips or tricks for compressing the lifters without the tool from Ford? Also does it take very much force to compress the lifters? These are new lifters so they should compress easily.

Also, my understanding is the when adjusting the lifters you tighten the lifter until the push rod no longer turns then tighten the lifters one additional full turn to preload the valves. When I did this today it opened the valves, so either one turn was to much or the lifters were not compressed.

Any tips or suggestions is greatly appreciated..

My first question is if there are any tips or tricks for compressing the lifters without the tool from Ford? Also does it take very much force to compress the lifters? These are new lifters so they should compress easily.

Also, my understanding is the when adjusting the lifters you tighten the lifter until the push rod no longer turns then tighten the lifters one additional full turn to preload the valves. When I did this today it opened the valves, so either one turn was to much or the lifters were not compressed.

Any tips or suggestions is greatly appreciated..

#4

If you've never fired the engine up and the lifters are new, they shouldn't be primed. They may have a lubrication in them from the manufacturer, but that's it. If you want to be sure they're completely empty (necessary when you need to measure to see if you need longer or shorter pushrods), you can disassemble the top of the lifters and drain them. Then you can be sure they're empty.

I tried finding the pictures I took, but can't locate them.

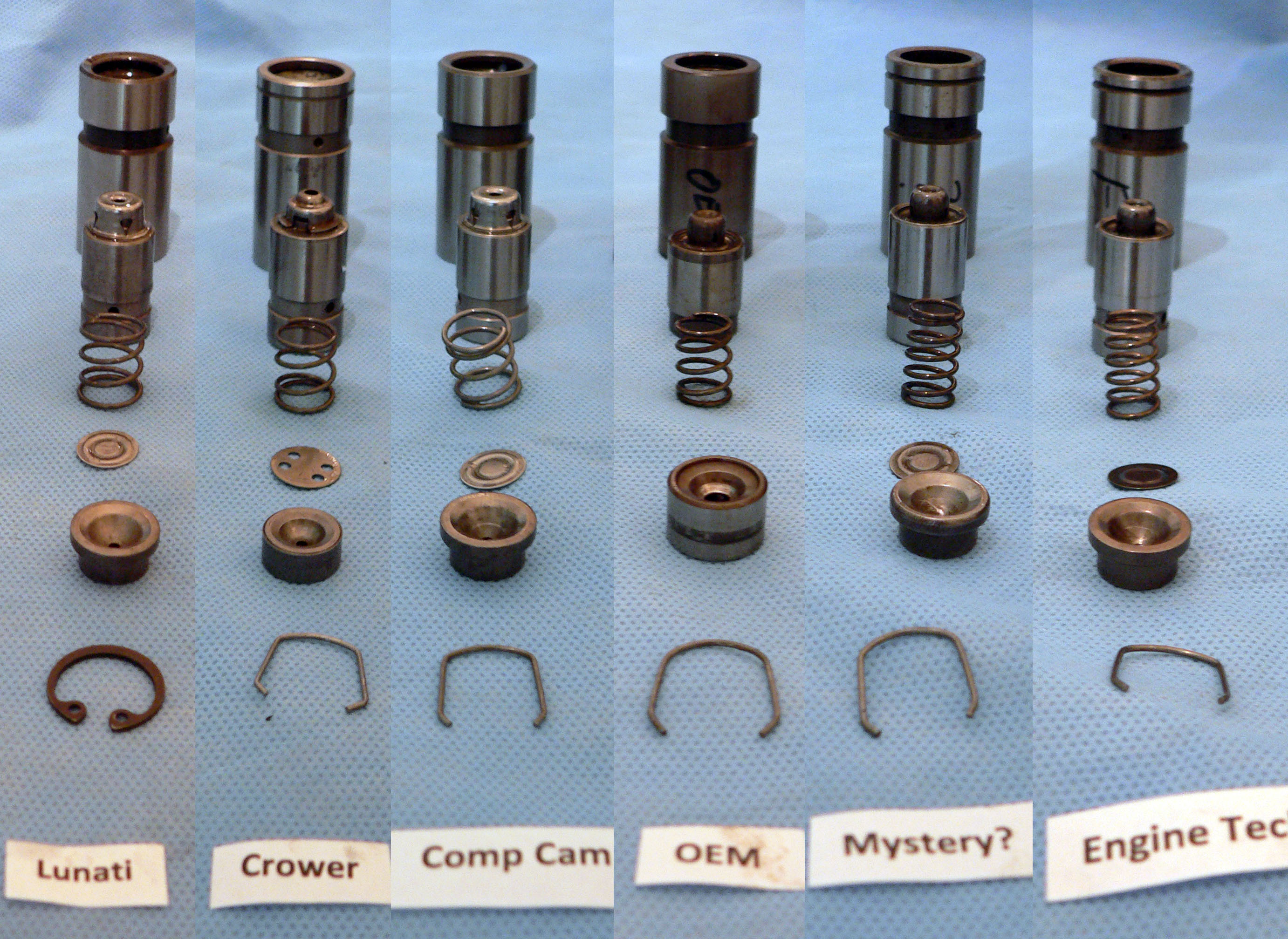

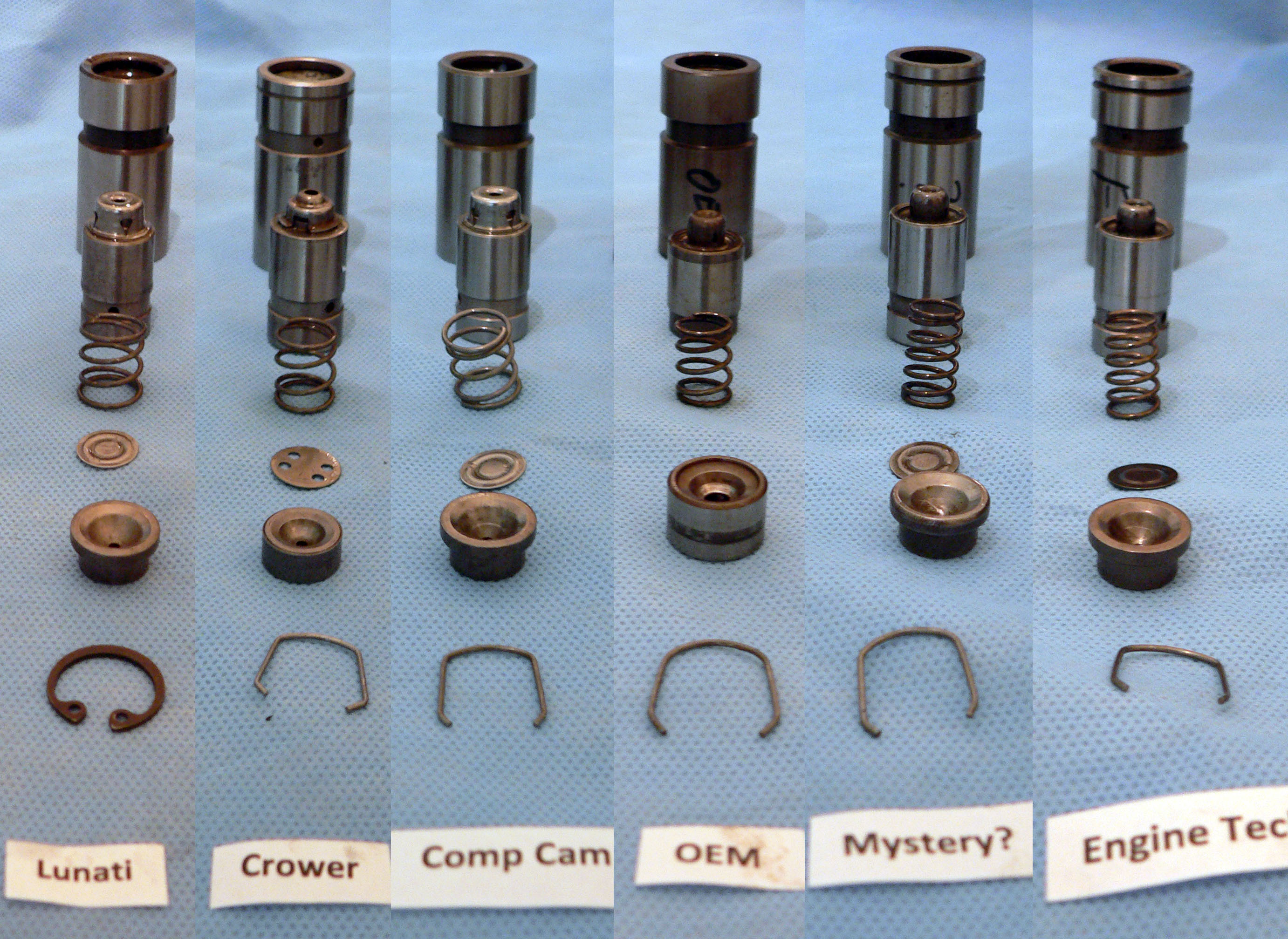

Here's a pic I found online though:

If I can mine, I'll post them up, since they're step by step.

But either way, there's just a retaining clip on the top. Remove that (be careful so it doesn't go flying) and then take out the internals. Everything should just fall out after that. If it doesn't, it's being held in place by the viscosity of the liquid. Sometimes a good smack against the palm will do it, or a dental pick.

You shouldn't have to take the piston out. Just the cap. When you get to the piston, look in the hole on the side of the casing and rotate the piston inside with your finger until it's hole lines up, and then you can press it down all the way. Or, hook the piston's hole with a pick and pull it out if you want to be thorough.

This is the best way I've found to guarantee they're completely drained. After about 2 - 3 of them, you'll get the hang of it, and it goes by really quickly. Reverse to put them back together.

Just don't lose the retaining clip. And when you take the little plate out, pay attention to which side was up and which side was down. If it accidentally falls out and you aren't sure, set it aside and take another one apart so you can see.

I tried finding the pictures I took, but can't locate them.

Here's a pic I found online though:

If I can mine, I'll post them up, since they're step by step.

