20" aluminum wheel stuck

#16

No, I haven't. They are all wearing very well from visual inspection and tire tread depth gauge readings

Anyway, this is being towed to the dealer for another tire, which was very competitive with other discount tire companies on their price. I will have them do a rotation at this time...

Anyway, this is being towed to the dealer for another tire, which was very competitive with other discount tire companies on their price. I will have them do a rotation at this time...

#17

In my younger days at the dealerships I would typically use the "drop kick" method. Couple shots on the bottom and then rotate for a couple more. If that didn't work then the mini sledges came out.

On occasion though we would have to burn the wheels off (steel wheels, aluminum always came off with enough pounding).

Now I make sure there is a very thin coating of never seize or something I have been using since owning a SuperGlide hitch is "Slip Plate"

Don't think so. How will oiled studs lead to over torquing?

If you install the lugs correctly they should not be over torqued.

And on the DRW's you are supposed to oil the lug nuts (between the actual nut and the washer)

"It is important to follow the proper wheel mounting and lug nut torque

procedures.

On all two-piece flat wheel nuts,

apply one drop of motor oil between

the flat washer and the nut."

On occasion though we would have to burn the wheels off (steel wheels, aluminum always came off with enough pounding).

Now I make sure there is a very thin coating of never seize or something I have been using since owning a SuperGlide hitch is "Slip Plate"

If you install the lugs correctly they should not be over torqued.

And on the DRW's you are supposed to oil the lug nuts (between the actual nut and the washer)

"It is important to follow the proper wheel mounting and lug nut torque

procedures.

On all two-piece flat wheel nuts,

apply one drop of motor oil between

the flat washer and the nut."

#18

In my younger days at the dealerships I would typically use the "drop kick" method. Couple shots on the bottom and then rotate for a couple more. If that didn't work then the mini sledges came out.

On occasion though we would have to burn the wheels off (steel wheels, aluminum always came off with enough pounding).

Now I make sure there is a very thin coating of never seize or something I have been using since owning a SuperGlide hitch is "Slip Plate"

Don't think so. How will oiled studs lead to over torquing?

If you install the lugs correctly they should not be over torqued.

And on the DRW's you are supposed to oil the lug nuts (between the actual nut and the washer)

"It is important to follow the proper wheel mounting and lug nut torque

procedures.

On all two-piece flat wheel nuts,

apply one drop of motor oil between

the flat washer and the nut."

On occasion though we would have to burn the wheels off (steel wheels, aluminum always came off with enough pounding).

Now I make sure there is a very thin coating of never seize or something I have been using since owning a SuperGlide hitch is "Slip Plate"

Don't think so. How will oiled studs lead to over torquing?

If you install the lugs correctly they should not be over torqued.

And on the DRW's you are supposed to oil the lug nuts (between the actual nut and the washer)

"It is important to follow the proper wheel mounting and lug nut torque

procedures.

On all two-piece flat wheel nuts,

apply one drop of motor oil between

the flat washer and the nut."

#19

Originally Posted by Permatex

Does Permatex suggest applying anti-seize to lubricate lug nuts when installing or tightening the nuts?

Permatex does not recommend the use of any anti-seize product on wheel studs. Although anti-size has been used for years by many people on this application, there is the potential for over torquing and therefore higher clamp loads and potentially dangerous bolt stretch. Because of the lubricity of anti-seize, there is a tendency to over tighten because of the ease with which the nut will bear down on the lug. For this reason, even if you try to torque the nuts to factory specs, the clamp load may become too high depending on the type of bolt, size and manufacturer.

Permatex does not recommend the use of any anti-seize product on wheel studs. Although anti-size has been used for years by many people on this application, there is the potential for over torquing and therefore higher clamp loads and potentially dangerous bolt stretch. Because of the lubricity of anti-seize, there is a tendency to over tighten because of the ease with which the nut will bear down on the lug. For this reason, even if you try to torque the nuts to factory specs, the clamp load may become too high depending on the type of bolt, size and manufacturer.

Originally Posted by MachineToolHelp.com

Proper torque spec varies depending on the material, bolt grade or wether lubrication is used such as oil, wax, or anti-seize Always go to the manufacturer for proper torque specs if needed. Lubrication added to a dry bolt will typically reduce the torque value 15-25%.

#20

#21

OK - lets leave Permatex and never-seize out of the equation. Never-seize is not the same as a drop of oil and Permatex has a liability issue with recommending something that is not specially addressed in the owners manual.

For every quote you find like the one from MachineToolHelp.com (not related to vehicles) you could also find one like this from Normark Industries Wheel Service Bible

1. Fasteners wear out. The nuts and studs that hold wheels to the hub are designed for heavy-duty application but they do wear. After they have been fastened and removed a number of times, the threads and seats wear.

2. Fasteners corrode. For that reason, lubrication must be applied sparingly to the threads. Wheel manufacture guidelines and RP222 say a couple of drops of machine oil should be applied to the threads of the stud.

