driveline slip repair

#1

driveline slip repair

I have noticed for a while now that when I take of from the lights or change from drive to reverse there is some slip in the driveline before it bites. Clay noticed it as well when he drove it so its time I fixed it. Easy job (1/2 hour) just couldn't be bothered getting around to it.

first thing to do is mark the joint and shaft so it goes back on the same spline

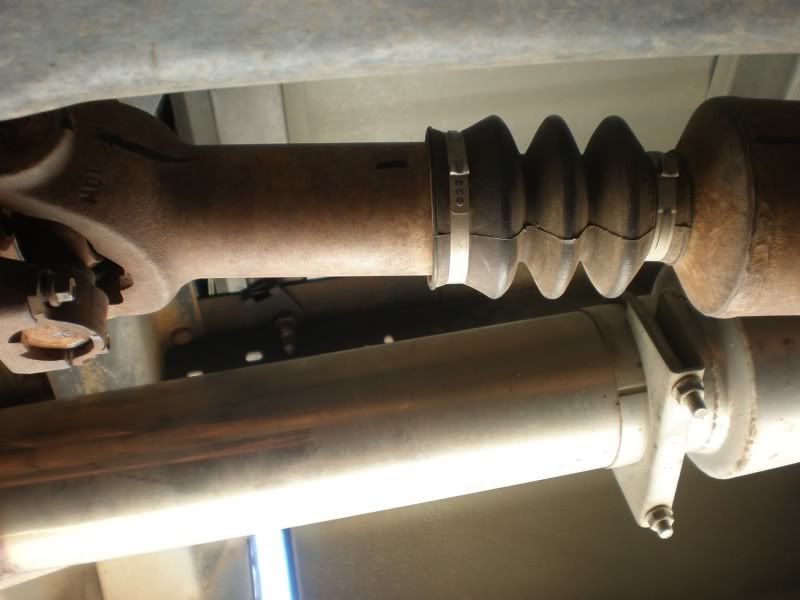

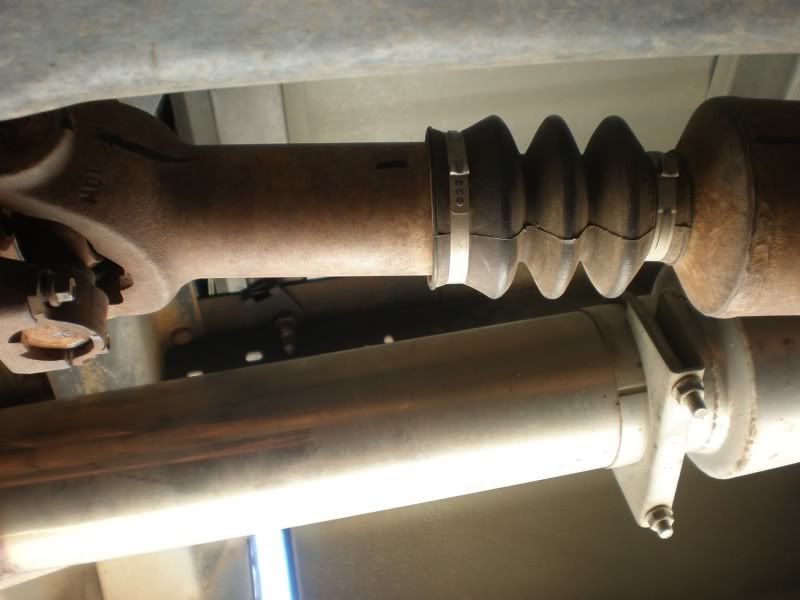

then if you are careful you can pry open the clamp so you can reuse it (gotta think of the environment)

then undo the four 8mm bolts on the uni joint, get a pry bar behind it to compress the spline and rest the shaft on something

as you can see mine was bone dry

grease up the spline - I put a bit to much on at first. You will notice when you try and put it back on the spline if there is to much