But either way, there's just a retaining clip on the top. Remove that (be careful so it doesn't go flying) and then take out the internals. Everything should just fall out after that. If it doesn't, it's being held in place by the viscosity of the liquid. Sometimes a good smack against the palm will do it, or a dental pick.

You shouldn't have to take the piston out. Just the cap. When you get to the piston, look in the hole on the side of the casing and rotate the piston inside with your finger until it's hole lines up, and then you can press it down all the way. Or, hook the piston's hole with a pick and pull it out if you want to be thorough.

This is the best way I've found to guarantee they're completely drained. After about 2 - 3 of them, you'll get the hang of it, and it goes by really quickly. Reverse to put them back together.

Just don't lose the retaining clip. And when you take the little plate out, pay attention to which side was up and which side was down. If it accidentally falls out and you aren't sure, set it aside and take another one apart so you can see.

#5

you are blessed to have adjustable lifters.

I am looking for some tips with bleeding and adjusting Hydraulic Lifters in a 300. I have a 300 in my my 84, it has a remanfactured long block, when the head was reman, the pressed in studs where replaced with threaded studs, so the lifters are now adjustable.

My first question is if there are any tips or tricks for compressing the lifters without the tool from Ford? Also does it take very much force to compress the lifters? These are new lifters so they should compress easily.

Also, my understanding is the when adjusting the lifters you tighten the lifter until the push rod no longer turns then tighten the lifters one additional full turn to preload the valves. When I did this today it opened the valves, so either one turn was to much or the lifters were not compressed.

Any tips or suggestions is greatly appreciated..

My first question is if there are any tips or tricks for compressing the lifters without the tool from Ford? Also does it take very much force to compress the lifters? These are new lifters so they should compress easily.

Also, my understanding is the when adjusting the lifters you tighten the lifter until the push rod no longer turns then tighten the lifters one additional full turn to preload the valves. When I did this today it opened the valves, so either one turn was to much or the lifters were not compressed.

Any tips or suggestions is greatly appreciated..

I think the idea is to get the lifter about half way in it's range of travel (and each mfg'er's specs may be slightly different) so wear won't have you doing this once a month.

If you do it cold, after going thru all the valves and cycling the cam a few times the lifters should bleed off and your 3/4 turn should be about right. (if your lifters are healthy)...the valves will eventually close at 3/4 turn...

I just recently checked the pedastal rockers on my 86...and with the thread count being approx the same for the pedastal mount bolts..the average setting was 3/4 turn or so from zero.

On edit, if you haven't started the engine yet, and the lifters are dry it may be hard to tell where "zero lash is" if you have never done this before. if there is any doubt where you are you can turn the engine over a few times with the plugs out, and coil disconnected etc..(or using a remote starting trigger with the ign off) to build some pressure in the lifters

I myself would pre-oil the lfters so there was some lube in them to start with...

Here is an excellent source of info along with a video..note some say that 1/2 turn from zero is adequate for modern lifters..

http://www.crankshaftcoalition.com/w...raulic_lifters

#6

I am looking for some tips with bleeding and adjusting Hydraulic Lifters in a 300. I have a 300 in my my 84, it has a remanfactured long block, when the head was reman, the pressed in studs where replaced with threaded studs, so the lifters are now adjustable.

My first question is if there are any tips or tricks for compressing the lifters without the tool from Ford? Also does it take very much force to compress the lifters? These are new lifters so they should compress easily.

Also, my understanding is the when adjusting the lifters you tighten the lifter until the push rod no longer turns then tighten the lifters one additional full turn to preload the valves. When I did this today it opened the valves, so either one turn was to much or the lifters were not compressed.

Any tips or suggestions is greatly appreciated..

My first question is if there are any tips or tricks for compressing the lifters without the tool from Ford? Also does it take very much force to compress the lifters? These are new lifters so they should compress easily.

Also, my understanding is the when adjusting the lifters you tighten the lifter until the push rod no longer turns then tighten the lifters one additional full turn to preload the valves. When I did this today it opened the valves, so either one turn was to much or the lifters were not compressed.

Any tips or suggestions is greatly appreciated..

The easiest and most foolproof way is to jiggle the push rod up and down, slowly tighten the rocker nut until the pushrod just stops moving up and down and then tighten anywhere from 3/4 to 1 full turn more. Don't be concerned with the lifter being primed or not, or if the valve opens slightly, it doesn't matter. Just make sure that each cylinder is at TDC, when you adjust.

If you can, use a oil pump prime tool or hex drive to prelube the system before start up while slowly rotating the crankshaft over.

That's all there is to it.

Thread

Thread Starter

Forum

Replies

Last Post

wagonerkl

Ford Inline Six, 200, 250, 4.9L / 300

10

12-07-2008 06:57 AM

PHetrick

335 Series- 5.8/351M, 6.6/400, 351 Cleveland

13

02-12-2007 11:58 PM

marine73

FE & FT Big Block V8 (332, 352, 360, 390, 406, 410, 427, 428)

4

07-28-2002 06:42 PM