• Do not over or under lubricate. Too much oil, or no oil leads to false torque wrench readings with potential wheels-off incidents.

If you go and re-research the oli on threads and limit any finds to only vehicle wheels I think you may find different results.

What is key whether you believe it is OK or not, is to ensure that no oil or lube gets on the nut face or the "bowl" surrounding the stud.

The key to any of it is to properly torque the nuts and don't get any lube on the nut face or the bowl.

Now that said, I always use a torque wrench on this truck and the 5th wheel.

But I did over 20 years in the automotive field and I have to say, proper use of impact guns lead to very few failures.

I'm not saying that is the right way to do install wheels, but I would venture to say between myself and the hundreds of other techs over the years that amounts to 10's of thousands of wheels being zipped on and off with a gun.

I can't even remember if there were any direct resulting problems, aside from the occasional broken wheel stud.

I haven't seen a Ford tech yet (my serving dealers) use a torque wrench and properly torque to 165 foot pounds any DRW wheels.

And by the time you get to the 4th wheel at multiple steps, 165 gets pretty old.

For every quote you find like the one from MachineToolHelp.com (not related to vehicles) you could also find one like this from Normark Industries Wheel Service Bible

1. Fasteners wear out. The nuts and studs that hold wheels to the hub are designed for heavy-duty application but they do wear. After they have been fastened and removed a number of times, the threads and seats wear.

2. Fasteners corrode. For that reason, lubrication must be applied sparingly to the threads. Wheel manufacture guidelines and RP222 say a couple of drops of machine oil should be applied to the threads of the stud.

• Do not over or under lubricate. Too much oil, or no oil leads to false torque wrench readings with potential wheels-off incidents.

If you go and re-research the oli on threads and limit any finds to only vehicle wheels I think you may find different results.

What is key whether you believe it is OK or not, is to ensure that no oil or lube gets on the nut face or the "bowl" surrounding the stud.

The key to any of it is to properly torque the nuts and don't get any lube on the nut face or the bowl.

Now that said, I always use a torque wrench on this truck and the 5th wheel.

But I did over 20 years in the automotive field and I have to say, proper use of impact guns lead to very few failures.

I'm not saying that is the right way to do install wheels, but I would venture to say between myself and the hundreds of other techs over the years that amounts to 10's of thousands of wheels being zipped on and off with a gun.

I can't even remember if there were any direct resulting problems, aside from the occasional broken wheel stud.

I haven't seen a Ford tech yet (my serving dealers) use a torque wrench and properly torque to 165 foot pounds any DRW wheels.

And by the time you get to the 4th wheel at multiple steps, 165 gets pretty old.

#22

#23

Never seize I would not use.

#24

#25

#26

I'd recommend being very careful tightening the lugs if you got oil on the studs. Oiled studs can lead to dangerously overtightening the lugs and can cause all manner of problems.

The above suggestions on using a sledge to the inside of the tire are dead on. Be careful not to hit the rim though, those are over $700 from your dealer!

The above suggestions on using a sledge to the inside of the tire are dead on. Be careful not to hit the rim though, those are over $700 from your dealer!

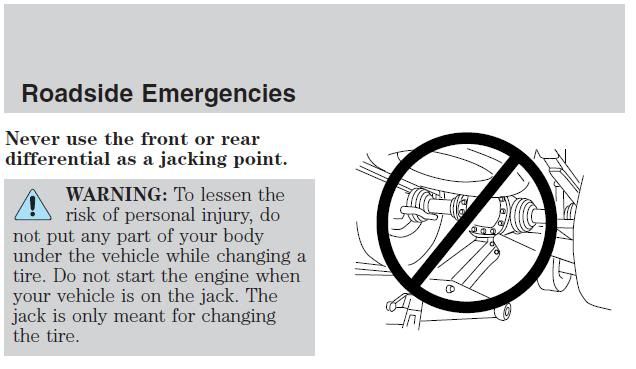

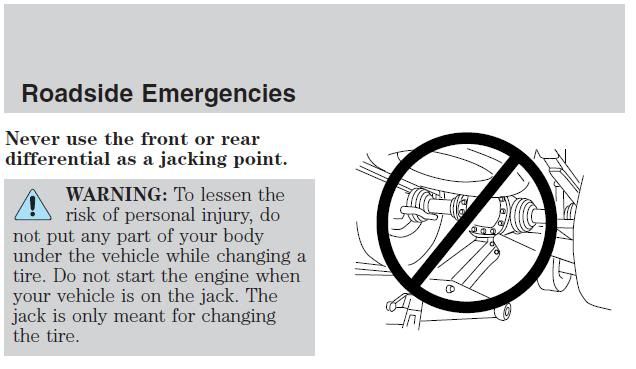

(Tom, you love posting that jack pic lol....btw, the manual kinda sucks for explaining where to jack from the front if your not using a bottle jack)

Thread

Thread Starter

Forum

Replies

Last Post

ona6day

1948 - 1956 F1, F100 & Larger F-Series Trucks

17

05-29-2006 05:51 AM