bolt her all up. Dont forget ya marks and no more slip

first thing to do is mark the joint and shaft so it goes back on the same spline

then if you are careful you can pry open the clamp so you can reuse it (gotta think of the environment)

then undo the four 8mm bolts on the uni joint, get a pry bar behind it to compress the spline and rest the shaft on something

as you can see mine was bone dry

grease up the spline - I put a bit to much on at first. You will notice when you try and put it back on the spline if there is to much

bolt her all up. Dont forget ya marks and no more slip

#2

#6

havent really looked at it but I have read that you should shim the carrier bearing for every inch of lift. Dont know what Bryan would do with he's airbag. If its up he would have to jump under and shim it up. When he puts it down out he goes again and takes em out. Man it would take a long time getting anywhere

#7

Trending Topics

#9

#10

#12

Thanks, I had a great ANZAC day!

Hunted down a few electrical gremlins with the truck's alarm system.

I had a big of a creep underneath to check out the drive shaft center bearing. With the truck raised about 3" there is a slight angle through the center uni-joint, but no more than the angle between the shaft and the diff center. In theory it looks possible to undo the 2 support bolts which protrude about an inch through the center bearing support bracket and put in some spacer material, like a steel piece with holes drilled in, it for the bolts to go through, the reattach the bearing bracket with the shaft being marginally straighter.

Has anyone done this sort of thing? Surely the guys running 8" lift must have done something like this...

Hunted down a few electrical gremlins with the truck's alarm system.

I had a big of a creep underneath to check out the drive shaft center bearing. With the truck raised about 3" there is a slight angle through the center uni-joint, but no more than the angle between the shaft and the diff center. In theory it looks possible to undo the 2 support bolts which protrude about an inch through the center bearing support bracket and put in some spacer material, like a steel piece with holes drilled in, it for the bolts to go through, the reattach the bearing bracket with the shaft being marginally straighter.

Has anyone done this sort of thing? Surely the guys running 8" lift must have done something like this...

#13

I didn't realize your truck is lifted... yes, you will need to space it down.

Yes, it is designed to have spacers put in there, and I have done it on a few customers trucks. There are Ford official parts that are spacers... but no doubt $$$, just get a bit of 1/8" mild steel that is cut to size and drill 2 holes for the mounting bracket. Use 2 spacers if you need.

The guys running the crazy lifts need to both space it down and get their shafts lengthened (pun intended )

)

Yes, it is designed to have spacers put in there, and I have done it on a few customers trucks. There are Ford official parts that are spacers... but no doubt $$$, just get a bit of 1/8" mild steel that is cut to size and drill 2 holes for the mounting bracket. Use 2 spacers if you need.

The guys running the crazy lifts need to both space it down and get their shafts lengthened (pun intended

)

)

#14

Will do. My truck is a 4WD with 3" blocks under the rear springs, with the short 1/2 inch thick spring removed (for comfort) and Firestone lift bags on 30psi, and a 2" leveling kit which consisted of a fairly long 4 leaf spring pack added to each side at the front.

No vibrations down low, but I get some sort of harmonic resonance at about 80kph which I suspect might be the rear tail shaft/s slightly out of balance. Not a huge issue as the noise is gone by 90kmh, but annoying enough in the 80 kph zones...

See: https://picasaweb.google.com/1077641...32428351644114

for picture of truck

No vibrations down low, but I get some sort of harmonic resonance at about 80kph which I suspect might be the rear tail shaft/s slightly out of balance. Not a huge issue as the noise is gone by 90kmh, but annoying enough in the 80 kph zones...

See: https://picasaweb.google.com/1077641...32428351644114

for picture of truck

Thread

Thread Starter

Forum

Replies

Last Post

XSoph

1973 - 1979 F-100 & Larger F-Series Trucks

30

04-28-2018 09:44 PM

flamesoldier

1948 - 1956 F1, F100 & Larger F-Series Trucks

13

11-18-2014 02:53 PM

clintonvillian

1948 - 1956 F1, F100 & Larger F-Series Trucks

5

11-29-2013 06:01 AM