1964 F100 brake job

#1

1964 F100 brake job

How do you get the rear drum open? (Picture 1)

There is a little slit on the back of the brake that has an adjustment wheel inside. The teeth on the wheel are tiny. I tried to adjust it, but no way. The screwdriver just slips off the teeth. (These brakes are in incredibly bad condition.) Which direction is does what? (Picture 2)

The brake fluid line comes to the top of the rear axle. It splits and goes to both brakes. At the junction is another hose that is broken in my case. Where is that going? What is it for? (Picture 3)

Picture 1:

Picture 2:

Picture 3: (This is the left side, looking from the rear.)

There is a little slit on the back of the brake that has an adjustment wheel inside. The teeth on the wheel are tiny. I tried to adjust it, but no way. The screwdriver just slips off the teeth. (These brakes are in incredibly bad condition.) Which direction is does what? (Picture 2)

The brake fluid line comes to the top of the rear axle. It splits and goes to both brakes. At the junction is another hose that is broken in my case. Where is that going? What is it for? (Picture 3)

Picture 1:

Picture 2:

Picture 3: (This is the left side, looking from the rear.)

#2

You need to buy a brake spoon. A screw driver isn't ideal for loosening that adjuster. Once you get your brake spoon, it will be much easier. You will figure it out once you get the proper tool. The rubber hose which is cracked in pic 3 is the axle vent tube. You need to replace it so water doesn't get in there.

Mark

Mark

#4

Make sure you don't have the parking brake on. If you do it won't come off. Once you have the parking brake off, spray everything with liquid wrench or something similar and let it sit for a few minutes. They spray it again. Then hit it with a hammer. It should come off.

All the lines hook up to a cross and connect to the master cylinder. The rubber line goes to a steel line. Its rubber so that when you hit bumps and things of that nature it bends and doesn't bend the steel lines.

It looks like you could use an entire brake rebuild. I recommend you hone and rebuild all the wheel cylinders and master cylinder as well as replace all the lines. Thats what I did to mine. Its a good weekend project. You absolutely need new rubber lines at the minimum.

All the lines hook up to a cross and connect to the master cylinder. The rubber line goes to a steel line. Its rubber so that when you hit bumps and things of that nature it bends and doesn't bend the steel lines.

It looks like you could use an entire brake rebuild. I recommend you hone and rebuild all the wheel cylinders and master cylinder as well as replace all the lines. Thats what I did to mine. Its a good weekend project. You absolutely need new rubber lines at the minimum.

#5

The drum might be rusted in place. Try soaking it with penetrating lubricant at the center where it mates the axle.

#6

I took the from drum off with little problem. There is a nut - and a cotter pin - that need to be removed. It would seem like they keep the drum from falling off. Does the rear drum just pull off without removing anything? If so, what keeps the drum from falling off while you are driving down the road?

See pictures 1 and 2 above. Where would I spray? Just spraying on the front of the drum won't do anything, will it?

This might help - I have worked on old VW brakes, but I have never seen one of these before. I'm not sure what configuration is ...

See pictures 1 and 2 above. Where would I spray? Just spraying on the front of the drum won't do anything, will it?

This might help - I have worked on old VW brakes, but I have never seen one of these before. I'm not sure what configuration is ...

#7

By the way, once I get the 66 F100 on the road again, I start working on the 61 Karmann Ghia.

Trending Topics

#8

Thanks, Marf!

It's true - a picture is worth a thousand words! Now I see why I've been confused. I assumed the lug nuts came off with the drum - like they did on the front.

OK - I've sprayed Blaster on the lugs and the axle. Waited about 15 minutes. Tapped between the lugs with a hammer. Still "tight as a drum". (Bad joke).

Is it possible that the shoes are holding it on? I can spin the wheel and it turns the driveshaft. It's takes some effort to spin it, but not a lot. I've tried to turn the adjustment wheel through the hole in the back, but it will not go either direction. (The teeth are so tiny!)

It's true - a picture is worth a thousand words! Now I see why I've been confused. I assumed the lug nuts came off with the drum - like they did on the front.

OK - I've sprayed Blaster on the lugs and the axle. Waited about 15 minutes. Tapped between the lugs with a hammer. Still "tight as a drum". (Bad joke).

