Stella's '47 updates

#16

Did some more reading today about the junk yard motor I found. It appears that there is a left and right cylinder head as the stampings show. Stock compression ratio is suppose to be 6.2:1. Have to find out if the 59a series heads I have already have a lower or higher ratio as I'd like to use the higher comp. heads. Also hoping that the parts I have taken off my original block will work with this new block. Hoping to reuse my original distributor instead of the large football style distributor that is on the new motor. It would facilitate the original look of the engine setup that would have come from factory in 1947. Also looks like I might not beable to swap rods from one crank to the other if needed, or at least until I get it pulled apart and measure. The crankpin journals on my crank is 2.1390 but the junk yard motor maybe 1.9990, unless of course the junk yard motor is a true 95hp motor then I should be good.

#17

Its a 59-A block all will fit, you just may have to change the timming cover plate if its a 3 bolt one to accomodate your distributor which is a 2 bolt.

If the heads on the Junk yard engine are okay then just leave them on, there the correct heads for that engine. The ones on you old block if memory serves me correct are mismatched. Also higher compression heads on that engine won't do you any difference.

If the heads on the Junk yard engine are okay then just leave them on, there the correct heads for that engine. The ones on you old block if memory serves me correct are mismatched. Also higher compression heads on that engine won't do you any difference.

#18

STELLA1

I don't know where you are getting all this information with compression ratios, and crank journal specs from. Fact is it really doesen't mean a damm thing.

Your dealing with a 70+ year old engine, and there is wear in this engine so whether you have it machined or what ever all that will change.

I've taken an 8BA engine from a 1951 did a bunch of changes used a Merc Crank 1951 a 59A Cam, Front mounted Distributor, the list goes on and unless you knew what you were looking for you couldn't tell it from a 1939 Engine.

I don't know where you are getting all this information with compression ratios, and crank journal specs from. Fact is it really doesen't mean a damm thing.

Your dealing with a 70+ year old engine, and there is wear in this engine so whether you have it machined or what ever all that will change.

I've taken an 8BA engine from a 1951 did a bunch of changes used a Merc Crank 1951 a 59A Cam, Front mounted Distributor, the list goes on and unless you knew what you were looking for you couldn't tell it from a 1939 Engine.

#19

Well finally got to do a little work on my junkyard find motor.

Here is the casting mark on the bellhousing, haven't seen this mark before.

Then of course we have to get past the rats nest in the lifter valley

I have found out so far that the camshaft is broken in half and once I took off the front gear the crank is now free to spin moving all pistons as it should. Will end up replacing all the valve train as the springs and tappets are pretty rusted and probably convert over to solid valve guides as these appear to be the split version. The pistons and cylinders appear to be in great shape and factory sized. Still have to pull the oil pan and check out the bottom half yet but feeling pretty good so far that everything will be ok.

Also not sure what to make of this little cover pinned to the side of the bellhousing.

Here is the casting mark on the bellhousing, haven't seen this mark before.

Then of course we have to get past the rats nest in the lifter valley

I have found out so far that the camshaft is broken in half and once I took off the front gear the crank is now free to spin moving all pistons as it should. Will end up replacing all the valve train as the springs and tappets are pretty rusted and probably convert over to solid valve guides as these appear to be the split version. The pistons and cylinders appear to be in great shape and factory sized. Still have to pull the oil pan and check out the bottom half yet but feeling pretty good so far that everything will be ok.

Also not sure what to make of this little cover pinned to the side of the bellhousing.

#20

The actual number you're looking for is usually right next to the oil pressure sending unit. The heads on your 'new' engine indicate possibly a '38 as 81A was the official number for that year. For some general information, the first 81A engines were 21 stud and evolved into 24 stud during the production year. 1939 officially used 91A (Mercury 99A with 40 being 01A/09A and so on and so forth. Most '39 engines I've seen had 91A/99A on the heads although I've been told that some can also come with 81A. Ford also used the designation such as 81A as a part number prefix indicating the year it was either brought out or revised. The Ford engine has a 3 1/16 bore giving a CID of 221 while the Mercury (and heavy truck option) is 3 3/16 for 239 CID, same as the 59A. The stroke for both is 3 3/4. It looks like you've got a late '38 or early '39 engine. Like 5 Star says, you can interchange a lot of parts between the two engines. Personally I think that if you rebuilt the old engine with the 59A heads you wouldn't notice a heck of a lot of difference in performance. Just some information I thought you might like to know.

