'76 highboy rebuild... with a cummins

#16

Not going with an intercooler, at least for now. I am debating whether to remove the "dodge ram" on the air horn, or leave it there. Would look better without it, but has great potential for allowing plenty of jokes about how poorly built those early dodge trucks were....... 120K miles, 2 dash fires, and then the frame broke. Have to put the engine in a Ford, in order to stand a chance of wearing out the engine, before the chassis......

The swap looks good.

#17

Im currently swapping my 76' with a 12 valve as well. I like what you did with boxing the frame and fabbing up a new cross-member. Im doing some of the fab work this weekend and I have the frame boxed. Im wondering how much clearance from the top of frame to the top of the member is needed to clear the 5.9? Thanks!

#19

finally getting around to uploading some pictues. lots of progress in the last few months.

cleaned up and painted the under the cab section of frame, had to fix the cab mounts, they had the usual under the bushing rust.

rolled it outside and hoisted the cab back on

back inside, ready to start fabbing

bolted the system together

cut the cross member for clearence

fit the engine

bolted the front clip back together to set the spacing, i cant belive how nice it ended up fitting. no more than an inch spacing front to back.

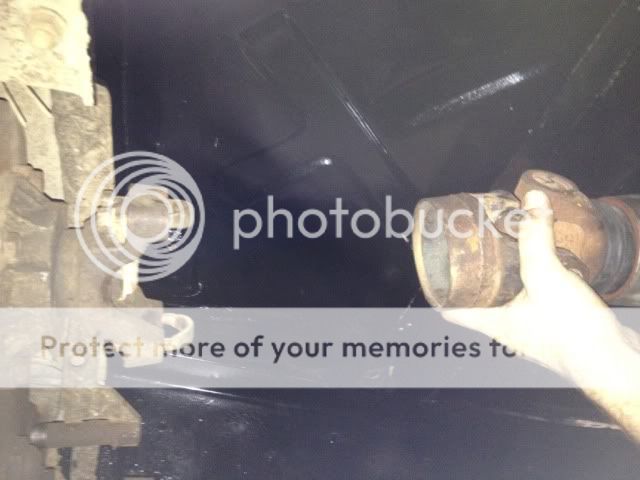

drive shaft will be pretty short

i decided to keep the 89 style engine mounts, i fabbed these up to bolt to the stock ford bolt holes. i positioned the engine basically where the 360 was, more to the passenger side.

me making sure the mouts are sturdy.

after pulling the engine again i got to work on the x-member, i decided to box the frame and start from scratch.

frame painted and mounts installed

engine back in and bolted up. finally feeling like it might actually come together

now is the fun time, putting everything back together. installed my brake lines, i bought the stainless kit from bronco graveyard. fit awesome except for one line having the wrong fitting.

i adapted the dodge clutch system, made a doubler plate either side for strength.

added a mounting point to the ford pedal for the pushrod.

Thats all for now, next up is to work on the engine, need to do the killer dowel pin fix, re install the injector pump and line, and then get on doing the exhaust and turbo set up. should keep me busy

cleaned up and painted the under the cab section of frame, had to fix the cab mounts, they had the usual under the bushing rust.

rolled it outside and hoisted the cab back on

back inside, ready to start fabbing

bolted the system together

cut the cross member for clearence

fit the engine

bolted the front clip back together to set the spacing, i cant belive how nice it ended up fitting. no more than an inch spacing front to back.

drive shaft will be pretty short

i decided to keep the 89 style engine mounts, i fabbed these up to bolt to the stock ford bolt holes. i positioned the engine basically where the 360 was, more to the passenger side.

me making sure the mouts are sturdy.

after pulling the engine again i got to work on the x-member, i decided to box the frame and start from scratch.

frame painted and mounts installed

engine back in and bolted up. finally feeling like it might actually come together

now is the fun time, putting everything back together. installed my brake lines, i bought the stainless kit from bronco graveyard. fit awesome except for one line having the wrong fitting.

i adapted the dodge clutch system, made a doubler plate either side for strength.

added a mounting point to the ford pedal for the pushrod.

Thats all for now, next up is to work on the engine, need to do the killer dowel pin fix, re install the injector pump and line, and then get on doing the exhaust and turbo set up. should keep me busy

#20

That clutch master plate isn't going to be big enough to keep the rest of the firewall from flexing. I know from experience. You not only need thicker plate but a larger area to absorb the pressure your foot is going to exert on the firewall everytime you engage the clutch.

Thread

Thread Starter

Forum

Replies

Last Post

bad_habit_F350

1973 - 1979 F-100 & Larger F-Series Trucks

16

06-02-2020 10:54 PM