Is it possible that the shoes are holding it on? I can spin the wheel and it turns the driveshaft. It's takes some effort to spin it, but not a lot. I've tried to turn the adjustment wheel through the hole in the back, but it will not go either direction. (The teeth are so tiny!)

#9

spray the threads on the adjuster (right next to the wheel with the tiny teeth) with PB blaster and get one of these to help you loosen it:

Brake Adjustment Tool (Brake Spoon) at National Tool Warehouse

Brake Adjustment Tool (Brake Spoon) at National Tool Warehouse

#10

Im a little late to this one. Looks like your truck is inside. You need to have a torch with the very least mapp gas. Rotate the brake drum as you heat around the outside between the studs close to the center of the hub. This will cause the drum to expand and pop loose. They can break loose with quite a bang so be ready. You can probably dump cans of bp blast there and never break it loose until you heat it. If you had an ox acetalen set up that would be ideal. Remember to run your torch around evenly so that the drum expands evenly. I dont think propane will get it hot enough but you can try that too. Good luck lots of rust there to deal with. Has this truck been on the road and used. If not you might expect the brake cylinders to be siezed up and bleed screws frozen. The rubber hoses should probably be replace too. Just some advice.

#12

It seems that the shoes are not the problem if you can spin the wheel. The torch is a good idea. I had a hard time with the fittings on the brake line to the wheel cylinders. Most were seized. NAPA sells a flexible brake line replacement that can b field bent. But you might as well get all those brake line fittings soaking as well.

#13

The shoes wear into the drum and will prevent it from releasing even if the drum spins.

As others have mentioned go buy a brake spoon for ten bucks at the local parts house. Back off the adjuster all the way. To tell which way to turn it try up first and see if the drum gets tighter. If it does back off the other way.

Once the shoes are relaxed fully, tap on the drum with a 3 pound hammer around the rim face and next to the wheel studs to help knock it loose.

Garbz

As others have mentioned go buy a brake spoon for ten bucks at the local parts house. Back off the adjuster all the way. To tell which way to turn it try up first and see if the drum gets tighter. If it does back off the other way.

Once the shoes are relaxed fully, tap on the drum with a 3 pound hammer around the rim face and next to the wheel studs to help knock it loose.

Garbz

#14

The shoes wear into the drum and will prevent it from releasing even if the drum spins.

As others have mentioned go buy a brake spoon for ten bucks at the local parts house. Back off the adjuster all the way. To tell which way to turn it try up first and see if the drum gets tighter. If it does back off the other way.

Once the shoes are relaxed fully, tap on the drum with a 3 pound hammer around the rim face and next to the wheel studs to help knock it loose.

Garbz

As others have mentioned go buy a brake spoon for ten bucks at the local parts house. Back off the adjuster all the way. To tell which way to turn it try up first and see if the drum gets tighter. If it does back off the other way.

Once the shoes are relaxed fully, tap on the drum with a 3 pound hammer around the rim face and next to the wheel studs to help knock it loose.

Garbz

First step is to get the drum loose to see if you even need to try and back the shoes off. The drum becomes rusted to the axle front. You may get lucky banging on it with a 3 pound hammer more than likely you will just dent the drum and if you dont end up breaking it you will at least bugger one or two of the wheel retaining studs. If you are bound and determined to hammer on the front of the drum at least put the lugs back on until the lug comes down flush with the top of the thread to protect the studs from possible damage. I havent looked to see where the poster of the pics is from judging from the looks of the rust on the undercarrige and axle housing I would say its from a state that is in the upper midwest or somewhere where they have or are currently using salt on the roads to melt the snow and ice. Once you have the drum LOOSE you will then find out weather or not you have to back off the shoes to take the drum off. Alot of what ifs deal with them as you come to them. If you cant turn the rear wheels with the wheel removed you could have a siezed ebrake cable as well. Anyway good luck with it. Get some bandaids ready I see some busted knuckles comming up.

edit: I went and looked at the posters location he is in Florida. Truck is either a northern transplant or the salt air is having its way. Not sure which is worse the air or road salt.

#15

There is joy in Mudville! The drum is off. Heat finally did it. I used mapp gas instead of propane. It took about 10 minutes of heating.

