Thoughts on this wvo setup

#16

tom,

if your ever going to be down this way let me know so maybe you, me, and ted can get together. were having a mini tech day this saturday starting 0830 tomorrow morning in my driveway. 2 fuel bowl rebuilds and injector torque check on teds truck. after reading jason's explanation of his setup i know exactly how i want to do mine... now just to assemble the parts.

if your ever going to be down this way let me know so maybe you, me, and ted can get together. were having a mini tech day this saturday starting 0830 tomorrow morning in my driveway. 2 fuel bowl rebuilds and injector torque check on teds truck. after reading jason's explanation of his setup i know exactly how i want to do mine... now just to assemble the parts.

#17

tom,

if your ever going to be down this way let me know so maybe you, me, and ted can get together. were having a mini tech day this saturday starting 0830 tomorrow morning in my driveway. 2 fuel bowl rebuilds and injector torque check on teds truck. after reading jason's explanation of his setup i know exactly how i want to do mine... now just to assemble the parts.

if your ever going to be down this way let me know so maybe you, me, and ted can get together. were having a mini tech day this saturday starting 0830 tomorrow morning in my driveway. 2 fuel bowl rebuilds and injector torque check on teds truck. after reading jason's explanation of his setup i know exactly how i want to do mine... now just to assemble the parts.

#18

#19

The good news is, its likely cheaper to do a good 2-tank conversion on your IDI than it is on our PSD's. I just did a conversion on a 2005 med. duty Isuzu truck and used greasecar valves. There is nothing else I would buy from that company, but the Hydraforce SV98 valves are good for this application and GC has had a manifold built that neatly houses (2) valves and is fairly easy to mount.

https://www.greasecar.com/sites/grea...ofittings2.jpg

What you DON'T wanna do is use a typical 6-way switching valve that is commonly used to switch tanks on a truck with (2) fuel tanks. You need to switch the supply back to diesel and continue returning to the VO tank until all of the VO is out of the engine - then switch the return to the diesel tank before ya shut down. If you switch both at the same time, you are slowly contaminating the diesel tank with WVO. Besides, if you manage to get the VO as hot as it needs to be (>160*) - the motor-driven pollak valve won't last long anyway...

What you DO wanna do is use a heated fuel pick-up in an aluminum tank, heated fuel lines (TIH - 3/8" aluminum tubing inside 3/4" heater hose) and at least a 16plate flat-plate heat exchanger to make sure the fuel is HOT. Adding a 3rd 3-way valve to the 'return' line and 'looping' the return fuel back to the supply valve while running on VO will add a considerable amount of heat to the VO and reduce the strain on the lift pump.

The system I just installed on the Isuzu has a simple on/off switch. When ON, both valves switch to VO - when switched OFF, the supply switches back to diesel and a timer relay was used to keep the return valve open for an additional 30-40 secs. The driver watches the coolant temp on dash and switches at 'operating temp', then turns the switch off when he returns to the facility. When I get back out there, we'll install a temp switch that will automatically switch over to VO when coolant temp gets high enough and maybe even incorporate a DIY 'turbo timer' to automatically trigger the purge cycle at shutdown - for a fully automated VO system.

#20

Thanks for the info. I wracked my brain on where that aux fuel port was, but of course, my IDI didn't have one.

I ended up tying into the supply line after the diesel filter head, so that I don't contaminate my stock diesel filter with veg. The veg return line was simple: just removed a section of hose on the back of the motor. I mounted two viton-sealed hydroforce valves for the system i designed (I already had lots of spare HF parts in the garage, and I don't think I'm too worried about cycling heat to install a third valve.) With this van, it already had a rear coolant circuit stock for the rear heater core, so I just bundled my aluminum 3/8" fuel lines with them, and insulated around them. Also, I have a 30-plate FPHE, heated alum filter head, facet pump, and horizontally mounted hotfox in my custom undermount 32-gallon aluminum tank. it's pretty sexy. All i have left is to mount my gauges and switches.

I was able to do this whole install on the cheap, except for the custom tanks. Almost all my parts (except for the heated filter head) i had laying around in the garage.

Not trying to hijack the thread, but hopefully my custom/homemade setup helps others in this forum.

I ended up tying into the supply line after the diesel filter head, so that I don't contaminate my stock diesel filter with veg. The veg return line was simple: just removed a section of hose on the back of the motor. I mounted two viton-sealed hydroforce valves for the system i designed (I already had lots of spare HF parts in the garage, and I don't think I'm too worried about cycling heat to install a third valve.) With this van, it already had a rear coolant circuit stock for the rear heater core, so I just bundled my aluminum 3/8" fuel lines with them, and insulated around them. Also, I have a 30-plate FPHE, heated alum filter head, facet pump, and horizontally mounted hotfox in my custom undermount 32-gallon aluminum tank. it's pretty sexy. All i have left is to mount my gauges and switches.

I was able to do this whole install on the cheap, except for the custom tanks. Almost all my parts (except for the heated filter head) i had laying around in the garage.

Not trying to hijack the thread, but hopefully my custom/homemade setup helps others in this forum.

#22

i know it has been answered, but I'm not understanding, if i were to put a wvo 2 tank system in a 94 7.3 power stroke, and had the wvo filtered and heated, why can i not use the stock mechanical pump? is the oil too hot for the diaphragm? i do like the redundancy idea with a separate pump for the vo, but how do i keep the mechanical pump from deadheading? or are you bypassing it completely, and putting in an electric aftermarket one? maybe if someone could do a quick sketch i could get it.