GMS

GMS

#21

Made some decent progress today. Plasti-gaged the main bearings, within spec and looking good. Rod bearings need to be replaced as bearing material is coming off and there is small pits in the material. Have to replace at least 2 pistons as one had a jacked up clip boss for the wrist pin clip, which in turn gouged a cylinder nicely, what a crappy design there. Another piston has a chunk missing from being hit by a chunk of camshaft. 1 rod needs replacing as it too was hit by camshaft. All cylinders except the one look beautiful. A fast bar hone should clean them up nicely. Camshaft was in 3 pieces, 2 being in the oil pan. My guess is the wrist pin clip worked its way to the cam some how and caused a bind. Got half the valve train out. Having to cut the springs into pieces as they are rusted and can't get them to compress enough to undo the goofy lock at the bottom. Also cutting the heads of the valves so I can push the valve guide down as the guide clips are basically fused to the guides. Its a shame about the valves as they are in great shape but I refuse to waste time trying to save items that won't get reused anyways. All tappets will be replaced as most beat to snot trying to get them out. That mice urine sure does a number on metal. Bore size is 3-1/16". Hoping to swap over to the non split valve guide system instead of the split stuff.

So the main parts I think I'll need now is pistons w/rings, conn. rod bearings, valve train kit, adjustable tappets, and camshaft and bearings.

So the main parts I think I'll need now is pistons w/rings, conn. rod bearings, valve train kit, adjustable tappets, and camshaft and bearings.

#22

Well finally got it completely stripped down, except for 6 head studs that broke off, and to the machine shop. Got to talking with the machinist about the cylinders. Definitely have to re-sleeve the one and possibly the rest as he said the wear seemed to be quite a bit. He recalls people in the past just removing the sleeve completely, then boring and honing the original hole. So instead of re-sleeving back to the factory 3-1/16" bore, might be able to go to 3-3/16". Basically go from 221cid to 239cid. Would definitely be easier on the bank account going that way. I talked to my uncle about this idea and was told by him that back in the day owners of the ford 8n tractors use to do this with their motors when rebuilding after re-sleeving and the motors would burn up piston rings. Anyone have any thoughts on going this route?

#23

Stella1

There used to be lots of 9N/2N/8Ns around my neighborhood (and still some around). I understood (and I may need to be corrected) that they were actually half of the Mercury engine from the start and they simply used the Mercury pistons and rings but with the dry sleeves (which weren't used in the automotive applications). I know of one owner who fried several sets of rings but that was due to cylinders that were running around .010" taper. I've never heard of them eating rings with good cylinders. Just ensure that the cylinders are true and the ring gap is within specs.

I just checked my engine specs and the 30 hp 4 cyl. that was offered in the light trucks in '41/'42 had the same bore as the 239 V-8. That engine also used the updraft carb; same as the tractor engine. I wasn't able to confirm this but I've been told by several sources that it was the tractor engine that was installed in trucks in hopes that they would be better on gas for the war effort.

Just reading your last entry again, am I understanding correctly that your engine is already sleeved? If so and if it was my engine I'd be tempted to ditch the sleeves and go with the 3 3/16 bore unless the original cylinders were in such horrible shape that sleeves had to be installed.

Hope that your project goes well for you.

There used to be lots of 9N/2N/8Ns around my neighborhood (and still some around). I understood (and I may need to be corrected) that they were actually half of the Mercury engine from the start and they simply used the Mercury pistons and rings but with the dry sleeves (which weren't used in the automotive applications). I know of one owner who fried several sets of rings but that was due to cylinders that were running around .010" taper. I've never heard of them eating rings with good cylinders. Just ensure that the cylinders are true and the ring gap is within specs.

I just checked my engine specs and the 30 hp 4 cyl. that was offered in the light trucks in '41/'42 had the same bore as the 239 V-8. That engine also used the updraft carb; same as the tractor engine. I wasn't able to confirm this but I've been told by several sources that it was the tractor engine that was installed in trucks in hopes that they would be better on gas for the war effort.