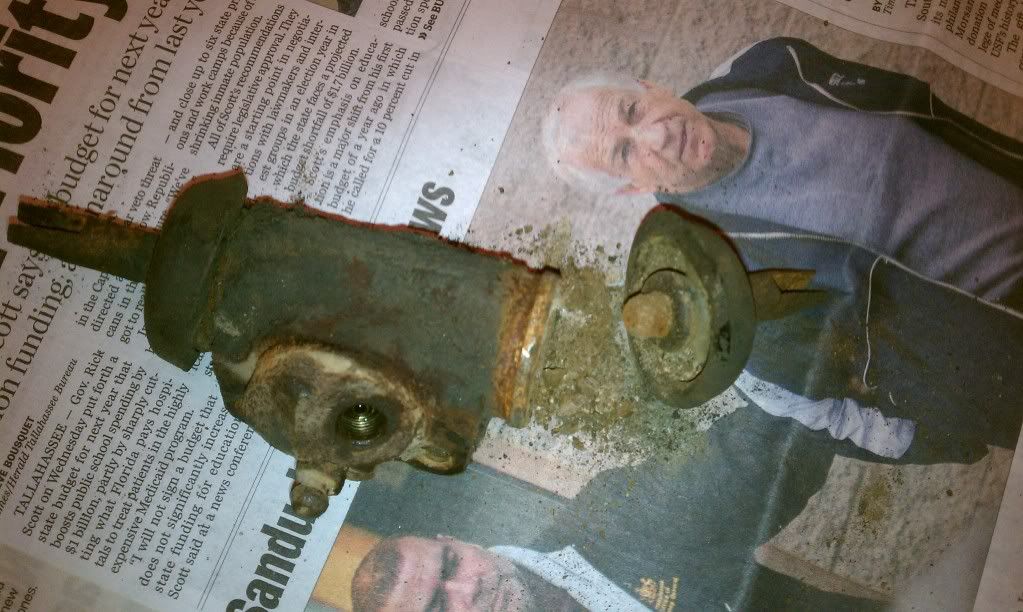

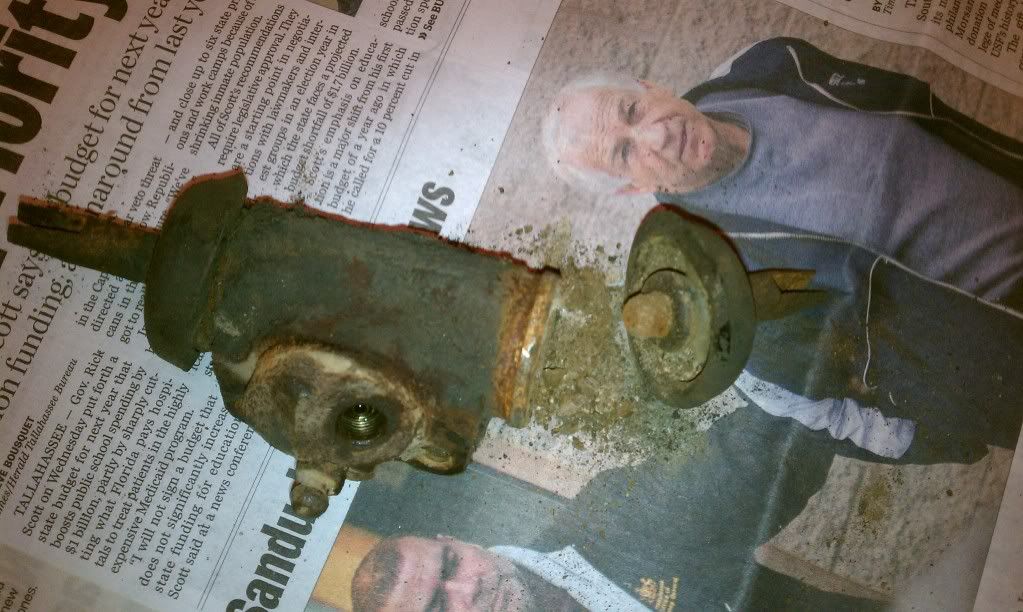

Check these pictures. Those of you who suggested rebuilding the cylinders, hmm, I guess so! And the fact that I spilled dirt onto a picture of Jerry Sandusky, just an interesting coincidence.

And as far as I know, the truck grew up in Dooley county, Georgia.

Check these pictures. Those of you who suggested rebuilding the cylinders, hmm, I guess so! And the fact that I spilled dirt onto a picture of Jerry Sandusky, just an interesting coincidence.

And as far as I know, the truck grew up in Dooley county, Georgia.