#23

i know it has been answered, but I'm not understanding, if i were to put a wvo 2 tank system in a 94 7.3 power stroke, and had the wvo filtered and heated, why can i not use the stock mechanical pump? is the oil too hot for the diaphragm? i do like the redundancy idea with a separate pump for the vo, but how do i keep the mechanical pump from deadheading? or are you bypassing it completely, and putting in an electric aftermarket one? maybe if someone could do a quick sketch i could get it.

stock pumps will get clogged or damaged by the vo plus you don't want to ruin your stock pump if you get a problem with yoru vo pump, which will probably be compromised from all the veg and heat flowing thru it. Plus all the fuel lines leading up to and after the stock pump are steel, so those will react with the WVO.

The best way is to get a duralift pump dedicated for the vo.

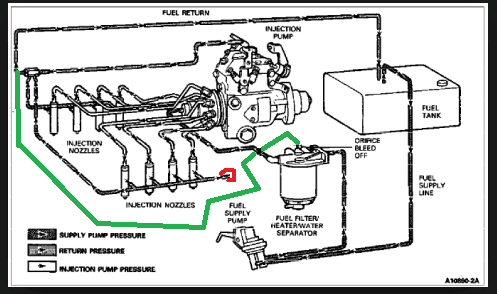

Do avoid deadheading, just make sure you bypass your return from the filterhead to somewhere on the return to the diesel tank after the second or third selector valve. something like this:

From the thread..... https://www.ford-trucks.com/forums/1...ne-delete.html

#24

i know it has been answered, but I'm not understanding, if i were to put a wvo 2 tank system in a 94 7.3 power stroke, and had the wvo filtered and heated, why can i not use the stock mechanical pump? is the oil too hot for the diaphragm? i do like the redundancy idea with a separate pump for the vo, but how do i keep the mechanical pump from deadheading? or are you bypassing it completely, and putting in an electric aftermarket one? maybe if someone could do a quick sketch i could get it.

Here's the last OBS truck I did a conversion on:

wyomingowen's Vegistroke install

#25

#27

Very true.

Now for my 1.5 cents. I have a 7.3 idi and have been running some very nasty wvo that looks like coffee mixed with grits for 4 years now at a rate of 30-40 gallons a week. The texture is of course solid fats from the chicken wing skins that were fried in it. I filter and burn it all. Solid fats and oil alike. In the winter I have to bring it into the basement ahead of time and let it warm up before it will flow through the window screen i use to catch the big chunks of food as my first step other wise it will just set on the screen, its that thick.

I do not have a heated fuel pickup. I used a 3/4 cpvc pipe up to the top of the tank where it goes into my heated fuel line. Its large and hard to clog. I have run it in temp of single digits with no problems. In the winter I mix 10% diesel into it to cut the fats so it will flow. From there it goes to my factory fuel pump that I run diesel and wvo through. This is the biggest weak spot in my system and because of that I put a new one on every year for safety. I had been planning to go with separate electric pumps but have never gotten around to it. From the pump I seperated the lines back out into two systems again. Wvo goes through 36 plate heat exhanger from ebay and then though a seperate filter. From there it ties into the steel line going to injector pump. The way I use cutoff valves to isolate the fuel pump from the separate systems means I do not have to use check valves.

Return lines is where if differ the most.

I have another valve that switches back and forth from the diesel to the wvo return lines at the back of the motor. I do not worry about the contamination of wvo into my diesel. Its such a small amount of contamination in the return lines that it has never been a problem. I do not have timed switches mine switch at the same time. I usually burn about 10 gallons of diesel a week switching and it has never been enough to bother my truck.

I also elected to run a separate return line all the way back to my wvo tank. This is important for people with an idi motor. Air intrusion is a constant battle with these engines that most people do not have to deal with. From return lines orings that will need replacing even more often because of the oil. Even the caps themselves will get hard and brittle from the oil and heat. I installed a seperate 50 gal wvo tank that doesn't have a fuel gauge so when I run completely out of fuel the lines are full of air, or turn real sharp on a low tank. Its a lot easier to pump air into the tank than to pump it through your injectors. This is also another reason for an electric pump on these trucks.

Most important things in my opinion:

Heat the fuel to 160 min. The thermostat in your truck is 185deg so if your truck isn't completely warm its not hot enough.

Start and stop on diesel. Make sure your system is clean from wvo before you stop. I drive the last 1-2 miles on diesel before I stop.

If your not using your system every day then you need a separate aluminum tank and aluminum lines. Polymerization is of the most concern in systems that are not used daily. My tank is steel and my fuel line is copper but the oil does not sit there long enough to polymerize. It is the oil that polymerizes, not the metal and it takes a little time to change. Mine is fresh every week so its not a problem for me.

Being over cautious and building a better system in your truck or filtering set up will not hurt you. But trashing your motor will cost you more than a few cheap trips on oil is worth.

Filter your oil. then filter it again. then filter it again.

Filtering

I let my oil settle for 6-8 weeks

Then I pour the best off the top and run it though a series of sock filters.

I then send it through a cold up flow system.

Then a golden rod filter.

Now its ready for my truck and the filter on it

#28

#29

Following this CV is a tee. One side of this tee goes up to the engine and the other side has a normally-closed 12v solenoid valve.

#30

I am currently using a hydraforce 2-port valve for purge and Frybrid heated fuel pick-ups.

My heated sump design is an appendage below tank with a coolant loop of tubing running thru it. It has limited communication with the main tank, effectively placing a ceiling on the column of hot oil being created - but heating the oil above it enough so it can run into the sump. All conventional designs put the hottest oil at the top of the tank - furthest from the pick-up at the BOTTOM of the tank...

I do custom VO conversions for others as well. This is where I started for the current project:

This truck is getting a total makeover as well as veggie system using a 44gal Excursion tank in the spare tire location. Currently have (6) of these trucks to build!! (not all VO conversions)