Just reading your last entry again, am I understanding correctly that your engine is already sleeved? If so and if it was my engine I'd be tempted to ditch the sleeves and go with the 3 3/16 bore unless the original cylinders were in such horrible shape that sleeves had to be installed.

Hope that your project goes well for you.

#25

#26

Stella1

I''m inclined to ask that same question. I understand that there was no difference between the Ford and Mercury block save for the extra 1/8" bore. Some have told me that a Ford 221 can be bored out to the Mercury size. That's .125". Now when Ford went over to war production the 221 was eventually commuted to the 239. I don't know what year they actually did that. Your theory makes sense in that Ford needed to use up a stock of parts that wouldn't go for war production. I might add that in '42 Ford used steel pistons to conserve aluminum but I think that the 239 engine retained the aluminum ones. Maybe someone else has an idea?

I''m inclined to ask that same question. I understand that there was no difference between the Ford and Mercury block save for the extra 1/8" bore. Some have told me that a Ford 221 can be bored out to the Mercury size. That's .125". Now when Ford went over to war production the 221 was eventually commuted to the 239. I don't know what year they actually did that. Your theory makes sense in that Ford needed to use up a stock of parts that wouldn't go for war production. I might add that in '42 Ford used steel pistons to conserve aluminum but I think that the 239 engine retained the aluminum ones. Maybe someone else has an idea?

#27

Not much of an update today. Still awaiting word from machine shop on condition of block. No rush really as it's now cold and snowing here. Did get the truck re-titled to my name and registered. Total cost for a lifetime registration is $15 here in ND. Nothing to pay ever again except for insurance, which is also really cheap.

#28

Well, finally got some good news today. Went to check on the progress of the junkyard block and this is what was found. 4 individual cracks, 1 each between the first 2 cylinders and last 2 cylinders on both sides. Looks to have started at the small water jacket holes and ended at the stud holes. Basically the factory cracks with part numbers, haha. So since we're looking good as far as cracks go, the shop is going to start on the 6 broken studs and then the cylinder sleeves will be next. They basically said they would bore them out and get the parent bore to 239CUI bore of 3-3/16. If it doesn't look good at that point then we will bore it 30 over and go from there.

#29

Another long awaited update. Just got word from the shop that the 6 broken studs have been removed and that the cylinder sleeves have been removed. No cracks in the cylinder walls but will have to be bored 50 thousandth to get to the 239 cid bore of 3-3/16". Adds a few more dollars to the bill but poop happens.

Started researching cams and think I found one that will work quite well for my application. Thinking of using the Isky Max-1, duration@ .050 is 226, adv. duration is 249, lobe angle of 111, and gross lift of .364. Suppose to be good for low and mid range power with good idle. Not looking for anything crazy and wild but just something a bit above stock. Will be using a set of headers when if I can pin down the right style to use, and may also run a dual carb setup seeing as I already have 2 carbs.

Just waiting for the block to get finished before taking in the crank and rods from my original motor to have them cleaned and checked.

Started researching cams and think I found one that will work quite well for my application. Thinking of using the Isky Max-1, duration@ .050 is 226, adv. duration is 249, lobe angle of 111, and gross lift of .364. Suppose to be good for low and mid range power with good idle. Not looking for anything crazy and wild but just something a bit above stock. Will be using a set of headers when if I can pin down the right style to use, and may also run a dual carb setup seeing as I already have 2 carbs.

Just waiting for the block to get finished before taking in the crank and rods from my original motor to have them cleaned and checked.

#30

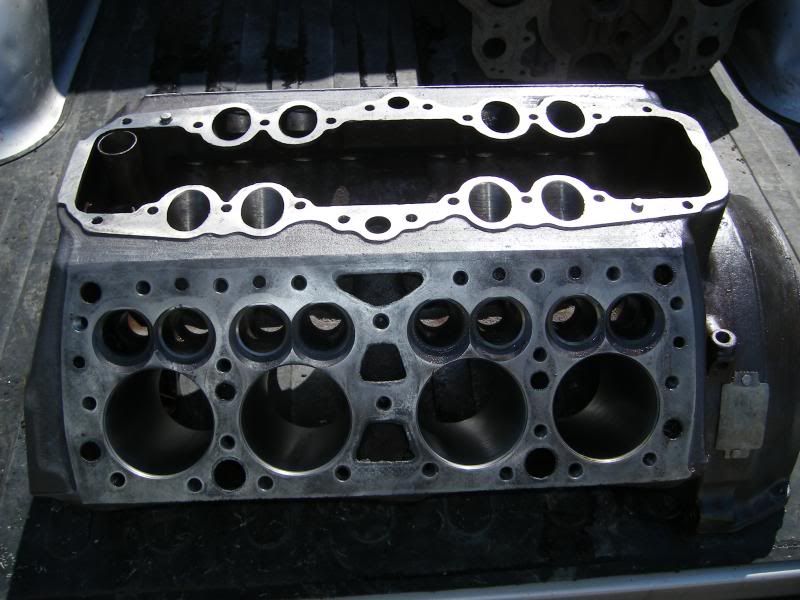

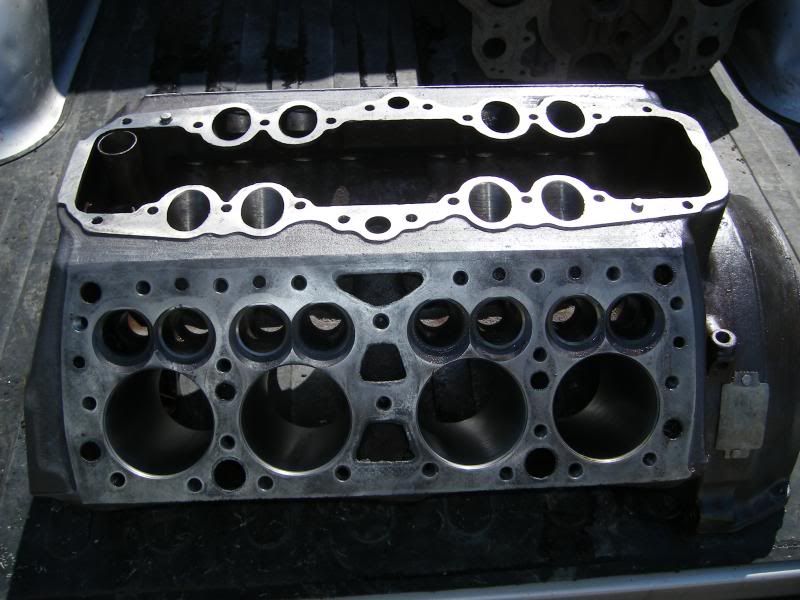

Finally got the block back from the shop. Must say they did a good job getting it set up. Total cost so far for the block work is $750 which included cleaning($75),magnafluxed($75), stud removal($150), boring out sleeves($200), boring a second time to get to 3-3/16" diameter($200), and shop supplies($50). Still need to have them put in cam bearing and grind valves after I finish some minor port and polishing. Gave them the crank to check out and turn down, the first main journal has some surface rust but should clean up at .010 or maybe .020 if it's worse than it appears. Going to give the rods to check and match to crank, also having flywheel resurfaced.

Found a carb rebuild kit for the Ford model 91-99 carb, it's a Hygrade kit #1434. Had the folks at O'reilly auto parts cross reference that number with one of their kits. It will be a Walker brand kit, will add number when I get it.

Looks like MAC's auto parts will be where I'll be getting most of my parts from. Looking to get the solid valve kit # 8BA-6501-KT as all the valve train was made unusable from the rats. Seems like a good price at $215 for all the items.

Here's some more photos for your enjoyment.

Found a carb rebuild kit for the Ford model 91-99 carb, it's a Hygrade kit #1434. Had the folks at O'reilly auto parts cross reference that number with one of their kits. It will be a Walker brand kit, will add number when I get it.

Looks like MAC's auto parts will be where I'll be getting most of my parts from. Looking to get the solid valve kit # 8BA-6501-KT as all the valve train was made unusable from the rats. Seems like a good price at $215 for all the items.

Here's some more photos for your enjoyment.